|

Humpage, Thompson & Hardy described themselves as "High-class machine-tool makers" and listed, amongst their products, gear hobbers, mechanical hacksaws, hacksaw blade sharpeners, special machines for the grinding of lathe centres, the backgear and screwcutting bench lathe shown below together with a miniature type shown on this page. Although nothing is known of P.A. Thompson or C.C. Hardy, Thomas P. Humpage is buried in Arnos Vale Cemetery in Bristol with a tombstone celebrating a lifetime of mechanical achievements with over twenty patents to his name. One interesting patent traced to Humpage, No. 15,289, was granted in England on November 9th, 1887 ) and in the U.S.A. under No. 628,469 on July 11th, 1899) for Improvements in gearing for lathe headstocks, drilling machines and similar mechanisms. The drawings submitted show a lathe headstock with what might best be summed up as a form of epicyclic gearing neatly contained within a 3-step come pulley; however, as far as is known the design was never employed on any production model.

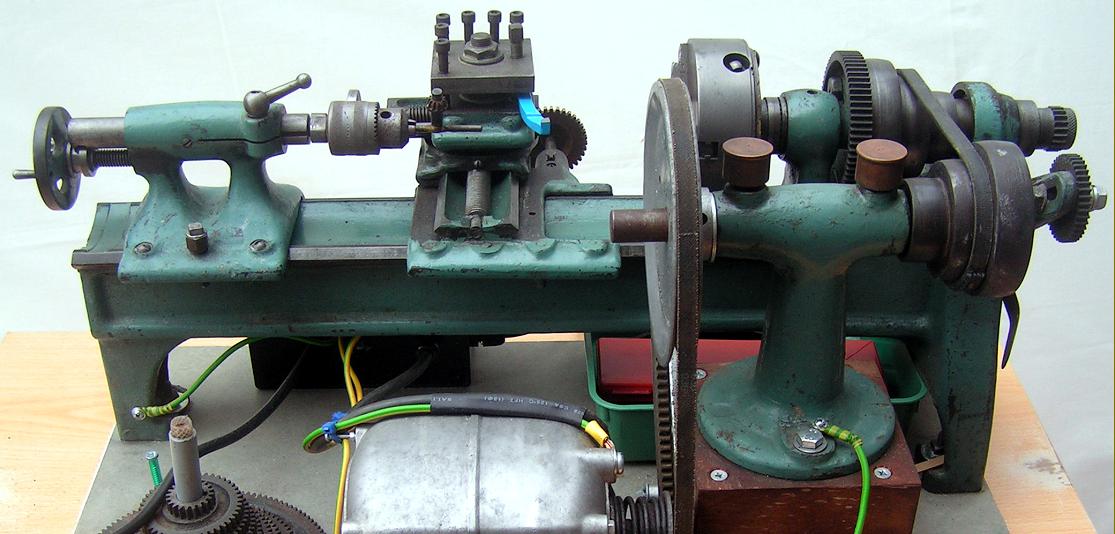

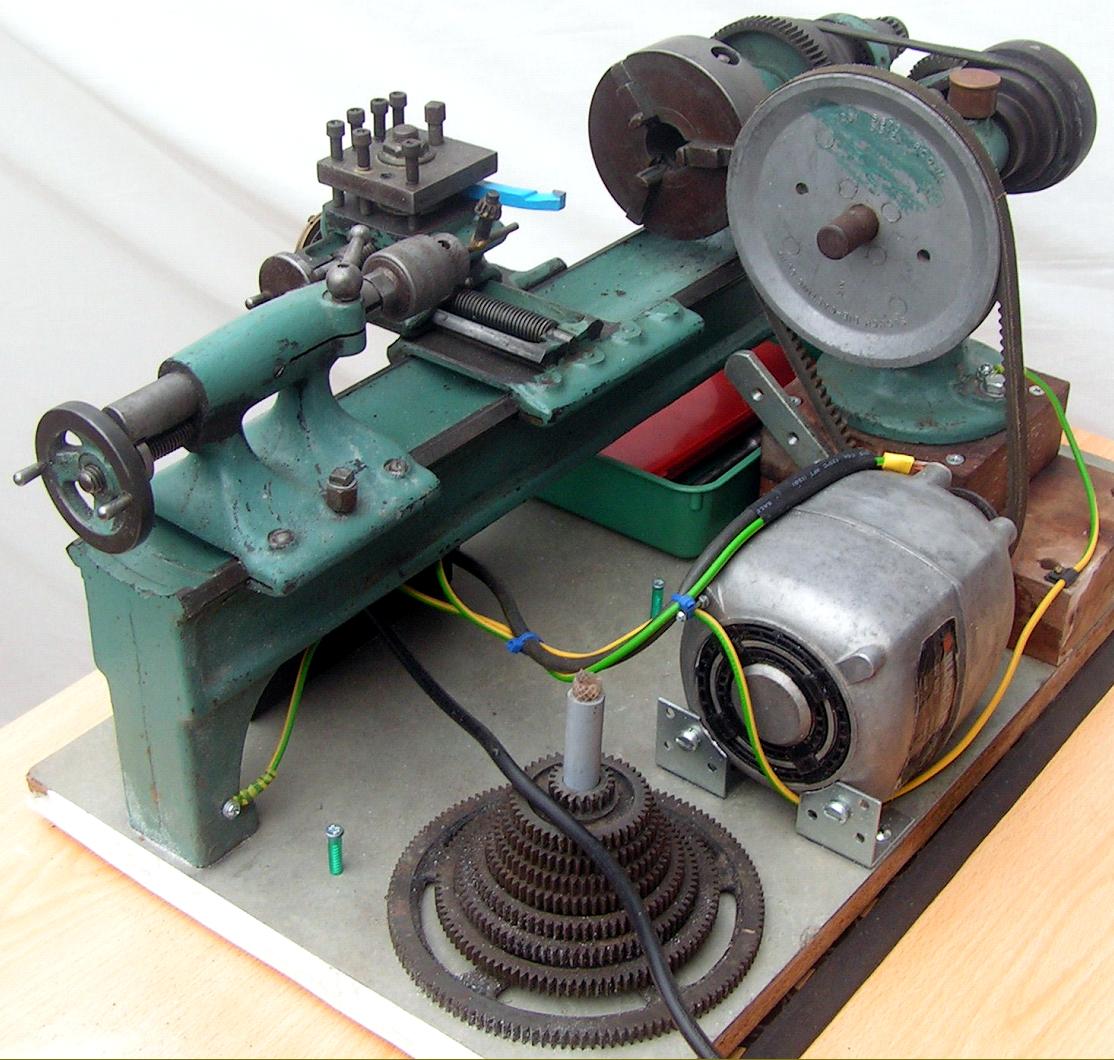

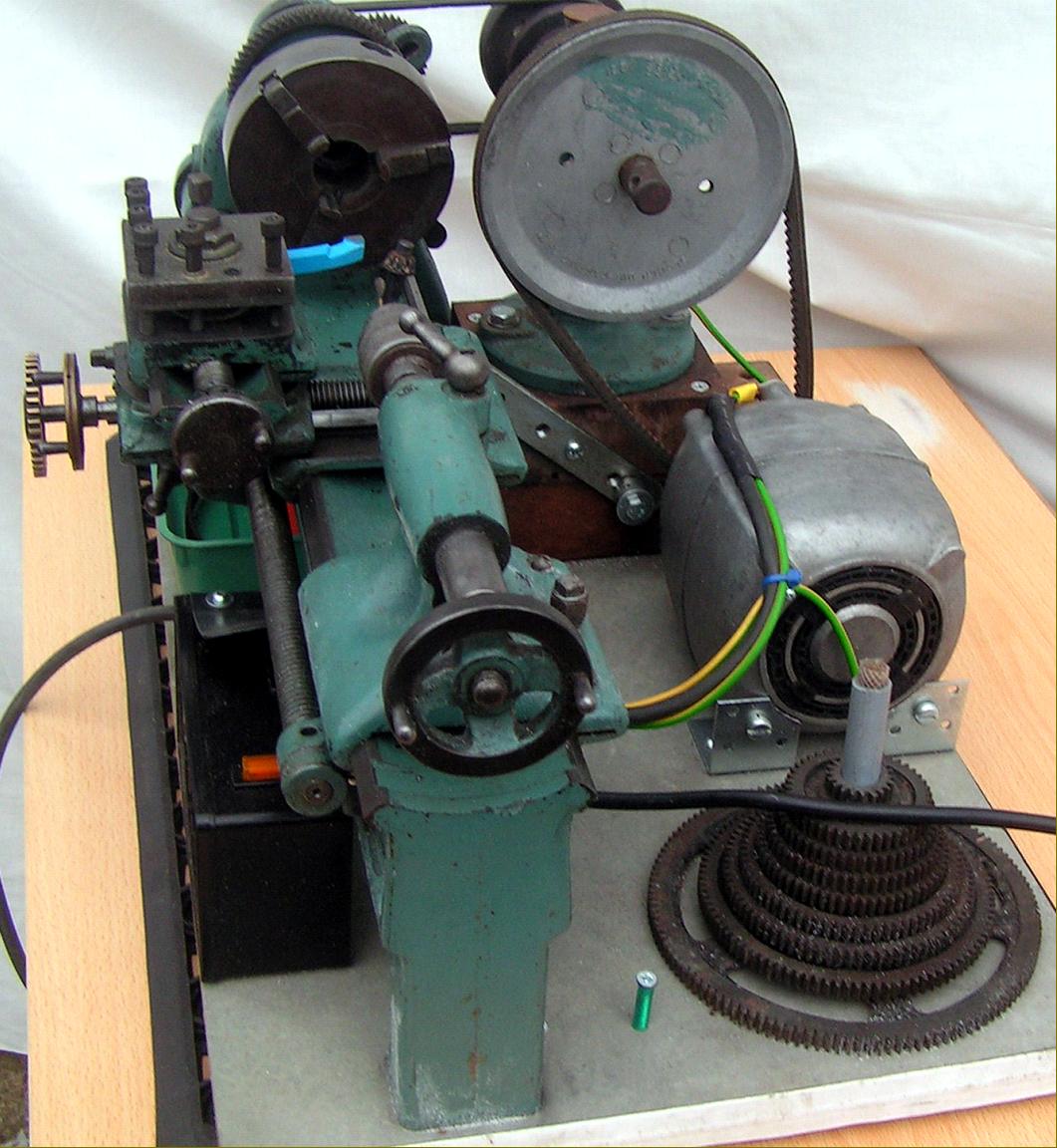

Of unusually high quality - certainly far superior to the offering from Portass and Zyto for example (and the equal of the fine machines by Faircut) - the middle-sized of the three known models of H.T.H. lathes was a small backgeared and screwcutting 2.75" x 12" machine that incorporated several most unusual and interesting features. The machine, protected by "Patent No. 4392 of 1922", must have been introduced just post the Great War (1914-18) when it was priced at £8 : 10s 0d. It appears to have been, from the numbers surviving, a relatively popular model and displayed a combination of ingenious design with attempts to keep construction costs to a minimum - two ideals which have always been difficult, if not impossible, to reconcile. The patent may have concerned (at least as fitted on some models) the unusual arrangement of the backgear mechanism, a full-length type mounted inside the lower part of the headstock casting with the engagement lever - a thin strip of steel - set between the end face of the headstock and the changewheel bracket. At the left-hand end of the headstock the casting was swollen to accommodate the larger of the backgears with the smaller positioned directly under the (unguarded) spindle bull-wheel. The headstock bearings, instead of being the simple, split-type frequently found on less expensive lathes, were (judging by the photographic evidence) obviously of superior construction, but details of their design are not known.

