|

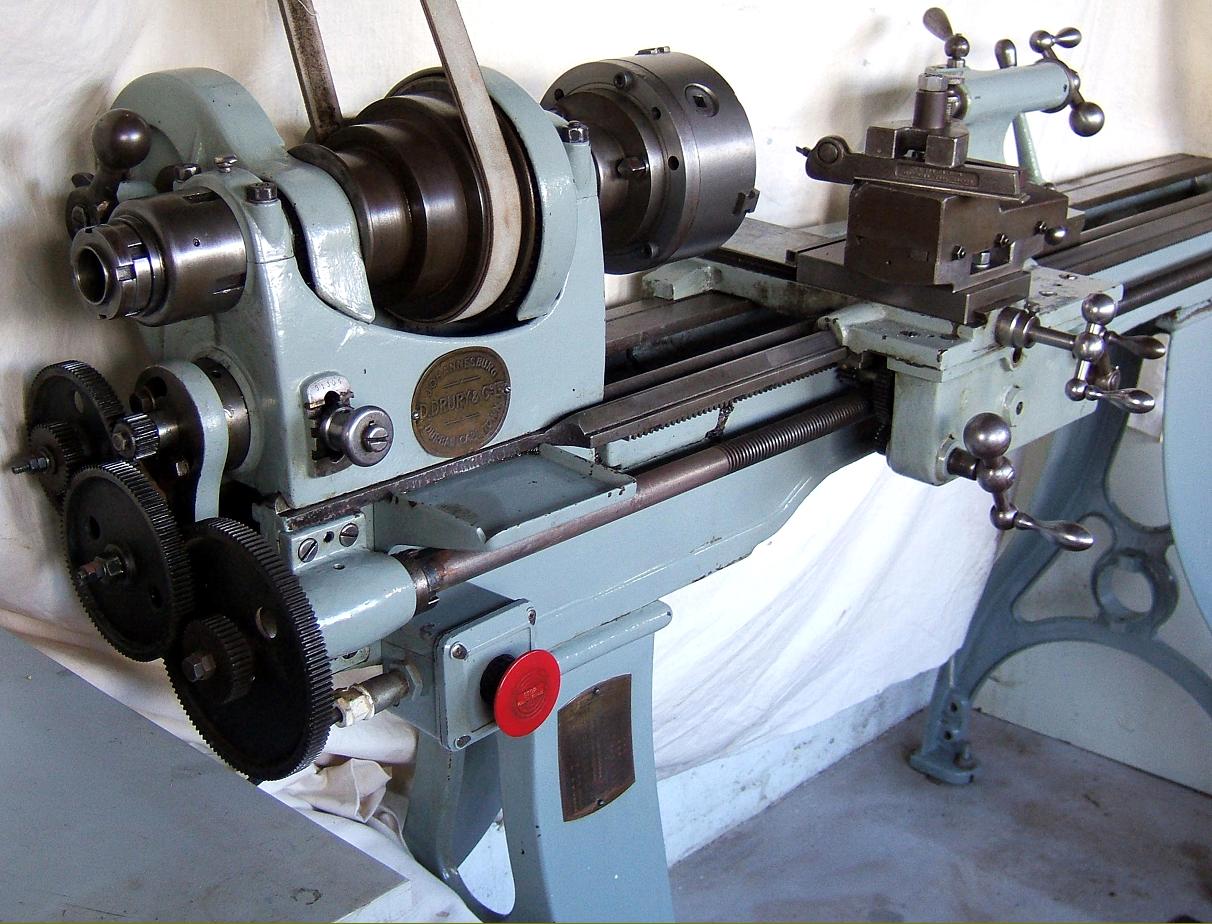

Almost certainly made in Germany by Ehrlich - a large manufacturer of conventional lathes - lathes branded as IXL were first factored in the UK early in the 20th century by Pittler (represented by George Adams in London, who had strong German connections) and then by Tyzack and J.G.Graves. The latter two were companies with very large mail-order businesses, Tyzack tending towards machine-tool sales but J.G.Graves (of Sheffield) having a very much wider and more general product spread.

Besides examples marked "Leader" (both with and without additional IXL markings), some IXL lathes have the prefix "BEC", standing for "B. Elliott Co.", once the largest UK machine-tool agents who, it is believed, may have had some designs constructed for them by Ransomes, Sims & Jefferies. However, the connection to Elliott is tenuous, for the appearance of IXL in catalogues of various independent tool dealers does not make sense - Elliott having their own distribution system and non of their (many other) machine tools are known to have been sold in this way. It is also possible that some versions of the IXL may have been constructed under a sub-contract agreement with the well-known Britannia company. One trick practised in the past (before it was made illegal) was to put "British Made" or "Made in England" on some easily detached part such as a changewheel cover or stand door; while the marked part might indeed have been cast in the United Kingdom, the rest of the lathe was an import. The same trick was practised by sellers of wallets with a little tab marked "Real Leather". You've guessed it - the tab might have been leather, the rest was a cheap imitation. However. whatever the truth of the matter as to the maker, lathes branded as IXL seem to have enjoyed buoyant sales and today appear regularly on auction sites and for-sale lists.

