|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Long established as a builder of fine machine tools including horizontal borers and radial-arm drills, today Meuser lathes are still made in Frankfurt, West Germany. In past years they were sometimes shown in north-American advertising literature carrying "Barer-Meuser" badges - reflecting the important part played in their distribution and servicing by the Barer Engineering and Machinery Company, a firm with offices at 229a Shaftsbury Avenue, London W.C.2 and 1365 Basin Street, Montreal, Canada.

Meuser concentrated on larger machines of 8-inch and greater centre height and by 1961 had sold over 27,000 examples. During the middle decades of the 20th century the company's fortunes were at their zenith with a product range that encompassed a wide variety of types and sizes: the popular and conventional L-Type "production and precision lathes"; S-Type Selekta "Super production, highest precision" types with 321 different threads, 174 longitudinal and cross feeds, 18 forward and 9 reverse speeds and 25 h.p. motors; the M-V1 and M-V1B "Extra heavy-duty universal lathes" with centre heights ranging from 32 to 72-inches, between-centres' capacities of up to 360-inches and power feeds and rapid traverses in 6 directions (each way to carriage, cross slide and tailstock) and the giant M-V11-S and M-V111-S models that could be had in sizes weighing up to 223 tons with a 112-inch centre height and 75-feet between centres capable of taking workpieces up to 100 tons or more. These huge lathes had 4 bedways (often with 2 carriages) and 6 rapid traverses, as the M-V1 and M-V1B models, but with the tailstocks additionally fitted out for boring and trepanning work with separately-powered speeds and feeds.

Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

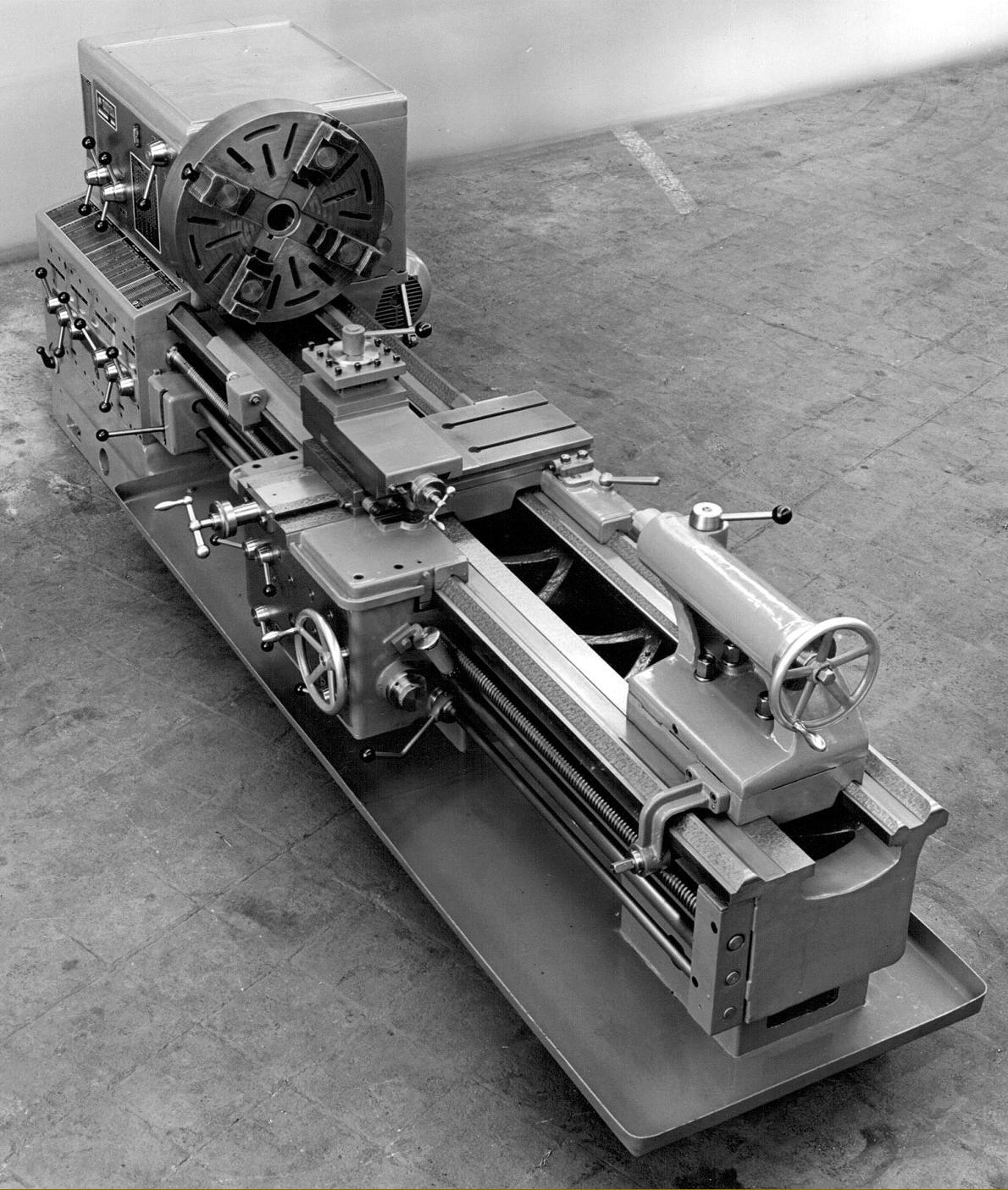

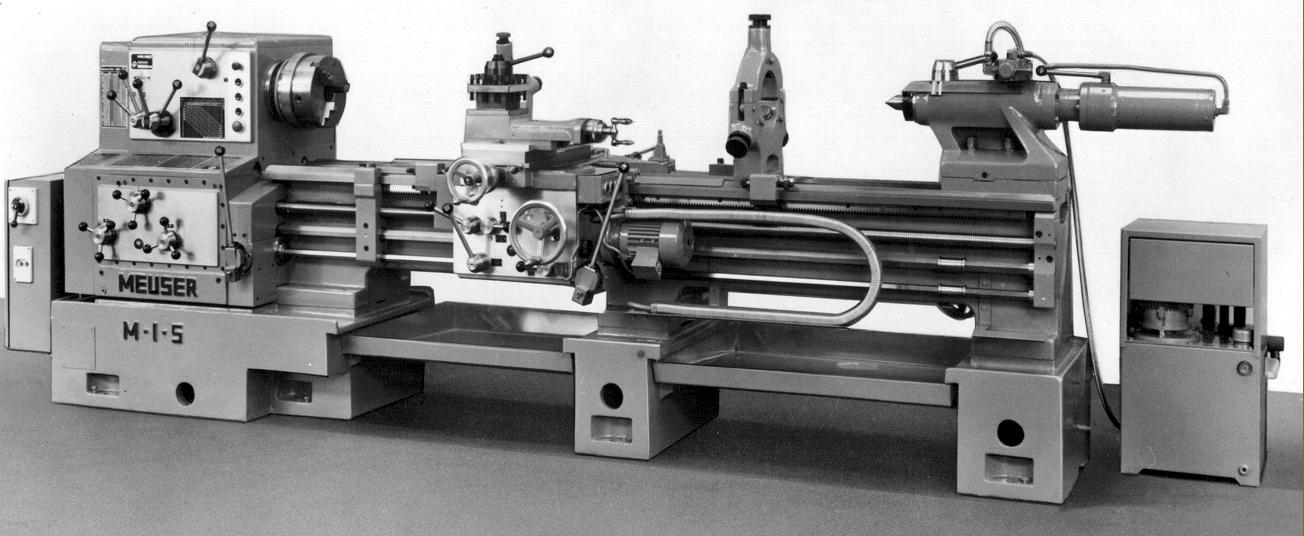

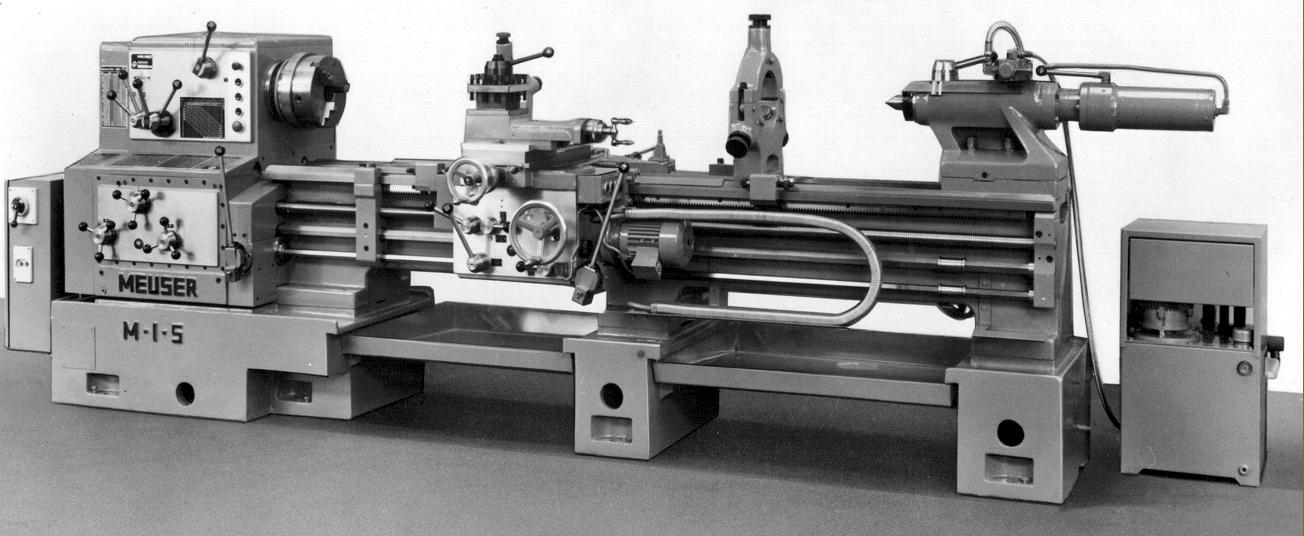

The popular Meuser Type L as manufactured during 1960

|

|

|

|

|

|

|

|

|

Continued:

Of all the models available the L-Type lathes were the most popular and could be had in a wide range of sizes with each designated by either a zero, double zero or a Roman numeral: the smallest was the 16-inch swing Model M-00-L, also produced in a slightly heavier-duty version the M-0-L. The next-largest machine, the M-1-L, could be had with 20, 18 or 16-inch centre heights; the M-11-L as a 22, 20 or 18-inch versions; the M-111-L as a 28, 24 or 20-inch machine and the largest in the range, the M-1V-L with 40, 36, 32 or 30-inch centre heights. Between-centres' capacities followed a similar overlapping range with the "baby" M-00-L admitting between 20 and 80-inches; the M-0-L 30 to 100-inches; the M-1-L 30 between 30 and 100-inches; the M-11-L from 30 to 160-inches; the M-111-L 40 to 200-inches and the M-1V-L40 to 240-inches. The makers were careful to ensure the beds were well supported and specified that machines with between 60 and 80-inches capacity had 3 cabinet legs; those from 100 and 120-inches required 4 legs; 140 to 160-inches demanded 5 legs and anything in excess of that 6 legs. The bed was in Meehanite iron, very heavily cross ribbed and with the carriage slideways protected from swarf by long covers protruding from each corner of the saddle. When the carriage was in motion an oil pump forced lubricant not only around the apron but also onto the bedways. All models could be had with or without a gap bed but, on early versions, only gapless models enjoyed bed that was flame hardened, the gap models were, instead, given either a ground or hand-scraped finish. Later machines, no matter of what type, all had beds that were hardened and ground.

Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Meuser Type L from the back clearly showing the enormous depth of the bed

Continued:

