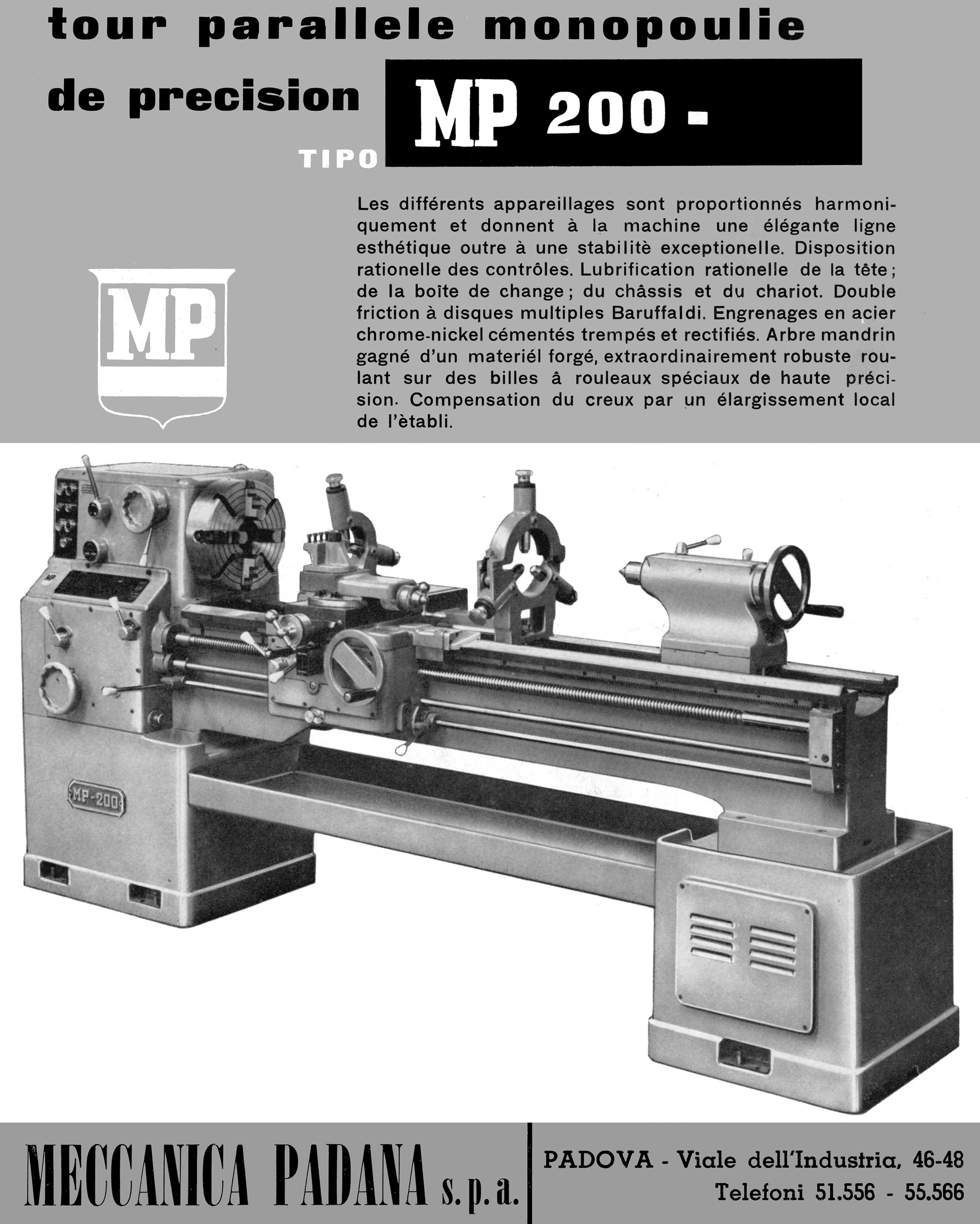

Padana MP200 Lathe (Italy)

Manufactured or sold (the details are uncertain) by Meccanica Padana s.p.a. a company founded in 1954 and trading from the Viale dell'Imdustria in Padova, Northern Italy, the MP200 lathe was of a conventional, heavy-duty, industrial geared-head type. The Company still exists, now specialising in equipment for the petroleum trade and still listing a single conventional lathe amongst its products>

