|

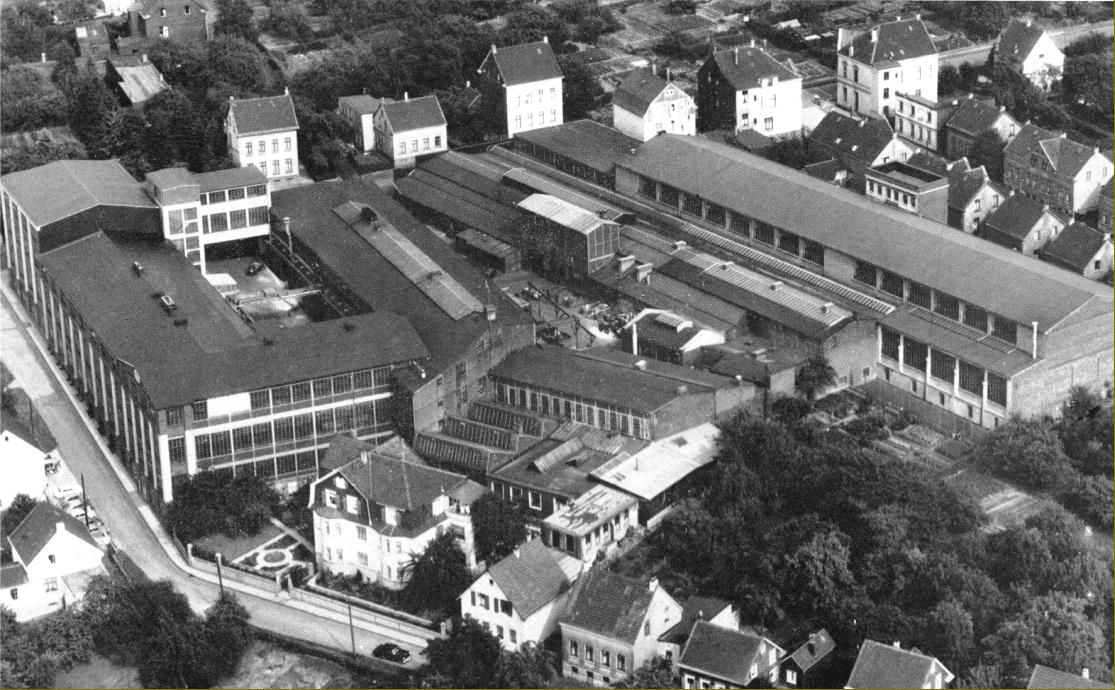

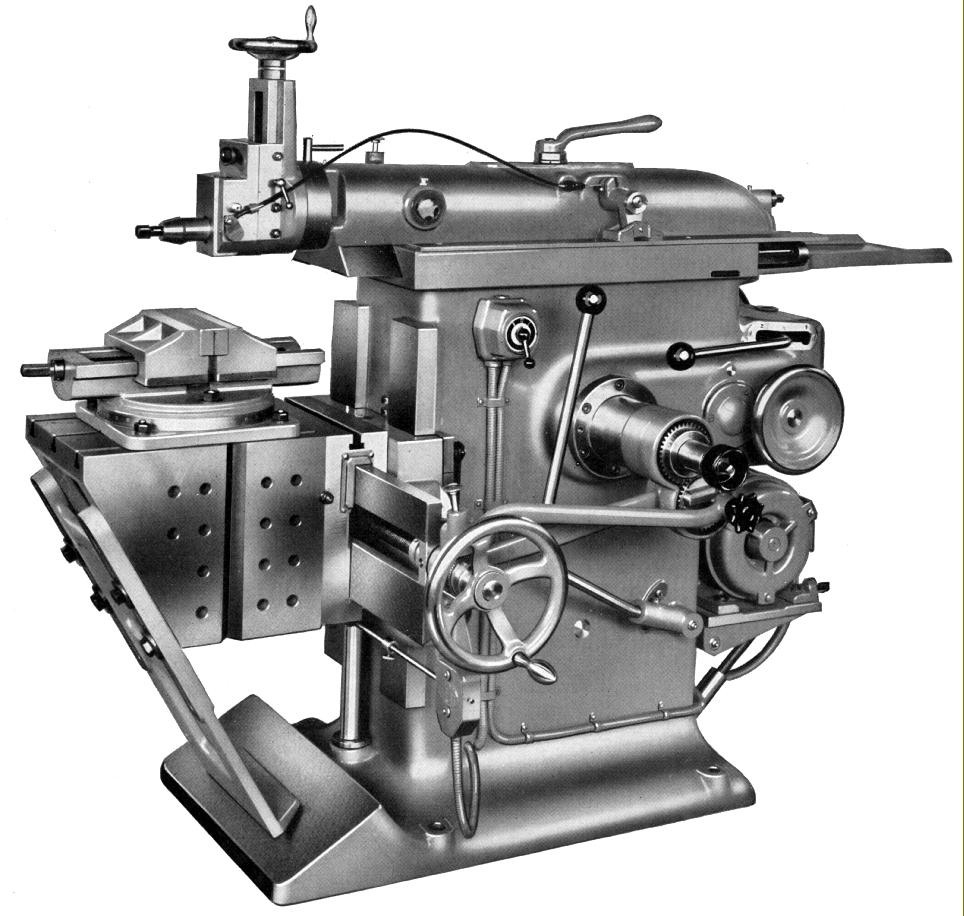

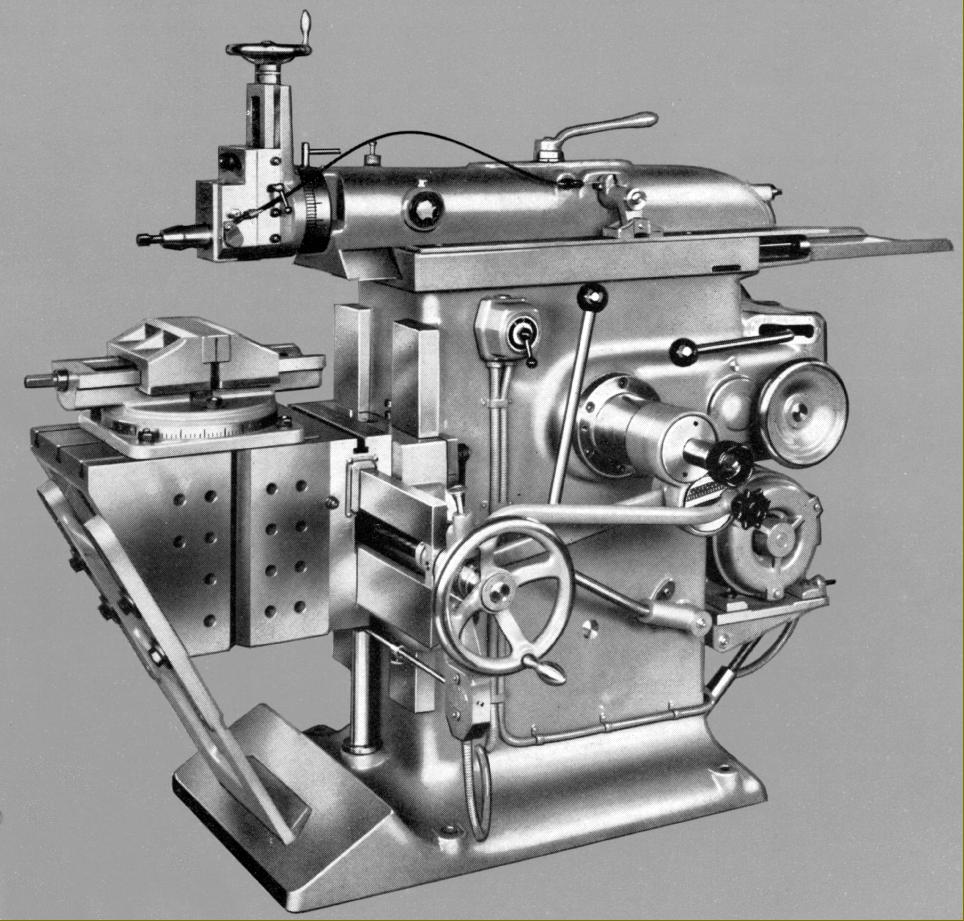

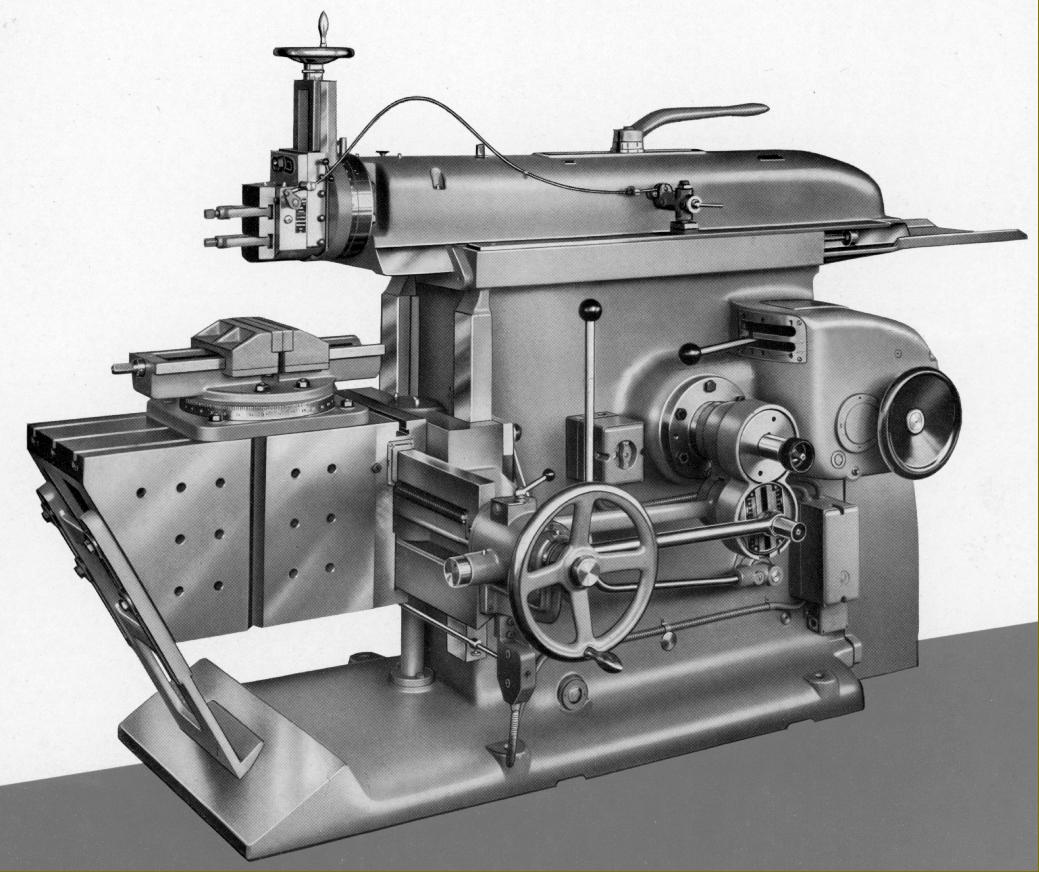

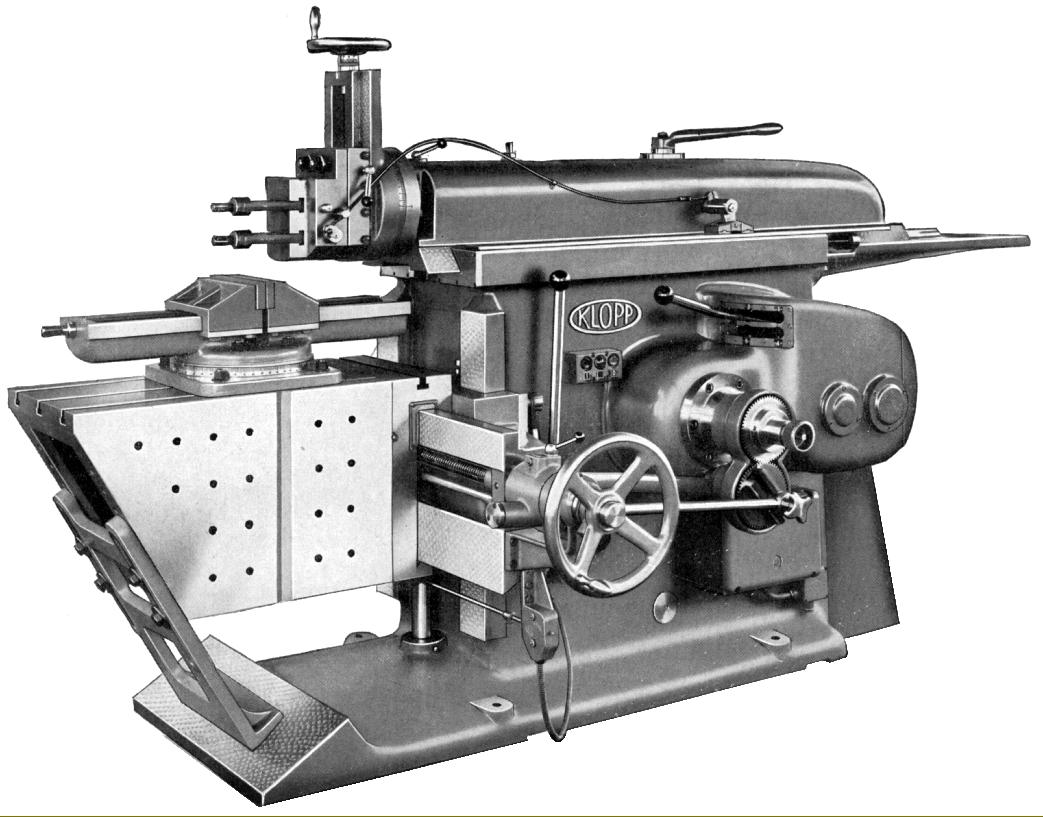

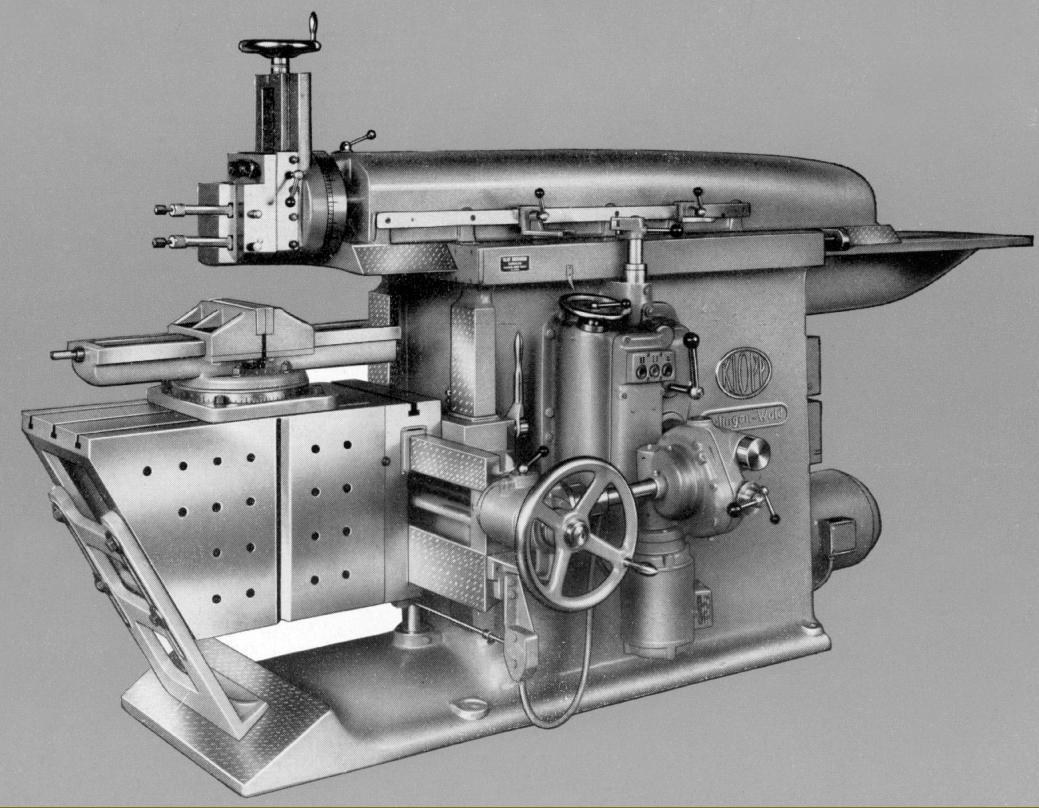

Manufactured by Klopp-Werke Gm, bH, in Soligen-Wald, a small town south of the main Ruhr industrial area and once famous as the "City of Blades" - or "Edge Trade" - where high-quality items in hard steel were made including swords, knives, scissors, razors and cutting tools. Klopp made not just shapers but also a small range of vertical slotters - these