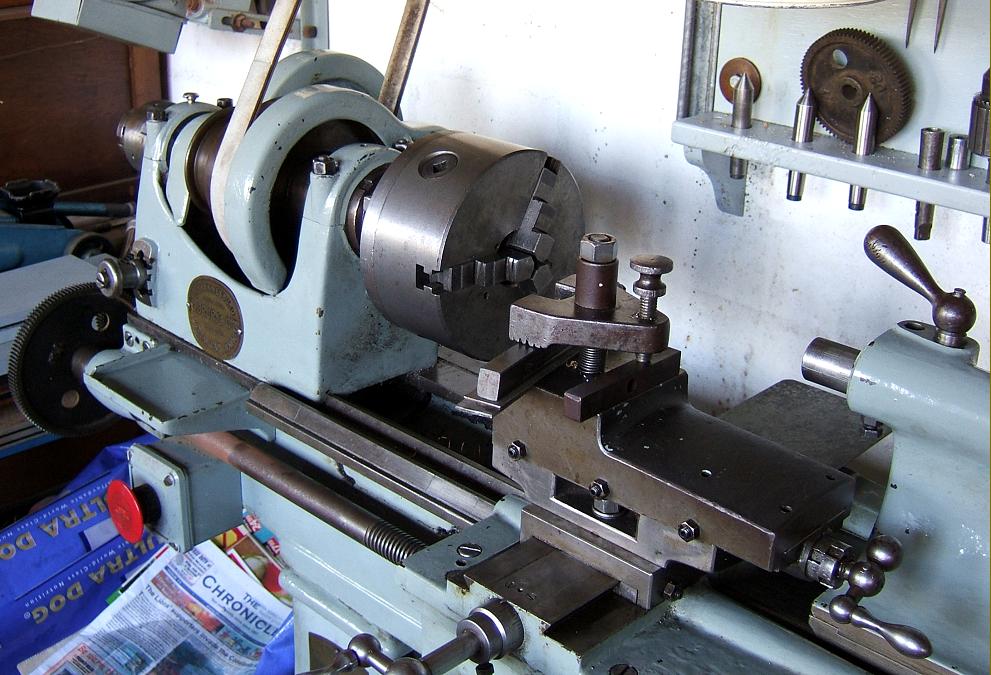

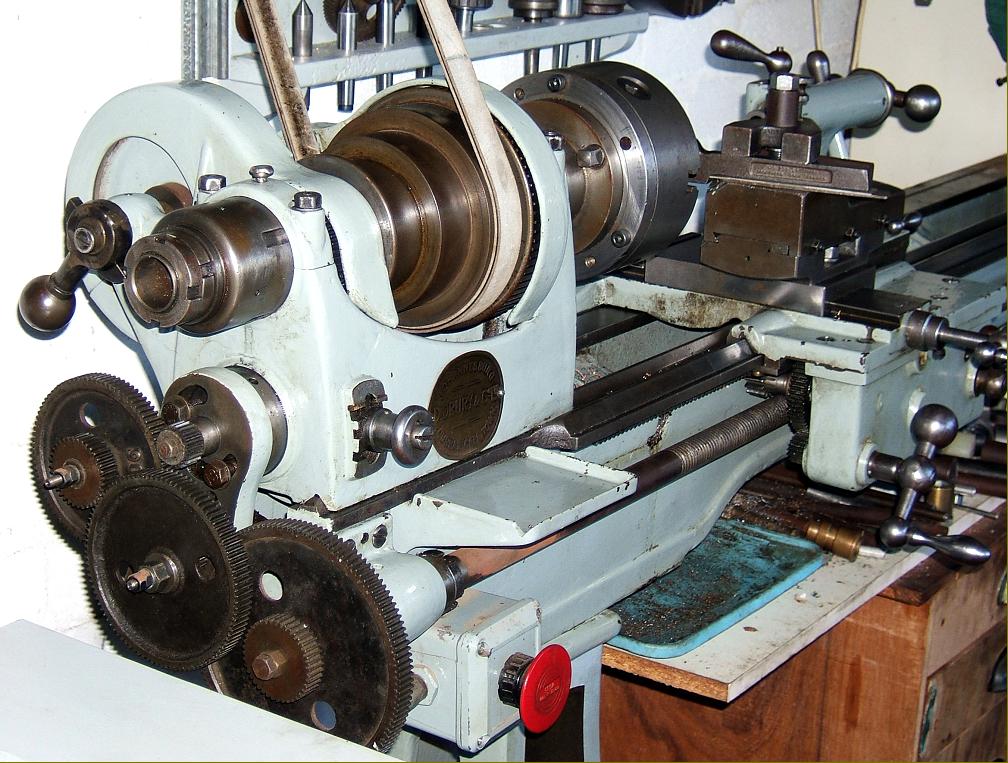

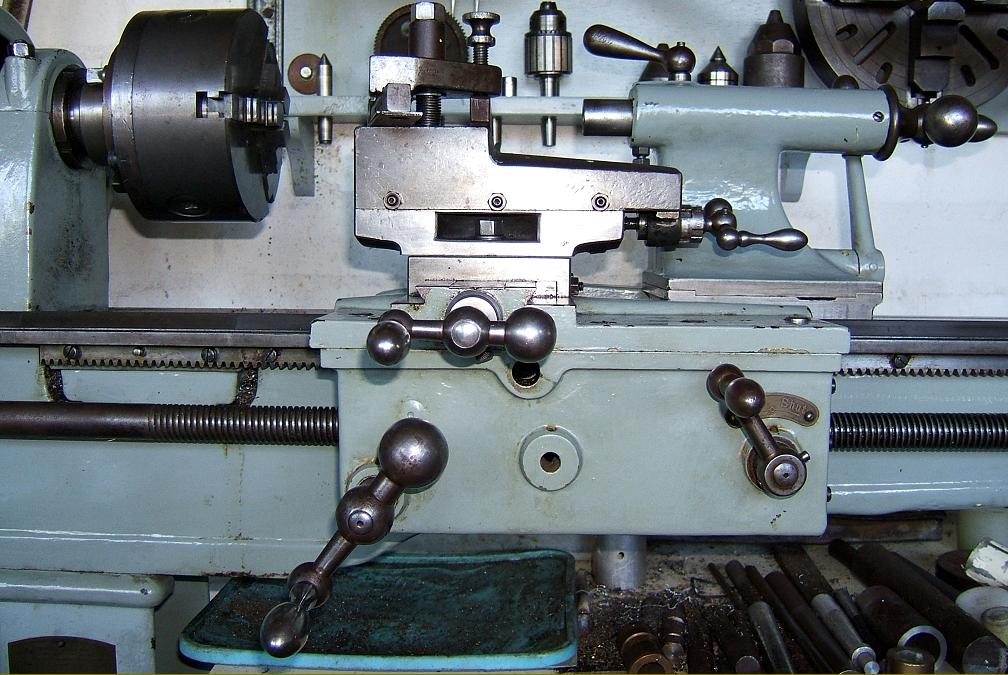

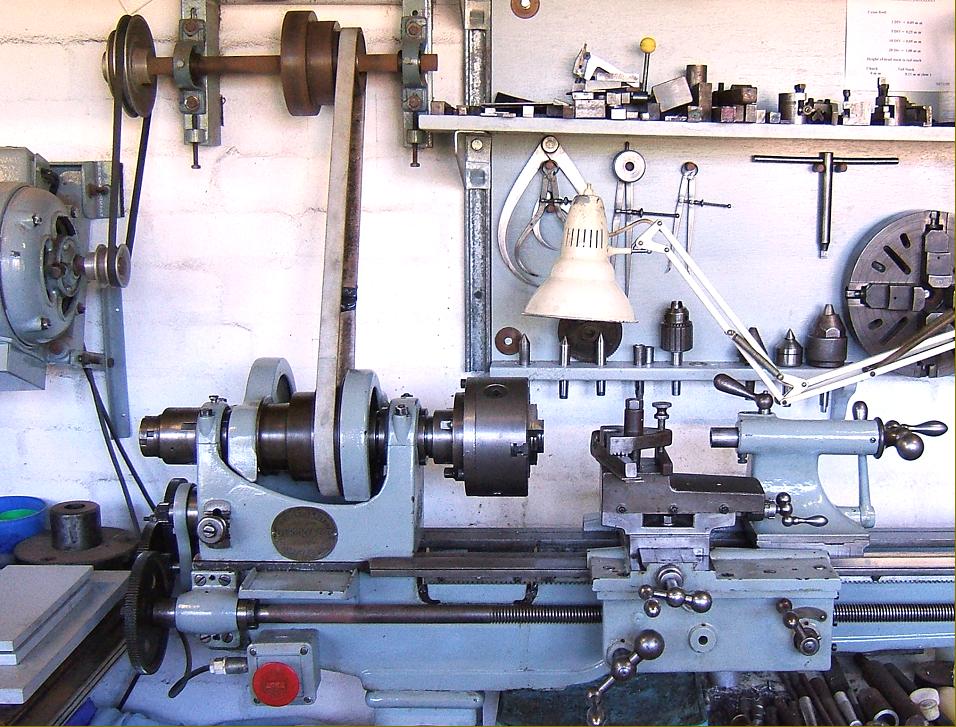

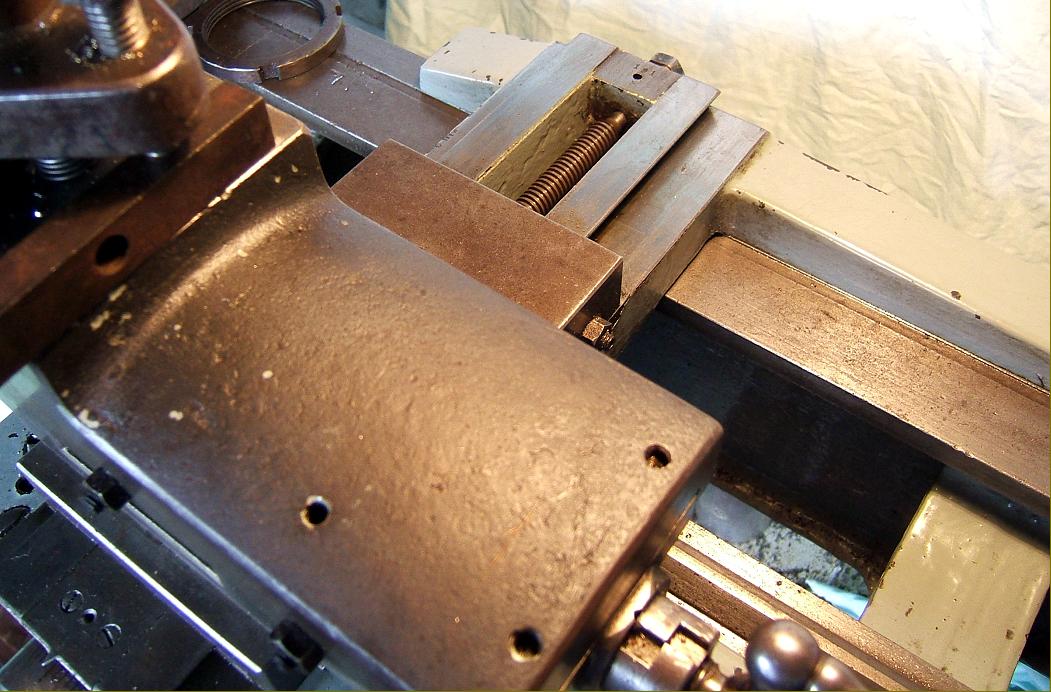

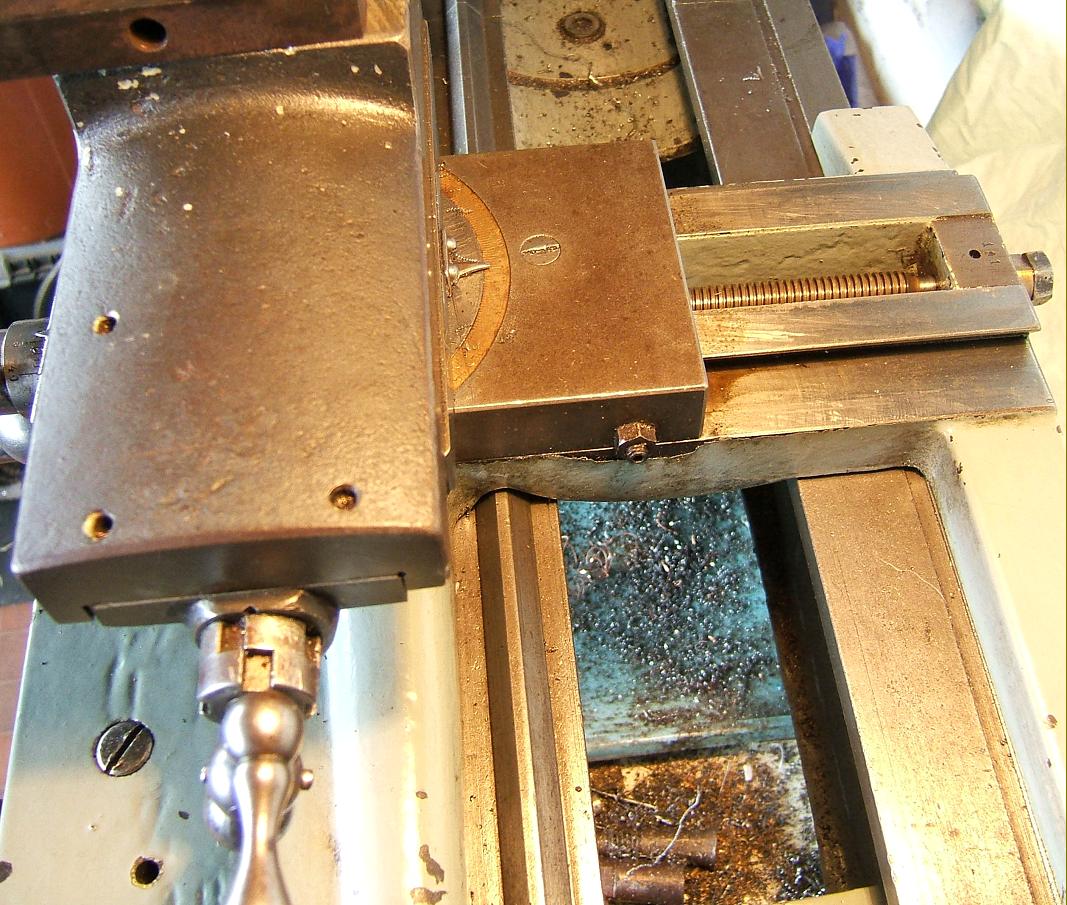

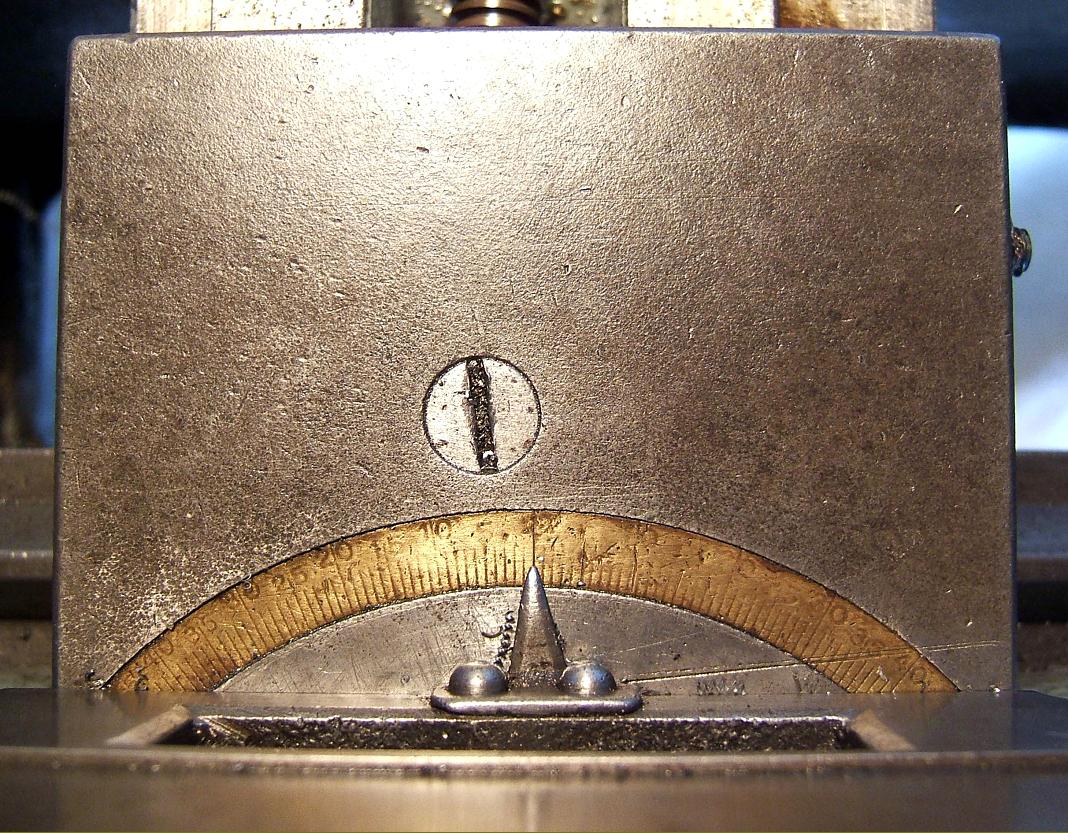

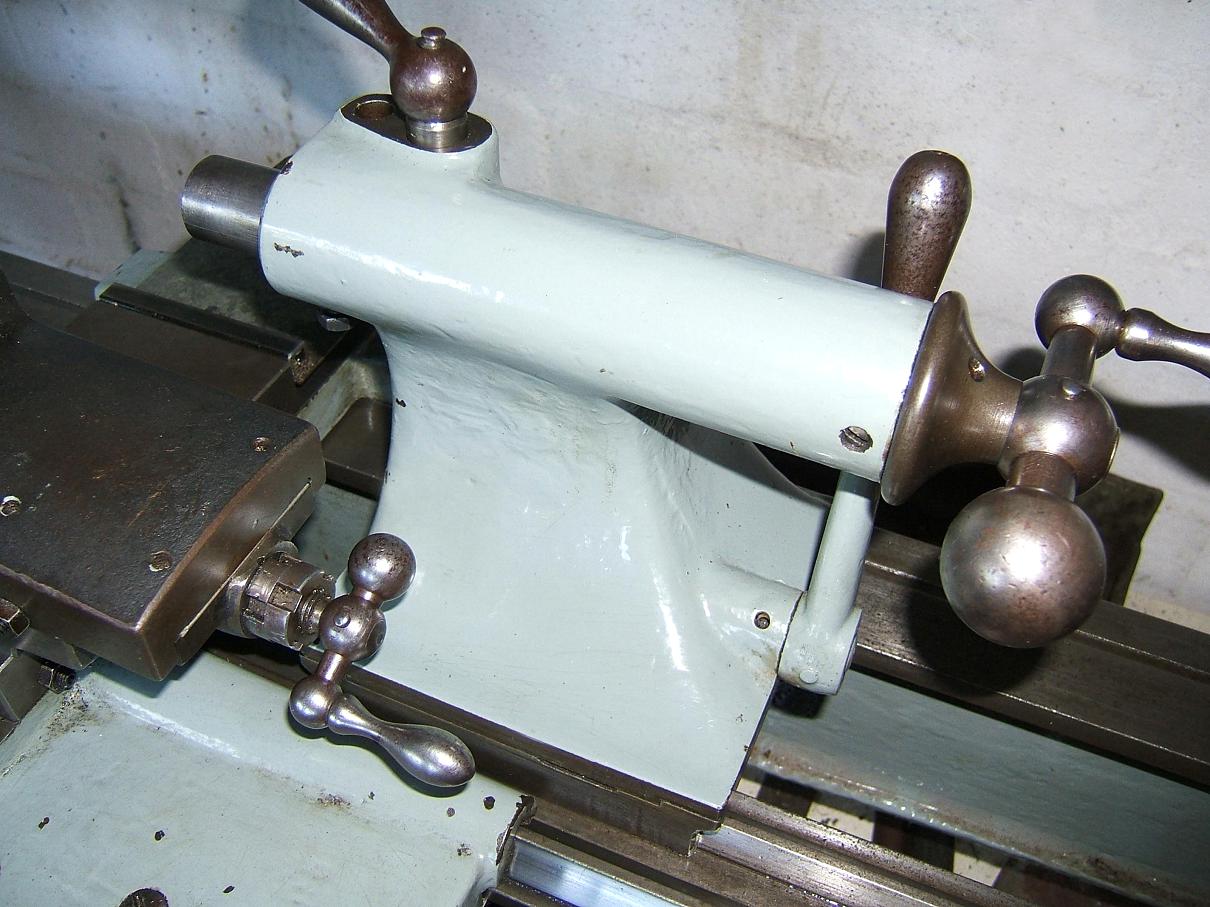

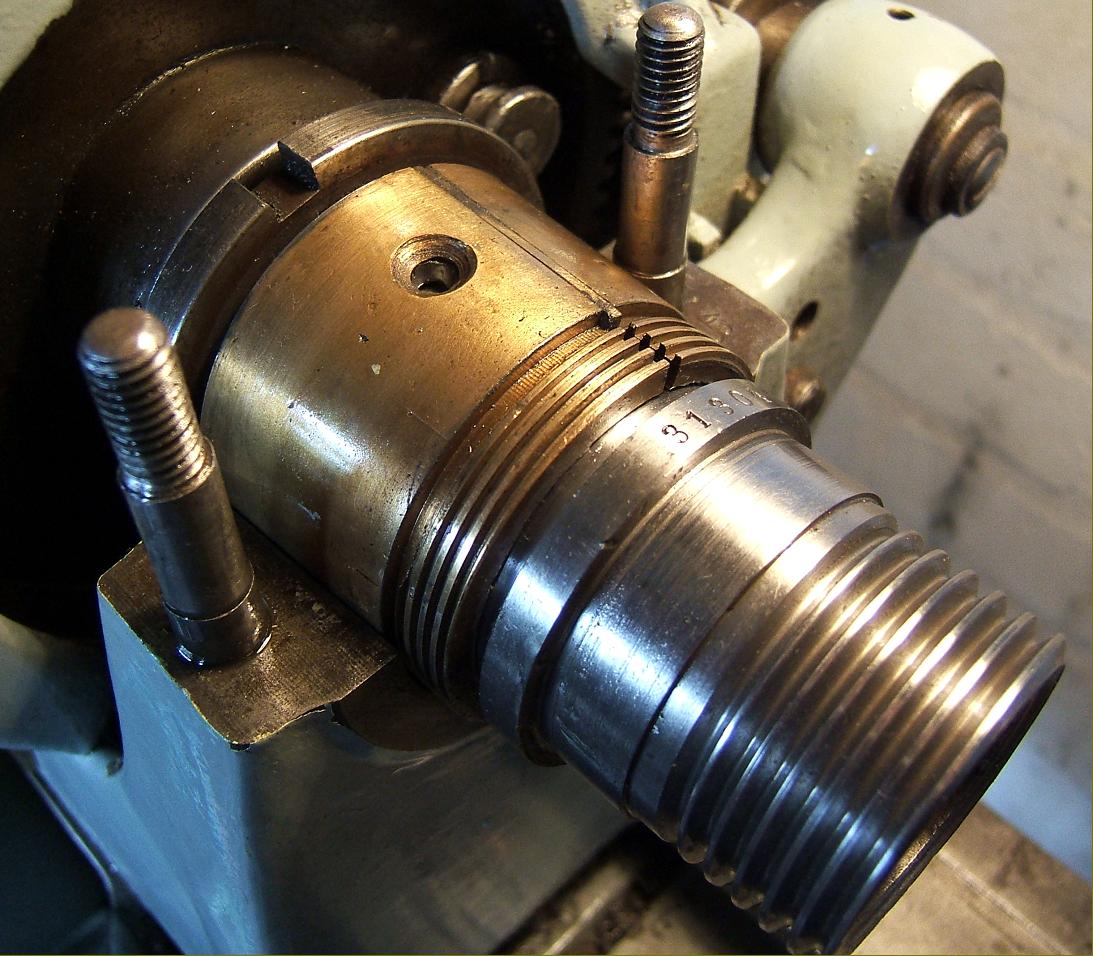

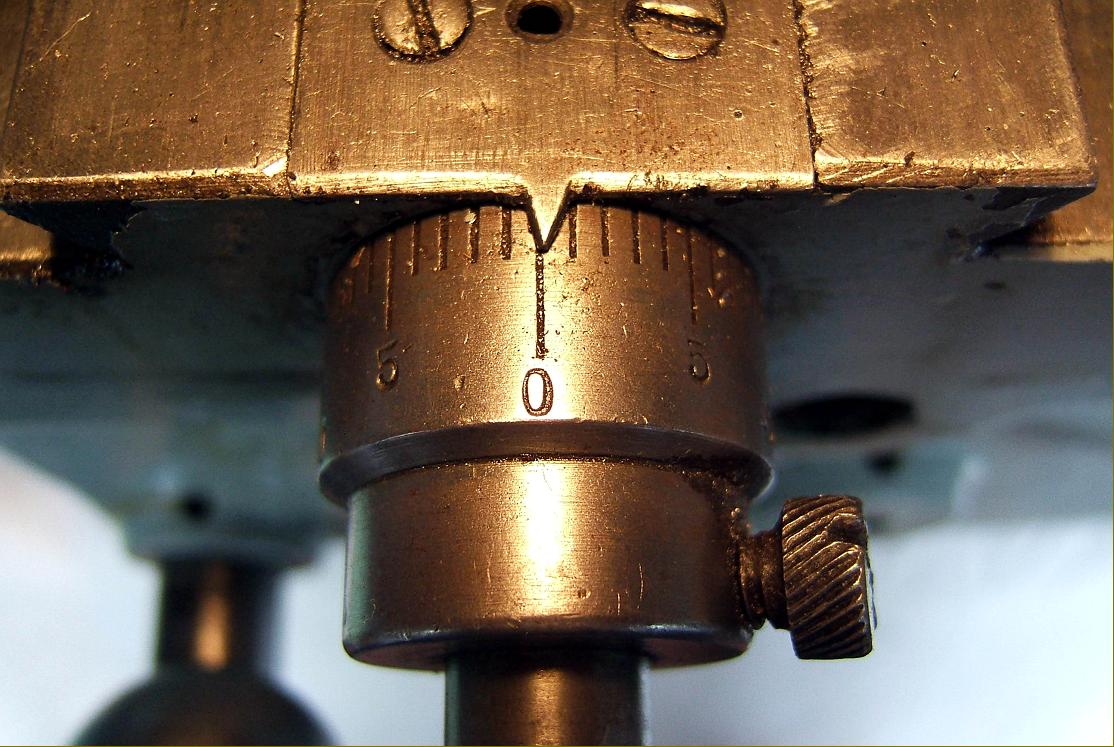

