|

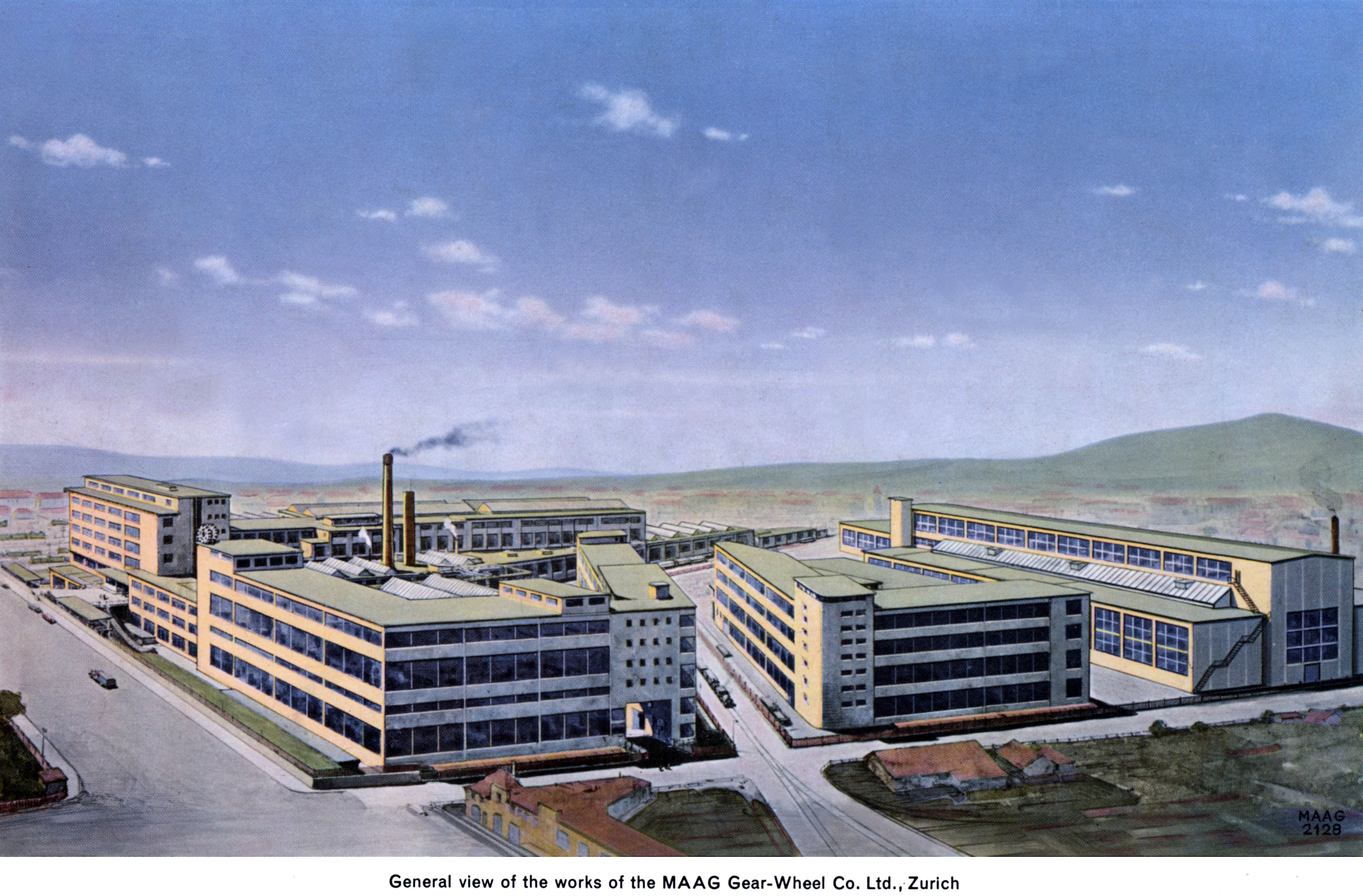

Having started his first workshop in Horgen, in 1913 the Swiss national Max Magg moved his embryonic company to the former works of the car maker Safir, a building situated in Hardstrasse 219, in Zurich, Switzerland. Now called Zahnräder Aktiengesellschaft, the firms aim was to make high-precision gearboxes. Sensibly, as making gearboxes involves making gears, the company branched out into the manufacture of gear-making machines, these including toothed planers, tooth grinders and gear testing and measuring machines. Manufacture of these machines continued until the end of 1989 when a decision was made to concentrated on their highly successful gearbox line. Today, specialising turbo gearboxes, integral gear units, synchronous clutch and toothed couplings and spare parts for older units, the Company is based at Sulzer-Allee 46, in Winterthur, Switzerland, and trades as RENK-MAAG GmbH.

