Do you have a LYN lathe ? If so the writer would

be very interested to hear from you

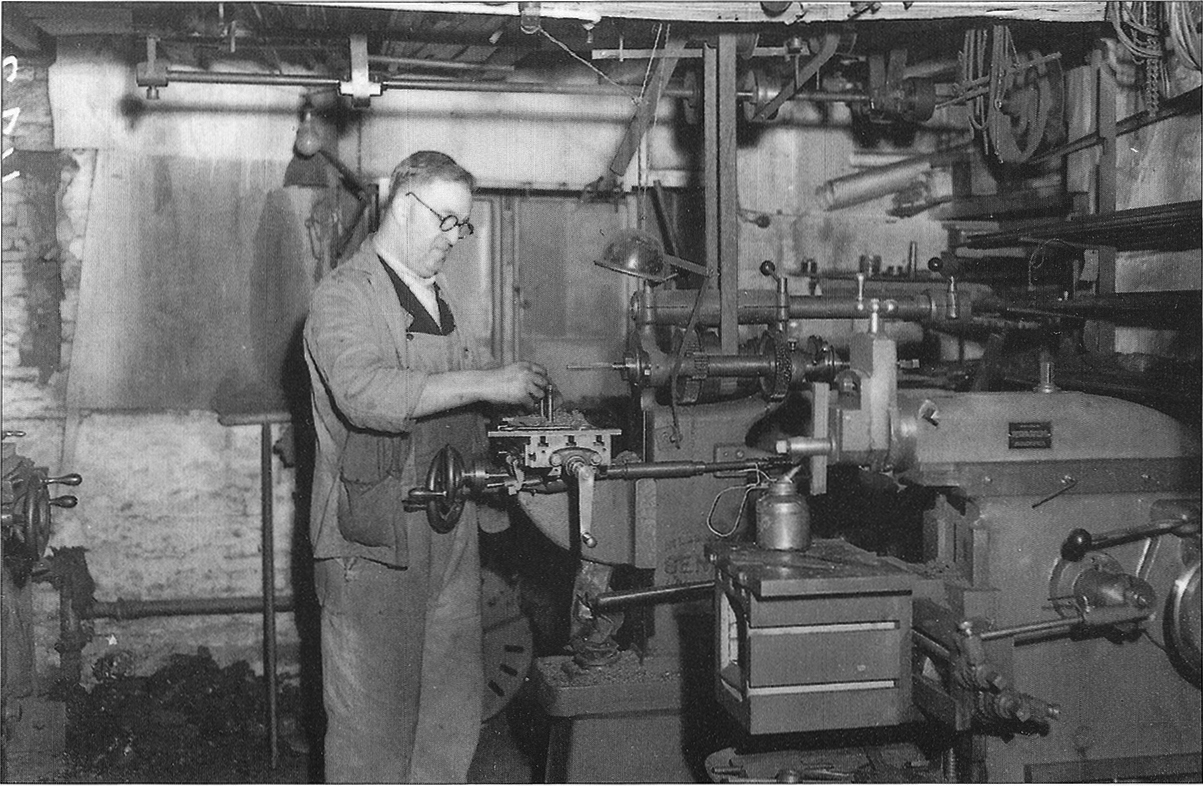

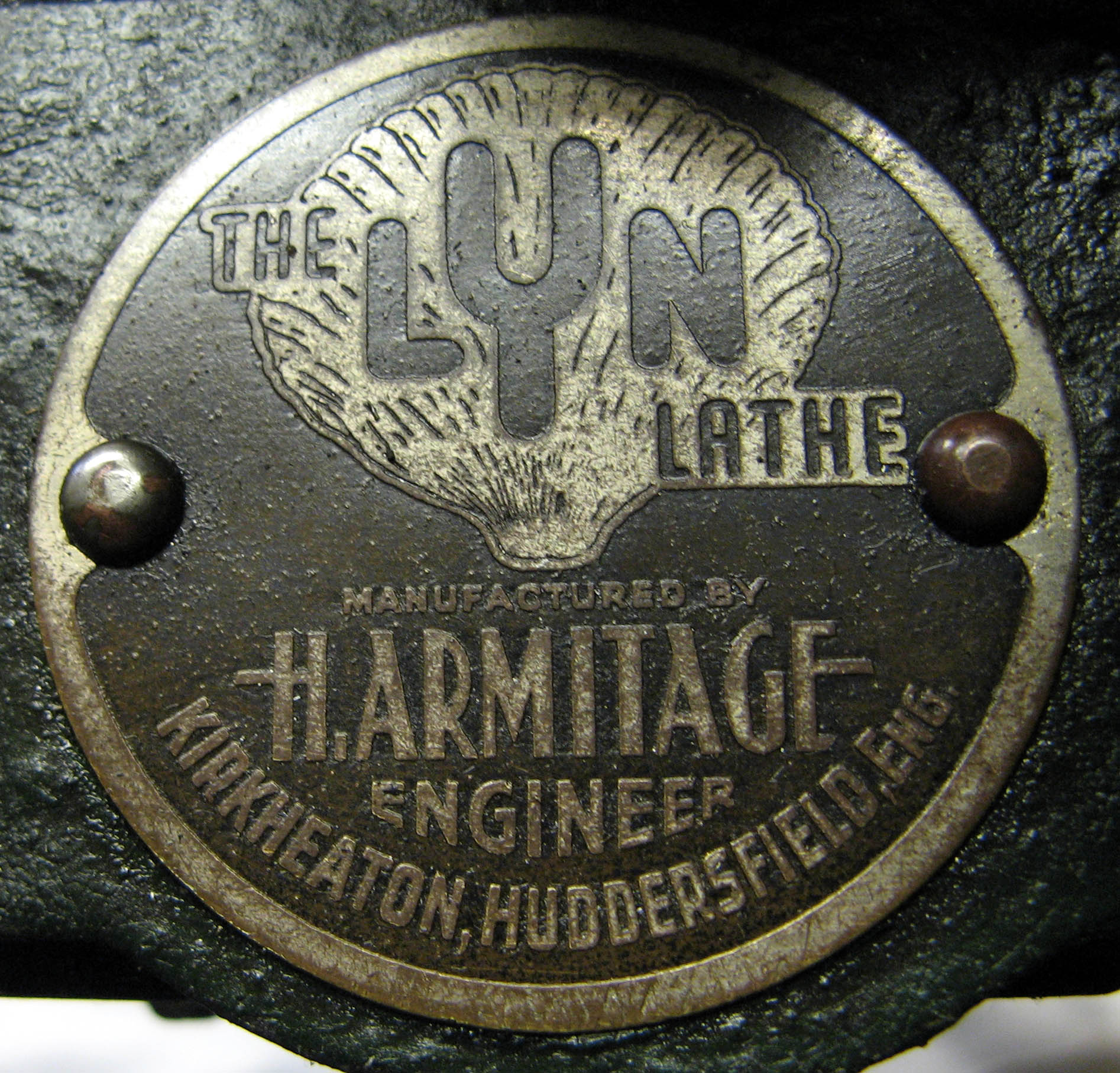

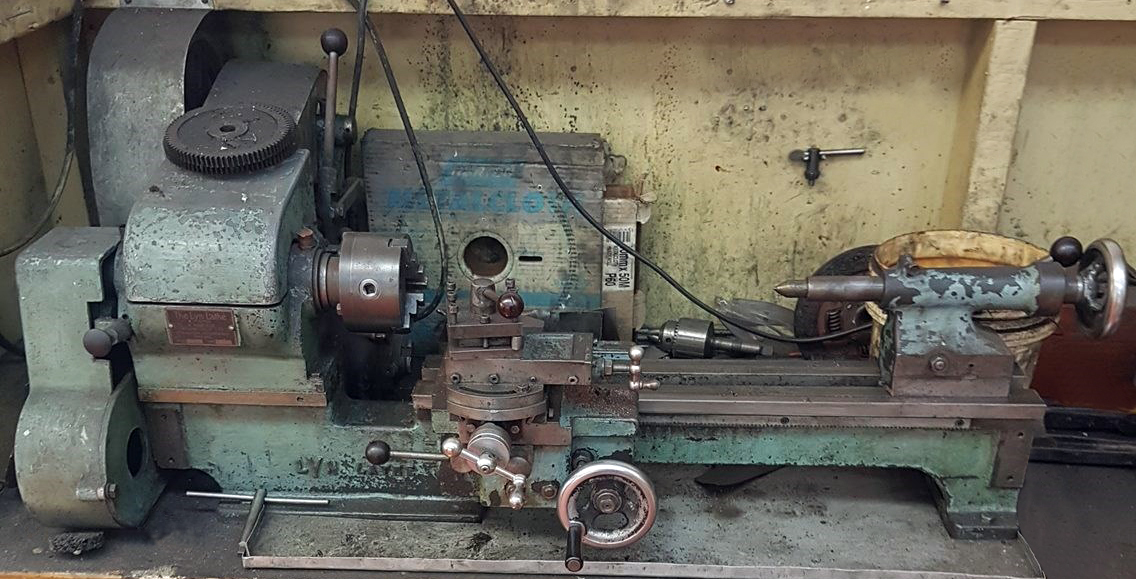

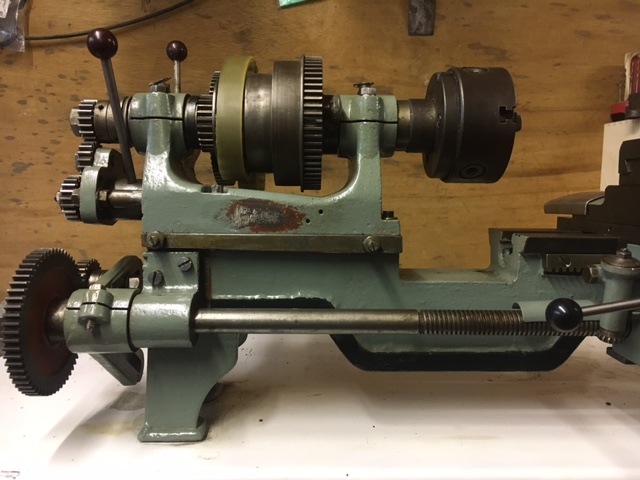

Produced from 1935 onwards, the Lyn lathe was manufactured by Harold Armitage (1898-1971) in a workshop attached to his 15th/16th-century house at the junction of Town Top and Cockley Hill Lane in Kirkheaton, Huddersfield. Harold worked alone and, although we have no details of his machine shop, such an enterprise shows that, in a previous occupation as a stoker on an aircraft carrier, the navy had failed to take advantage of his other considerable skills. Under the trade names Armitage Engineer Kirkheaton and H. Armitage Machine Tools Ltd, he was to produce three versions of the LYN Lathe until production finished at some point in the late 1950s.

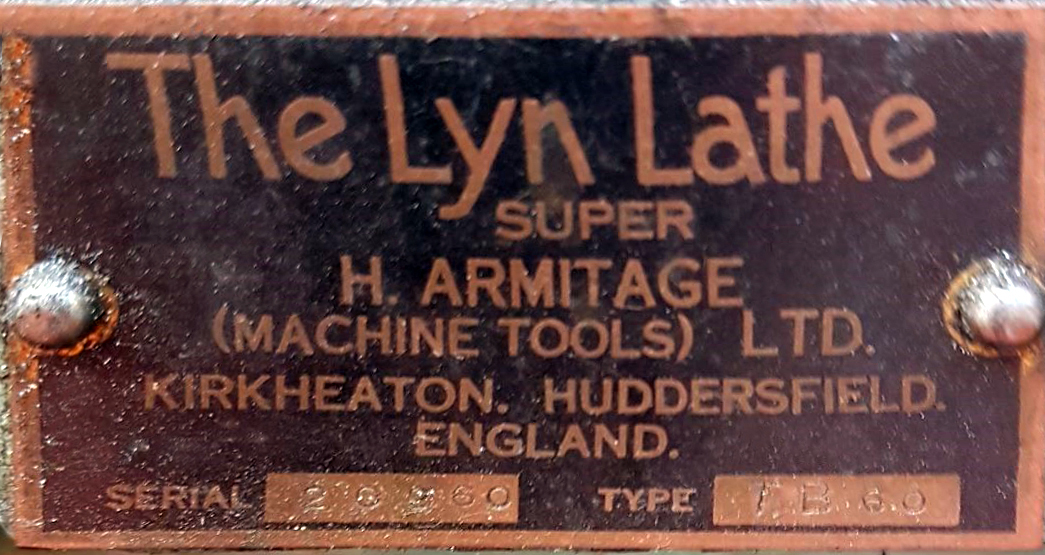