Of very unusual cross section, sketched below, the bed had a shape mirrored in the construction of the compound-slide, the V-ways being not on top, as usual, but set horizontally along the front and back faces. This unusual design can also being seen in the slide-rest of a beautifully constructed triangular-bed lathe, circa 1810-1815, preserved in the Bridwell Museum, Norwich. Attributed to Johnson Jex, a Norfolk blacksmith (though in reality he must have been a highly-skilled engineer) this lathe was used to turn clock parts. The Jex is mentioned (p.28) in Steeds' 'A History of Machine Tools 1700-1910', where, because the unusual ways were carried on a sub-bed, Steeds suggests they may be a later addition. How H.T.H. came to use the same design is, of course, a mystery.

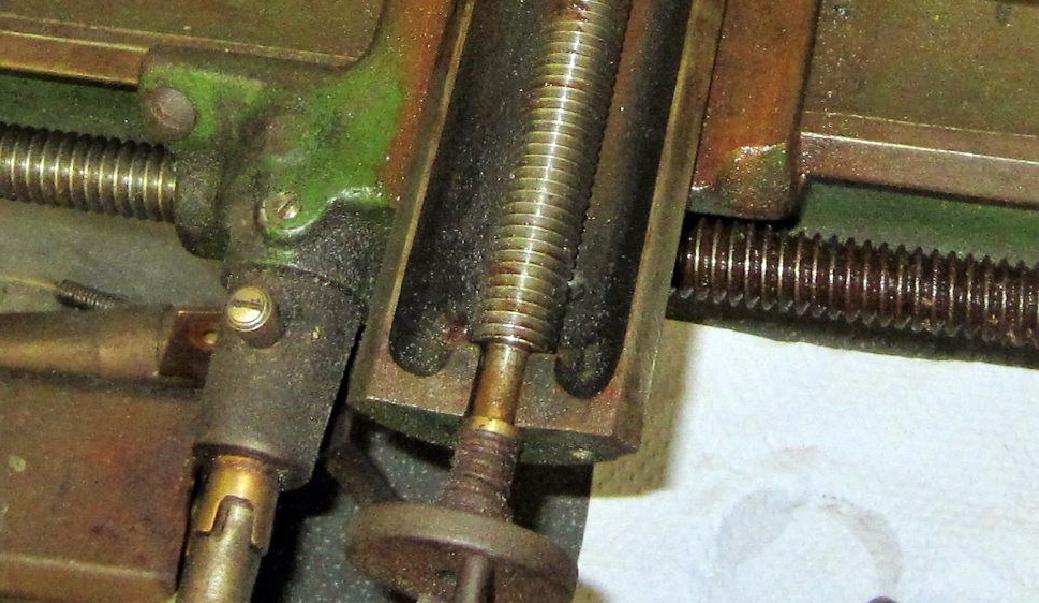

Cast as one piece, the saddle and apron of the H.T.H. were off-set to the left of the cross-slide centre line, with the carriage traverse driven by a gear that engaged directly against the leadscrew, exactly in the manner as employed, decades later, on the Myford ML10. For a small lathe the leadscrew was of unusually large diameter, with the clasp nut a double-split type engaged by lever on the apron incorporating a positive, snap-in-and-out action using a spring-and-ball indent.

Both top and cross-slide feed screws lacked micrometer dials and were threaded "right-handed" - an arrangement that caused the slides to move in a "cack-handed" way where turning the handwheel to the right caused the slide to retract rather than advance. Cack-handed screws are fine if the operator is confined to just that one machine - but legion are the spoilt jobs caused by him moving to another lathe in the workshop with its screws working conventionally. Instead of passing through a hole in the end face of their supporting castings, the cross and top slide screws dropped into slots with their thrust taken from each end of the screw by the inside faces of the casting. Not only was the retention system different, so was manner of connecting the screws to their slides and, instead of passing though bronze nuts in the usual way, each bore against the underside face of their respective castings into which a half-depth thread had been machined (a somewhat similar system was used on some of the high-class miniature milling machines made by Mikron in Switzerland). The top-slide was cast with a large boss on top machined to accept what must have been a standard-fitment round tool post, not unlike that used on the modern Hobbymat MD65 lathe.