Drive to the headstock was by multiple V-belts from an electric motor bolted to a pair of vertical rails at the back of the headstock; these, in turn, were carried on horizontal slides - so allowing almost any suitable motor to be mounted and adjusted without difficulty. 12 all-geared speeds (or 24 with the optional 2-speed motor) were available with a choice of 28 to 1250, 40 to 1800 r.p.m. forwards and (strangely) a faster set of 70 to 1550 or 100 to 2200 r.p.m. in reverse for the M-00-L, M-0-L and M-1-L models (using 5, 5.5 and 7.5 h.p. motors respectively); 25 to 1120 r.p.m. or 36 to 1600 r.p.m. forwards and 63 to 1400 r.p.m. or 90 to 2000 r.p.m. in reverse for the M-11-L (10 h.p. motor); 22 to 1100 r.p.m. or 32 to 1400 r.p.m. forwards and 56 to 1250 r.p.m. or 80 to 1800 rpm in reverse for the M-111-L (12.5 h.p. motor) and 20 to 900 r.p.m. or 28 to 1250 r.p.m. in forwards and 50 to 1120 r.p.m. or 71 to 1600 r.p.m. in reverse on the M-1V-L (20 h.p. motor). A double-disc clutch was fitted within the headstock for instant selection of forward or reverse to the spindle and an automatic brake included that operated immediately the drive was disconnected. Control of the spindle start, stop, reverse and brake was by a long control-rod set below and parallel to the powershaft with duplicated control levers to the right of the gearbox and (to ensure it was always within safe reach of the operator) pivoting from the right-hand face of the apron. Very long machines could also have, for additional safety and control, a third lever mounted at the tailstock end of the bed. The headstock used a mixture of hardened and ground spur and helical gears with the spindle running on 4 rows of the highest precision, machine-tool-class pre-loaded roller bearings with all the layshafts on ball bearings. A pump supplied oil directly to the spindle's main bearings with the gears lubricated by splash. A transparent dome in the roof of the headstock, into which the oil was first squirted before falling into a distribution tray set immediately beneath the headstock cover, assured the operator that the oil supply was functioning correctly. Headstock-spindle dimensions naturally varied with the capacity of the machine with the smallest having a 1.625-inch bore and the largest 3-inches. The two smallest lathes the M-00-L and M-1-L carried D1-6-inch spindle nose fittings, the M-1-L, M-11-L and M-111-L a D1-8-inch and the largest M-1V-L model a D1-11-inch.

Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Photographed in the works of J.H.Horne & Sons Co. Lawrence, Massachusetts (a long-established supplier of paper-mill machinery) a M-111-L 28-inch swing lathe is seen turning , with the use of a 12-inch hydraulic tracer attachment, a dielectric covering for missile-mounted radar instruments

Continued:

Screwcutting and feeds was taken care of by a remarkable gearbox with a choice of no fewer than 262 pitches on the three smaller types and 263 on the three larger. Without altering the changewheel drive 86 English threads from ¼ to 144 t.p.i could be set as well as 60 metric from 0.50 to 76 mm, 82 Diametral from 1 to 176 threads and 35 Module from 0.25 to 21 module. The three smaller lathes (M-OO-l, M-0-L and M-1-L) normally started their threading range from ½ t.p.i but could, on request, also be equipped to generate ¼ t.p.i (one pitch on a 4-inch length). Power sliding rates on all versions of the L-Series were identical and, by using both the coarse and normal feed settings, ranged from 0.00138-inch to 0.31496-inch sliding and 0.00035-inch to 0.07874-inch surfacing - all per revolution of the spindle.

The apron was very heavily built and fitted with two oil pumps - one for its own lubrication and another to supply oil to the bed and cross-slide ways. The leadscrew was clasped by an unusually long split bronze nut and the power-feeds drive shaft was of hexagon section. Power sliding could be set to automatically disengaged in either direction by micrometer stops, adjustable in increments of 0.001-inch; however. there was no such facility on the cross feed where, on such large lathes, it would have been especially useful. As an option on the M-1V-L models a rapid 4-way traverse unit by a separate motor could be fitted, a valuable aid in speeding up jobs on lathes with longer beds.

The compound slide rest was fitted with screws running through adjustable bronze nuts, taper gib strips and a cross-slide of the full-length type with its rear section carrying two longitudinal T slots in the fashion then common on German lathes. The cross-feed screw was fitted with anti-friction thrust bearings (either radial needle or ball race) and the top-slide could be swivelled through 180-degrees in either direction. The zeroing micrometer dials were marked in 0.0005-inch divisions enabling the operator to make direct readings of 0.001-inch off the diameter.

Each model had a precisely-engineered tailstock with the M-00-L, M-0-L 30, M-1-L 30, M-11-L, M-111-L and the M-1V-L40 taking, respectively, the following specifications: length of tailstock bearing on the bed: 9", 9.5", 11", 12.5", 14" and 16.5"; quill diameter: 2", 2.125", 2.375", 2.75", 2.375" and 4". quill travels: 4", 5.75", 6", 6.5", 7" and 9.5"; Morse centre: 3MT, 4MT, 4MT, 4MT, 5MT and 5MT.