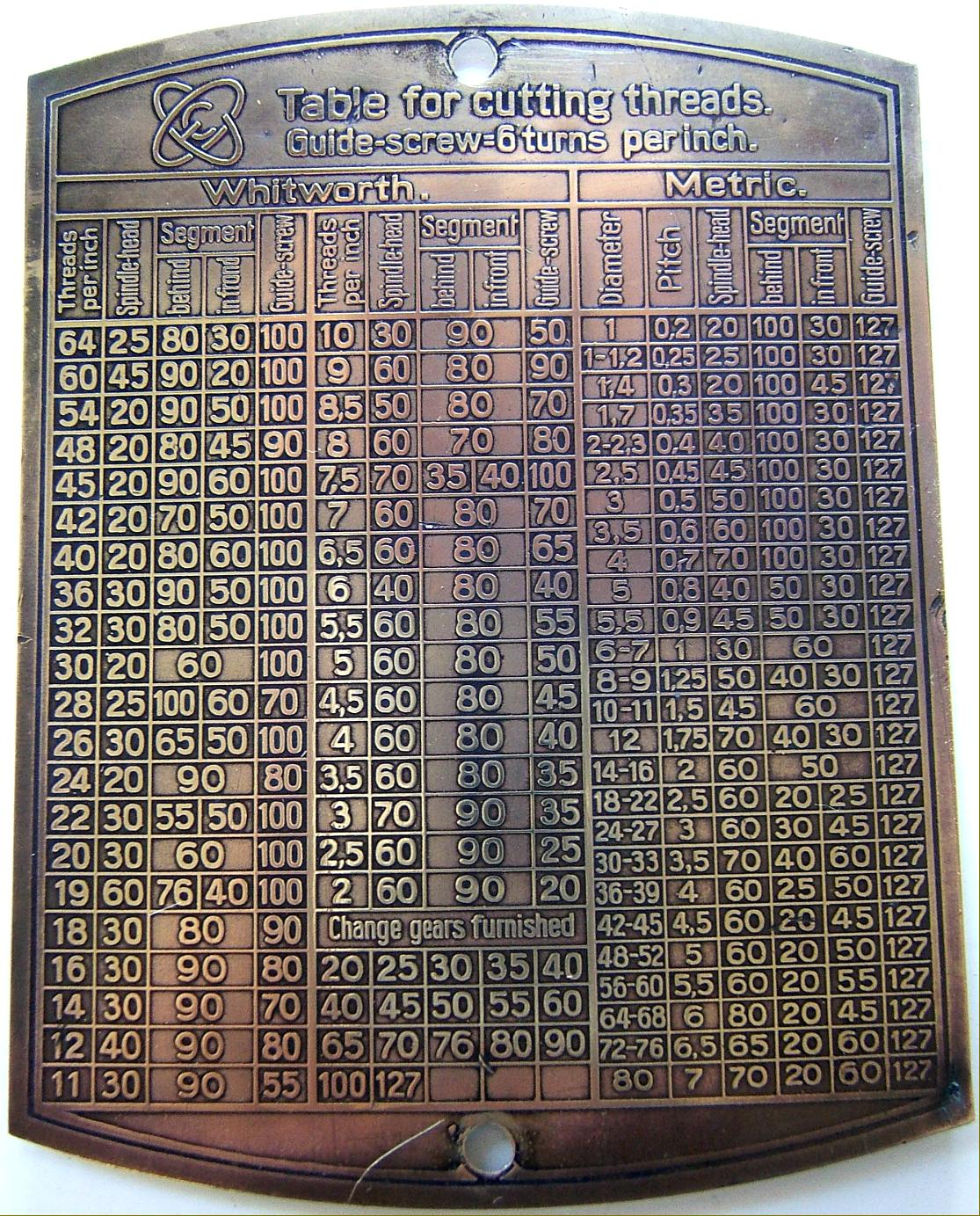

A mainstay of the range for many years was the 6-inch x 40" V-bed Model A.K.T., a machine sometimes found on a heavy treadle-powered stand but more usually with the optional "fast-and-loose" countershaft unit--the illustration of which below was taken from the "Graves" mail-order catalogue. Interestingly, this lathe was fitted with an apron mechanism to provide both power sliding and surfacing but, on the