being, in effect, the maker's shapers fitted with a vertical head - and a limited range of horizontal and vertical milling machines.

Almost certainly the makers of the most common shaping machine to be found in Germany - and considered the most popular - Klopp gave something of their background in a catalogue issued during September, 1960: We have been making machines since 1910. Originally they were all special machines. We took up the manufacture of high-speed shaping machines at the end of the First World War and already at that time had a team of specialists at our disposal. On the occasion of our fiftieth anniversary we looked for the oldest K LO P P high-speed shaping machine still in use. Among the large number of machines built in the early years we found a KLOPP high-speed shaping machine made in 1918. This was taken back by us in February 1960, and in exchange the owner was given a brand-new high-speed shaping machine No. 43007 from the latest batch..

Like virtually all German machine tools, Klopp shapers were carefully considered and thoughtful designs, built from good quality materials and capable of producing top class work. Users report a particularly long and reliable life, smooth running and the ability to take deep cuts without noticeable deflection. Klopp still list (2017) a twin table, hydraulically-driven traversing shaper, these appearing to now be only available from Far Eastern makers. However, as a very economical way of generating a flat surface (and in the right hands solving a myriad of other a myriad machining problems) the shaper still has a part to play in the workshop of the amateur and small professional repair and maintenance company. Many hundreds are offered on the used market every year, often at bargain prices, and are an interesting machine to get to grips with.

