|

Manufactured in Canada, MacGregor Gourlay made a range of shaping machines, including some very large examples, one of which is shown here.

The machine on this page was stamped by its makers as being completed on December 1st, 1903. Although of just 10-inch stroke (and so comparable with much lighter models intended for instruction and repair-shop work) this was a type intended for heavy work in a factory. Featuring a straightforward design, massive construction. (it weighed 1080 lbs) it had the ability (as proven by its present sound mechanical order) to absorb decades of hard use - it must have met, fully, its designer's brief.

Split into upper and base sections, the 45-inch high main column castings were held together by just four bolts and two dowel pins, the former accessible only through the underside of the foot, the makers probably reasoning that, once joined, the two sections would never need to come apart.

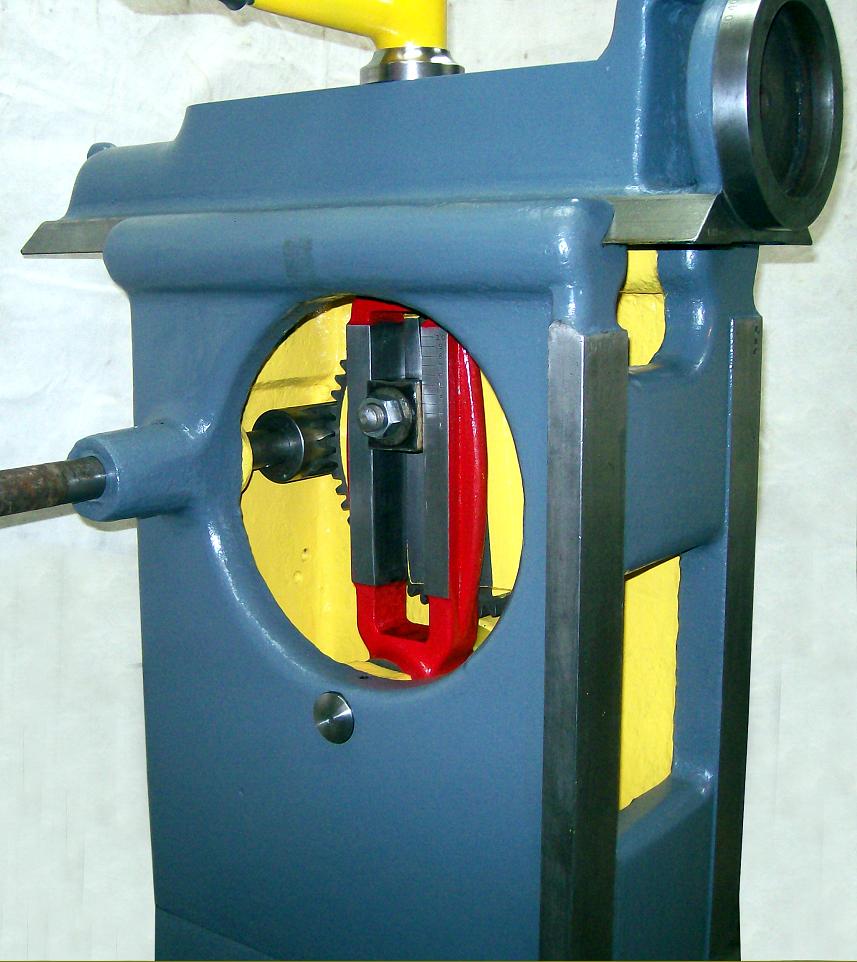

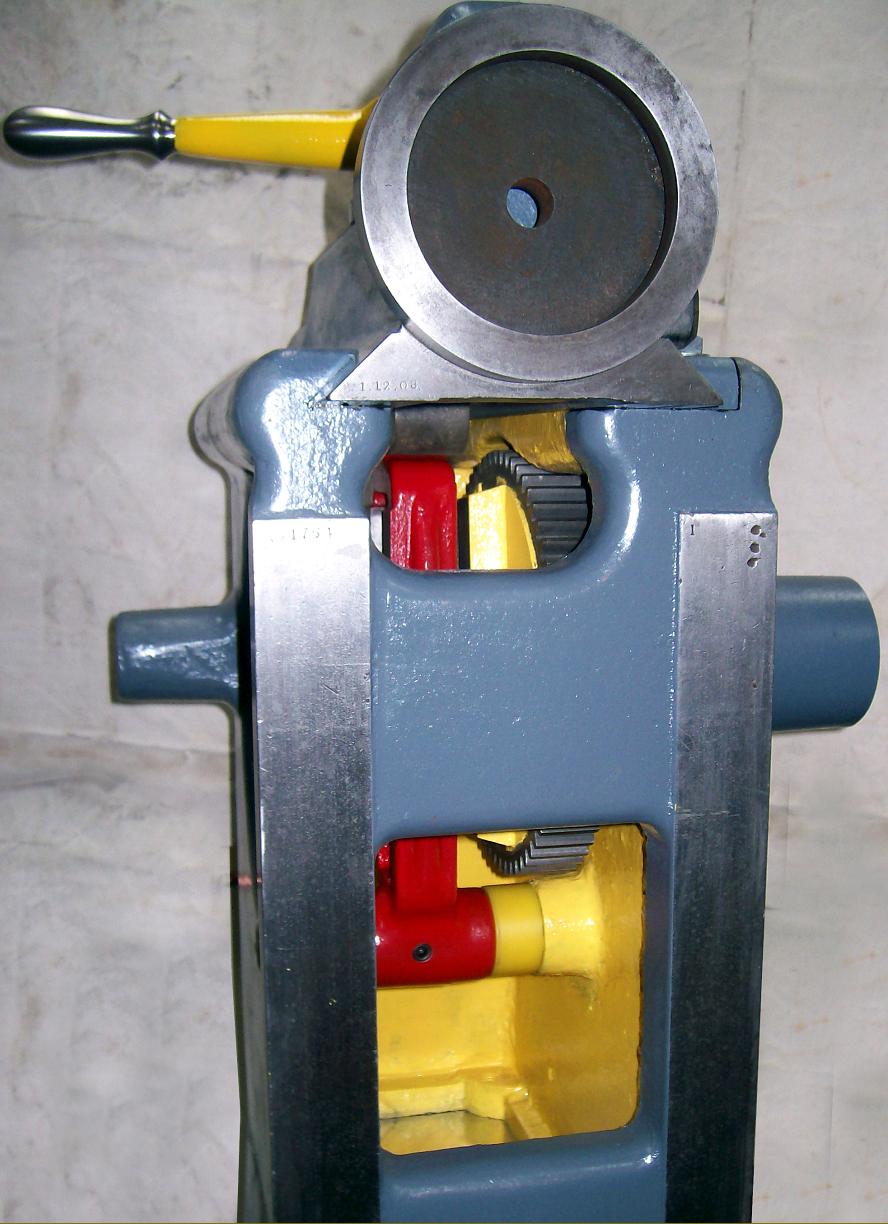

24 inches long, the ram was 7 inches wide with 45-degree sides (where 60 might have been expected) and ran in 16-inch long ways with the fit adjusted by a substantial, 2-inch wide, 1-inch thick gib block. Unfortunately, only three adjustment screws were provided, though the thickness of the gib would have prevented any high spots being produced by screw pressure. Slide rails for the cross slide were 20 inches high - giving the table a vertical travel of 10 inches. Nicely ground oil grooves were machined into all the bearing surfaces, though the lack of any sealing, and the open and unprotected oil ports meant that excess oil ran out and lubricated the floor.

