Kärger Lathes

Seldom found, the Kärger horizontal milling machine was made by G. Kärger of Kraut-Strasse 52, Berlin 0.27. From the late 1800s, the company was well known as a maker of high-quality. precision plain-turning and screwcutting lathes designed for use in the watch, clock and instrument-making trades.

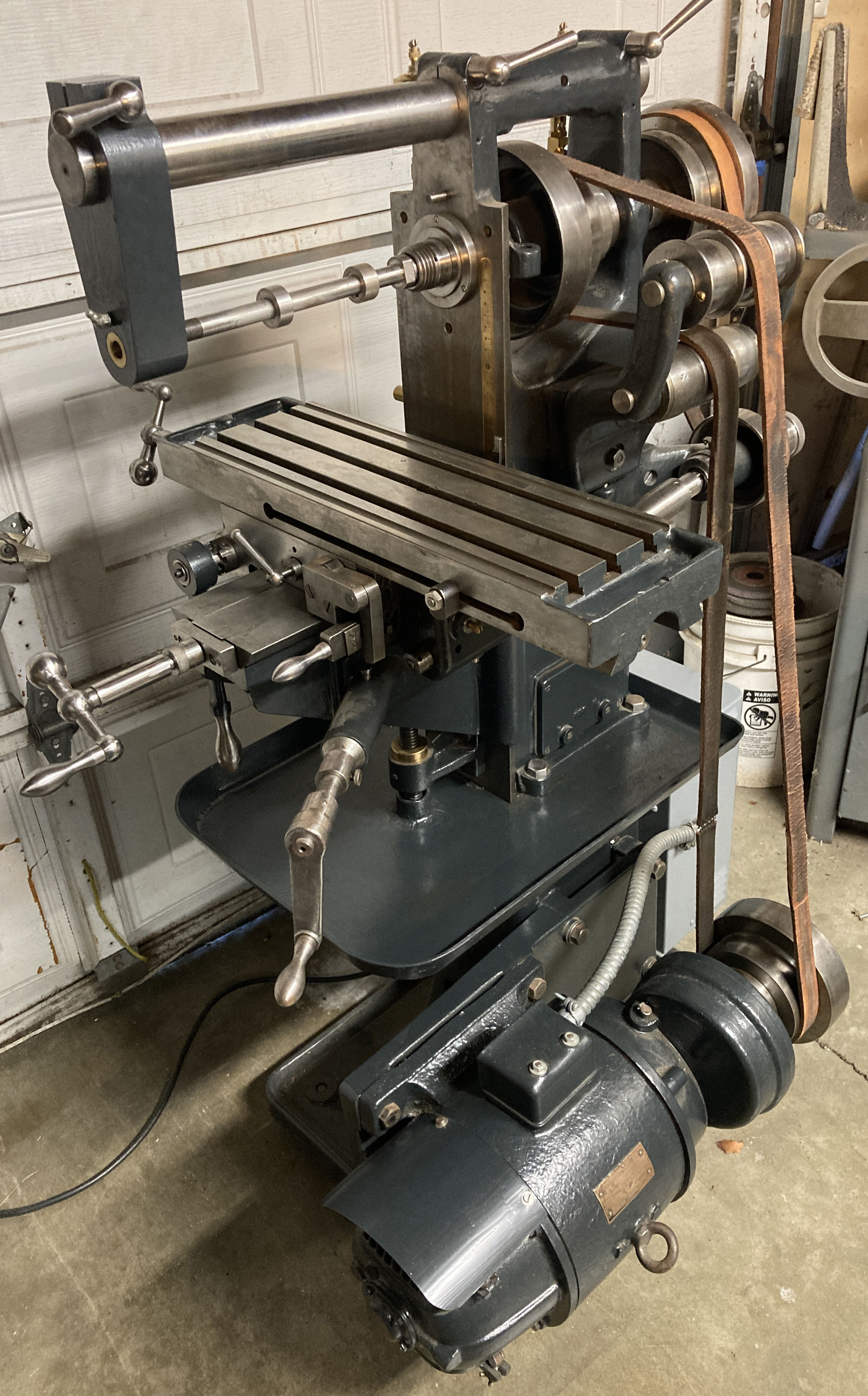

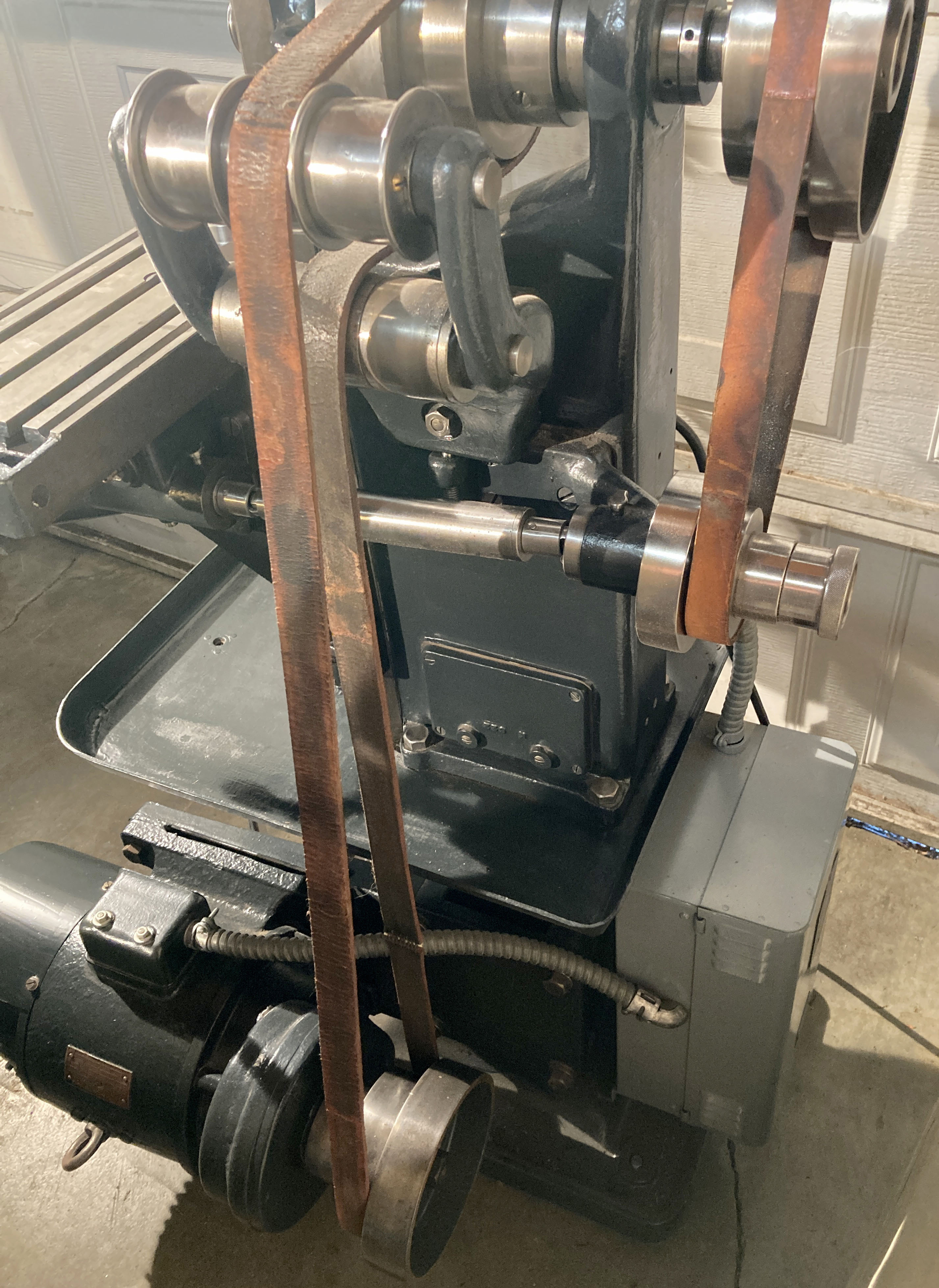

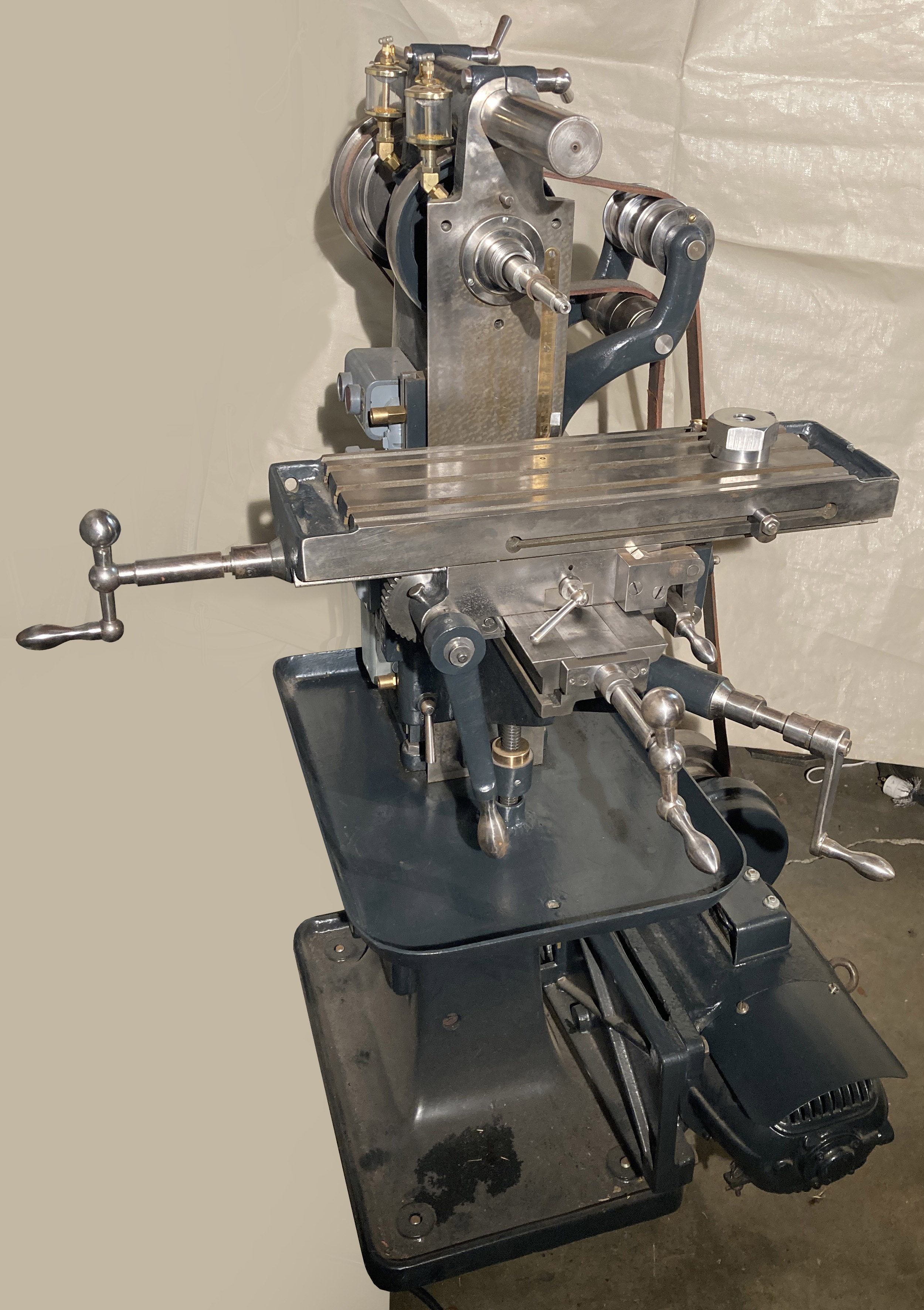

Containing a motor dated 1942 - but believed to be very much earlier - the miller shown below with its flat-belt drive and round overarm, was of a conventional design for the period, but of exceptionally robust construction and with a quality finish. The history behind its arrival in the United States is not known, but it might have been brought over having been used in an American Army repair unit based in Germany after WW2 - a not uncommon occurrence, apparently - or simply imported as a used machine in the late 1940s or early 1950s..