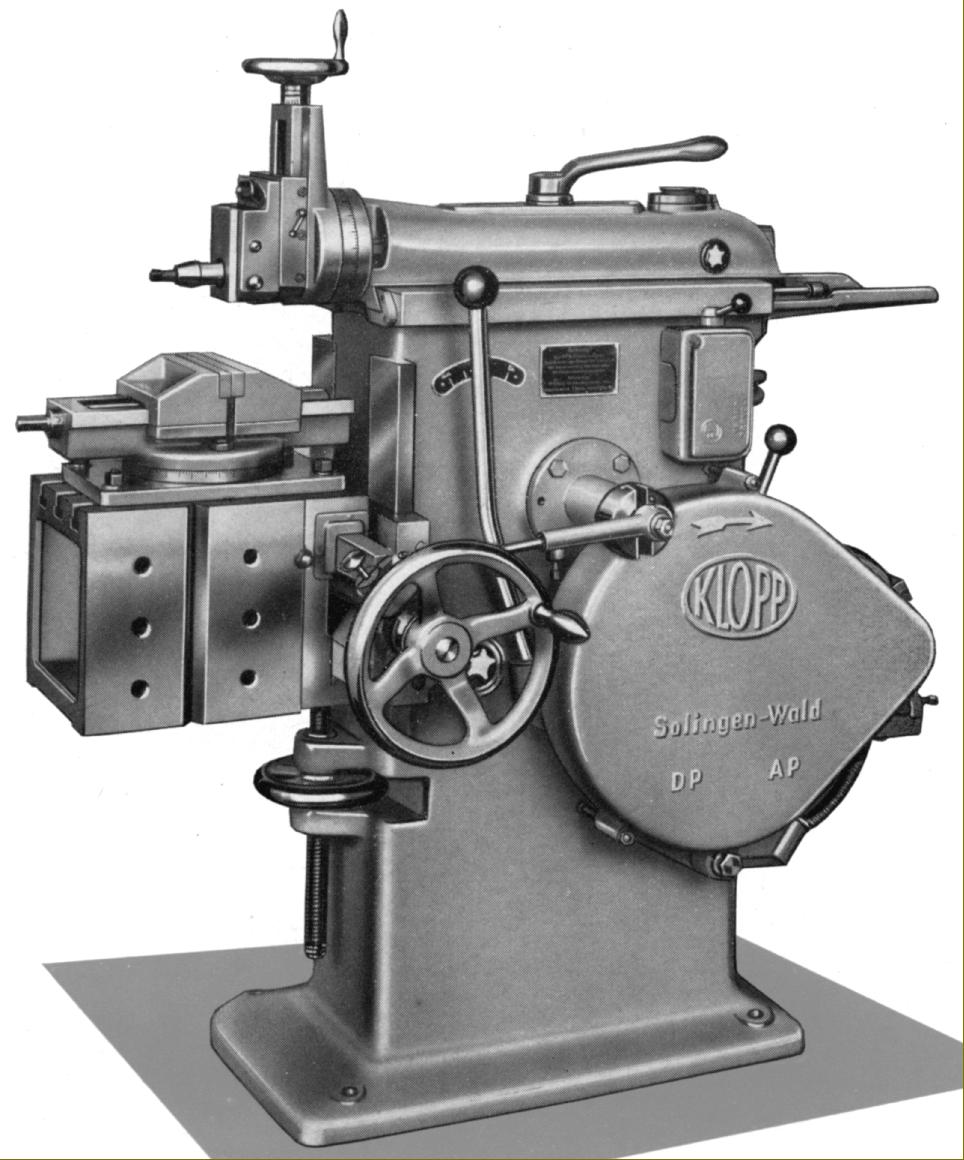

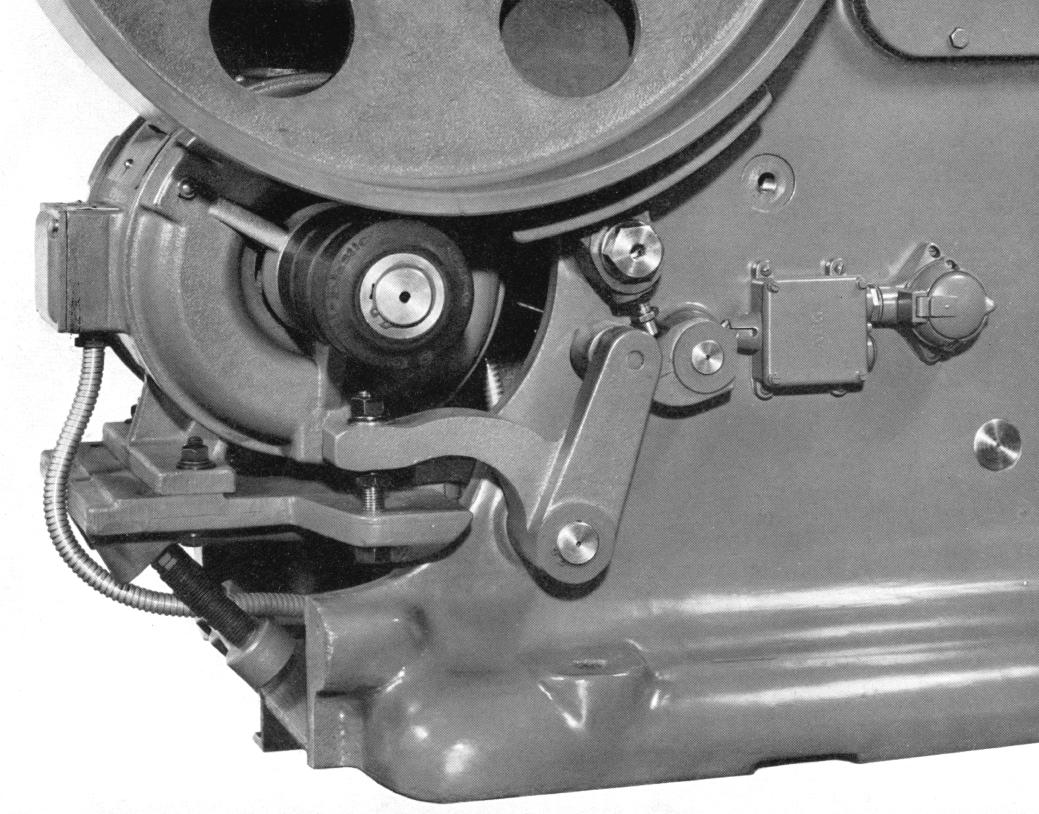

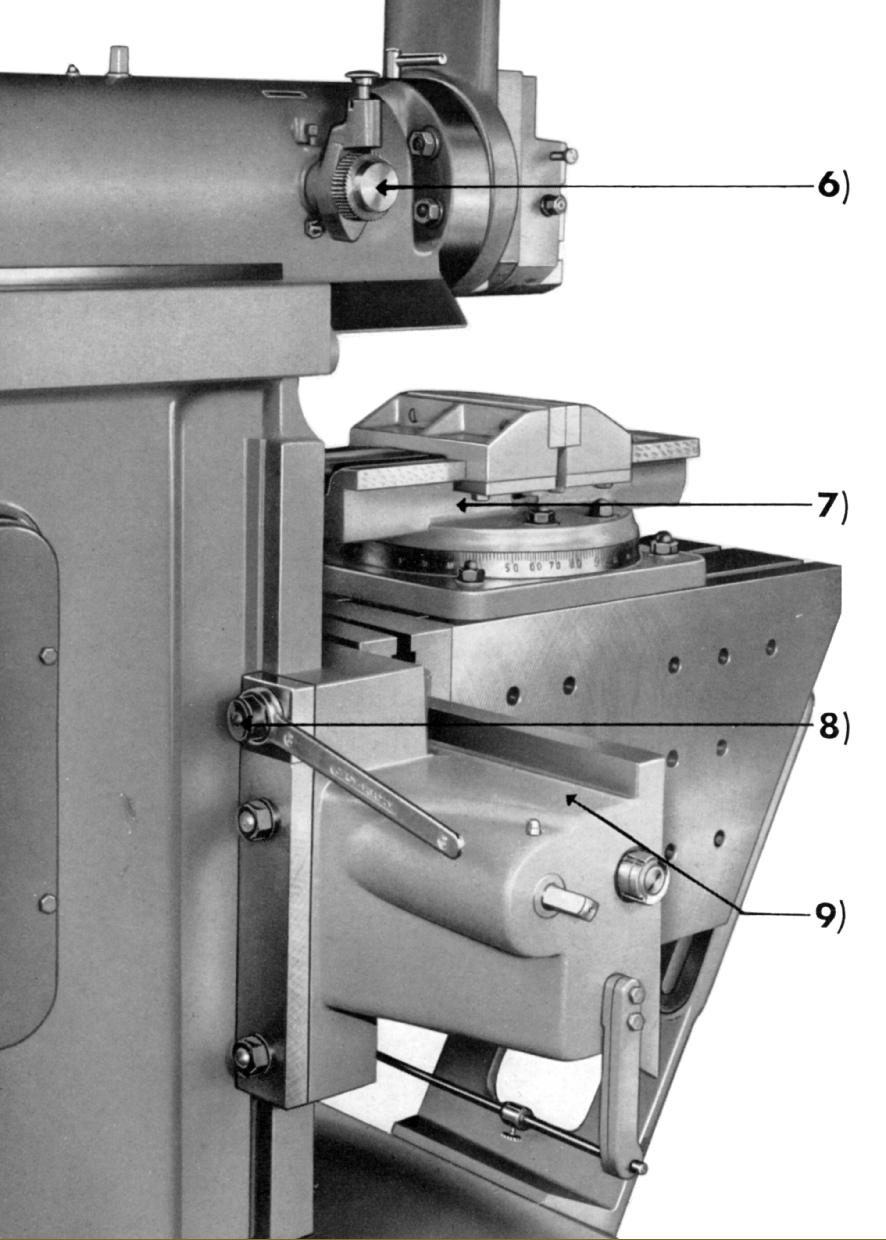

Klopp shapers were given Model Numbers that equalled their ram stroke in mm, with each a distinct design, developed specially for its intended work. An unusual feature was the drive system, this using a friction arrangement where a rubber-covered roller on the motor shaft pressed against, under spring pressure, a larger wheel on the machine's input shaft - these versions sometimes being listed using an additional descriptor " DP.-AP.". Some other, larger models - such as the 650-H, 850-H and 1000-H - had the option of an advanced hydraulic system and carried an H suffix to their Type Number, the arrangement operating both the ram and the table cross-feed mechanisms. The inclined table support bracket, set at 30° to the vertical, was common to all Klopp shapers, was possibly unique. The setting was arrived at by observing table flex under working loads, the makers deducing that the distortion was "5 points" downward and 3" points backwards, the resulting triangle of forces producing the 30-degree setting.