As might be expected, weights varied enormously: the lightest Model M-00-L tipped the scales at approximately a modest 2700 lbs (1.2 tons) whilst the heaviest long-bed M-1V-l weighed in at a considerable 10,900 lbs (4.9 tons)..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

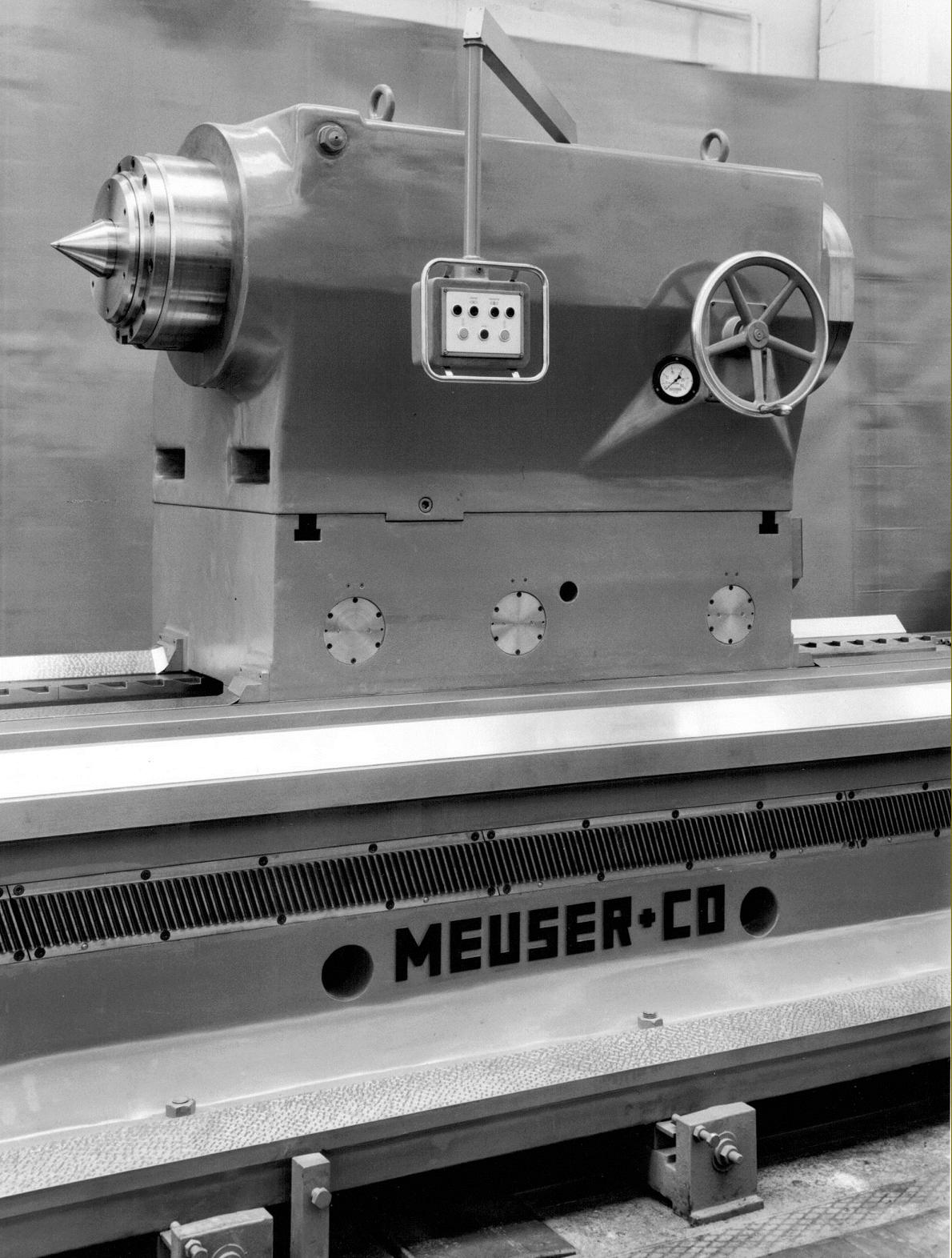

A large paper roll being turned on a Meuser Model M-V111-S lathe with an 84-inch swing and 34-foot centres

