|

Högbo machine tools were manufactured by a Swedish company, Högboholms Mek. Verkstad 340 37 Torpsbruk. Although their smallest lathe was a copy of the pre-WW2 Atlas 6-inch, their little bench-mounted vertical miller was an indigenous design and displayed in its construction all the quality you would expect from a machine tool manufactured based in Sweden - and of course, at a price to match.

Surrounded by a coolant channel, the 400 x 110 mm (15.7" x 4.3") table had movements of: longitudinally 225 mm (8.6"); in traverse 75 mm (3") and vertically 140 mm (5.5"); the maximum clearance between the nose of the No. 2 Morse taper swivelling vertical head and the table was 180 mm (7"). Instead of having a separate bolt-on end plate to support its feed screw, the table had an extended casting at its left-hand end to do the same job. Although the knee casting could not be modified in the same way, a large bolt-on bracket was provided instead with both zeroing micrometer dials being generously large in diameter and clearly engraved.

Accessed by a large, hinged cover at the rear, the drive system was completely enclosed within the body of the machine and consisted of a 1400 rpm, 0.5 hp 3-phase motor driving, via two-step V pulley, to a 3-speed V-belt countershaft. The latter was well constructed and employed SKF ball bearings contained within an eccentric mounting - an arrangement that provided a quick and easy means to tension and release the belt to change speeds. The spindle ran in precision class, taper-roller bearings and was fitted with either a No. 2 Morse taper nose, or adapted to hold 3C collets with a maximum through-capacity of 12 mm (though collets listed as Type "WW 16.5" have also been reported as fitted).

One interesting extra offered by the makers was a horizontal cutter-holding arbour support that replaced the vertical head and turned the miller into a horizontal miller. Also available was a robust stand made from heavy steel plate - though oddly, rather like the one made for the similar-sized English Centec 2A milling machine, it had a rather narrow base and looked rather unstable - this is a stand that it would be wise to bolt down.

For a small machine, the main column was especially robust and sat on a hollow base casting that doubled as sump for the built-in coolant pump, the drive coming from a separate V-pulley on the motor spindle.