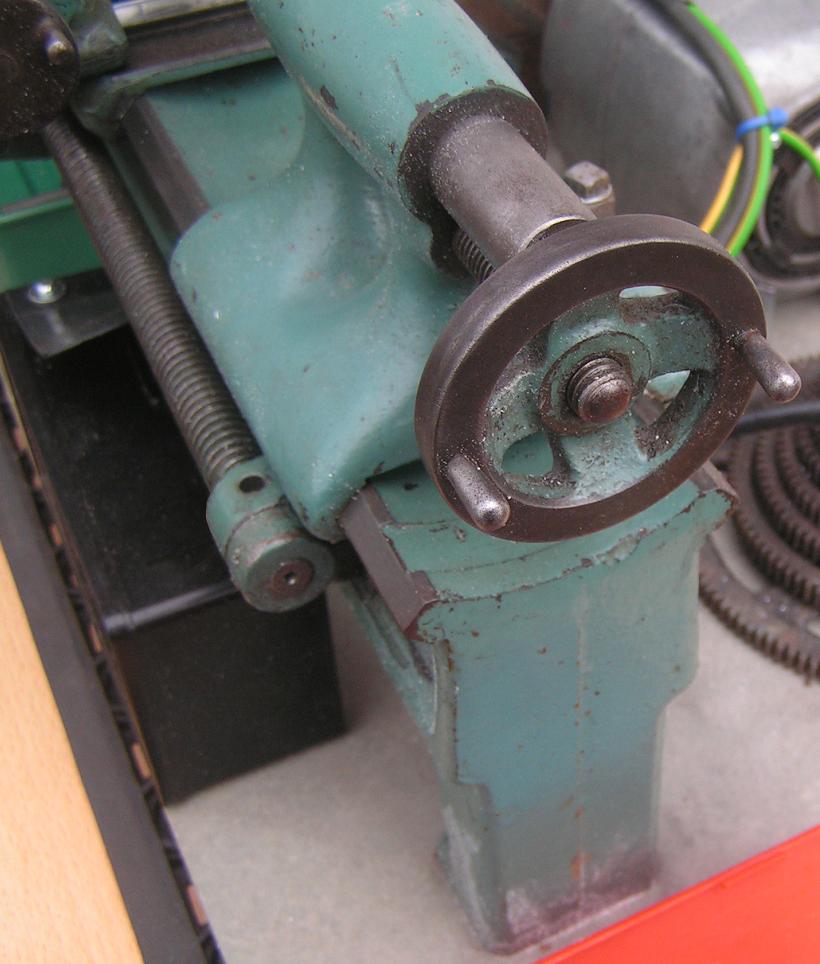

Another example of simple but effective engineering, the tailstock had its No. 1 Morse-taper barrel slotted on the underside to engage with a handwheel that ran up and down a screwed bar threaded into the casting beneath it. A small hole was drilled through the barrel so that the centre could be knocked out.

