A Generic Manual & Parts List is available for this machine

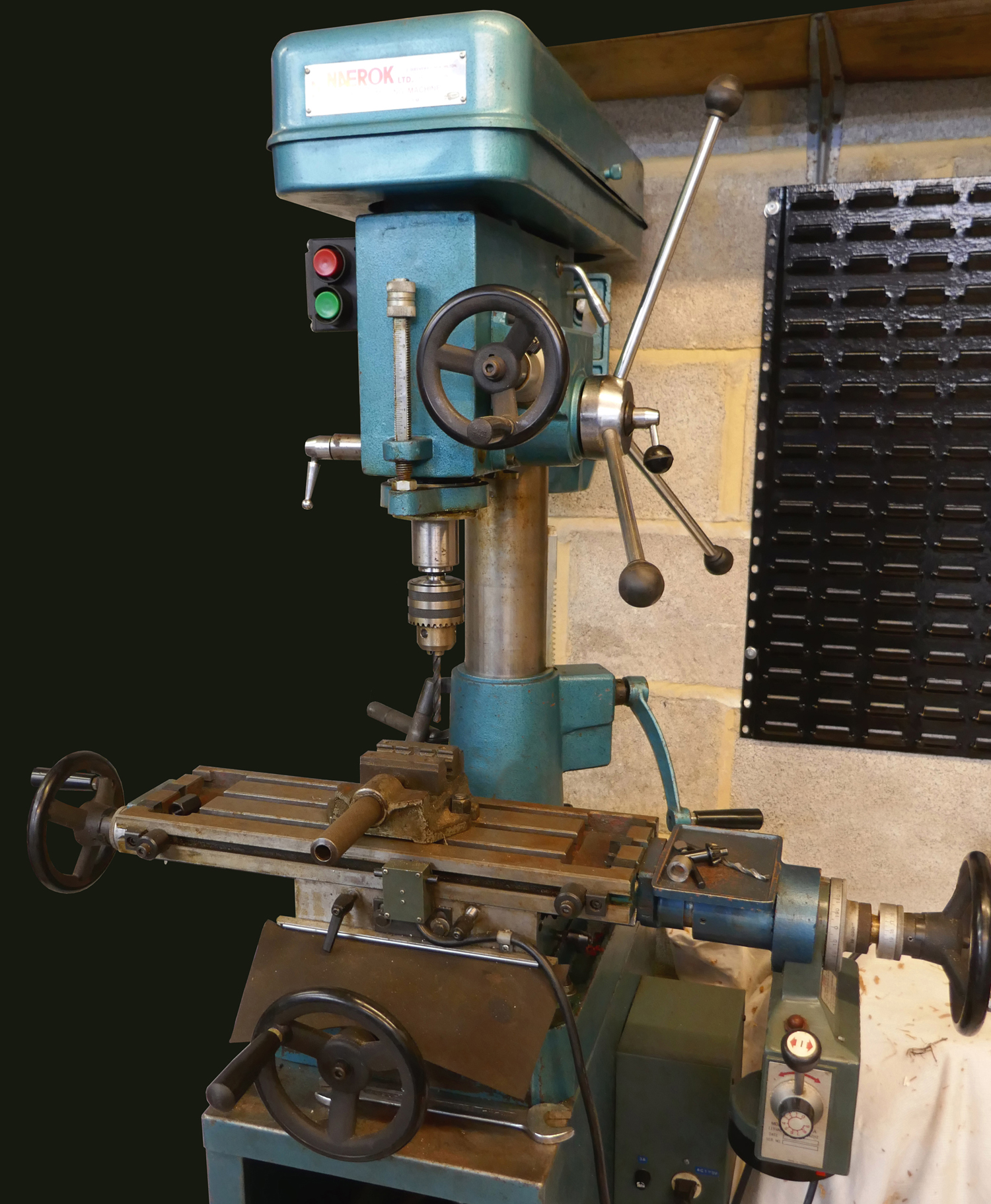

Typical of the generic Taiwanese-Korean "Mill/Drill" as made from the early 1970s, and marketed by various companies worldwide including, in the UK, as Alpine, Excel, Sealey, Nu-Tools, Pinnacle, Warco, Whitecote and Ajax, the example shown below branded "Naerok" (Korean written backwards) was certainly the best of the bunch. An almost identical model, with the electrical controls repositioned and a few very minor differences, was also sold branded as the "Alpine" - though most Alpine versions appear to lack the bevel gearbox fitted to the column elevation control (an example is shown in the last picture at the bottom of the page)