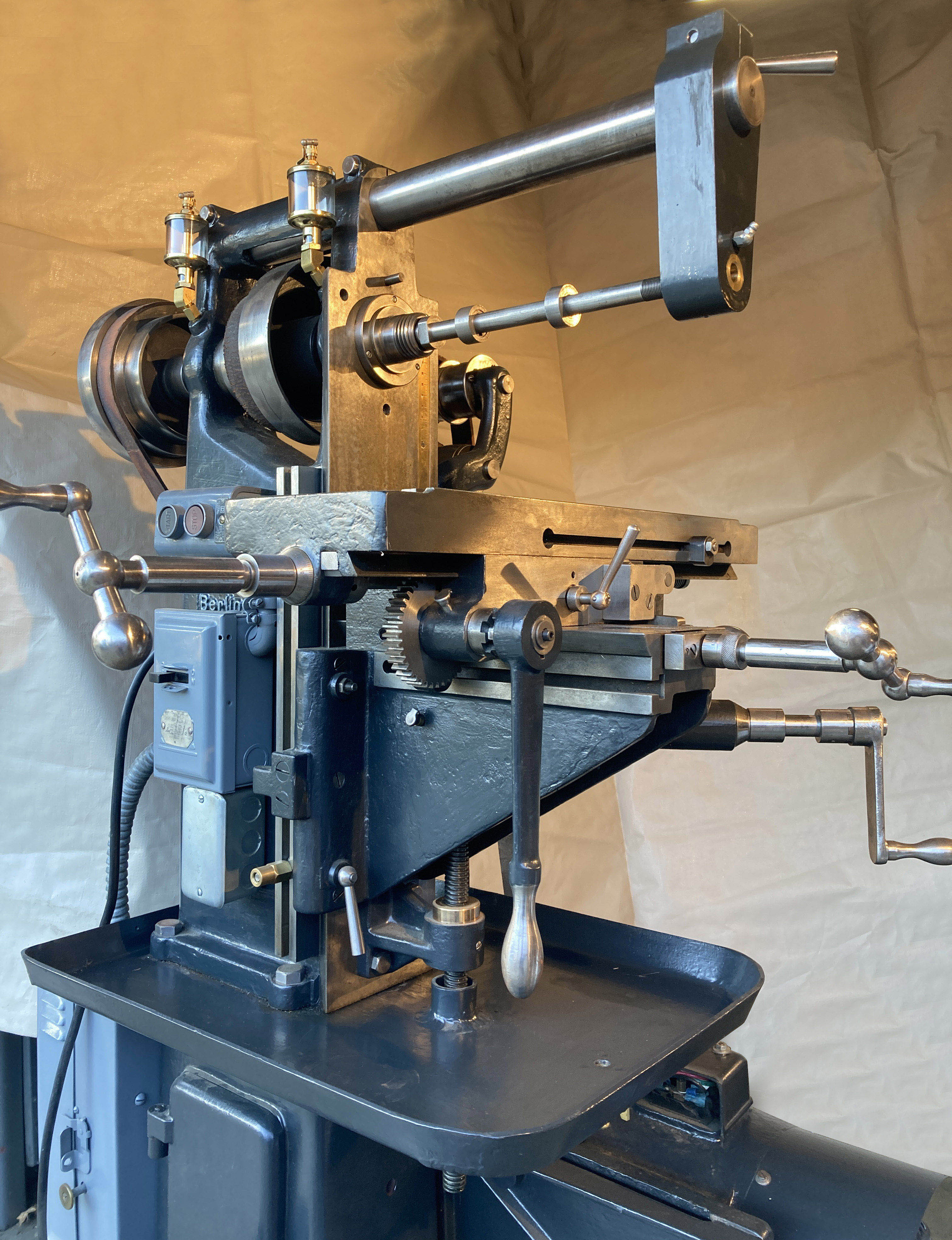

Fitted with a 3-speed power drive by flat belt to the usual carden shaft, the table was 21.625 inches long by 6.25 inches wide with three 17.875 inches long T-slots. Longitudinal travel was also by both a lever and a single, detachable handwheel at its left-hand end. The table drive appears to have incorporated that most useful of features, a drop-out worm by which means to drive could be instantly engaged or disengaged, adjustable stops, carried in a slot on the front face of the table, provided the means for an automatic release. Cross and elevation motions were by screw feed, the travels being 11 inches longitudinally, 6.26 inches in traverse and 8.75 inches vertically (though, oddly, the table could be lifted higher than the spindle nose). One unusual, though useful feature, was a ruler, graduated in mm, and let neatly into the front face of the column to measure vertical travel

