A Manual is available for the Meca TR-1

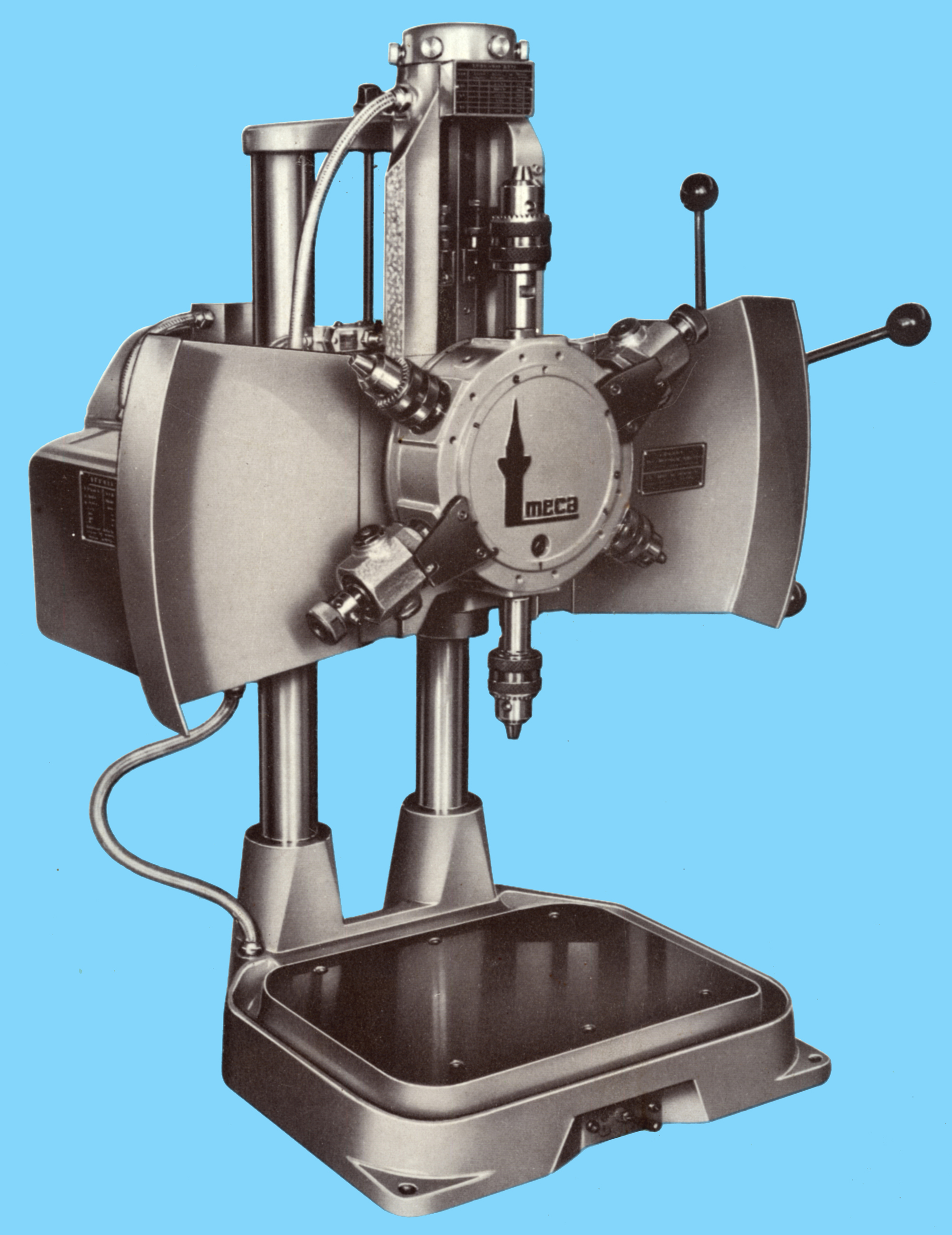

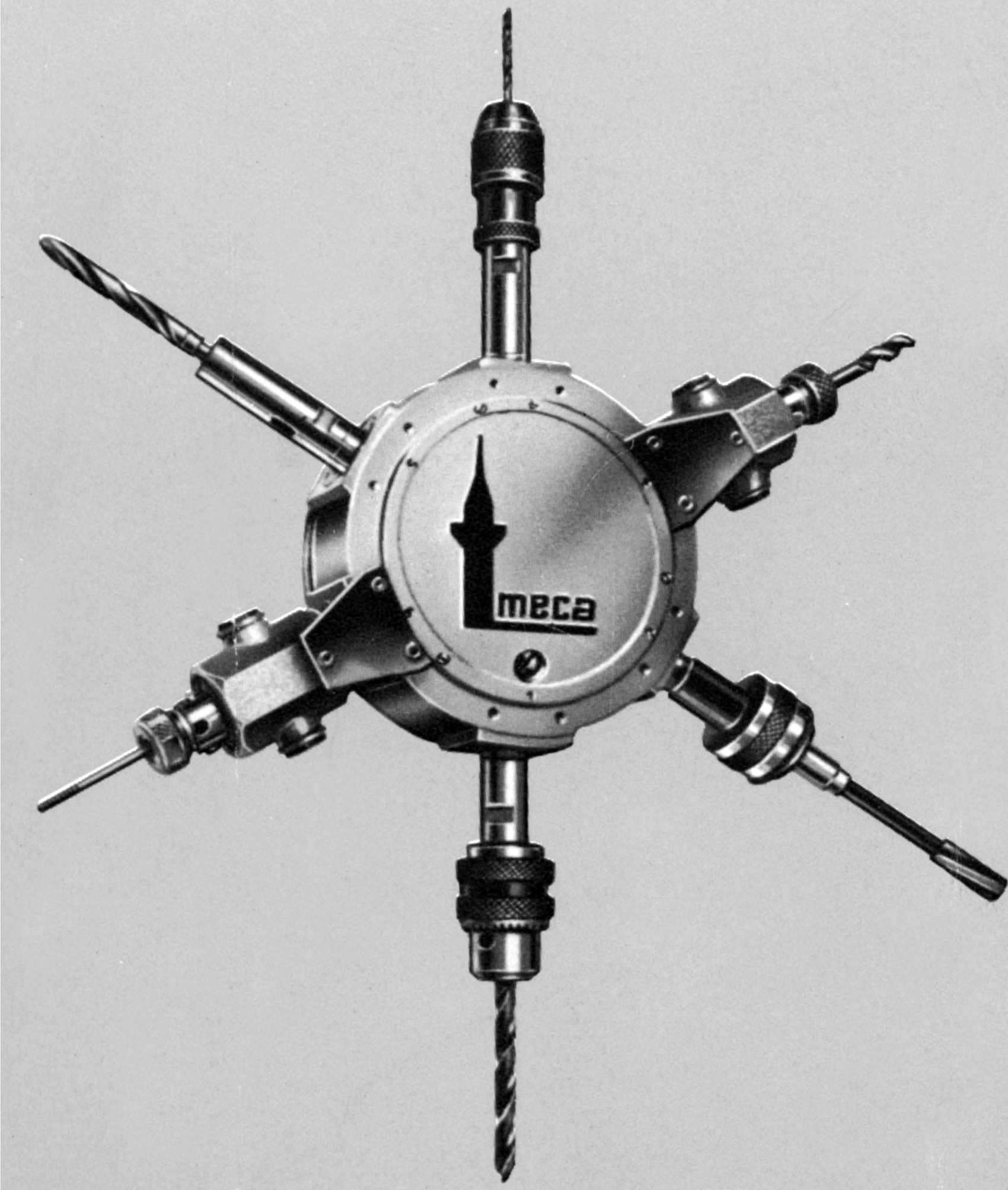

Built in Spain by the Mecatecnica Company, the Meca TR-1 was designed as a clever, multi-function machine able to drill holes up to 1/2" diameter in steel and 5/8" in cast iron and intended to replace several separate drilling machines. Fitted with a 6-station rotating capstan head it could, when fitted with the appropriate tooling, perform a sequence of operations that included combinations of spot drilling, spot facing, conventional drilling, thread tapping, counter-boring, counter-sinking and reaming, etc.

Moving up and down on a pair of vertically mounted, solid steel bars, the head was fitted with nickel-chrome steel spindles that rotated in precision ball races. In order to reduce slack time and keep the length of tools nearly the same as possible, the makers offered a set of spindle extensions in lengths of 1", 2" and 3" (25, 50 and 75 mm). A self-contained, power-driven auto-indexing facility was provided, this being engaged when the manually-operated down-feed capstan-handle lever was returned to within 3/4" (20 mm) of its starting position (though where an operation needed to be duplicated, the control could be set to prevent auto-indexing). The indexing drive passed through an adjustable safety clutch, this needing occasional adjustment to ensure that it operated without slipping and locked securely into the next position.