cheaper versions, only the power surfacing, operated from a push-pull knob on the face of the apron, was connected up. However, if the owners had realised it, they could have quickly rigged up a simple cam arrangement, operated by a rod passing through the already-drill second hole, and enjoyed a leadscrew-independent power sliding feed as well. The A.K.T. was also available in a "light" version, the Model "A". Although the two lathes appear to have been almost identical they were, in almost every respect, different with the Model A having, for example, a shorter headstock (11.125" against 13 inches), shorter but slightly larger diameter spindle bearings; smaller-diameter headstock pulleys, a smaller leadscrew (although at 1-inch it was only 1/8" less in diameter) and a tailstock shorter by 3/4-inch. However, one fitting on the "A" missing from the A.K.T. (and a useful recognition point) was T-slotted saddle wings (though of course, to confuse matters, this fitting is also occasionally found on other models). The writer has had several IXL lathes of various sizes pass through his hands and, though sold as a relatively inexpensive machine, all were made from good quality materials with an excellent finish. Detail touches included the leadscrew hanger bearings being properly doweled to the bed and castellated adjustment nuts used liberally wherever backlash had to be eliminated.

Today the most common IXL lathe seems to be the "Leader", a backgeared and screwcutting machine with a capacity of 5" x 24" that went through a steady evolution during its life. Many IXL lathes were available with a range of specifications including beds of various lengths with and without gaps, different stands and several kinds of countershaft - as well as the usual types of accessory. The smaller IXL lathes, of around 5" centre height, were also marketed by Tyzack using the Zyto name - and sometimes a confusion of names as well, with both Zyto and IXL names cast into different parts of individual machines. If you have an IXL of any vintage and would like to contribute to a photographic essay on the make, the writer would be pleased to hear from you.

Continued below:

|

|