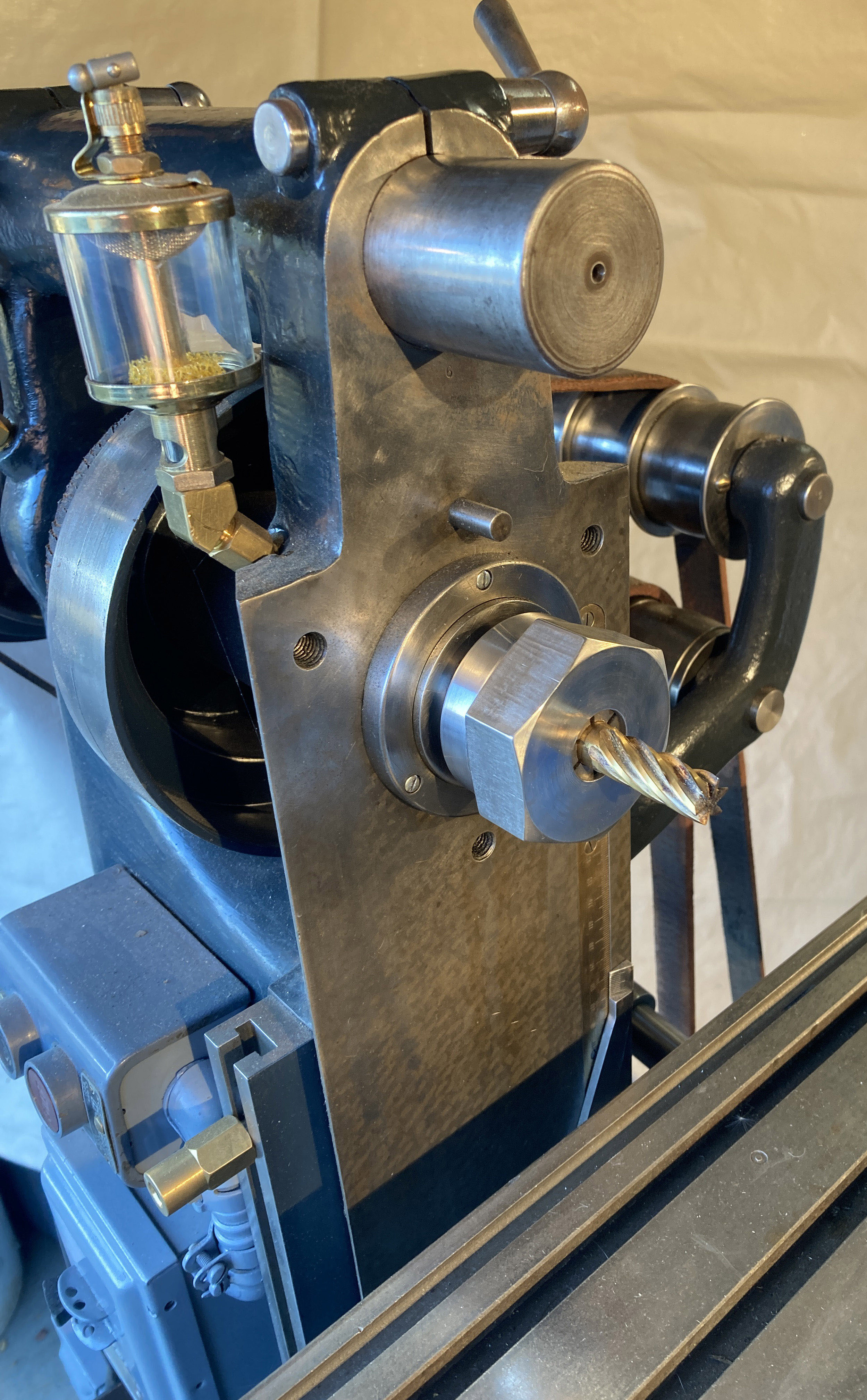

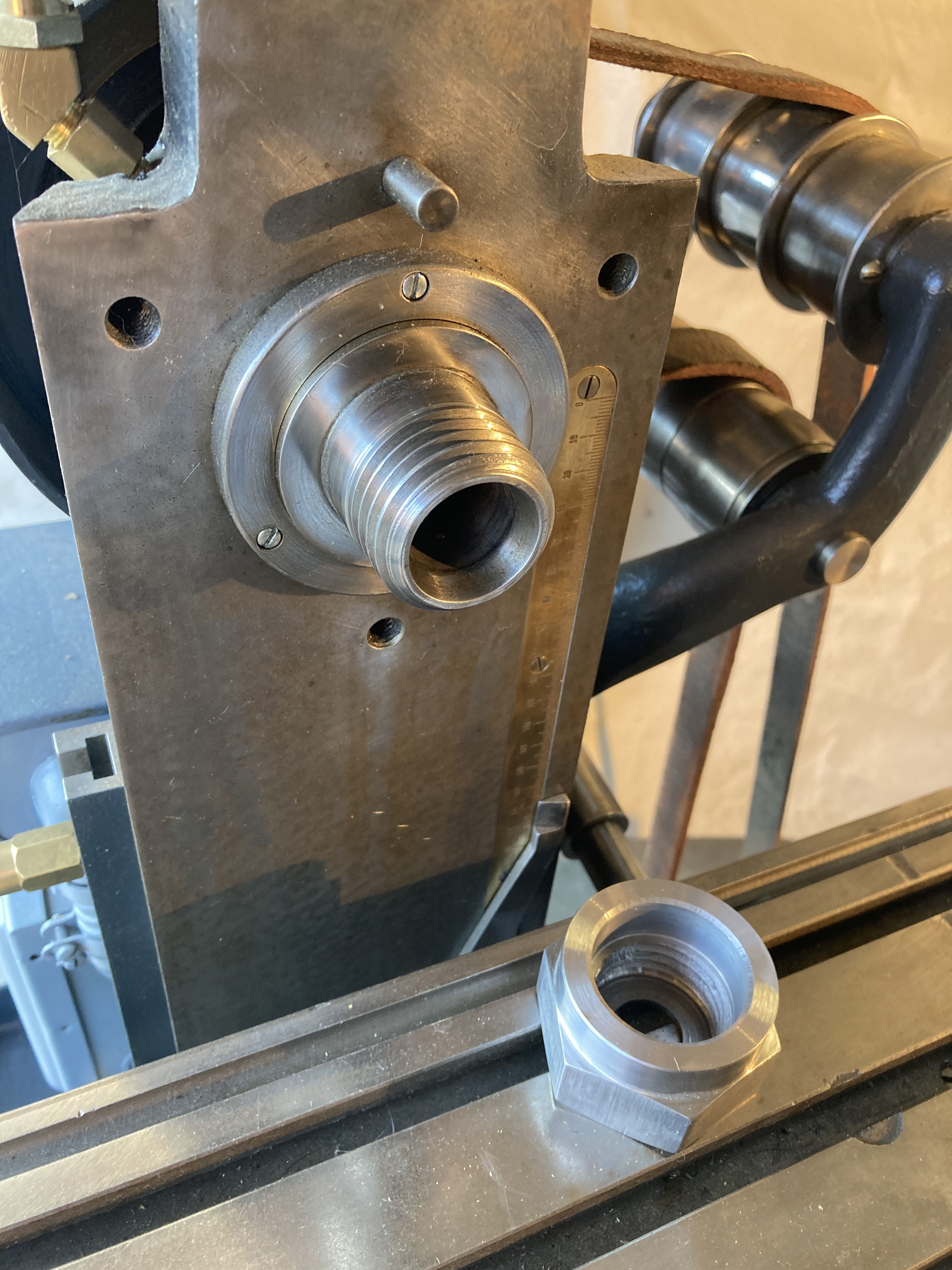

Looking very much like the spindle nose of a lathe shown in the Kärger lathe section of the Archive, this had what seems to be a No.3 Morse taper socket, machined on the end with a M39 x 4 thread and a short taper to take collets.

Now beautifully restored, the owner writes, "While I'm still working out a few bugs, the mill is now basically complete, and I've recreated the parts required to make it usable including an overarm drop-bracket support and locking handle, a large nut/collet closer for the end of the spindle, and a shield for the top of the motor - chips would have fallen into the open motor vents without one. The side of the cable inlet housing for the motor is still open to the elements as I need to find a way to cover the opening. The oilers are not original, but Chinese - but will suffice until I can find period ones. Everything else is either original to the machine or was attached when I got it, including the entire electrical system.