Smallest of the shapers made from the 1950s onwards was the 1 h.p. Model 300 weighing 1100 lbs and having a 300 mm (11.8") ram stroke with four double-stroke-per-minute speeds that ranged from 30-200. The table had a top surface 12" x 8", a cross traverse of 12.83", a maximum clearance between table and underside of ram of 11.5" and a toolslide travel of 3.5". Other models manufactured included the 375, 450, 525, 550, 625, 650H, 725, 850, 850H and 1000H.

Klopp Model 450

Fitted with a 2 h.p. motor, the Model 450 weighed 1810 lbs, had a 450 mm (17.7") ram stroke with six double-stroke-per-minute speeds that ranged from 15 to 160. The table had a top surface of 17.75" x 12.5", a normal cross traverse of 19.5" (maximum 25"); a maximum clearance between the table and underside of ram of 17" and a toolslide travel of 5.5"

Klopp Model 525

Fitted with a 3 h.p. motor, the Model 525 weighed 2750 lbs, had a 525 mm (20.7") ram stroke with six cutting stroke speeds of 16, 32, 57, 82, 114 and 164 per minute.. The table had a top surface of 19.5" x 12.5", a normal cross traverse of 19.5" (maximum 25"); a maximum clearance between the table and underside of ram of 17.5" and a toolslide travel of 4.875"

Klopp Model 550

Fitted with a 3 h.p. motor, the Model 550 weighed well over a ton at 2750 lbs; the ram stroke was 550 mm (21.65") with six double-stroke-per-minute speeds that ranged from 15 to 160. The table had a top surface of 19.75" x 12.5", a normal cross traverse of 19.5" (maximum 25"), a maximum clearance between the table and underside of ram of 17" and a toolslide travel of 5.5".

Klopp Model 725

Fitted with a 6.5 h.p. motor, the Model 727 weighed, at 5075 lbs, well over two tons; the ram stroke was 725 mm (28.5") with twelve double-stroke-per-minute speeds that ranged from 11 to 146. The table had a top surface of 28.5" x 13.5", a normal cross traverse of 23.5" (maximum 27.5"), a maximum clearance between the table and underside of ram of 19.75" and a toolslide travel of 6.75".