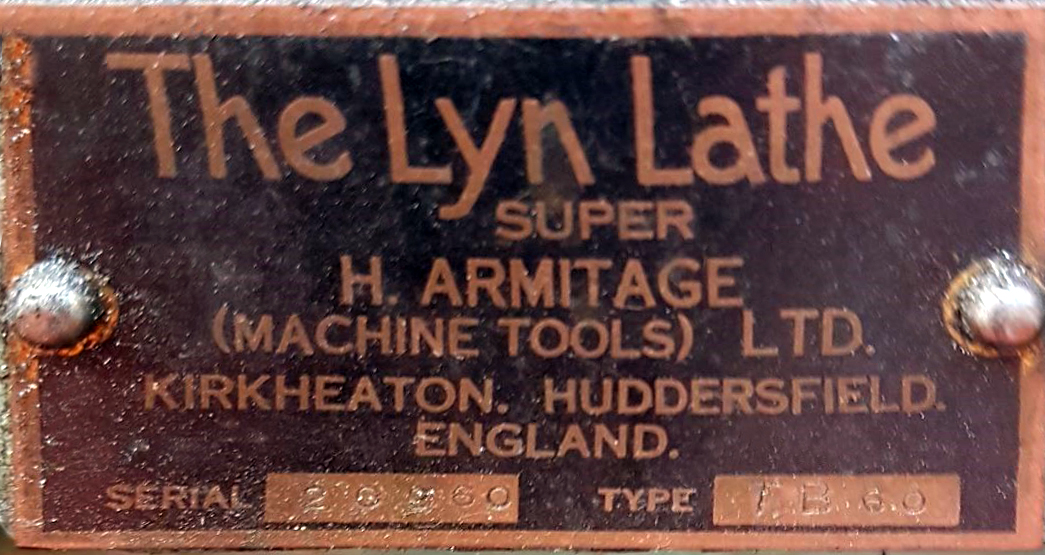

The first model had flat-belt drive to the headstock, a No.1 Morse taper tailstock and lacked any sort of tag to identify the model type. This was followed by the types A1 and TB60, both these carrying a rather fine round or rectangular etched brass plate stating, against a black background: The LYN Lathe , Armitage Engineer, Kirkheaton, Huddersfield" and sometimes: The Lyn Lathe (Super) H Armitage (Machine Tools) Ltd. Kirkheaton, Huddersfield, England. Serial ***** Type A1 and The Lyn Lathe (Super) H Armitage (Machine Tools) Ltd. Kirkheaton, Huddersfield, England. Serial ***** Type TB60

In late 2023 another version, badged as an A2, appeared. This version incorporated many of the features of the TB60, including the cam-operated tailstock locking mechanism, and a rod to adjust the tension of the drive belt that passed through the lathe bed immediately below the headstock.