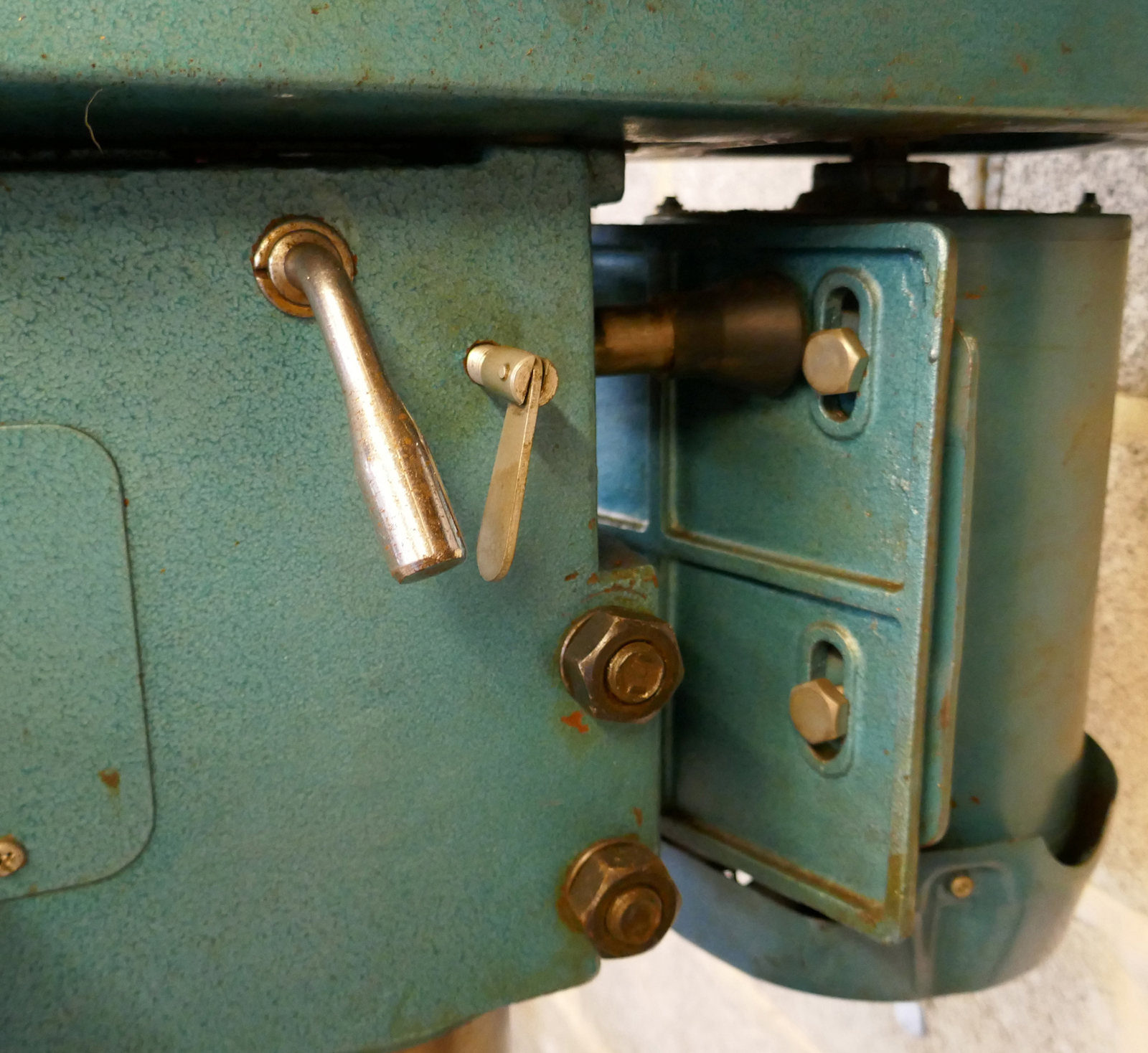

At 20" x 6.25", the table of the Naerok was usefully large with a longitudinal travel of 12.75" and in traverse of 5.5 inches (though beware, you may find that some are different together - with other details changes as well). Satin-chrome-plated, zeroing micrometer dials were fitted at both ends of the table's longitudinal feed screw, these being engraved with divisions of 0.001". Although the table locking handles had proper spring-loaded ends - allowing them to be pulled out and repositioned on their splines - on many machines they are made of plastic and so easily broken if over tightened The great advantage of the Naerok and Alpine - making them the least prosaic of the type - was the use of a bevel gearbox at the bottom of the column to elevate the complete head column assembly, this playing in important part in the usefulness of the machine for, instead of the head being able to swing freely from side to side when its clamping bolts were slackened (as on other makes), on the Naerok/Alpine alignment was maintained by a guide through the whole of the vertical travel. On the Naerok the column was locked into the base casting by two handles that closed down a slot in the casting; the handles were usefully long and hinged so allowing them to be positioned so as to get a good purchase from almost any direction.

In addition to the elevating head, the quill, which held either a Bridgeport R8 or a No. 3 Morse taper spindle, could be moved through a travel of 3.5 inches by either a handwheel fine-feed control (working through worm-and-wheel gearing with each division on the micrometer dial being 0.002") or by a 3-spoke, quick-action capstan handle. Of the two tapers, the R8 is probably the preferred one, there being a limitless quantities of inexpensive used fittings available such as collet sets, micrometer boring heads, direct-fitting collets and collets chucks, etc. On the Naerok, the spindle nose to table clearance is around 14 inches when fitted with the R8 taper (the spindle extends around 1.5 inches) so perhaps 15.5 inches with a No.3 Morse.