Klopp Model 800

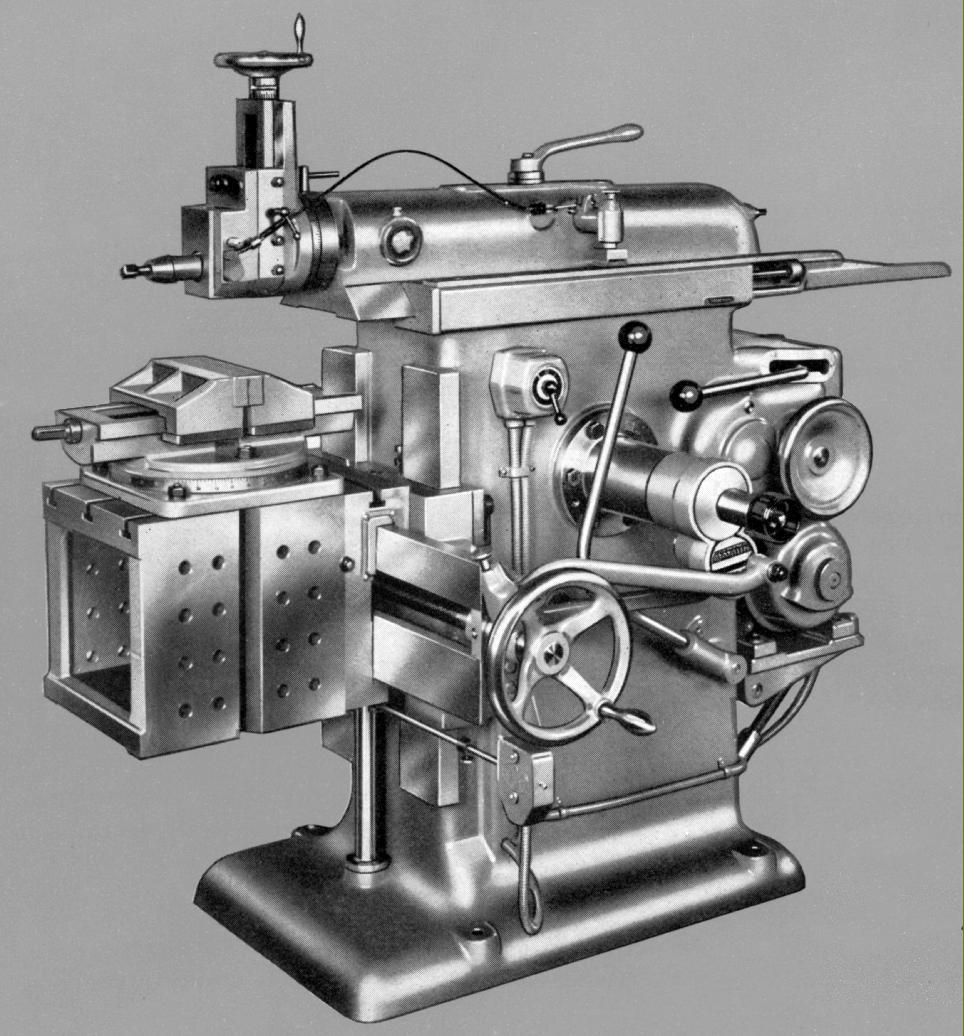

Introduced in 1953 the Model 800 was described as "...a new type and embodies novel features ….simple and speedy handling by the provision of readily accessible controls conveniently grouped on the operating side only; minimum transmission losses by virtue of friction-wheel drive to the mainshaft pulley; simple system of lubrication to all parts of the internal driving mechanism; ram-slide lubrication by forced-feed pump housed in the body of the machine…."Fitted with a 7.5 h.p. motor and using friction, the Model 800 weighed 7280 lbs; the ram stroke was 800 mm (31.5") with three speeds of 10.4", 16.5" and 27" per minute. The table had a top surface of 31.5" x 16.5", a normal cross traverse of 27.5", a maximum clearance between the table and underside of ram of 17.375" and a toolslide travel of 7.5".

Klopp Model 800H

A later model, fitted with a 6.5 h.p. motor, the Model 850H used a hydraulic drive system that moved both the ram and table cross feed. Weighing 7250 lbs (over three tons); the ram stroke was 850 mm (33.5") with two ranges of cutting speeds: roughing from 26 to 72 feet per minute and finishing from 72 to 110 feet per minute. The table had a top surface of 33.5" x 16.5", a normal cross traverse of 27.5" (maximum 33.5") and a range of automatic feeds that ranged from 0.008" to 0.1182 per minute. There was a maximum clearance between the table and underside of ram of 17" and a toolslide travel of 8.25".

In the UK, Klopp shapers can be found with an impressive bronze plate proclaiming "Wickman" - though the Wickman sales literature did admit to being agents for the German company, their association taking over Post-WW2 from the original representatives, Dowding & Doll Ltd. of Greycoat Street, London..

|

|