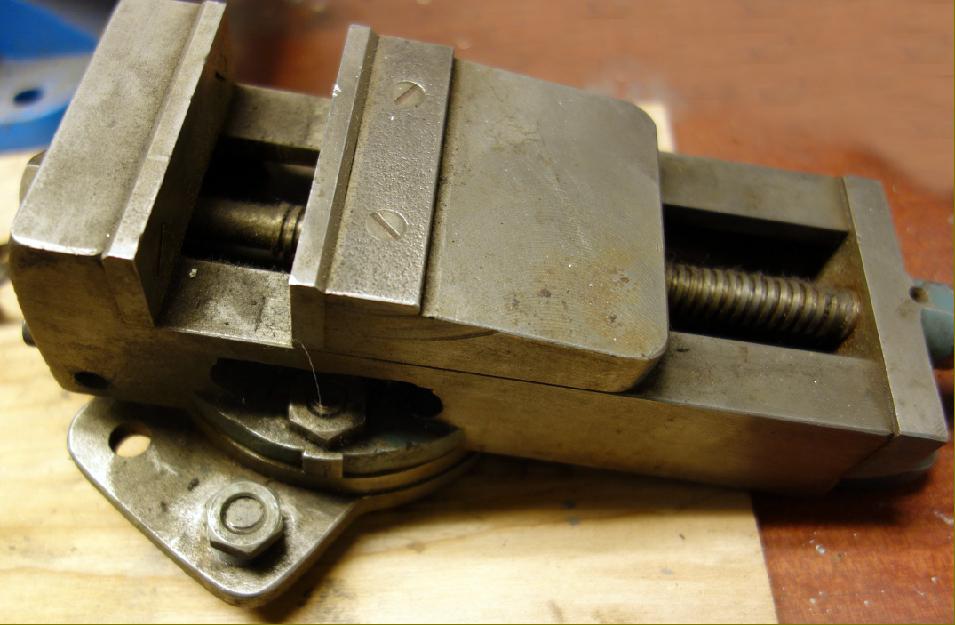

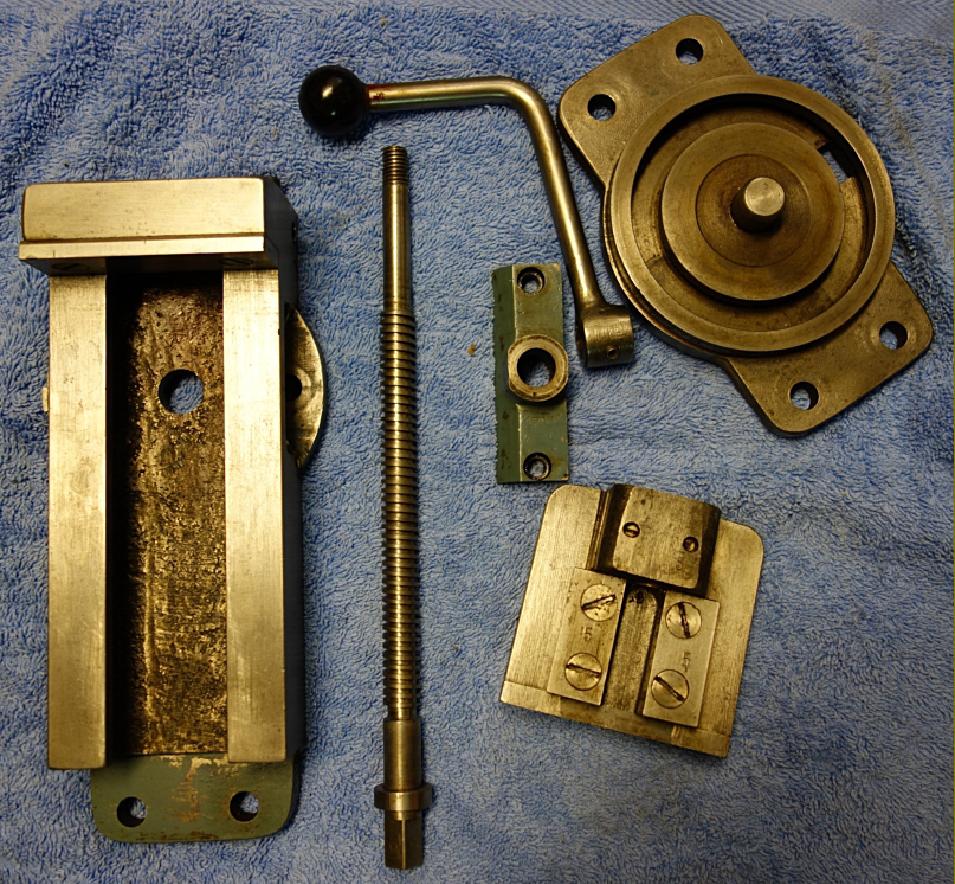

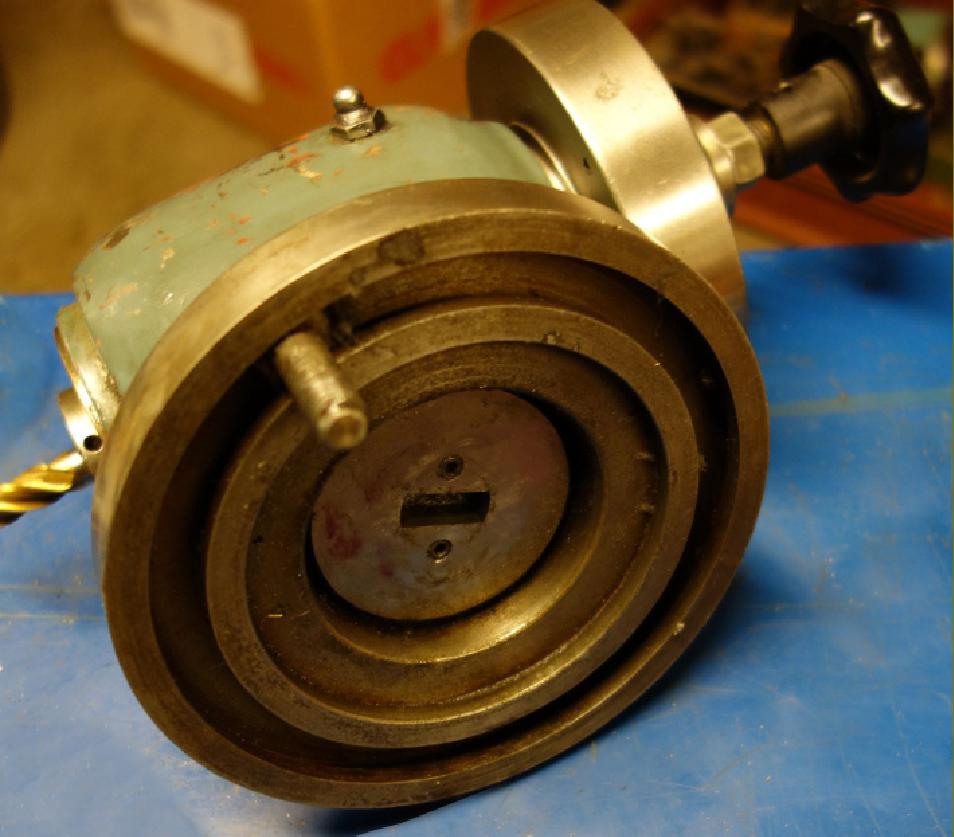

For all its quality of construction and heavy build (it weighted a not-inconsiderable 150 kg - approximately 331 lbs) the machines 'bête noire' was the lack of a quill feed on the vertical head; without this essential facility many small, awkward and complicated jobs would have proved difficult to accomplish - and required the used of time-consuming set-ups involving angle plates, brackets and a swivelling, tilting machine vice. As a safety precaution, the drive to the vertical head was by nylon collet, fitted with a rectangular drive tang end held in the horizontal spindle. Unfortunately, as the whole collet was in nylon, the stresses to which it was subjected caused wear and tear - however, a simple solution would be to make a steel collet with a suitable nylon, or similar, sacrificial tip..

|

|