All version of the Naerok seen by the writer had a rear-mounted, 1-phase 3/4 h.p. motor (other makes generally being fitted with ones between 1/2 and 1.5 h.p.) with drive by an "A" section V-belt from a 3-step pullet on the motor to an intermediate, self-aligning, 4-step jockey pulley and then to a 4-step front pulley, the arrangement giving 12 speeds that spanned a most useful 90 to 2150 r.p.m. or, in some cases 110 to 1750 r.p.m. Other makes often had a higher bottom speed of 200 r.p.m. or so, together with a higher top speed of 2500 r.p.m., this arrangement making them useful for drilling and milling with small-diameter cutters - but less so for tapping. If a particularly wide speed range is required, it's a simple job to fit a 3-phase motor controlled by a 1-phase to 3-phase variable-speed inverter.

The motor was held on a plate, hinged on its left-hand edge with tension applied to the belt by a simple push-rod on the right-hand side. The metal-to-metal contact of rod and plate can lead to rattles, the solution? Fit the rubber end from a walking stick over the end of the barů

A word of warning, the maker's spindle-speed figures for these millers are often slightly and sometimes very much out - it being likely that some were fitted with charts intended for American and other markets where a 60 Hz electricity supply resulted in speeds some 20% higher than on the UK's 50 Hz. The hinged pressed steel guard over the belt drive did leave something to be desired, being too flexible and with a nasty spring catch to hold it closed - together with hopeless rubber seal around its periphery.