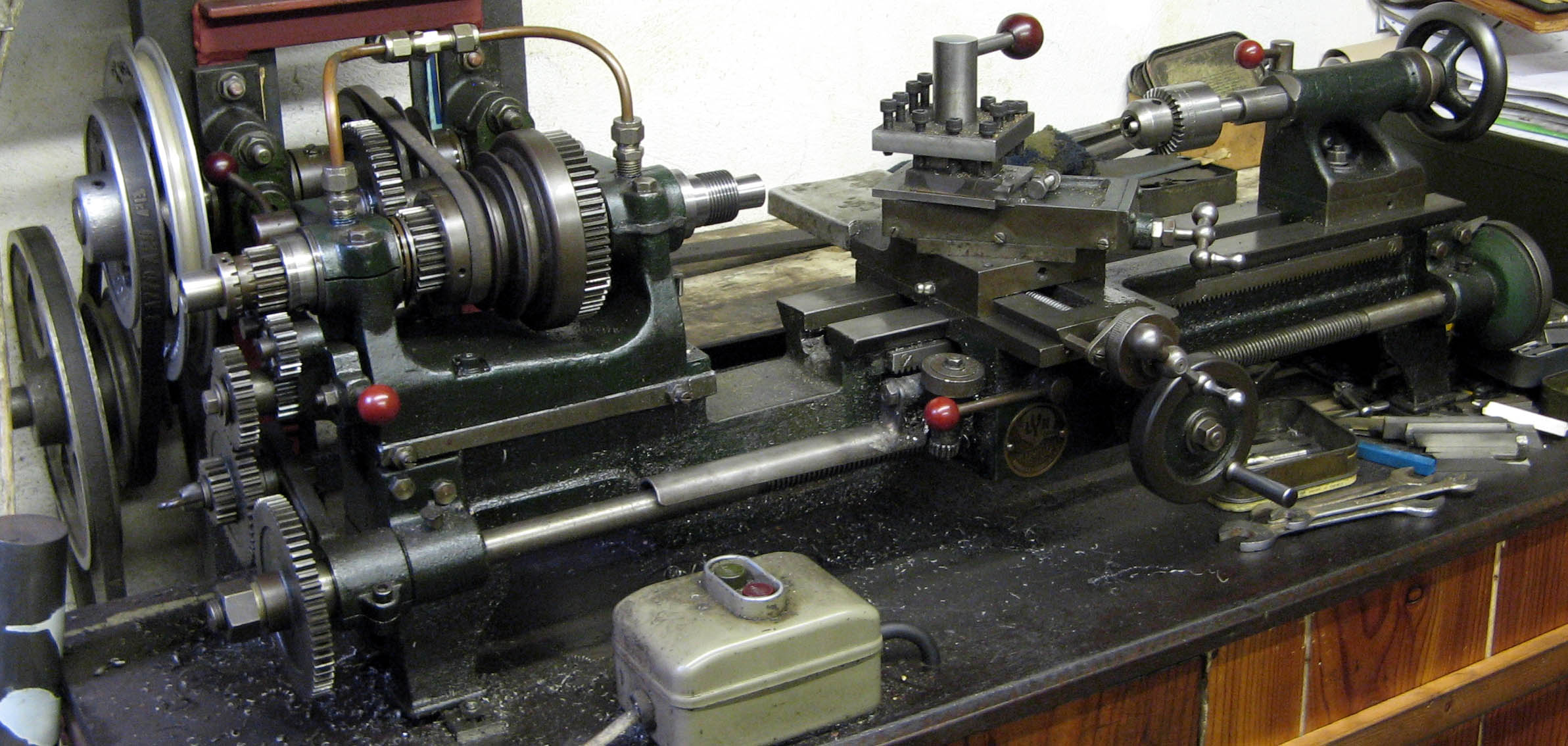

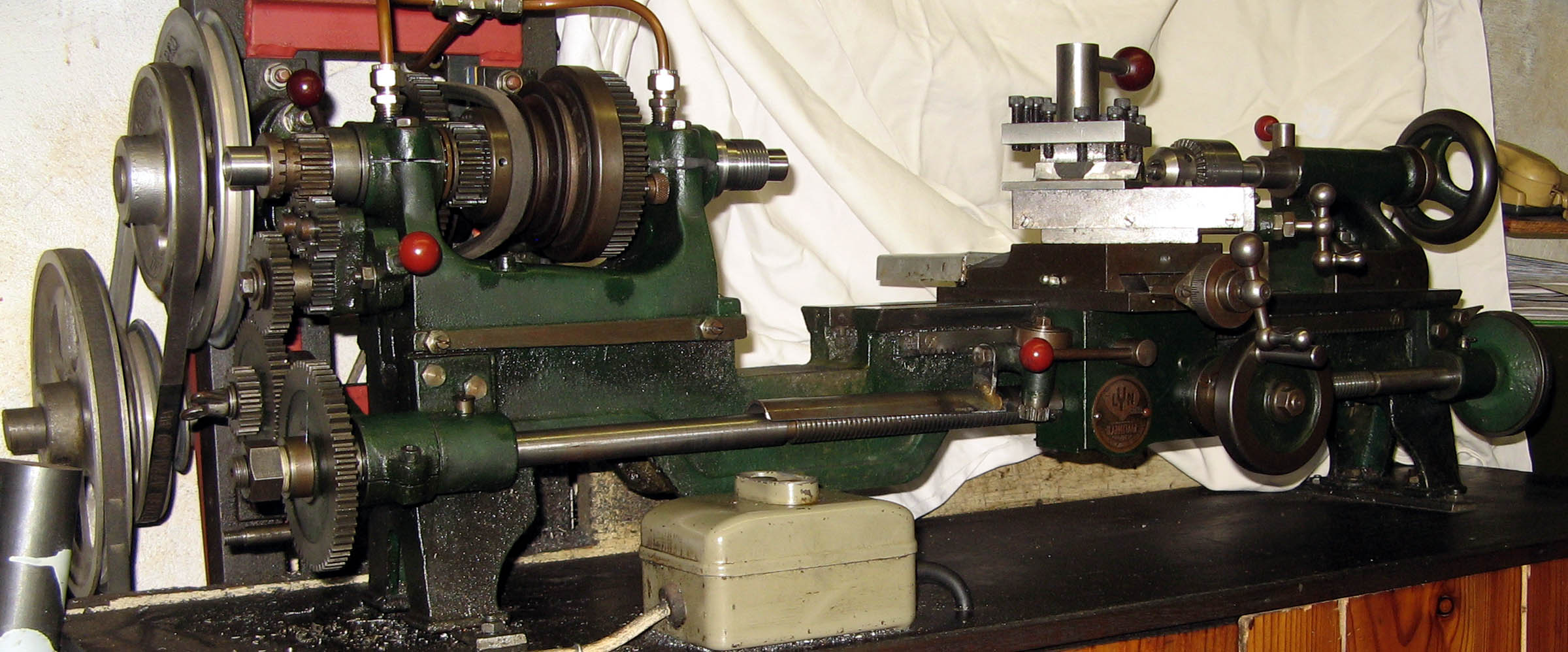

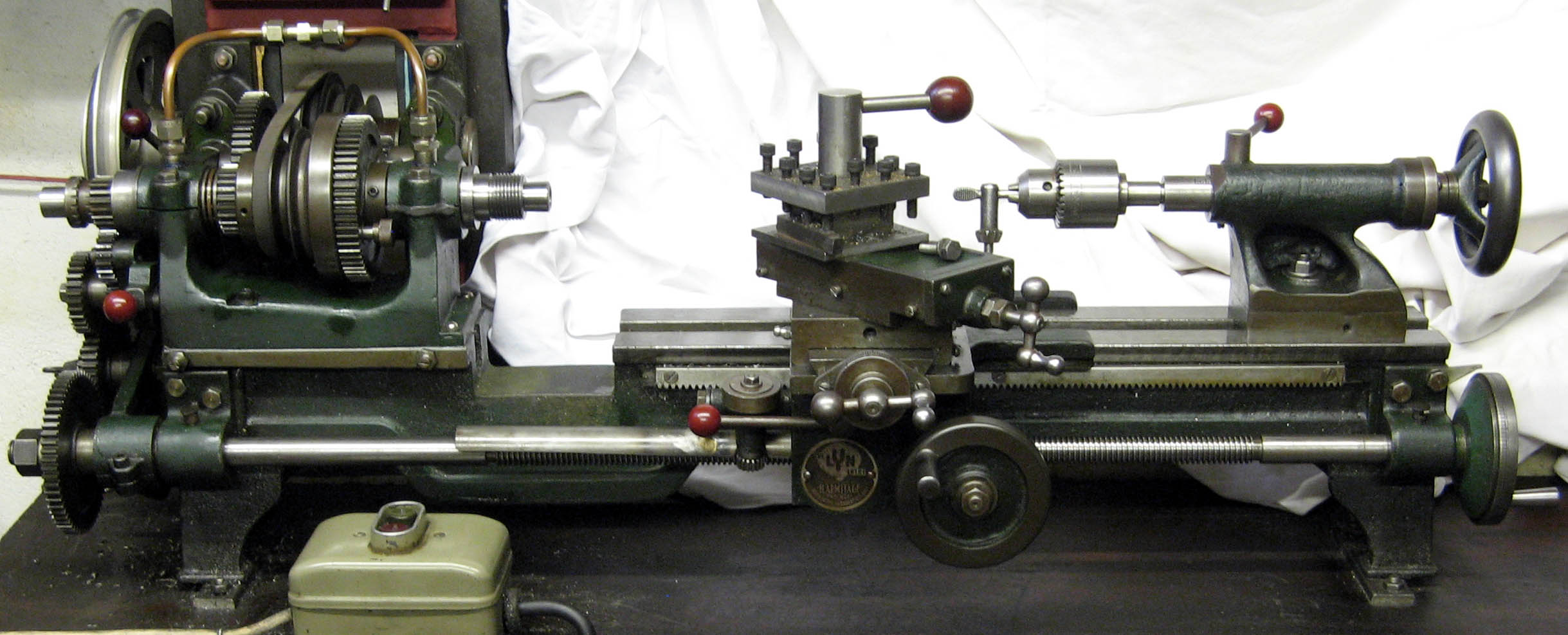

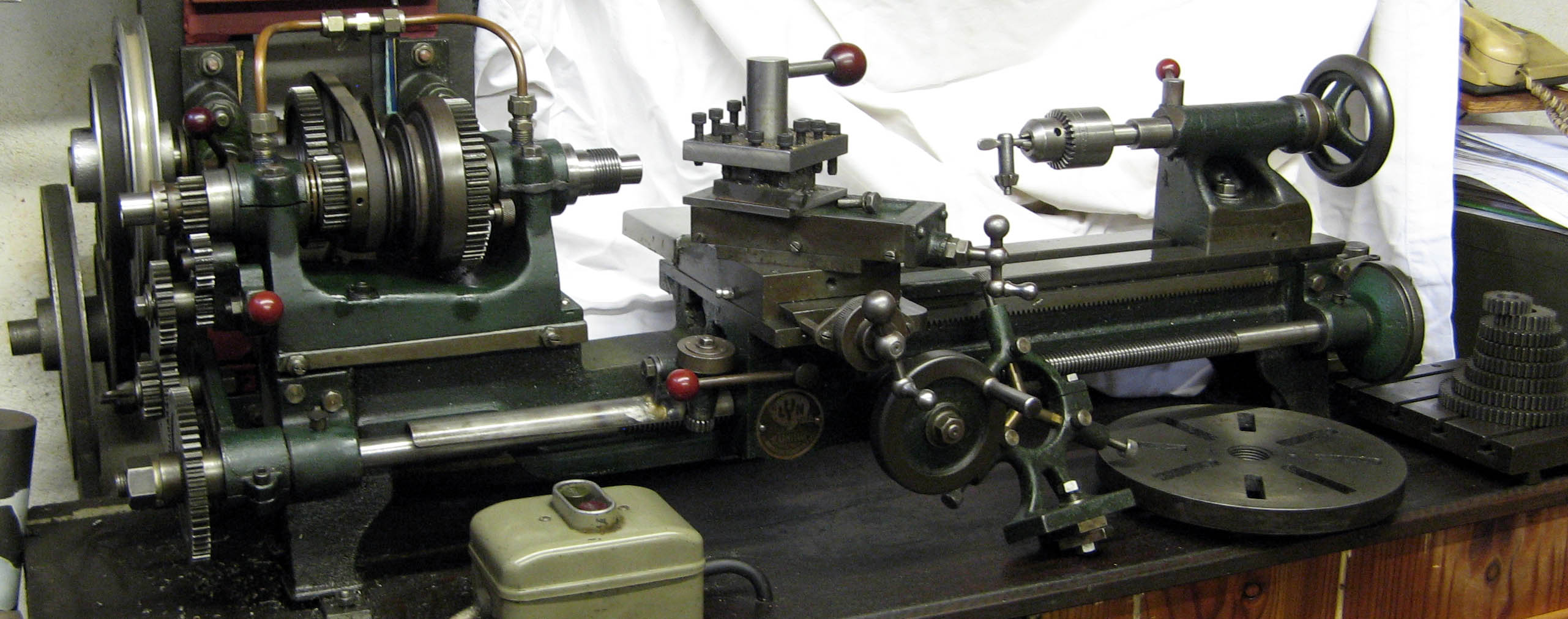

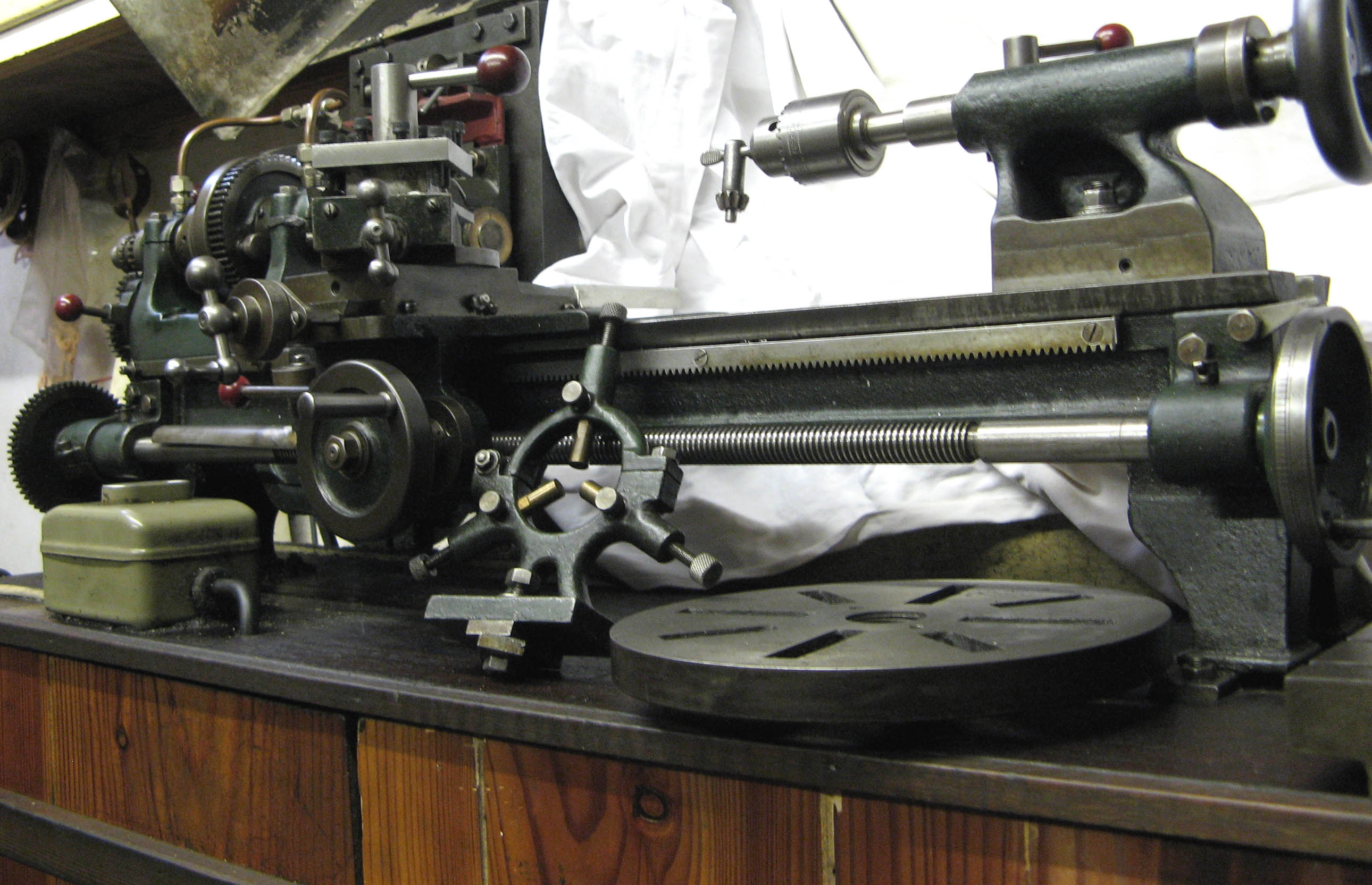

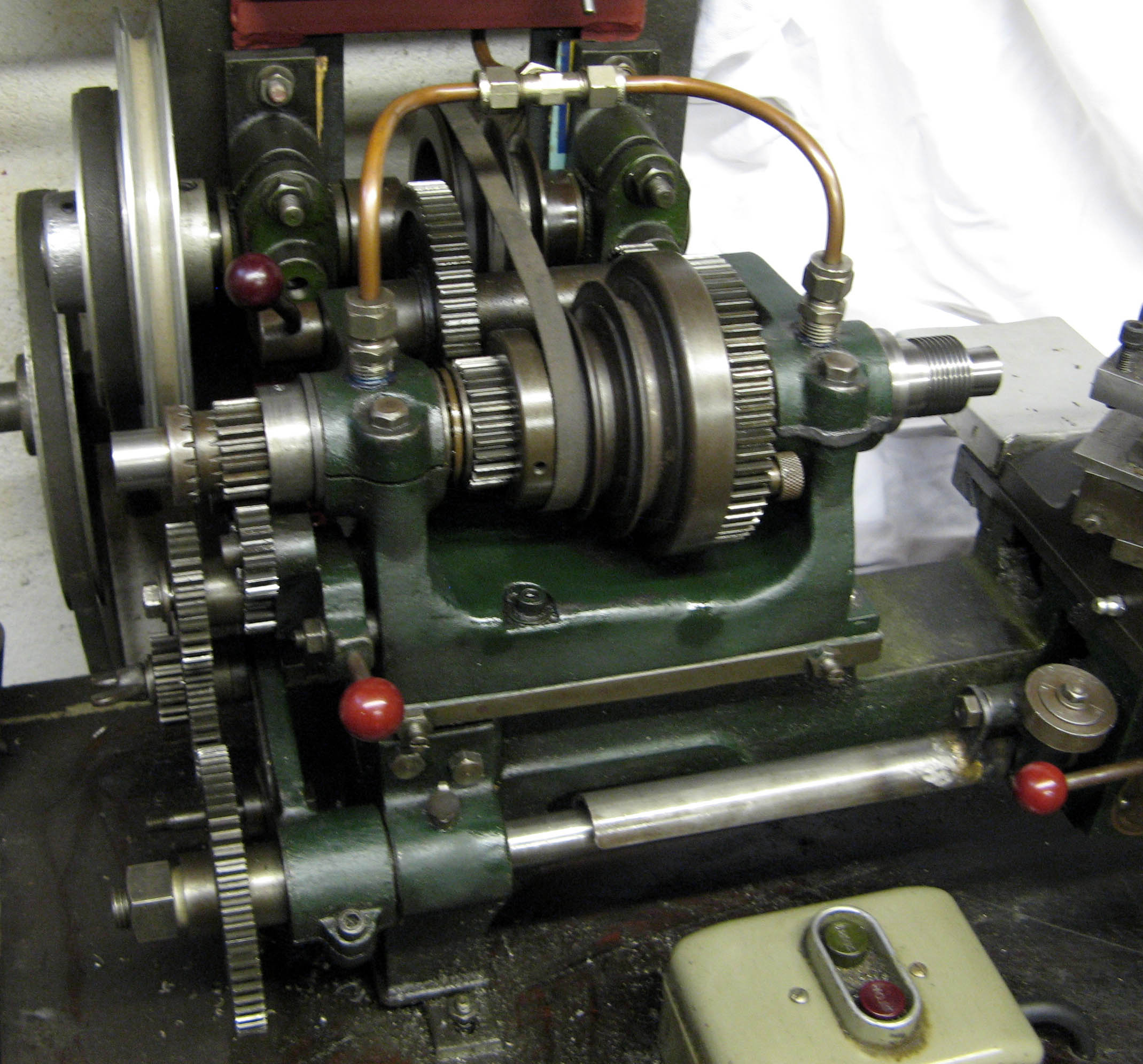

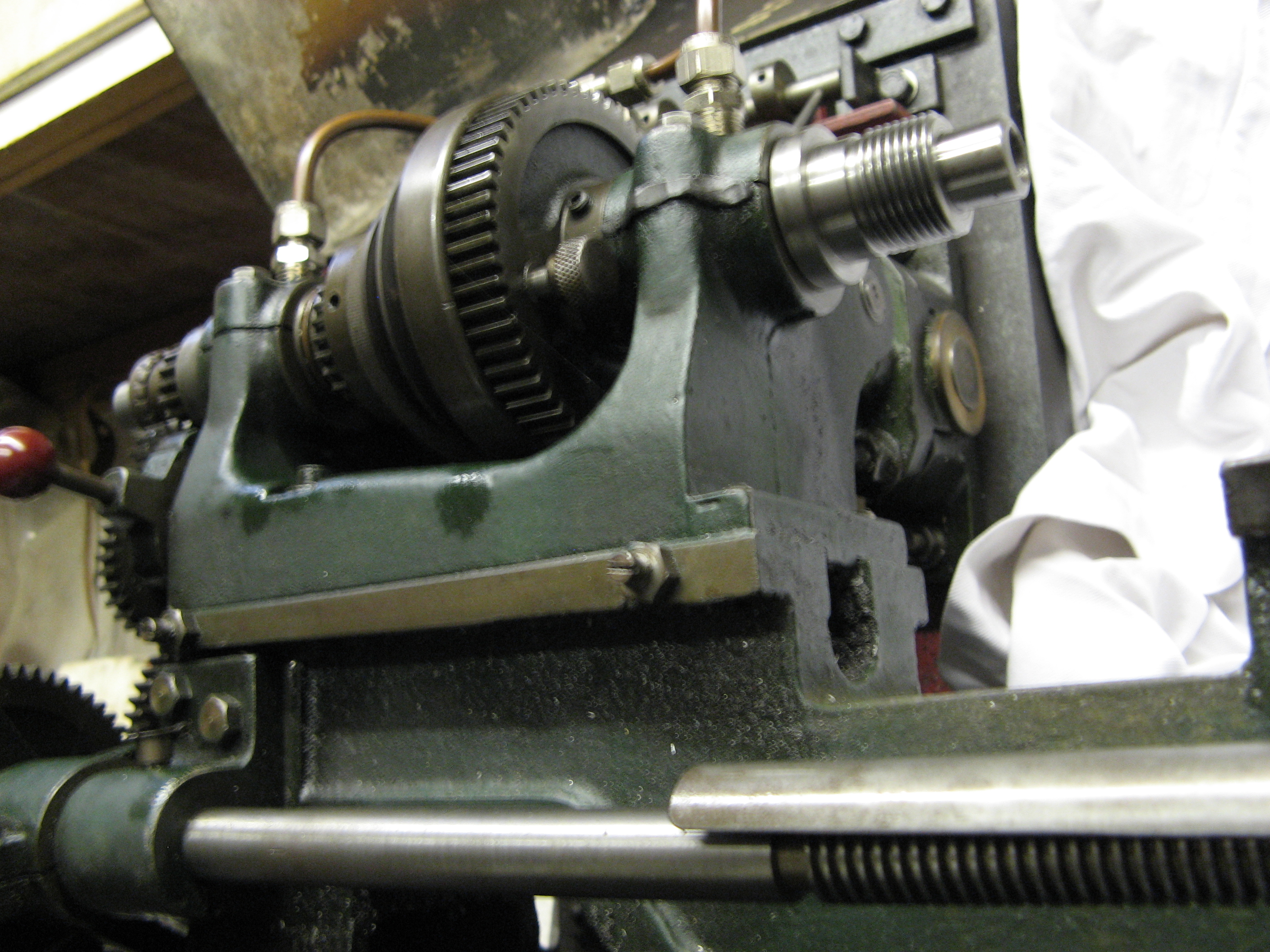

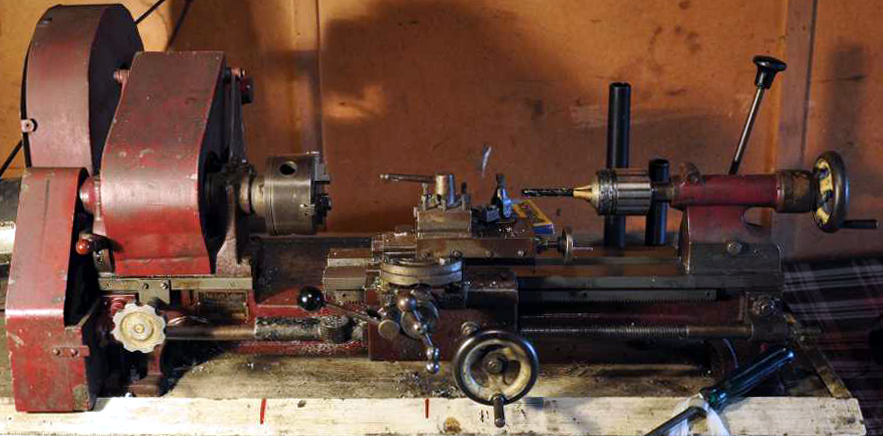

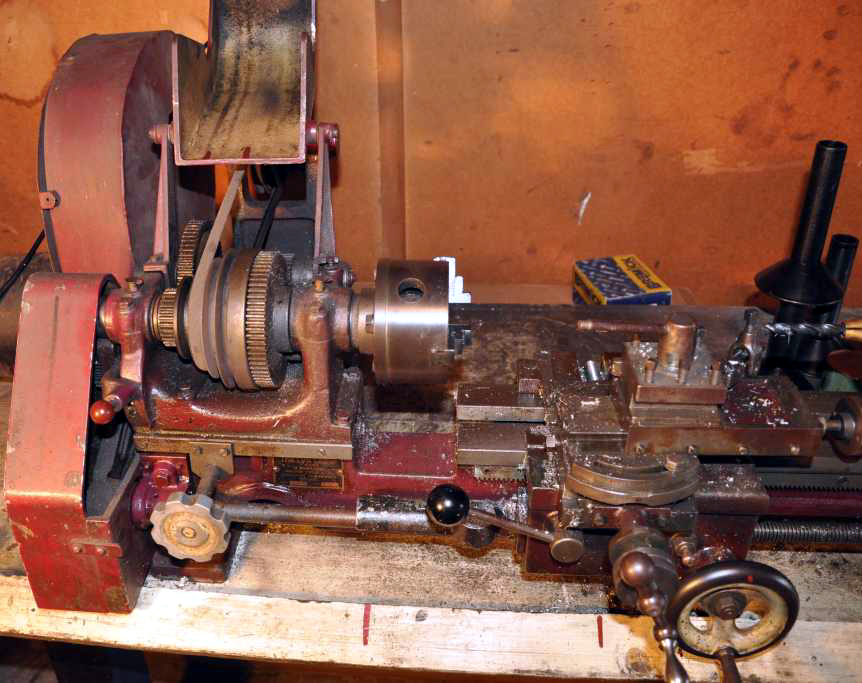

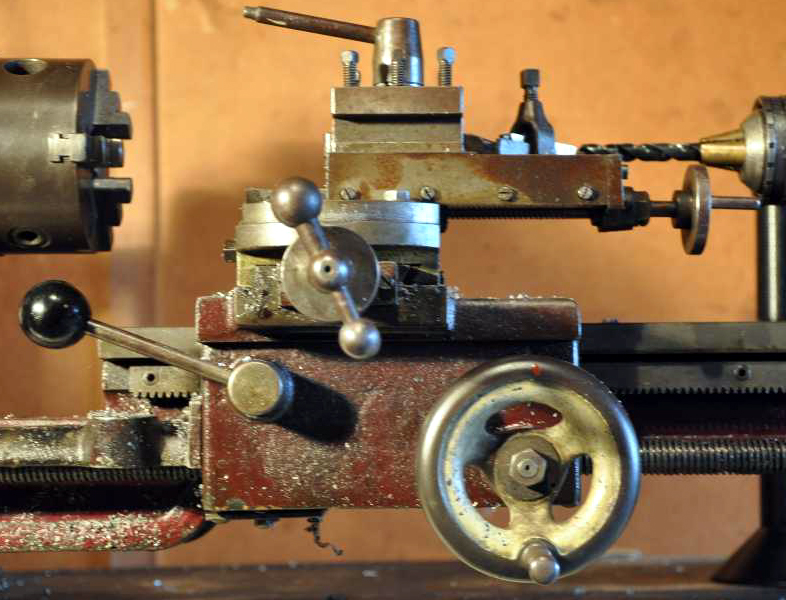

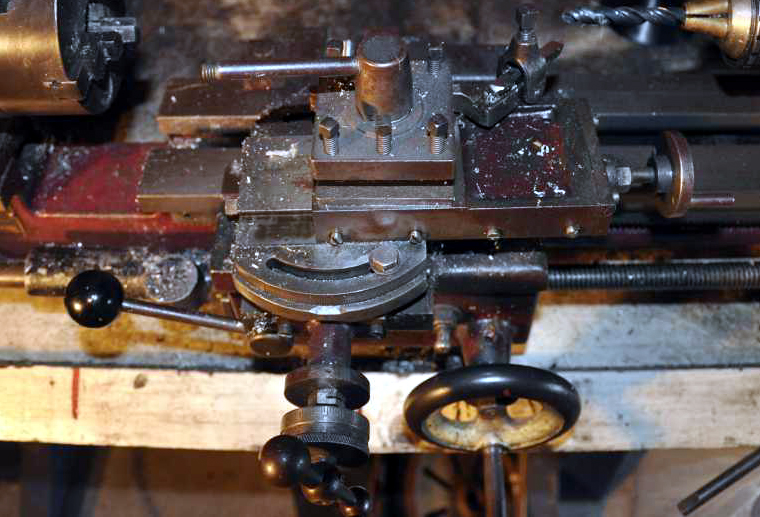

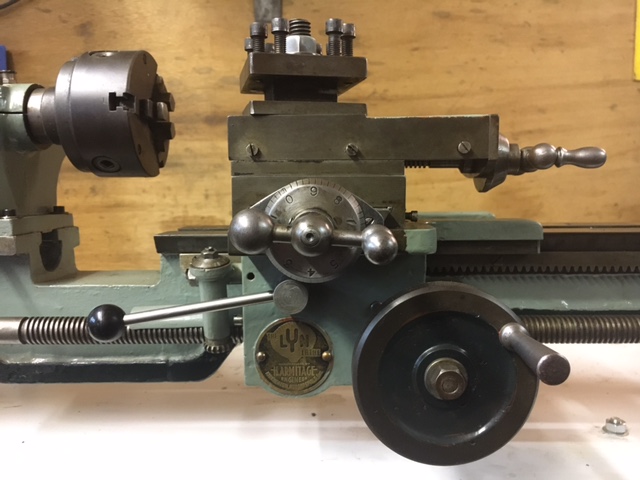

Backgeared and screwcutting, with a centre height of 3.2" and a capacity between centres of 15.5", the Lyn A1 was of entirely conventional construction - and typical of the period for a light machine designed for amateur use - though it stood out for its smooth castings and good quality, dark-green finish. The bed was fitted with a gap as standard and, while dovetail-edged sides guided the saddle (which, like more expensive lathes had extension wings left and right) the tailstock bore against the square vertical inner faces of the gap between the front and back bed ways. The apron was fitted with double clasp nuts closed down onto the 8 t.p.i leadscrew by a lever tipped with a red plastic knob. The carriage hand drive was properly engineered and passed through reduction gearing to give the correct "handed" action while also improving leverage and slowing the feed rate - with the thrust taken against a bed-mounted rack. The cross slide was not, like so many English lathes of the time, fitted with T slots but of plain section; however, a good-sized, robustly constructed T-slotted boring table was, unusually, included with the standard equipment (and can be seen in the pictures below). The top slide had one unusual feature: a small tray was cast into its top surface to hold the special T-handled key used to tighten the square-headed toolpost nuts. Whilst the toolpost was of the simple "clog-heeled" type (that trapped the turning tool against the top surface of the top slide) it did have a separate hole to mount a round-section boring tool.