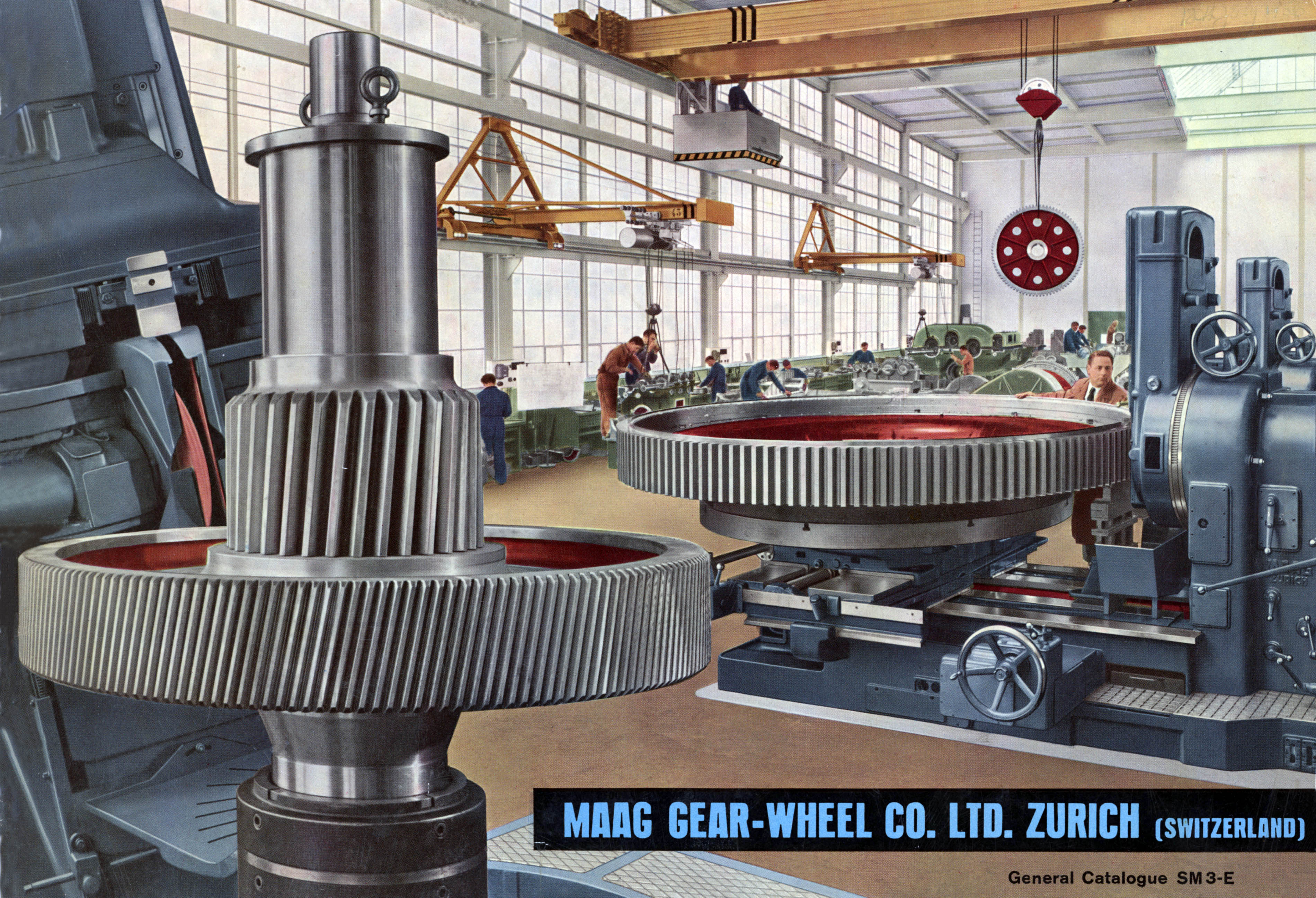

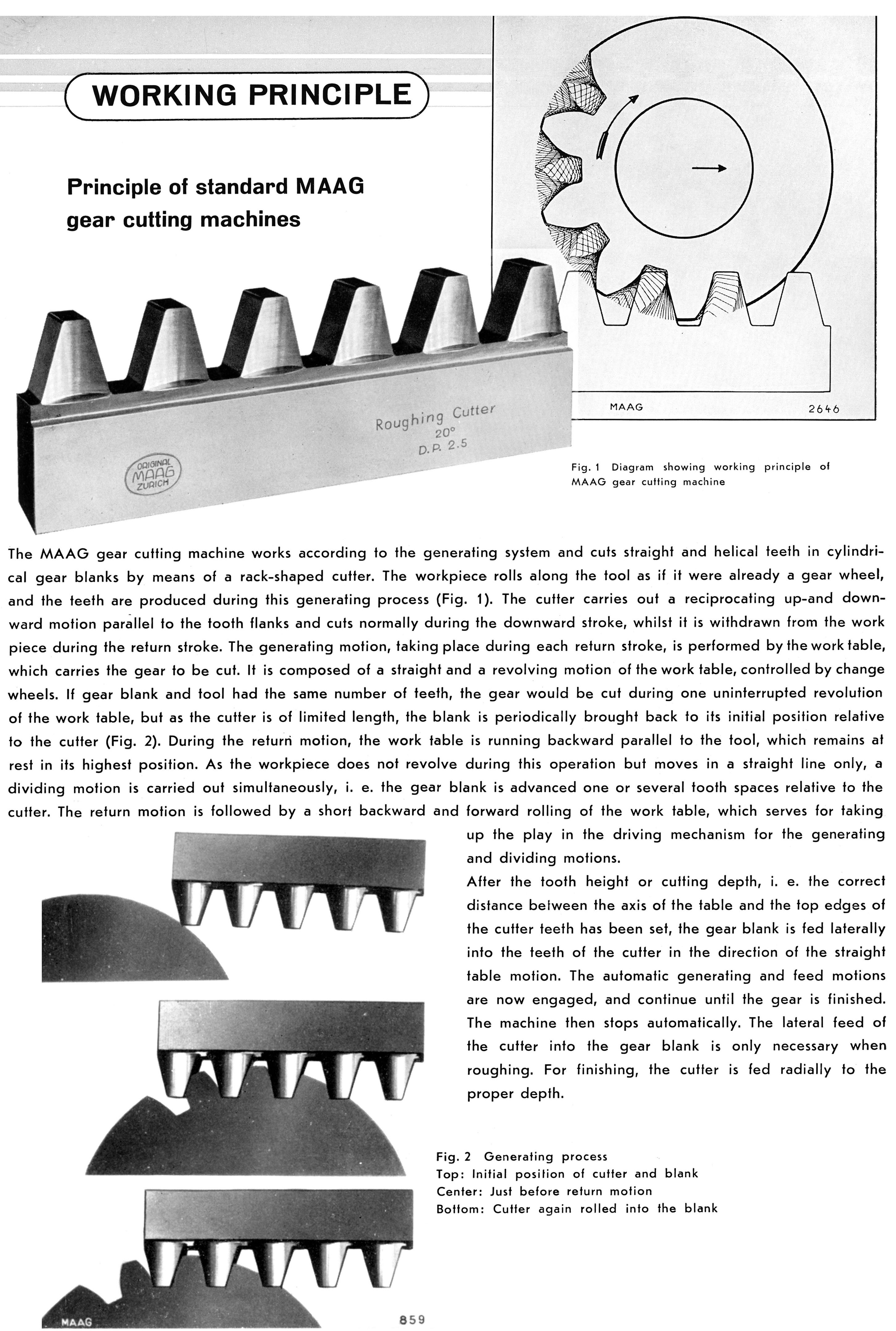

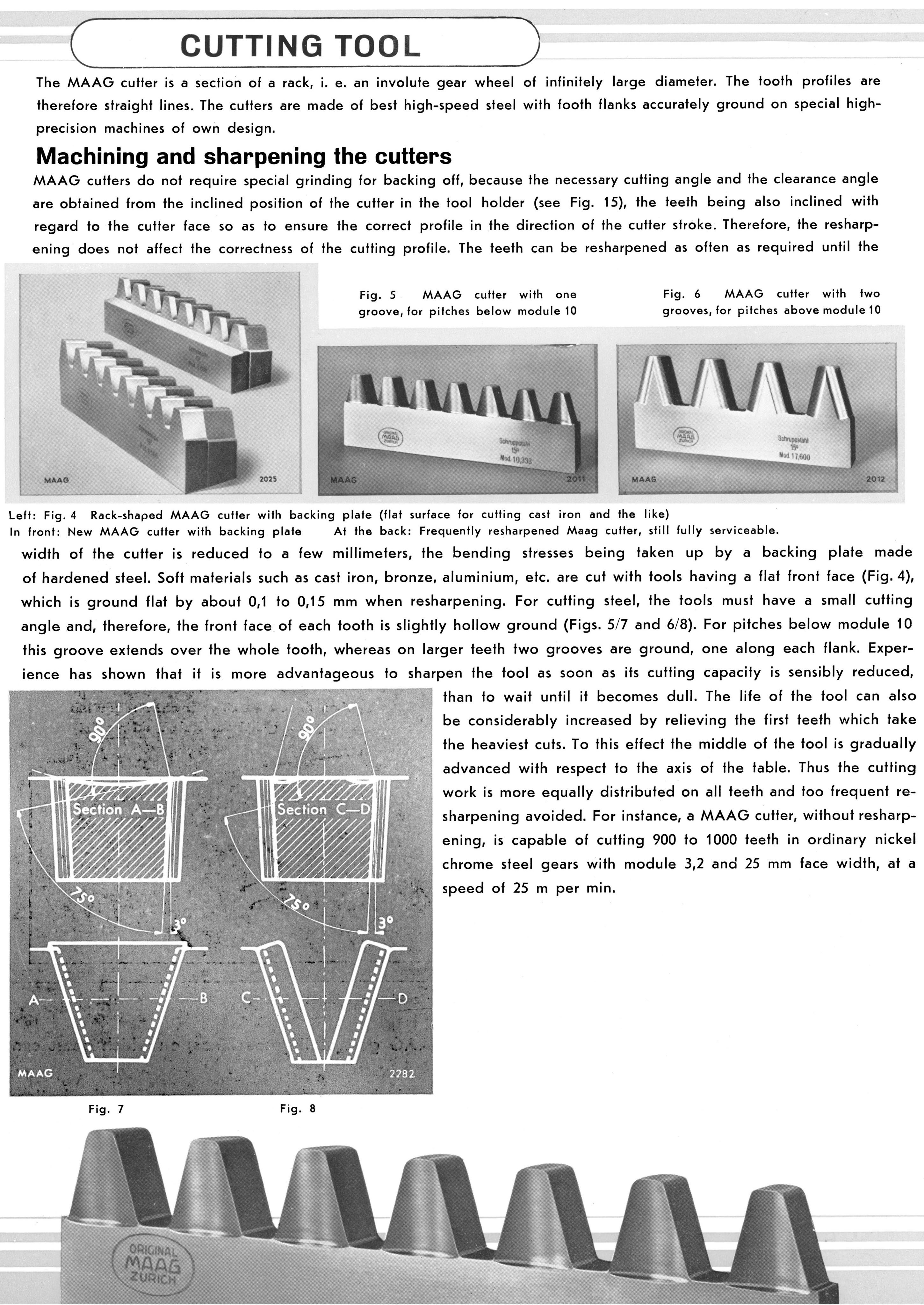

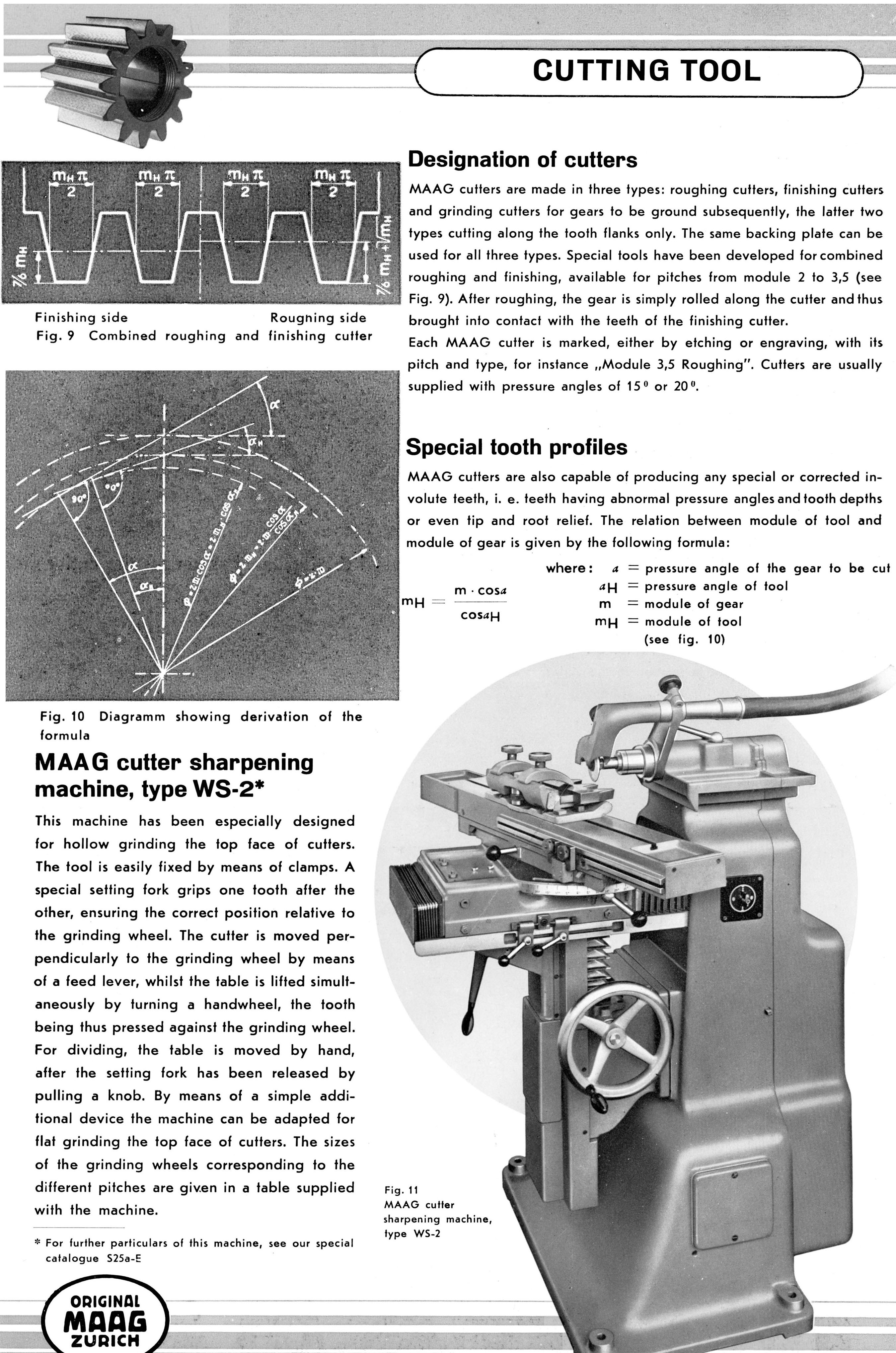

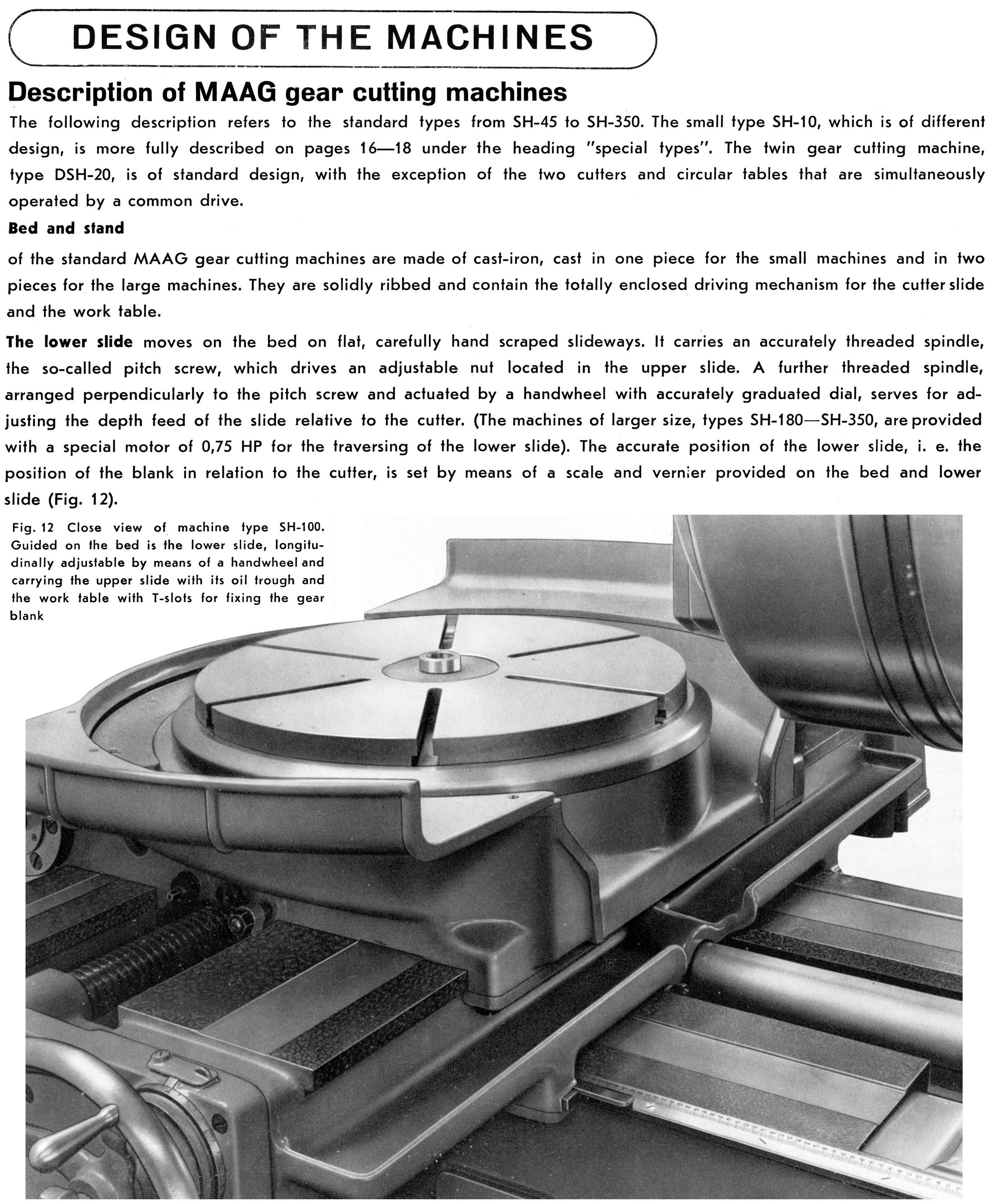

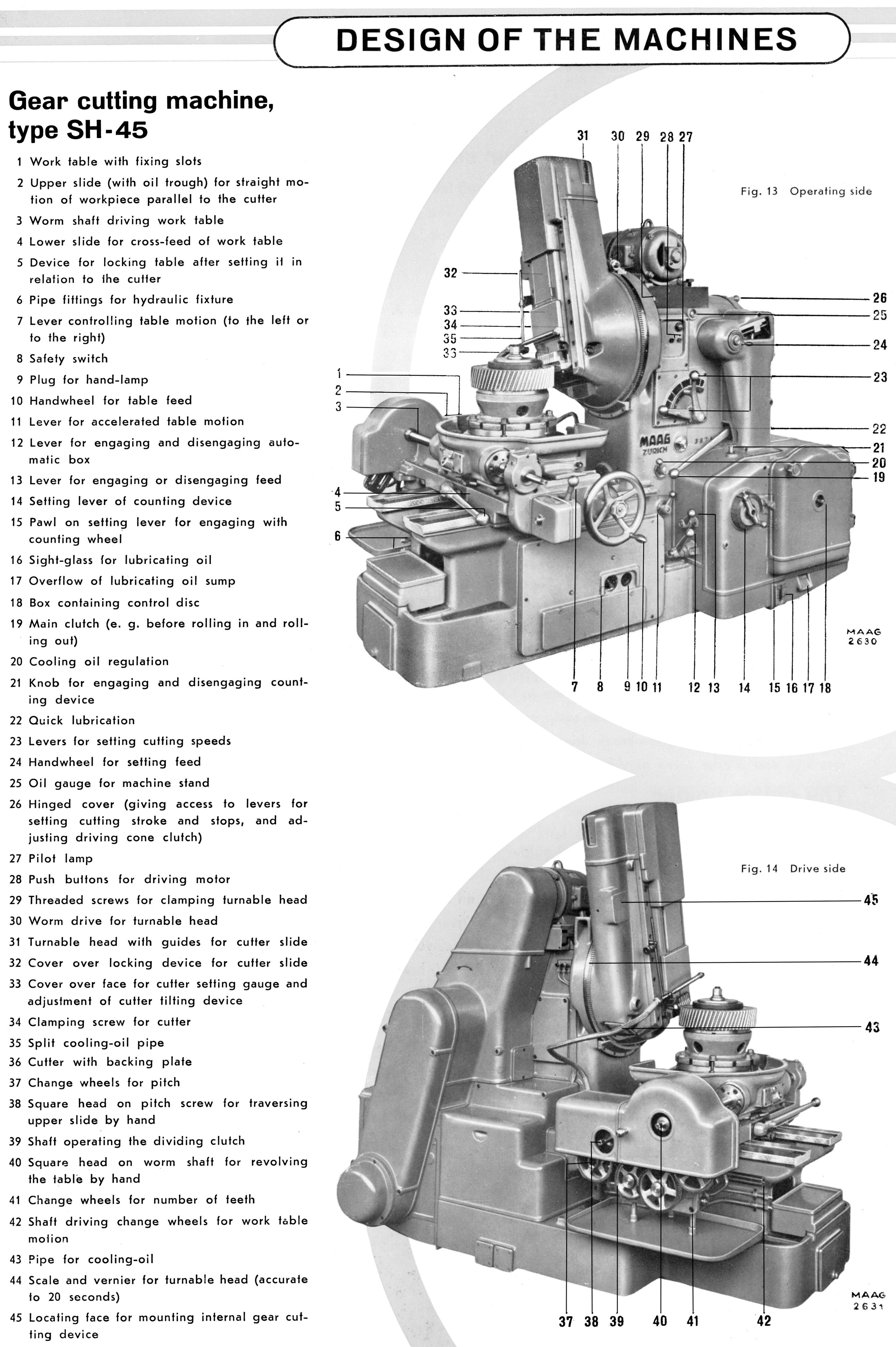

The publication below, printed in the early 1950s, gives a clear account of how MAAG gear cutting machines work - the "planing" type with a cutter in the form of a rack - as well as