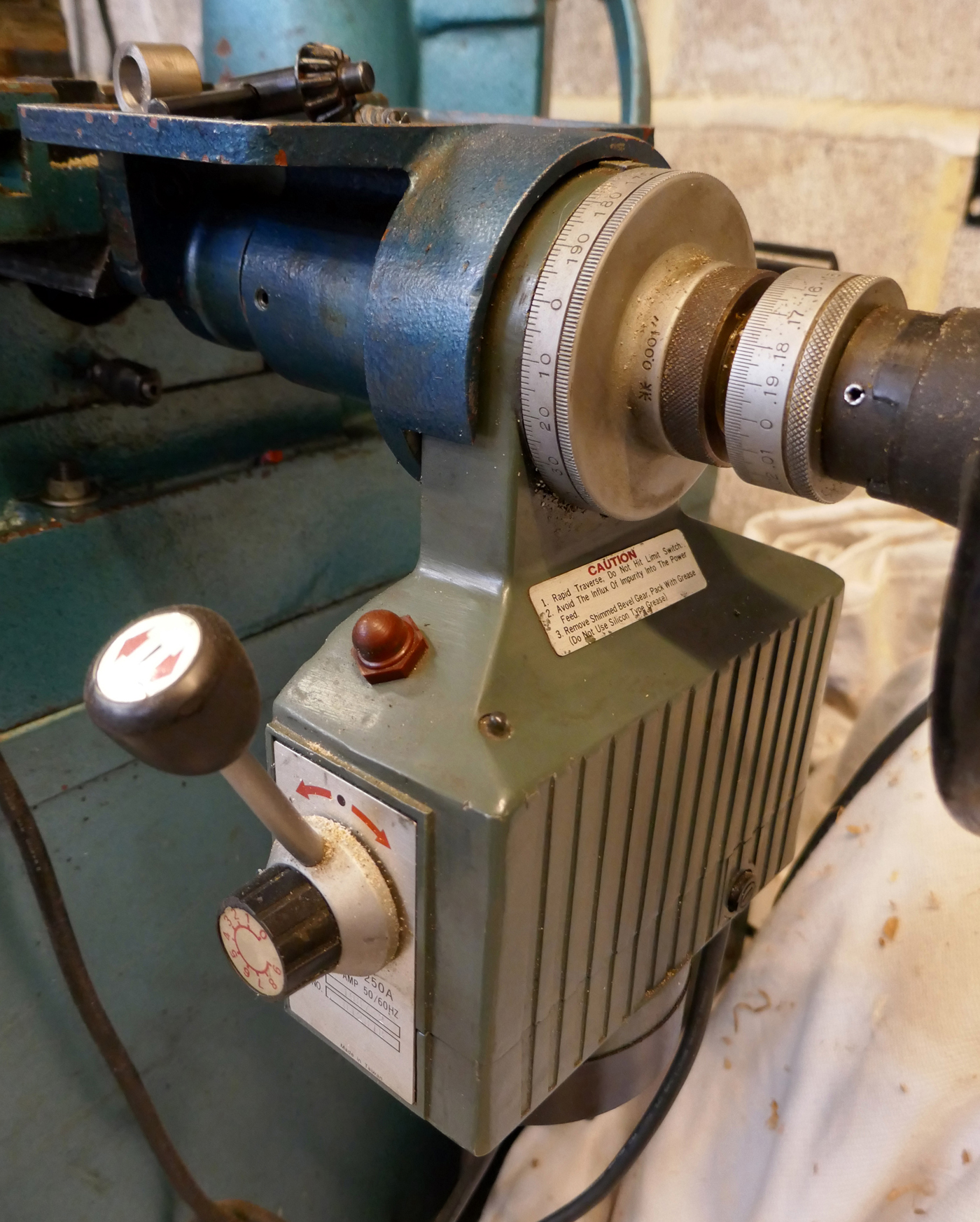

A further advantage of the Naerok was the availability of a very useful, infinitely-variable, auto-knock-off power longitudinal feed to the table. The unit was a third-party, Taiwanese-built type that was also offered for retro-fitting to other small milling machines. It came with a very large, satin-chrome plated, clearly-engraved inch or metric division micrometer dial locked by a "non-upset", screw-action face-ring. This unit is still made today - by various companies - and makes a handy addition to any small miller.

Although inexpensive and of relatively crude construction - and with a less-than-perfect cosmetic finish - this type of Korean/Taiwanese mill/drill is a most useful addition to any workshop. Able to mill to tolerable accuracy with either large or small cutters, it becomes additionally handy when used as a coordinate drill - the vice being bolted securely to the table and the slides then manoeuvred to bring the workpiece exactly into the required location beneath the drill bit.

Although the writer is reluctant to admit it - in case you think my opinion is infallible, which it is not - this is the mill/drill I've have chosen to use in my home workshop for casual, odd-job milling and drilling work.

Some high-resolution pictures - may take time to open