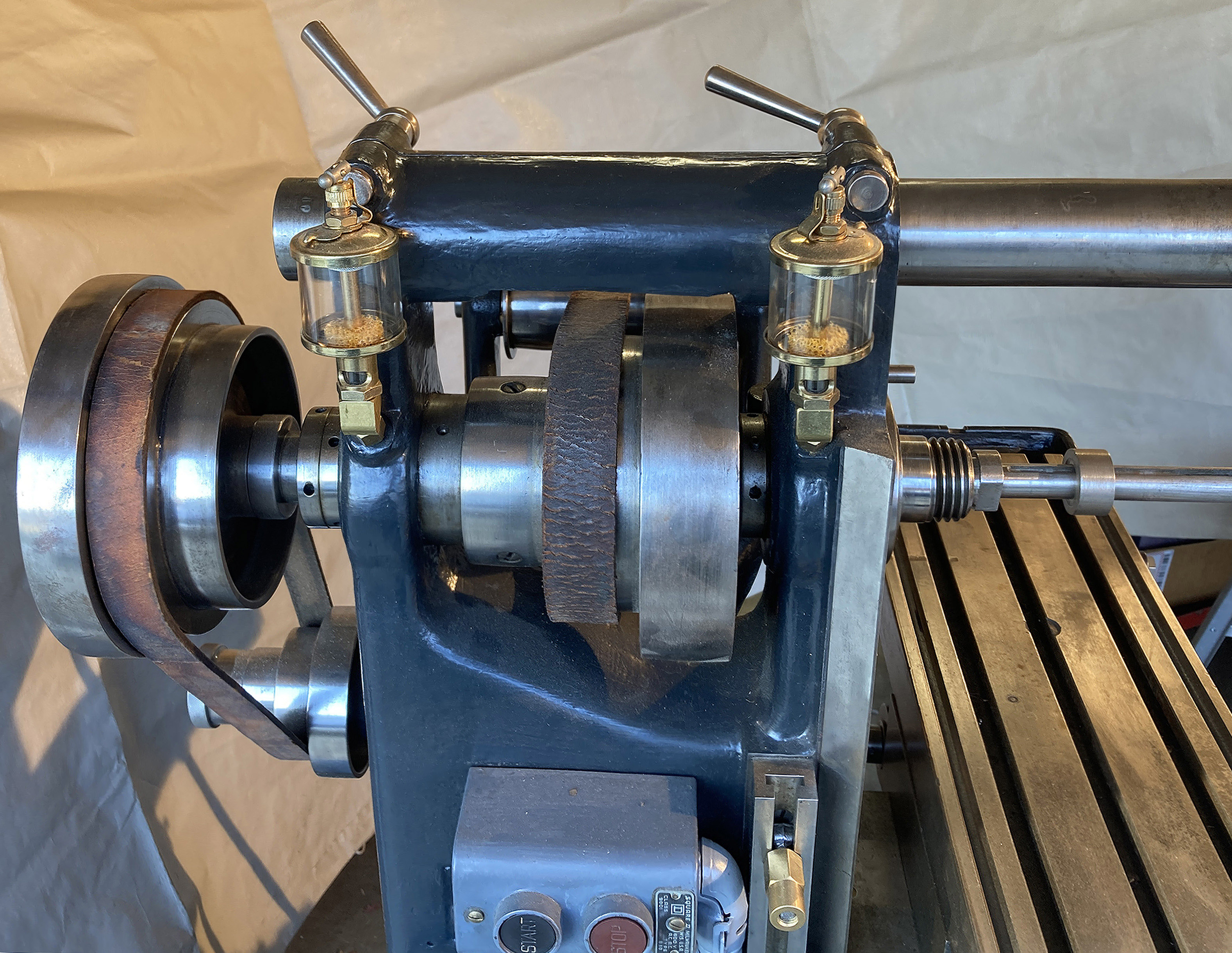

As with so many older machines, a previous owner had mistaken oilers for grease nipples and the oilways were packed with grease. With these cleaned out and oiled, although everything works, before using the machine I still need to add wicks to feed oil into the main spindle bearings; these are in bronze and in great shape - but do need a good supply of oil. Fitted with Morse taper, but spindle end is also cut with a steep taper so that that Erickson 180 style collets fit perfectly.

The patterns for the castings were made before 1920, as that was when the Berlin postal code system "O.27" was replaced, otherwise, I have found nothing that could help date the machine. There was a piece of paper between the upper and lower casting, which looks like a German diagram/schematic, but is barely legible and has no dates on it.

I've also been unable to find any dates for the motor, (AEG type VGN8). I had a contact at AEG, but he was unable to find anything.

All the castings have "6" stamped in them, except for one, which has a "7". This sort of stamping is common on "vintage" machines, the method of assembly at the time being for a man and apprentice to draw the parts from the stores, assemble and 'fit up' the machine (correcting minor machining errors) so that it worked smoothly and was accurate. It would then have been dismantled, the various parts stamped before another department or factory-hand painted it.

The actuators for X and Y travel are tapered, with a slot cut into them, which mates to an internal pin in the handles. Although the tapers are similar, they are different enough that handles are not interchangeable. This leads me to believe that there was a fair amount of hand-fitting done on this machine, which would tend to make it older, rather than newer.