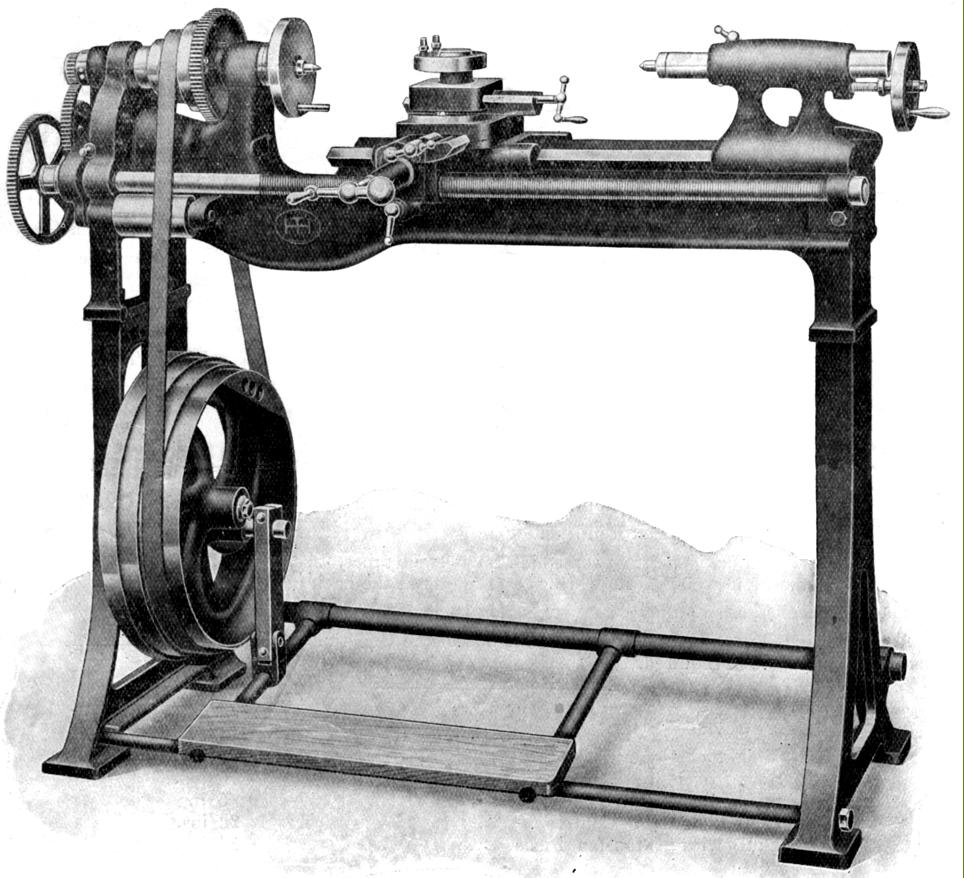

Available for either bench mounting - with a simpler, round-base countershaft that had the drive and driven pulleys arranged to overhang on opposite sides - or fitted to a steel-framed stand with one drawer and treadle drive, the HTH was supplied during the 1920s complete with a compound slide rest (with its circular toolpost) and a set of changewheels included in the basic price of £16. For an extra £4 : 15s : 0d it could be mounted on a rather wonderful oak stand of the type illustrated below - complete with a most unusual rigid 'dust cover' and storage for the changewheel provided on the inner right hand face of the tailstock-end plinth.