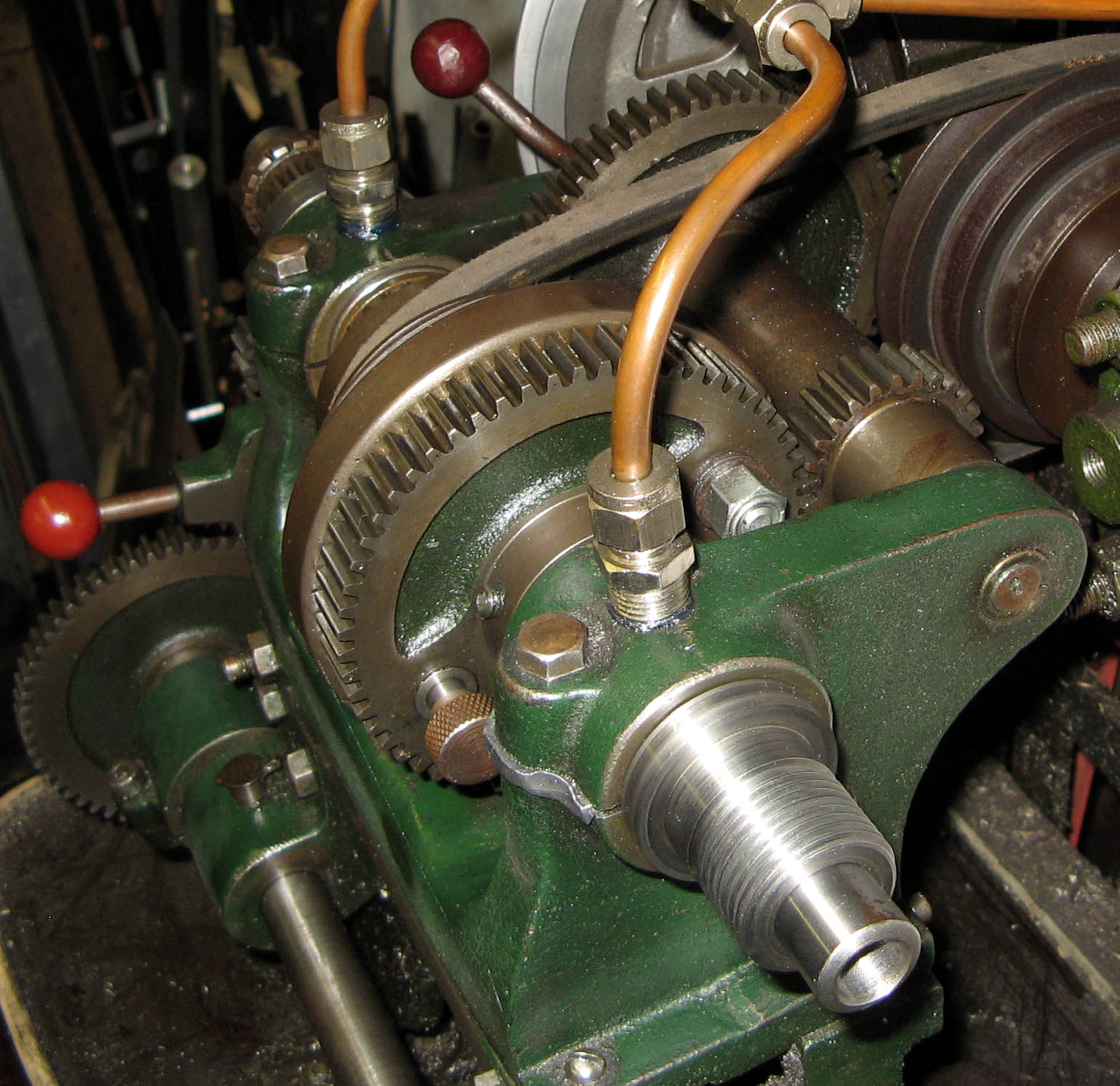

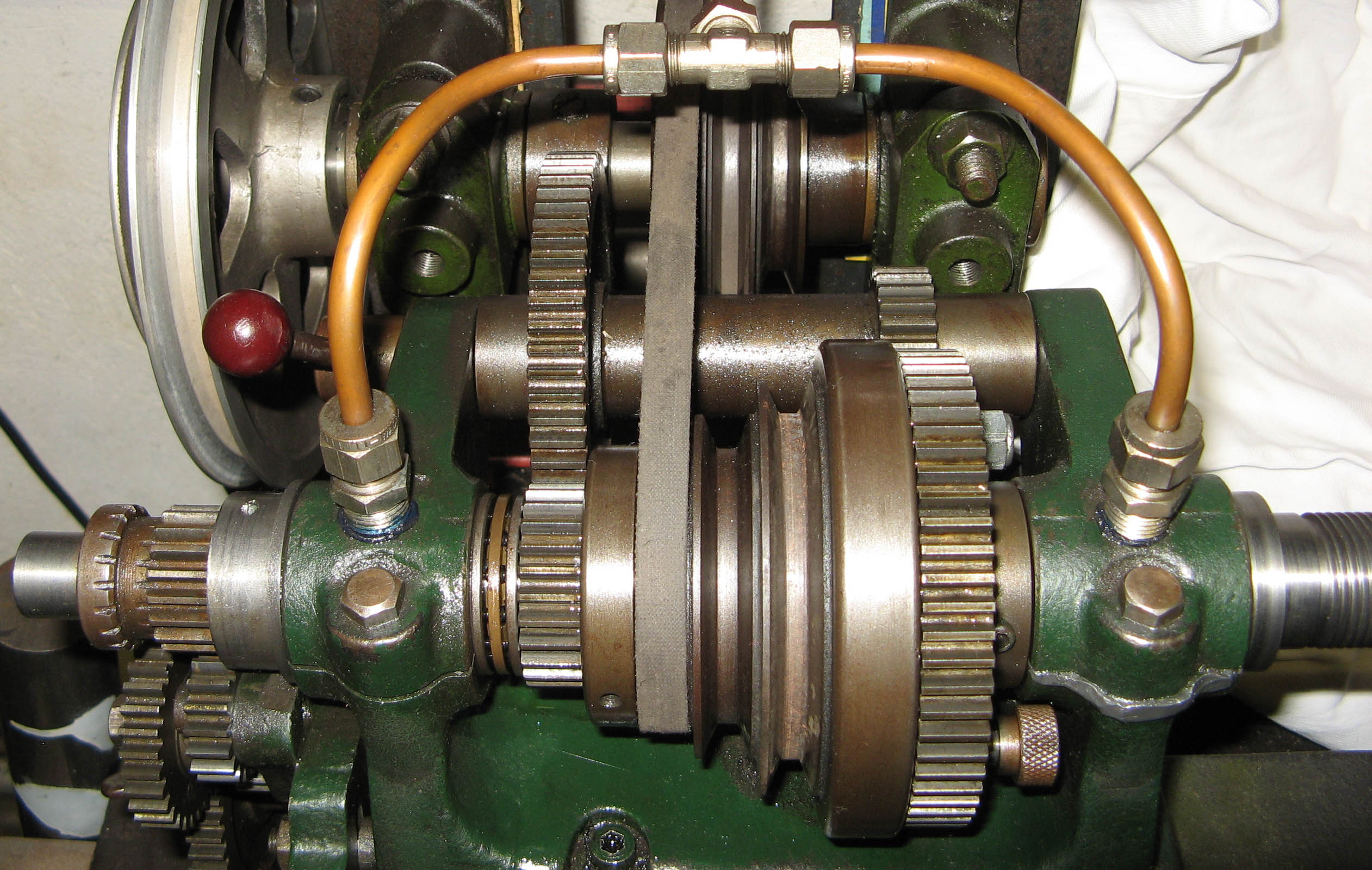

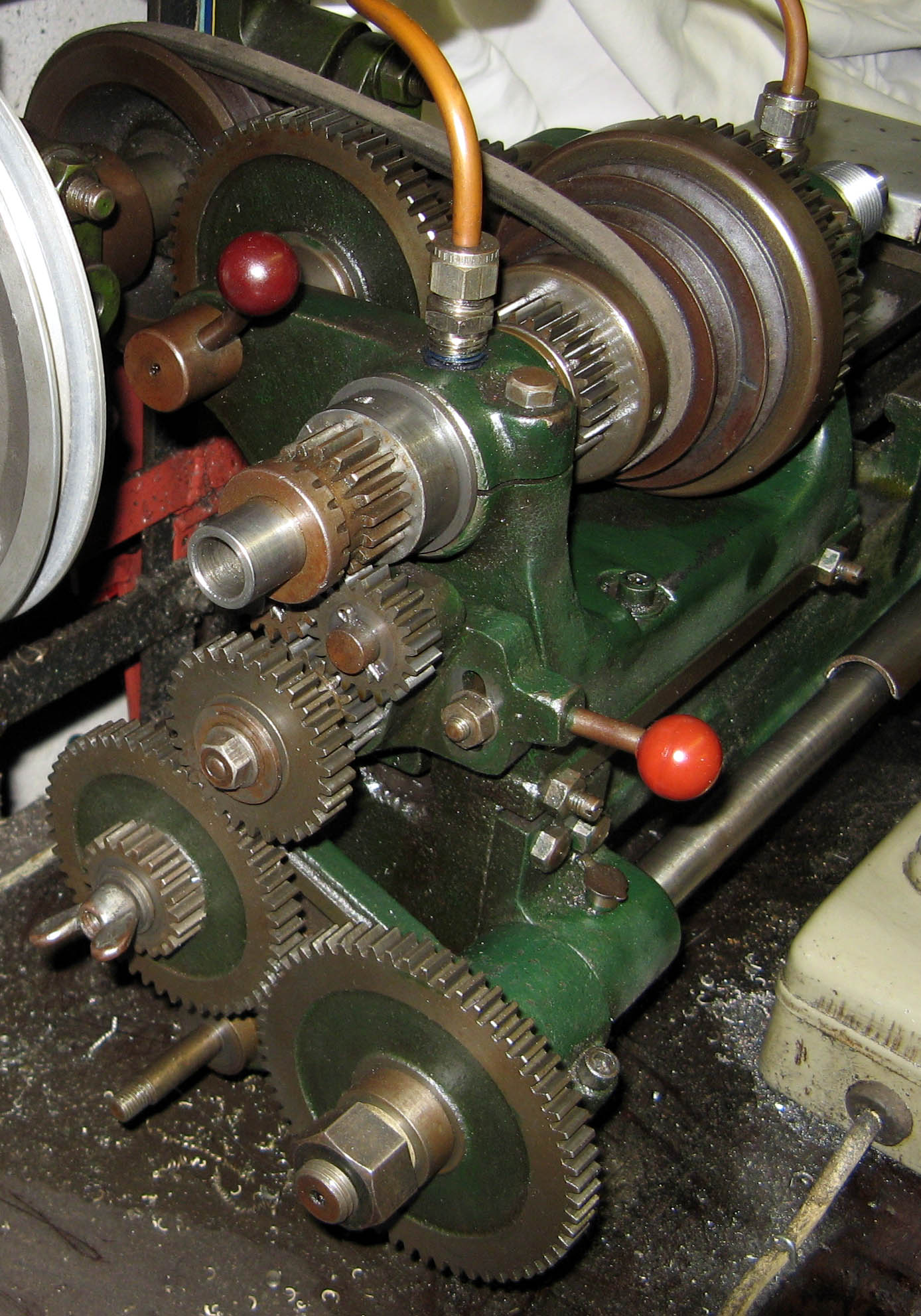

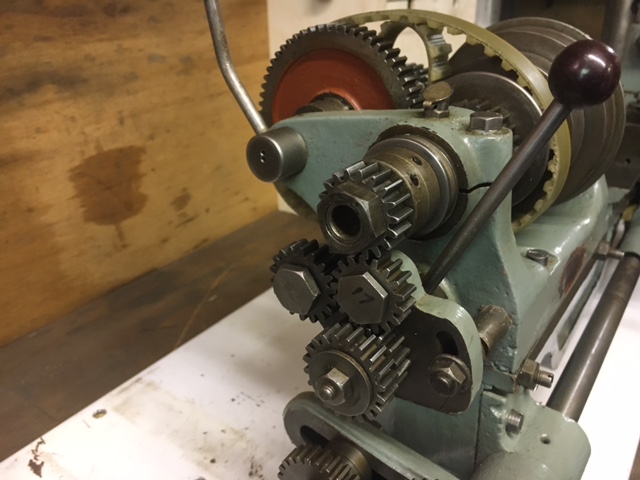

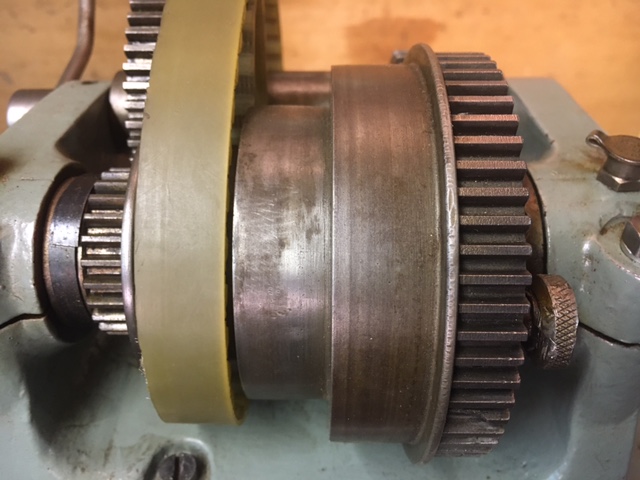

Of "open construction", the headstock was located to the bed by a machined tenon with screws passing through the front of the bed to push it back against an inner vertical way (in the manner also employed on the Myford Series 7 lathes). The 3-speed, V-belt drive No. 2 Morse taper spindle ran in generously-sized, half-split bronze bearing (lubricated through small flip-top, direct-feed oil cups) with a ball race at the left-hand face to absorb end thrust. The backgear was carried on an eccentric shaft at the rear of the headstock with the spindle bullwheel locked to the drive pulley by a quickly released, spring-loaded pin.

Screwcutting was by changewheels (two x 20, 25, 30, 35, 38, 40, 45, 50, 55, and 60t) with the drive passing through a tumble-reverse mechanism - though this, unfortunately, was not fitted with a spring-loaded indent; instead, like the popular South Bend 9-inch lathe, the operator was required to slacken a nut so that the unit could be swung up and down to engage the appropriate gear for left or right-hand traverse of the carriage. In common with many other cheaper lathes of the time and, in keeping with the then prevailing assumption that you were responsible for your actions, no guarding was provided for the backgear, drive belt or changewheels. On all but one example found, there was no guard over the headstock belt run or back gears - the exception having a stout cover, in cast aluminium, and carrying a large screwcutting chart.

