|

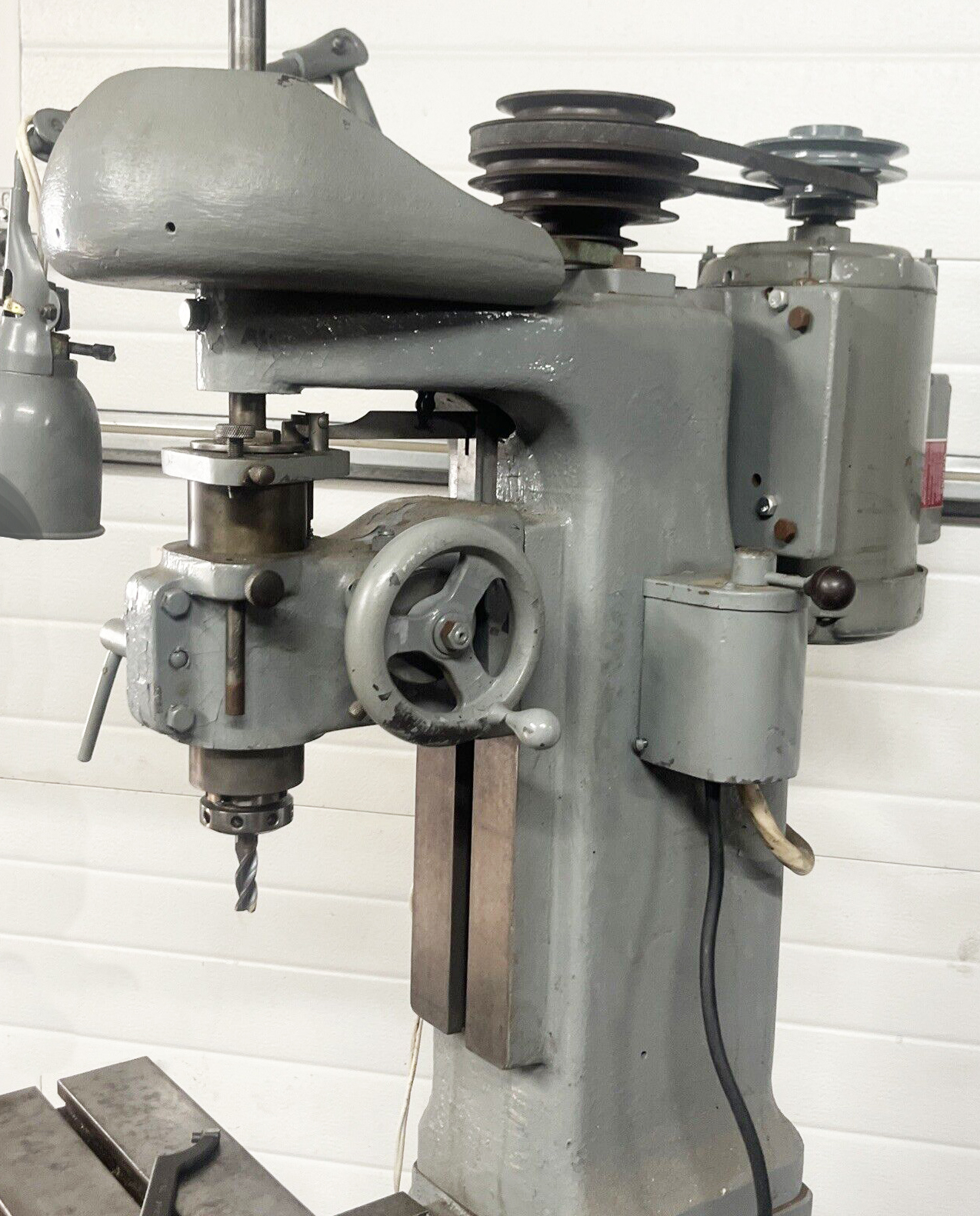

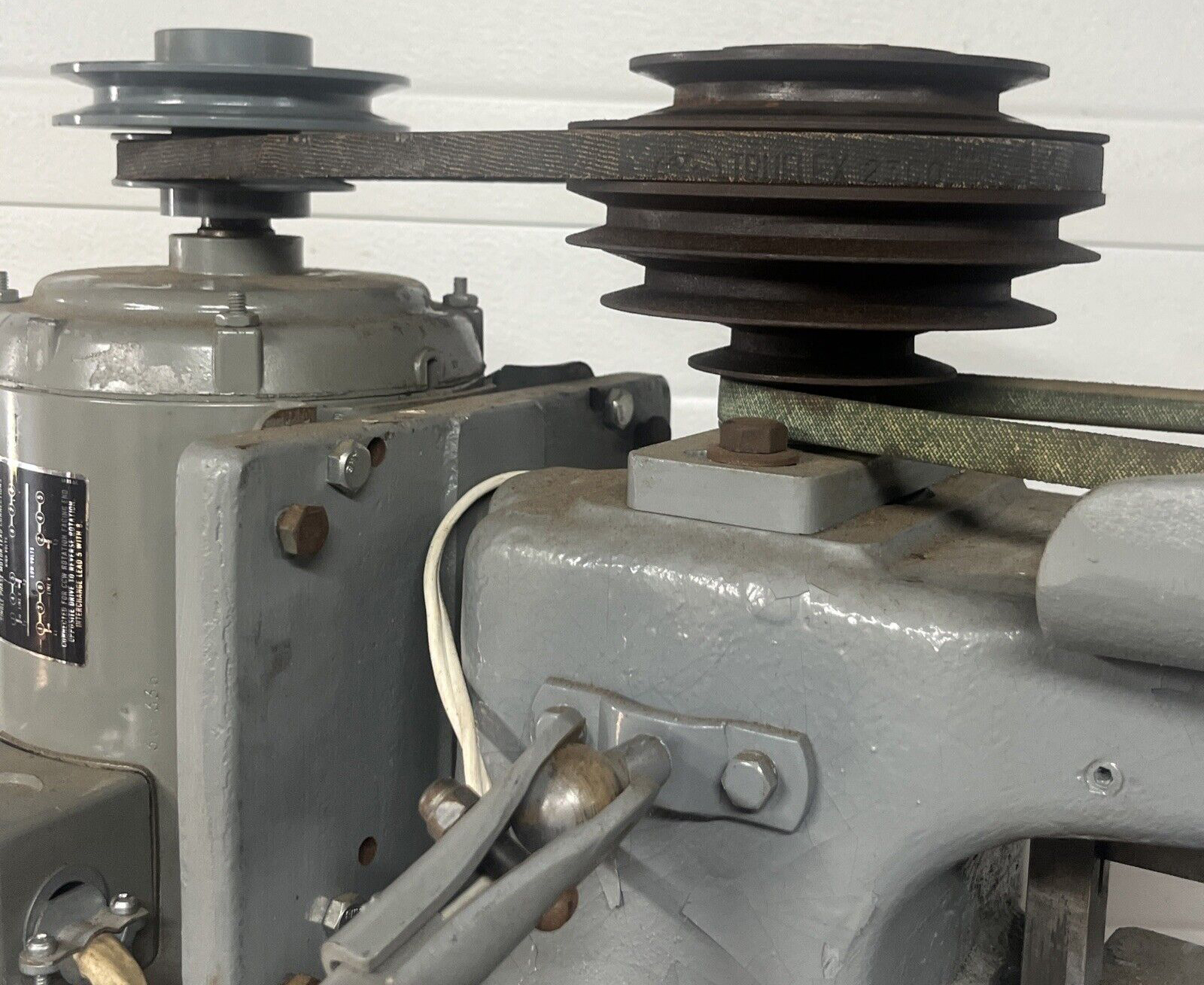

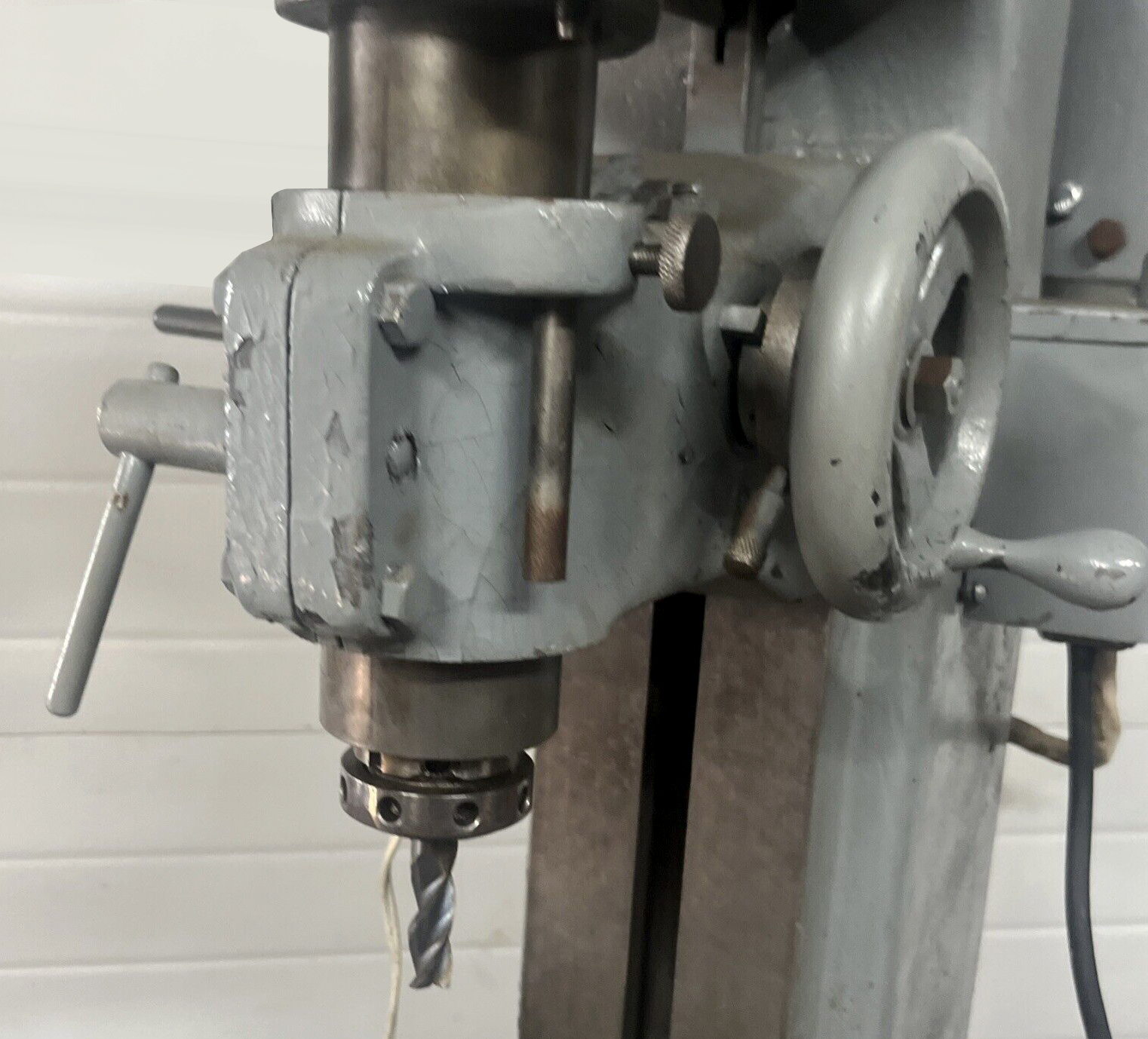