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

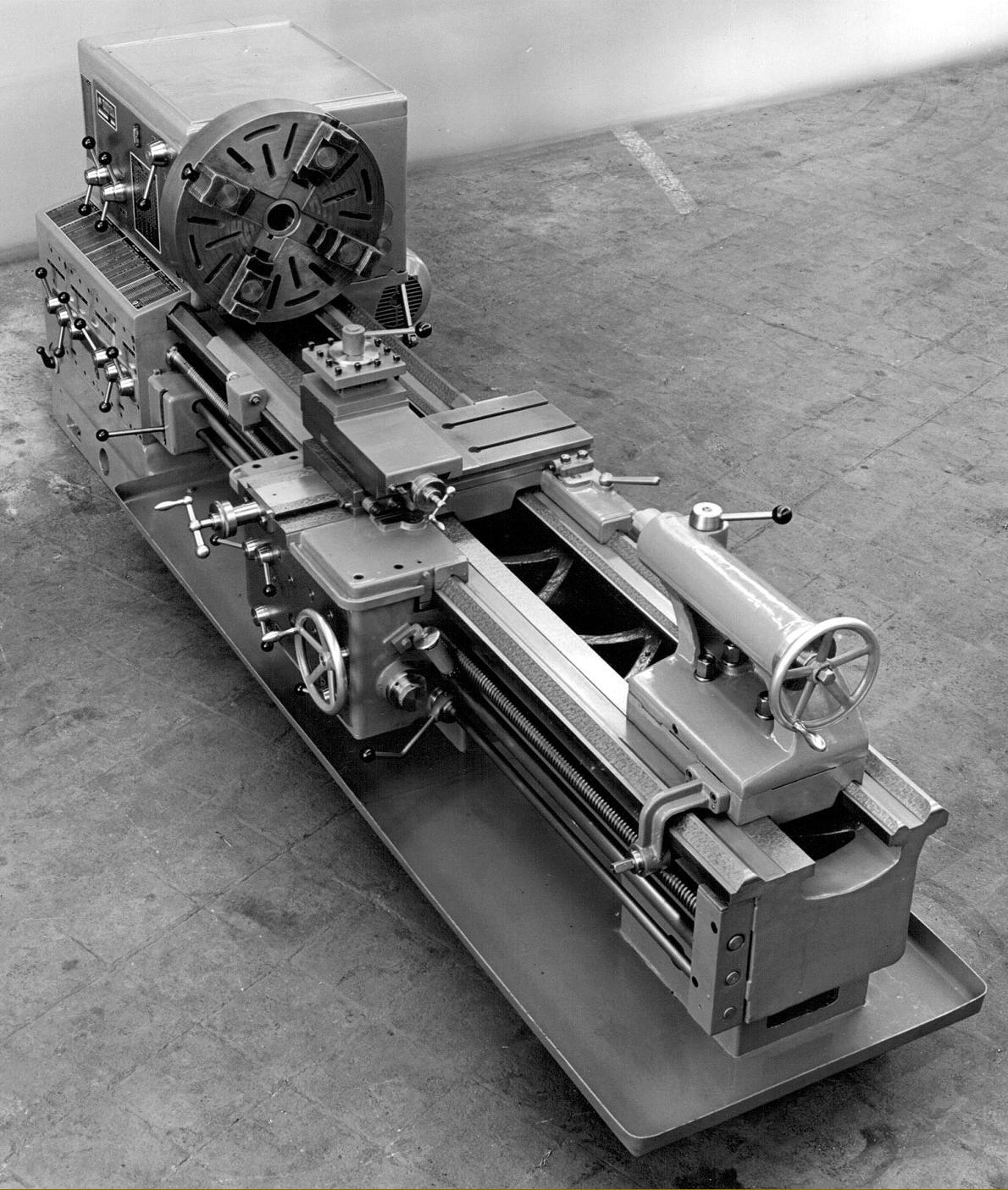

Barer-Mauser Model M-00-L-16-inch swing with 30-inch centres

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12-speed Meuser headstock built with in the form of a thick-walled, open-topped box with a strengthening lip around the top opening

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screwcutting and feeds was taken care of by a remarkable gearbox with a choice (as standard) of no fewer than 262 pitches on the three smaller types and 263 on the three larger. Without altering the changewheel drive 86 English threads from ¼ to 144 t.p.i could be set as well as 60 metric from 0.50 to 76 mm, 82 Diametral from 1 to 176 threads and 35 Module from 0.25 to 21 module.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Meuser S-Type Selekta "Super production, highest precision" type with 321 different threads, 174 longitudinal and cross feeds, 18 forward and 9 reverse speeds and a 25 h.p. motor