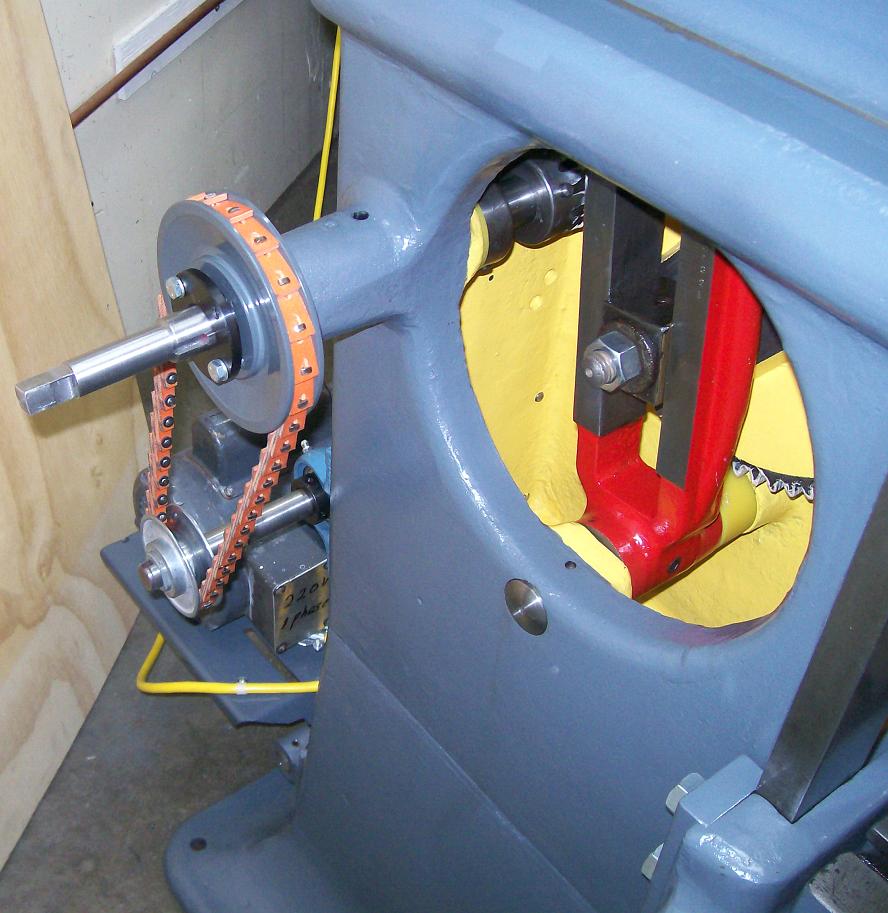

Drive to the ram came from a massive, 10-inch diameter one-piece bullgear, with 60 teeth, running on a 27/8" drive shaft - the latter fitted with a 2-inch diameter by 3/4" long fine thread on the end to take the plate for the "feed adjuster", a part that was simply screwed on and, when assembled, gave about 0.005 clearance to the casting. The 12-tooth pinion gear was secured on its 13/16-inch shaft by a tapered pin, peened over at both ends (and so awkward to remove) - the assembly running in plain babbit bearings (that, a century after being made, still had only 0.006" of radial play). Extended beyond one end of the machine by 8 inches, the pinion shaft would originally have been fitted with a flat-belt pulley intended pick up a drive from overhead line shafting. Now restored to full working order, the shaper is back in action.

A second, much larger MacGregor Gourlay - from a mining town in the Rocky Mountains - has also been found. At some point in its life this had been modified - very professionally - by the addition, on a cast frame behind the shaper, of a 4-speed gearbox that appears to have come (judging from an attached plaque) from the 1950s or 60s.

Upon stripping it was found that this was a very ruggedly built though perhaps rather crude machine - most of the machining on flat surfaces and keyways having been done economically with a shaper and planer - only a Wood-ruff key on the stroke-adjustment spindle showing evidence of a milling machine being used. All the plain bearings and slideways had oil grooves, these being hand cut with chisel. One groove in particular stood out as having required some skill to execute - inside a 1-1/2'' bore for a length of about 6''. The main spindle bearings had been poured with babbit (white metal) direct into the casting and all the major castings smoothed with a black concoction that appeared to have been some sort of lamp black and shellac - but could it also have had (as many earlier machines used some lead content?.

Two videos showing the shaper running can be seen here and here

|

|