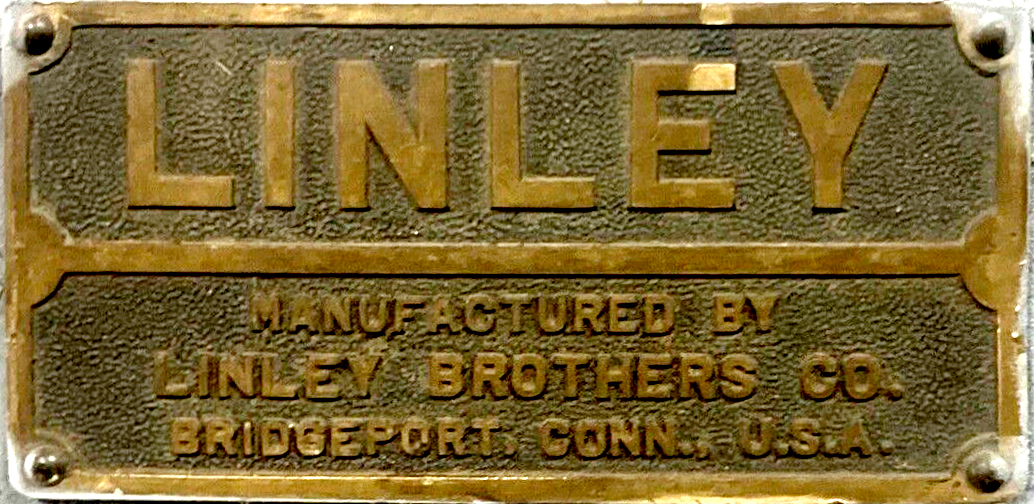

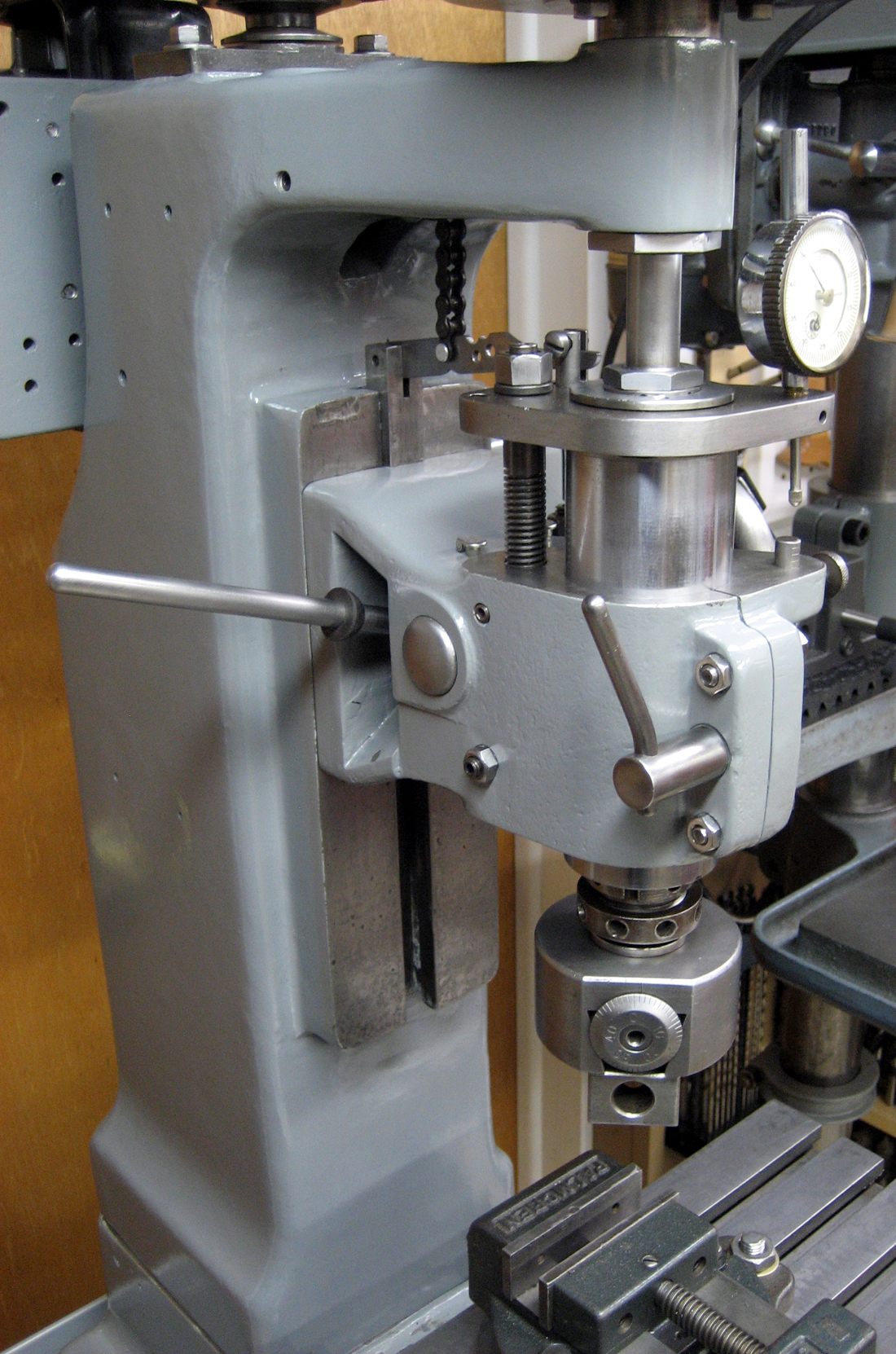

Home Machine Tool Archive Machine-tools Sale & Wanted What must be the earliest Linley so far discovered, this example is resident in England Unlike all other found, this has a cover over just the first part of the belt run, the entire rear section being left open. |

|

Home Machine Tool Archive Machine-tools Sale & Wanted

|