|

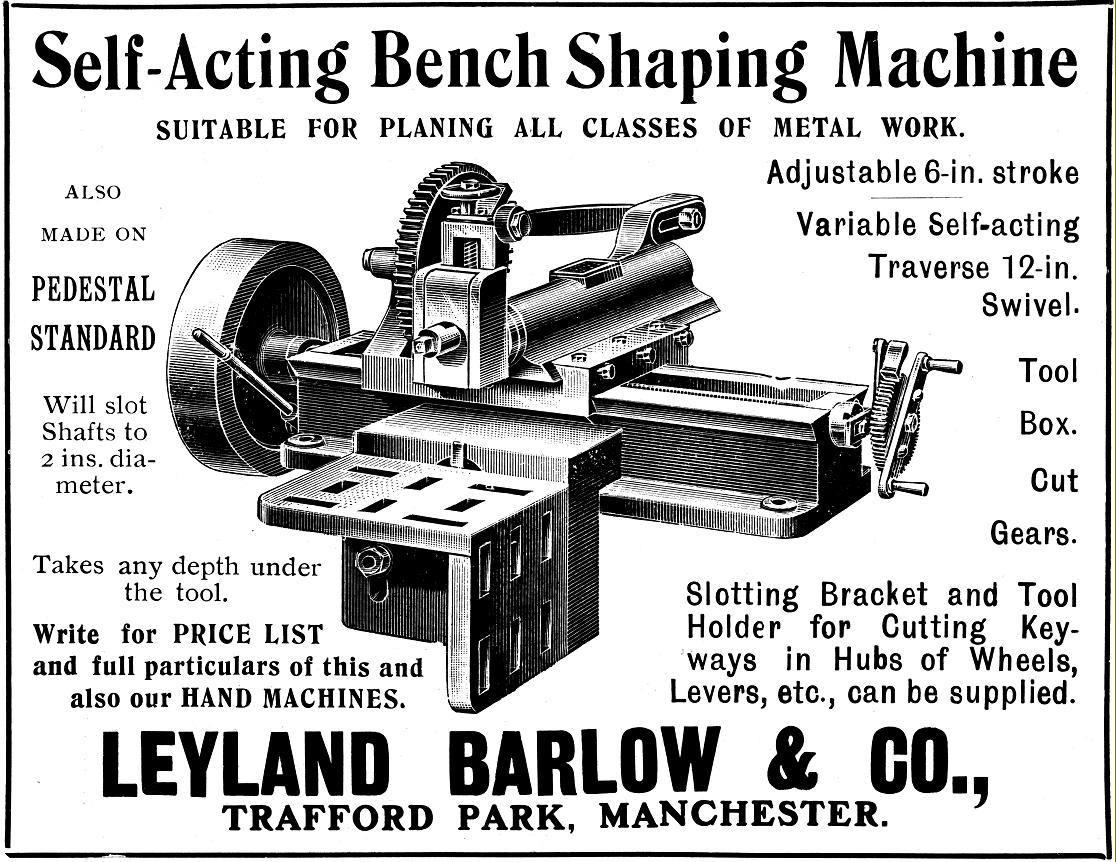

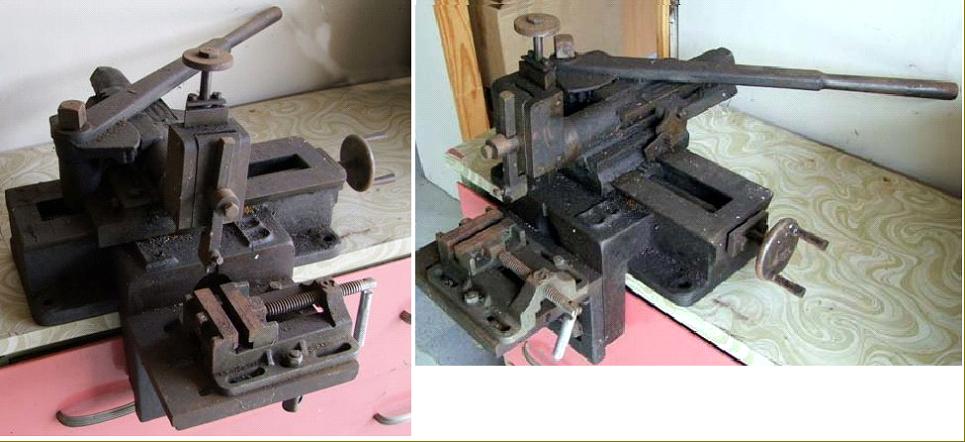

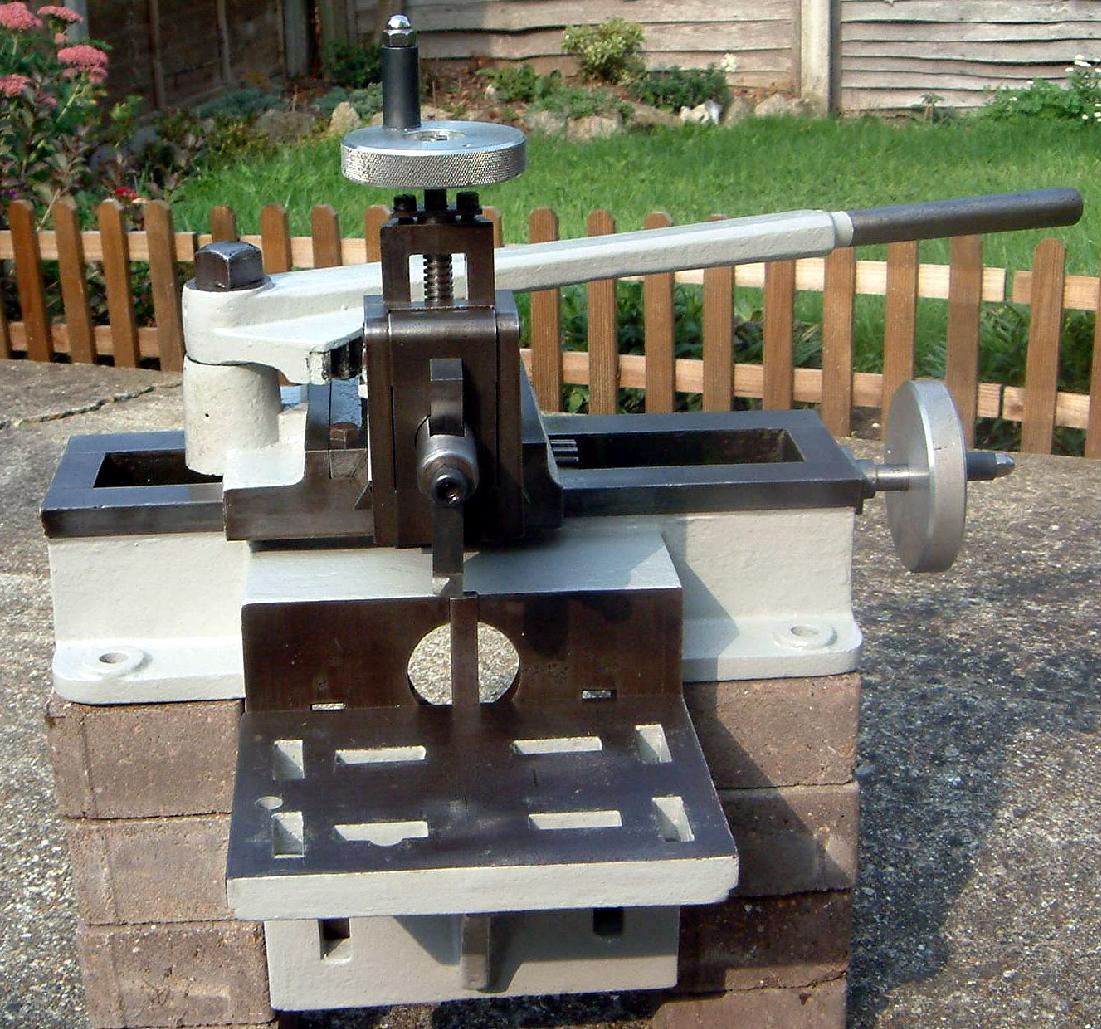

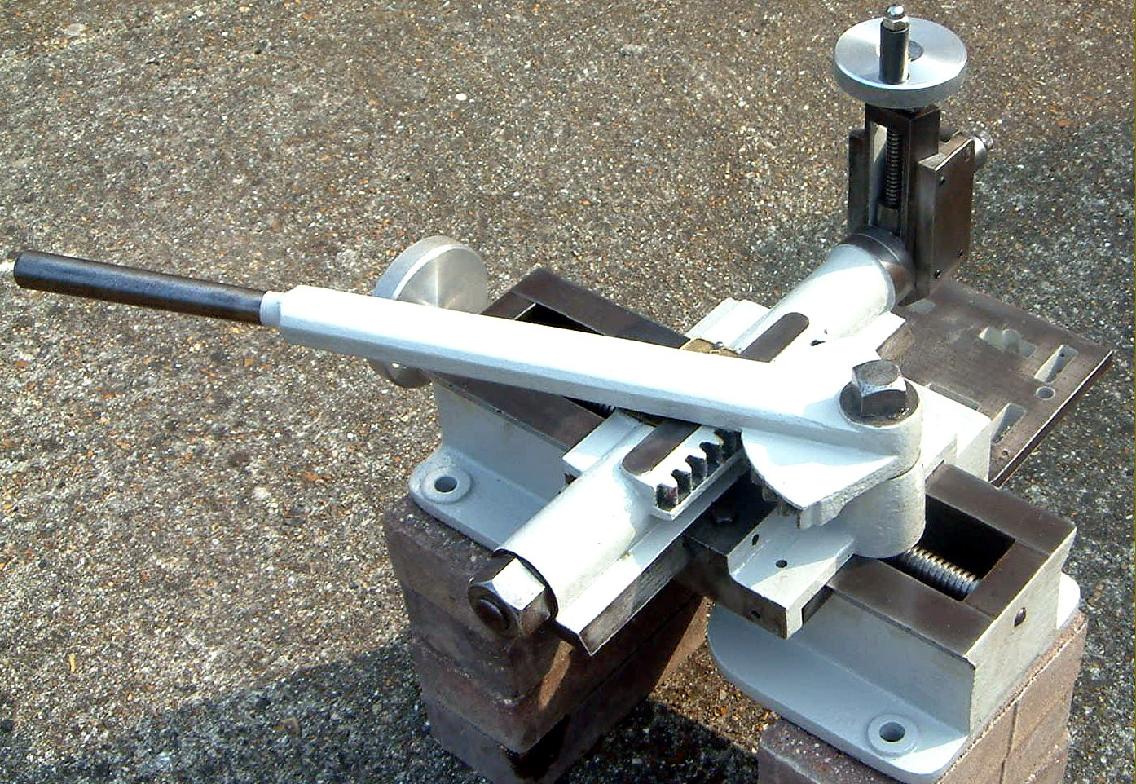

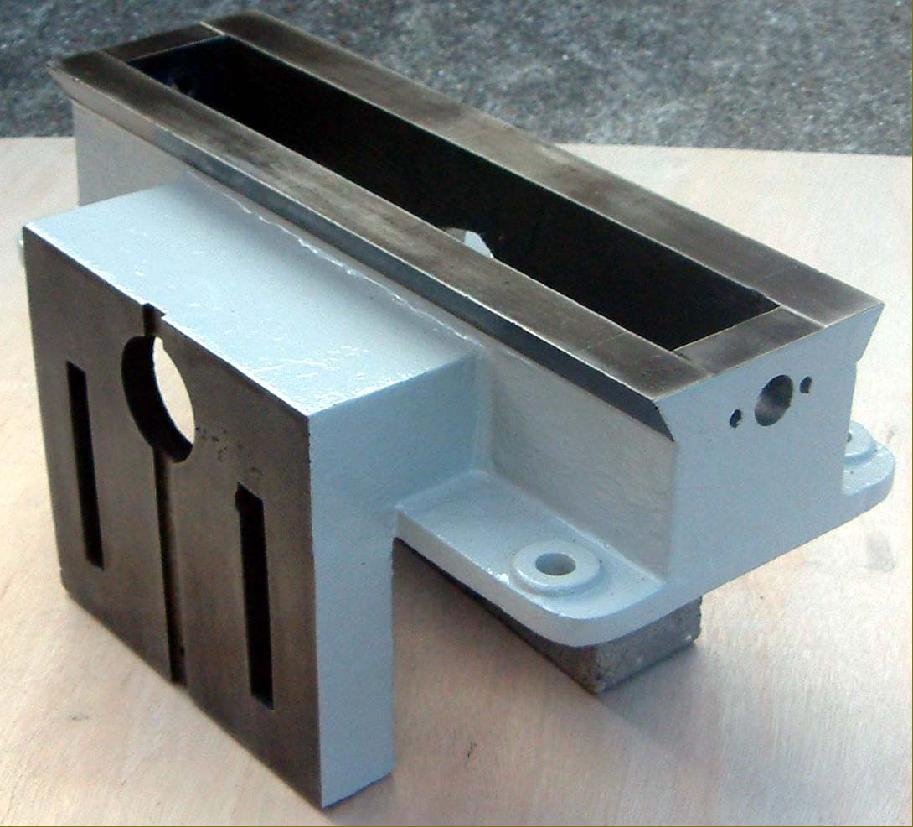

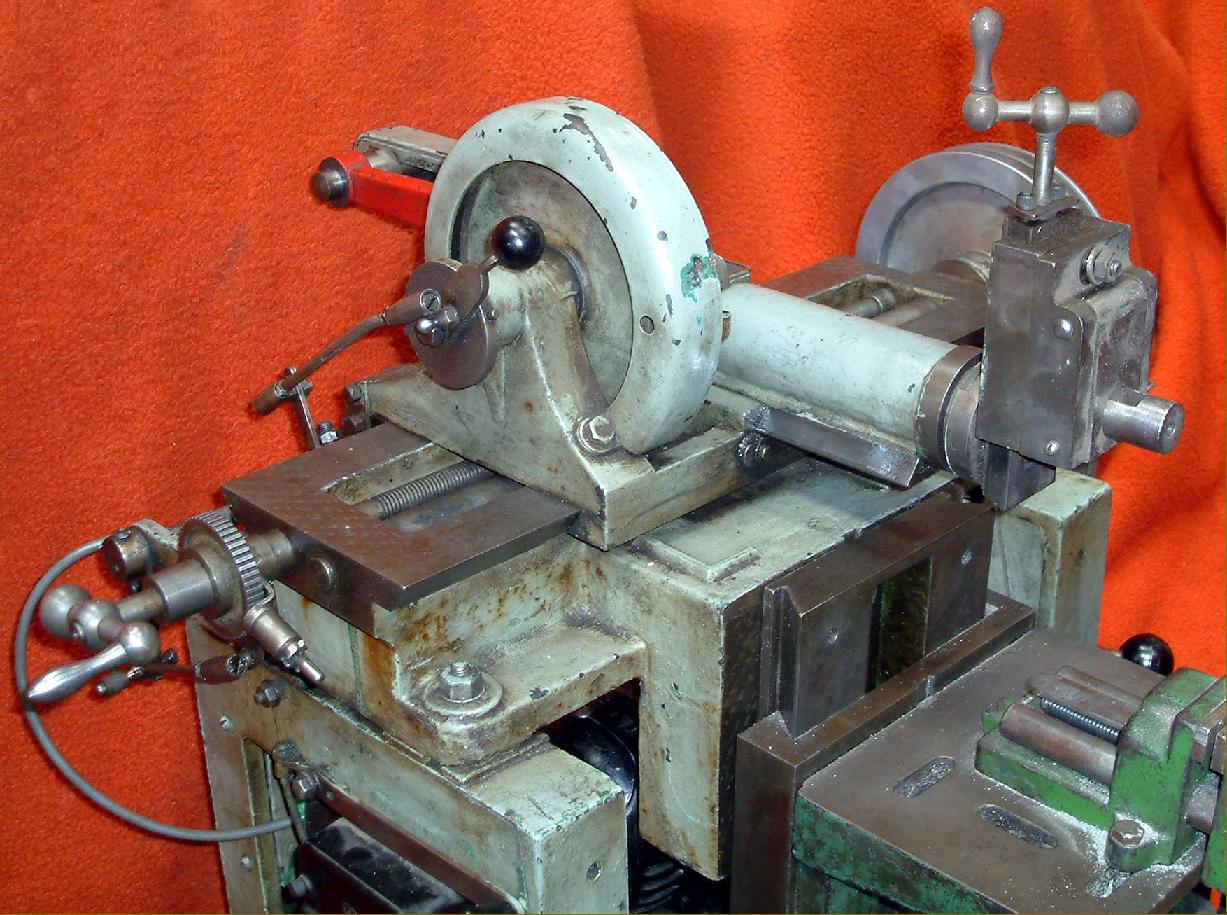

Now a long-forgotten Company, Leyland and Barlow were based in Trafford Road, Manchester and most active during and just after the late Victorian era. Today, examples of their products are rare, but the ones discovered have, upon examination, proved to be well made if simple machines of a