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

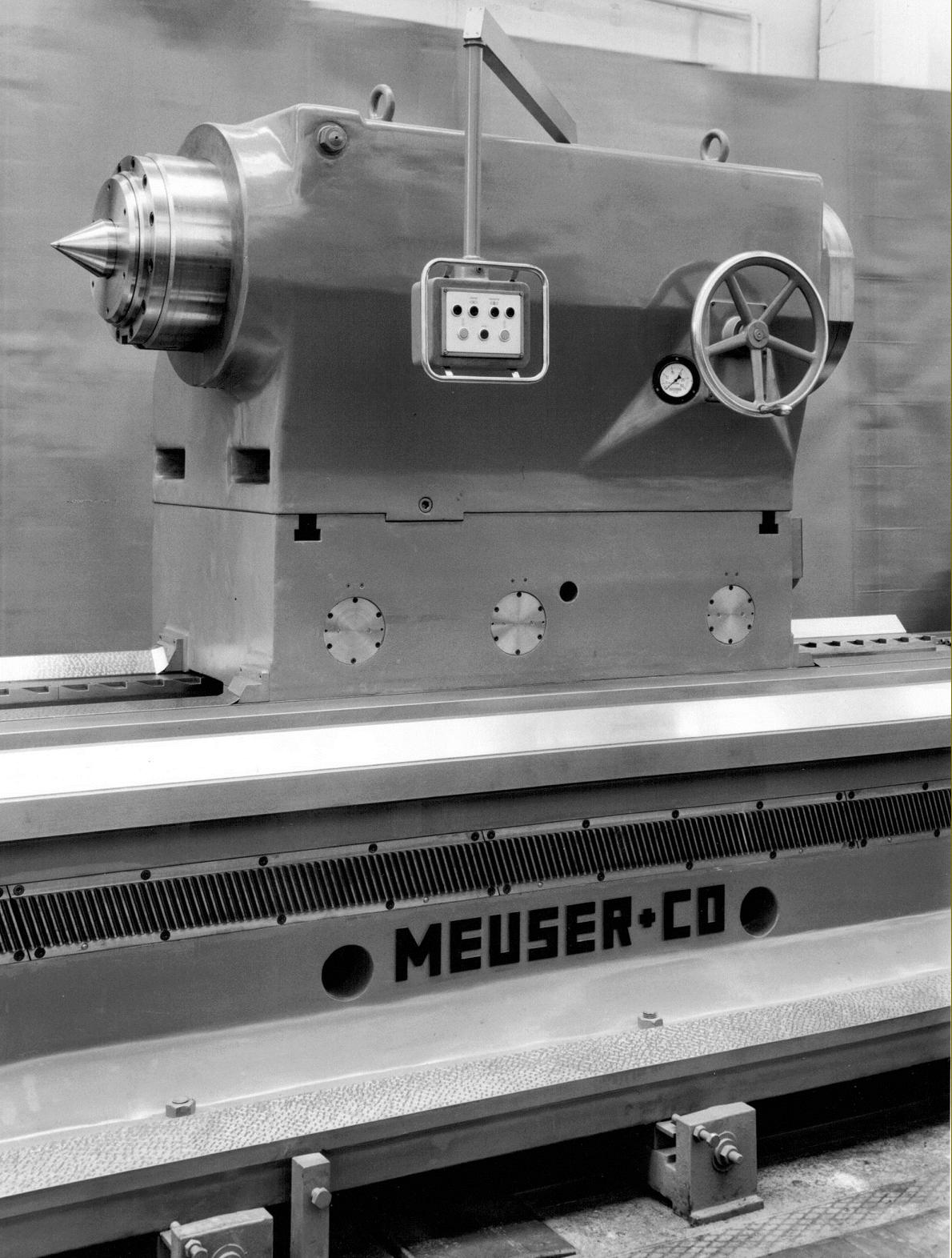

Meuser M-V1 and M-V1B "Extra heavy-duty universal lathes". These lathes were available with centre heights ranging from 32 to 72-inch and between-centres' capacities of up to 360-inches. Rapid traverses were available in all directions to carriage, cross slide and tailstock..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The giant Meuser M-V11-S and M-V111-S lathes could be had in sizes weighing up to 223 tons with a 112-inch centre height and 900-inches between centres capable of taking workpieces up to 100 tons or more. These huge lathes had 4 bedways (often with 2 carriages) and 6 rapid traverses, as the M-V1 and M-V1B models, but with the tailstocks additionally fitted out for boring and trepanning work with separately-powered speeds and feeds.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The photographs below are from the Meuser factory archives

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|