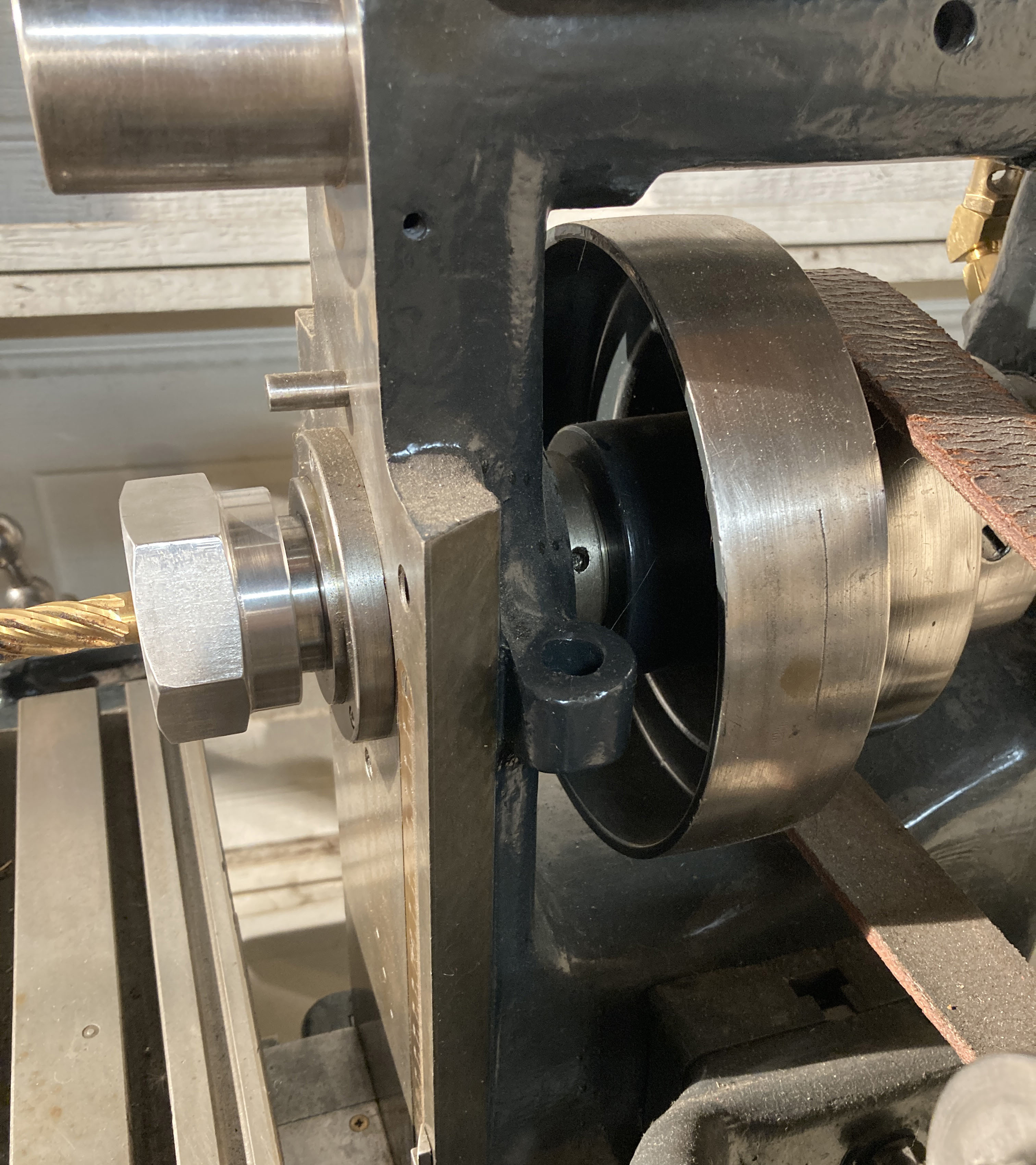

One thing still eluding me is the large boss on the frame between the pulley and the front of the spindle. It looks like a pivot for something, but I'm not sure what. It might be for mounting a belt guard, but machines of this age rarely had such things.

On the front of the machine, above the spindle, there is a large pin, together with three threaded holes surrounding the spindle. I believe these are all for an accessory which might also employ the pivot on the side of the unit. Could it have been a right-angle milling or slotting attachment or a vertical head right angle - though the lack of a positive key of any kind on the spindle would, in my opinion, make those less likely."

If you have a Kärger milling machine - or any literature about them, or other Kärger machine tools, the writer would be pleased to hear from you.