their design and particular features. All gear-planing machines work on a principle established in the early years of the 20th century by the inventor and patentee Sam Sunderland of Keighley in Yorkshire, England. Sunderland realised that if the principle of the involute curve could be applied to a gear-cutting machine, the gears produced would (to simplify matters) always mesh perfectly and so produce a smooth and consistent delivery of power from one to the other. Even better, when the gears (either spur or helical) were allowed the necessary clearances to accommodate expansion due to heat and the avoidance of excessive friction, the involute rule still held and the meshing remained unchanged. The practical solution lay in his realising that a rack (in effect a gear laid out in a straight line) would always mesh perfectly with a gear of the correct specification, if the rack were to be made be made of a cutting steel it could generate a gear with the correct involute form - but not only that, in normal use only a small stock of cutters would be needed as each could cut any number of teeth providing they were of the same pitch and pressure angle (in comparison, ordinary "form" cutters are limited to a small range of teeth and dozens are required to cover the needs of a commercial workshop).

Possibly the easiest way to understand the Sunderland planer method is to imagine a gear blank in a soft material being rolled backwards and forwards, under pressure, along a rack until the tooth form of the rack is reproduced in the blank - the analogy being that as the rack (cutter) is planing the blank to produce teeth and spaces, the blank is being rolled along the rack and the tooth form generated directly. In addition, even when blanks are over or under-size they can still be cut so as to run together correctly - an example being when stronger teeth are required by either increasing the outside diameter of a gear or the "addendum". As Sunderland wrote, "….uniformity in the shape of the teeth is obtained as perfectly as possible by a commercial method and all gears that are cut by the same cutter will gear correctly with one another."

|

|