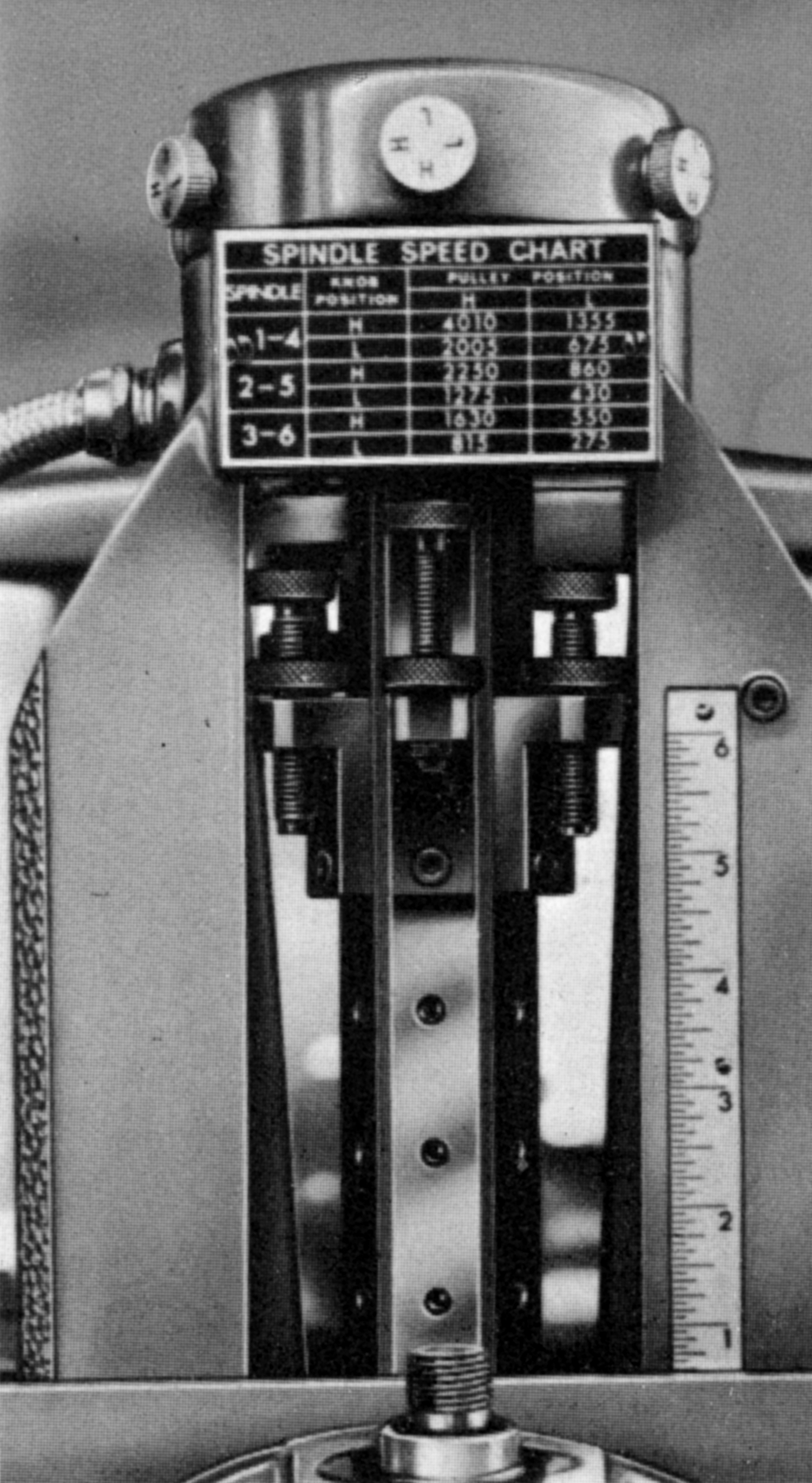

Unlike the better-known American-built Houdaille Burgmaster turret drilling machine, the Meca had four speeds available for each spindle (early versions had only two), these running from 275 to 4010 r.p.m. on a 50 Hz supply and able to be pre-selected. The drive arrangement used a 2-speed, 1 h.p. 1500 and 3000 r.p.m. 3-phase motor, a 2-step manually-changed belt drive, a universally-jointed drive shaft and an oil-sump lubricated gearbox - a separate speed-control knob being fitted for each spindle. The result was a range of 12 speeds for the operator to pre-select from - each set of four being as nearly perfect for a typical job sequence as possible with the complete set being, in low-range: 275, 430, 550, 675, 860 and 1355 r.p.m. and in high-range: 815, 1275, 1630, 2005, 2550 and 4010 r.p.m. In use, the operator would mount the required tooling - for example, to centre drill, drill and tap a thread - and then pre-set the particular speed required for each operation (a chart being fitted on the front face of the head that showed the various combinations of settings available). In addition to a vertical ruler in the machine's front face, adjustable depth stops were provided for each spindle, the mechanism rotating automatically with the head and so always in the correct position.

The turret travel was a reasonable 6 inches (153 mm), the maximum clearance between a spindle nose and the ground surface of the table 22 inches (559 mm) and the throat (spindle to column distance) 8.5 inches (216 mm).

Some pictures are high-resolution and may take time to load