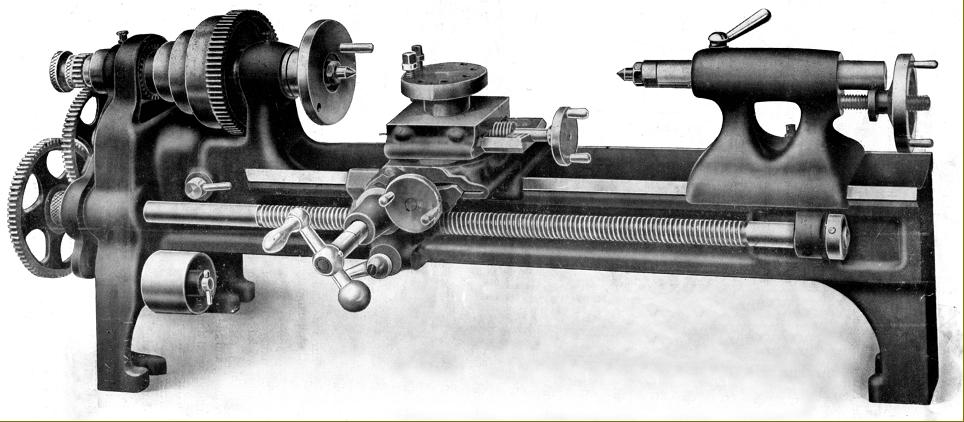

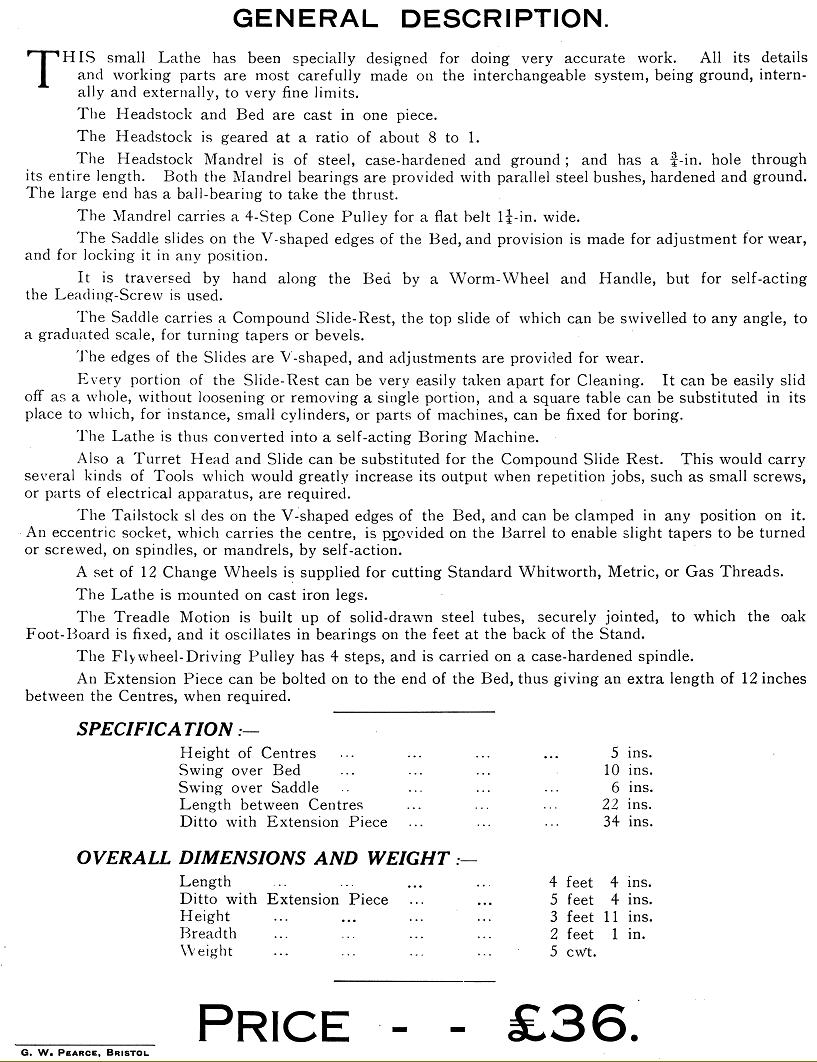

H.T.H. also offered a 2.5-inch centre height lathe that could be had either as a plain-turning machine or fitted with backgear and screwcutting. Both were of simpler construction than the 2.75" H.T.H. and incorporated several cost-saving features. The largest machine in the range, of which no surviving examples are known, was a treadle-operated 5" x 22" backgeared, screwcutting and gap-bed model aimed at garages and small engineering works. It appears to have been a scaled-up version of the 2.75" model with identical bed and slideway construction, the same arrangement of "hidden" backgear and an identical design of tailstock.

If you have an H.T.H. lathe (several were known to have survived into the early 2000s and occasionally turn up on eBay as "unknown") or other machine tools, or any literature about them, please do contact the writer. H.T.H. Lathes continued here and here

|

|