straightforward design. Those found include a small backgeared, screwcutting gap-bed lathe and a pair of bench-mount shapers - one hand-powered with the other, in complete contrast, an ingenious and beautifully-constructed 6-inch powered type.

Of a design common in the last 20 years of the 19th century, the lathe exhibited two design features found on many lighter lathes of the time: the headstock spindle thrust was taken against a bracket supported externally on two bars screwed into the end face of the headstock and the bronze spindle bearings were in the form of "boxes" retained by simple two-bolt top clamps. The headstock, located against a central tennon and held down by just a single stud and nut, was fitted with a conventional backgear arrangement with the rear gears carried on an eccentric shaft; naturally no guarding was provided, it being your fault if you tripped and took your fingers off.

Lightly-built, with flat-topped ways and 60-degree dovetail sides the bed, was further weakened by a very deep gap section - there being no effort to brace or deepen the casting at either side to compensate.

Fitted with T-slots on all four of its saddle wings, the carriage was driven by either by a 4 t.p.i. leadscrew (working through changewheels and a tumble-reverse mechanism or) or, by hand, using a large crank handle connected directly against a rack with no step-down gearing - the result being that the smallest movement of the handle produced a disproportionately long travel of the carriage that made it almost impossible to take a steady, gently cut by hand. Both screws of the compound slide were (as was common at the time) driven by awkward-to-turn crank handles and lacked micrometer dials; the threads were also left entirely uncovered and so exposed to the wearing effects of swarf and dirt. To compensate for the high-geared carriage travel the swivelling top slide was given a movement long enough for most hand-turned jobs to be finished by that slide alone. Perfunctory in the extreme, the apron was just wide enough to carry the double leadscrew clasp nuts closed by a snail cam.

If you have, or know of a Leyland and Barlow machine tool, please do make contact.

|

|