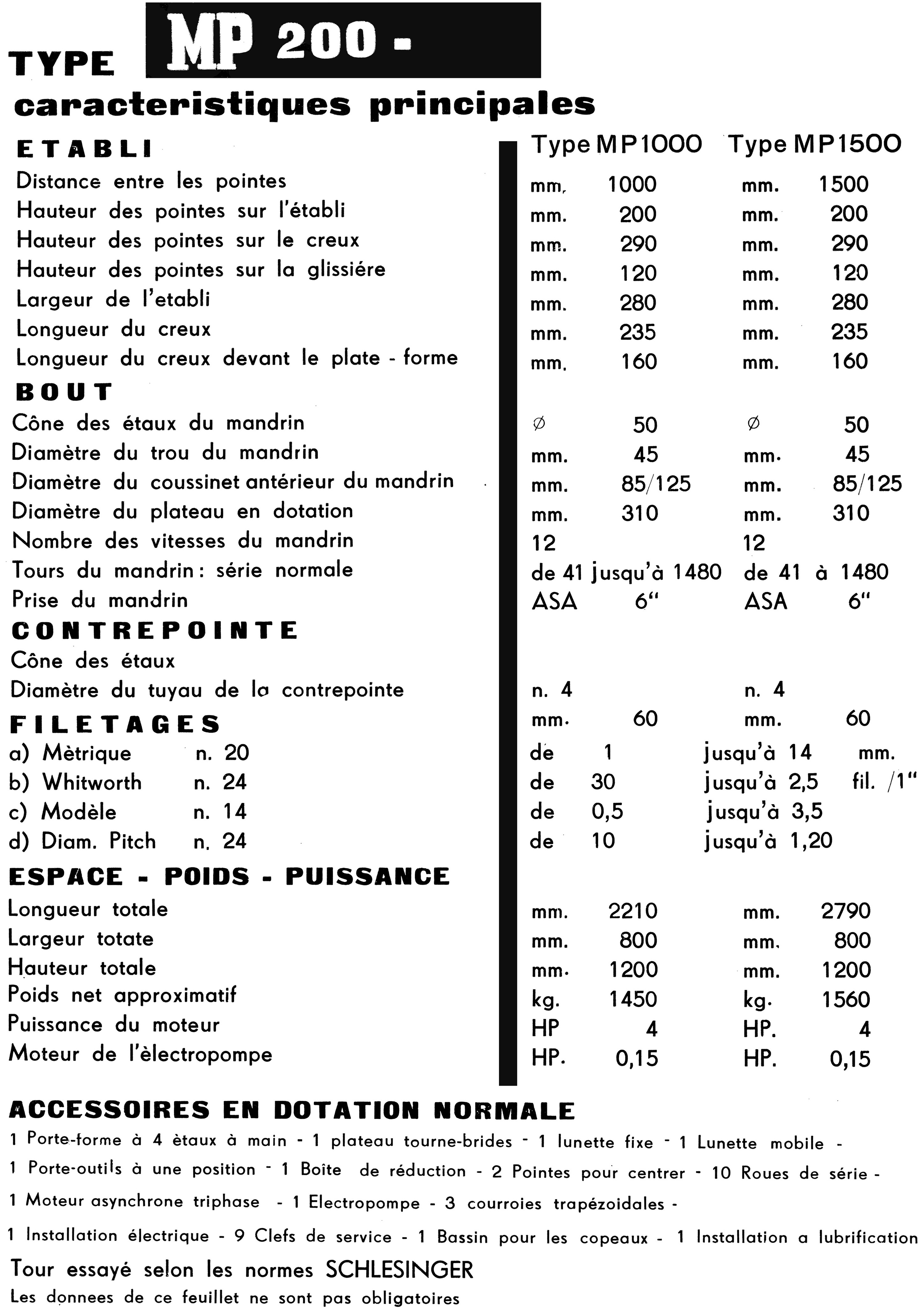

Built to Schlesinger standards, and with a centre height of 200 mm, the MP200 was built in short and long-bed versions, the former having a capacity of 1000 mm between centres and the latter 1500 mm.

Carried on heavy, box-section headstock and tailstock end plinths in cast iron and using V and flat ways, the bed was fitted with a detachable gap piece as part of the standard specification. With the gap removed, workpieces up to 580 mm in diameter and 160 mm deep could be turned when mounted on a faceplate.

Running in an oil bath with lubrication by splash, the headstock gears were in a nickel-chrome steel and hardened and ground. Turning in what the makers described as special high-precision taper roller bearings, the 45 mm bore spindle had an ASA 6" nose fitting and was driven by a 4 h.p. motor through three V-belts to a multi-disc clutch contained within the headstock. Twelve spindle speed, these ranging from a slow of 14 r.p.m. to a high of 1480 r.p.m. - a reasonable range for the size of machine.

Once started, electrical control of the lathe was by a third-rod system, two control lever being provided, one just outboard of the screwcutting gearbox, the other on the carriage, pivoting from the right-hand face of the apron.

Fully enclosed and oil-bath lubricated, the screwcutting and feeds gearbox could generate twenty metric pitches from 1 to 14 mm; 24 Whitworth from 2.5 to 30 t.p.i., fourteen module from 0.5 to 3.5 and 24 diametral from 1.20 to 10.

Locked to the bed by captive handle that doubtless worked through an eccentric cross shaft lifting a clap plate, the tailstock had a 60 mm diameter spindle fitted with a No. 4 Morse taper socket.

The shorter of the two models was 2210 mm long and the longer 2790 mm. Both were 800 mm deep front to back and 1200 mm high. The machines weighed, respectively, 1450 and 1560 kg respectively.

Included with each new lathe was a full electrical installation including a motor, coolant equipment, fixed steady, travelling steady, a large diameter 4-jaw-cum-faceplate, nine spanners and a chip tray to fit between the bed-support plinths.

Pictures are high-resolution and may take time to load