Although lighter lathes usually made do with a No. 1 Morse taper tailstock - adequate only for the lightest sort of work and used on the first, flat-belt drive version of the Lyn - on all models it was a No.2 and hence much more useful for the wide variety of tasks undertaken by the typical amateur. The tailstock was bolted to the bed by a simple clamp, the through-bolt of which required the services of a loose, self-hiding spanner (though the TB60 was improved by the incorporation of a handle-operated eccentric cross-shaft and draw-bolt).

A simple vertical bracket (with the motor bolted to its rear face), the maker's countershaft was intended to be mounted separately behind the headstock; no form of belt-tensioning was provided but by using a long V-belt at modest tension it was possible to move this from pulley to pulley without too much difficulty - yet still obtain a drive with enough grip for all normal work. Again, one exception to this has been found, a countershaft that does look to be a "factory" part rather than home-made. This unit incorporated an over-centre lever arrangement with a right-and-left-hand-threaded bar to set the final belt tension. Instead of the spindle running in bronze bearings, it turned direct in the cast iron of the headstock. This was a perfectly acceptable system for a small lathe - tens of thousands of highly successful South Bend 9-inch Workshop lathes also being so equipped. When lubricated frequently with a light spindle oil such as Mobil Velocite 1 (and combined with the free graphite in the cast iron) a very long life can be expected.

Incredibly, even though aimed at the model-engineering market, no mention of the machine, nor any advertisement for it, appeared in "Model Engineer", a magazine then bought by all serious home hobbyists from aspirant to expert.

If you have a Lyn lathe the writer would be interested to hear from you.