|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

lathes.co.uk

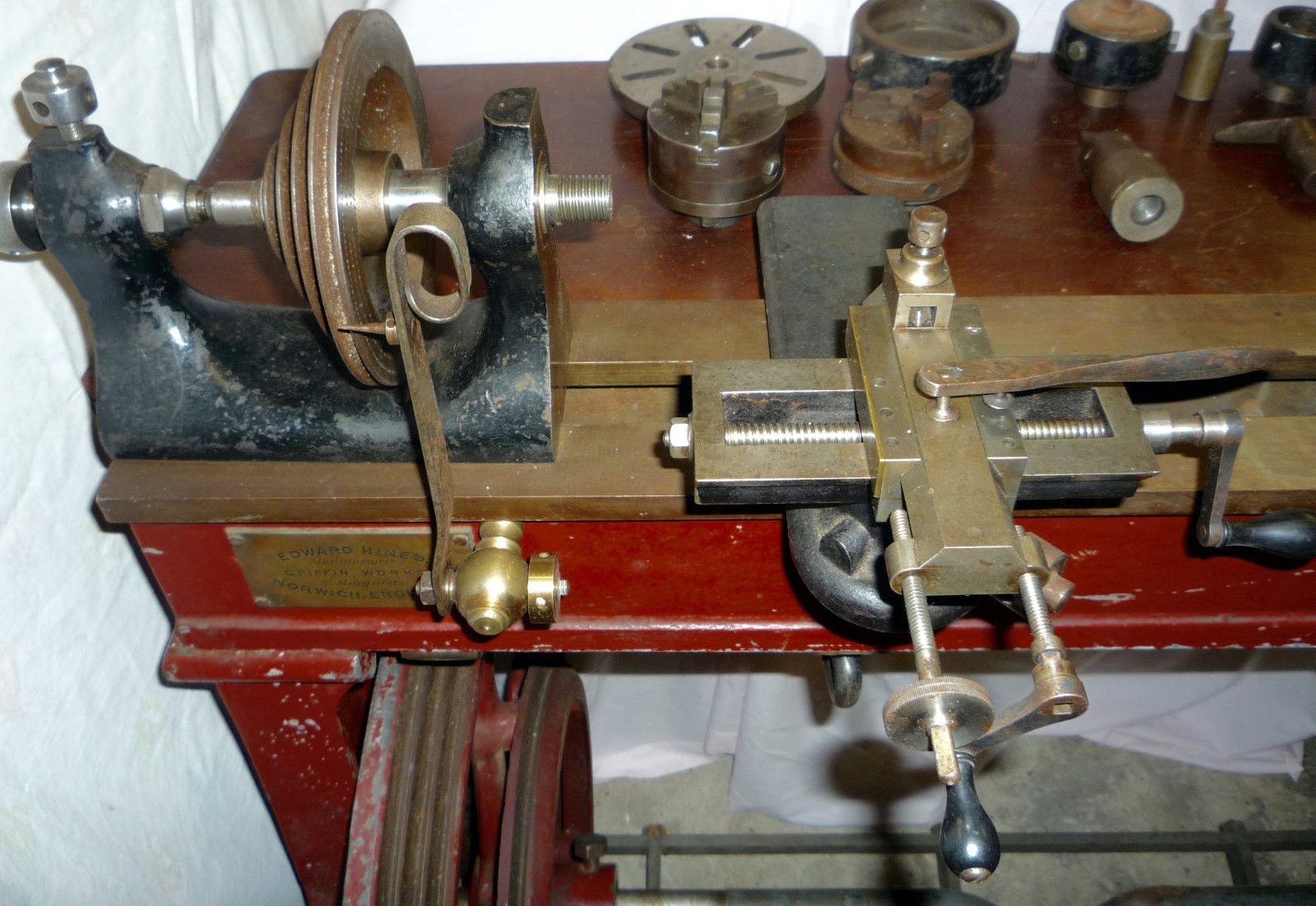

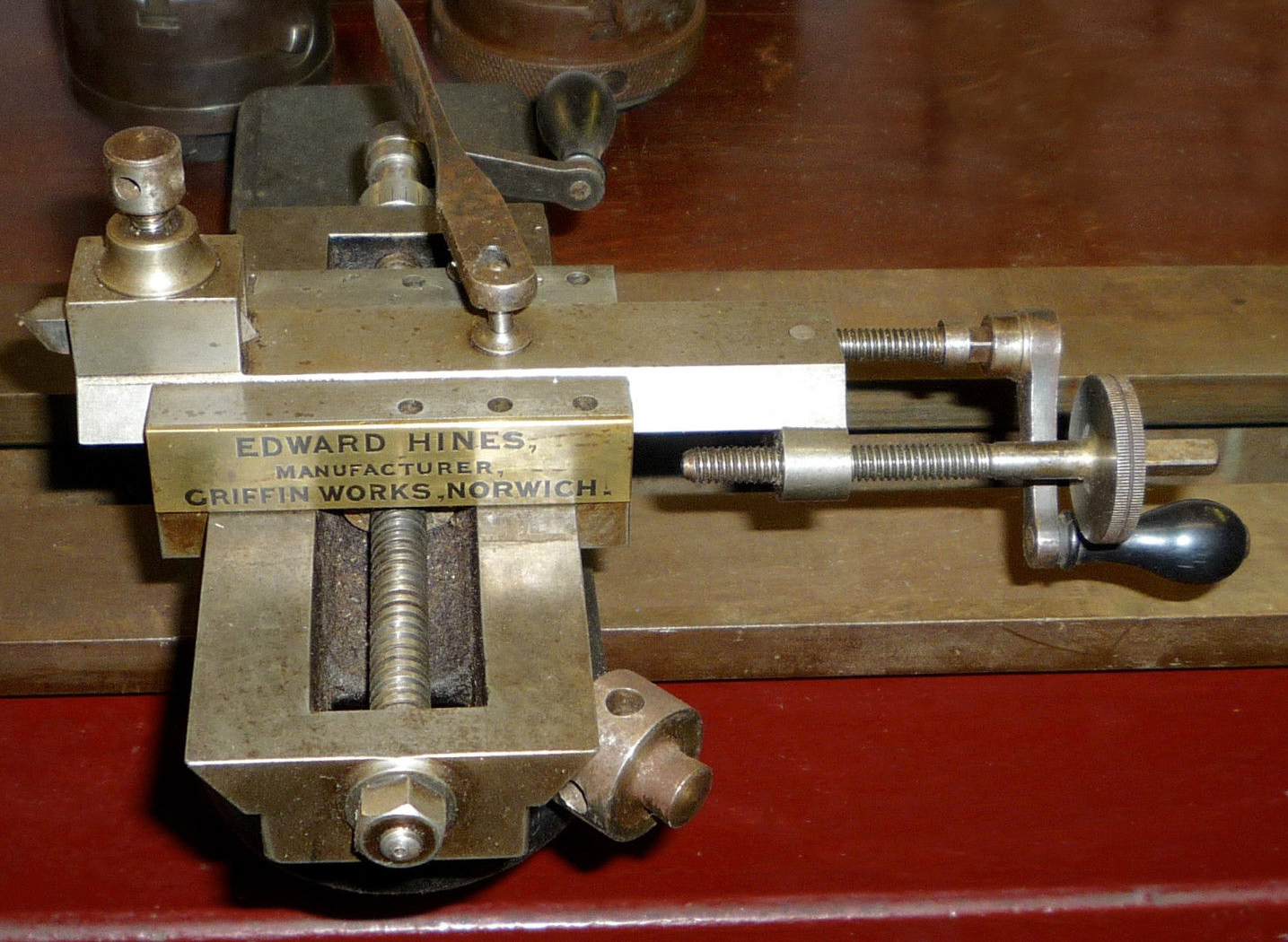

Edward Hines Lathes

Griffin Works, St. Margaret's, Norwich, England

Hines Lathes Page 2 Hines Lathes Page 3

Founded in 1820, Edward Hines engaged in a variety of engineering enterprises but became best known for their range of ordinary and ornamental-turning lathes. Models made included simple, plain-turning and screwcutting types of the lighter variety to complex and very expensive ornamental-turning models. All were well-made with close attention to detail, a fine cosmetic finish and several interesting mannerisms. These included a liking for hardened steel wherever possible and "awkward" construction details with, for example, the use of long narrow keys even on slow tapered fits and, in the case of the tailstock barrel, a very long thin key that was closely fitted to a long key press-fitted well inside the barrel. Unfortunately, the same lunatic, over-the-top method was also employed, on some, to fit the tailstock handwheel to the barrel - the latter of course being hardened and lapped to the bore. Mr. Hines took no prisoners and his workers must have had a "difficult" time….

Happily, a good number of lathes by Hines have survived in remarkable fine working order with, today, prices varying from very little for a simple model in poor order--to many thousands of pounds for an ornamental-turning type in perfect, original condition complete with a wide range of the essential accessories.

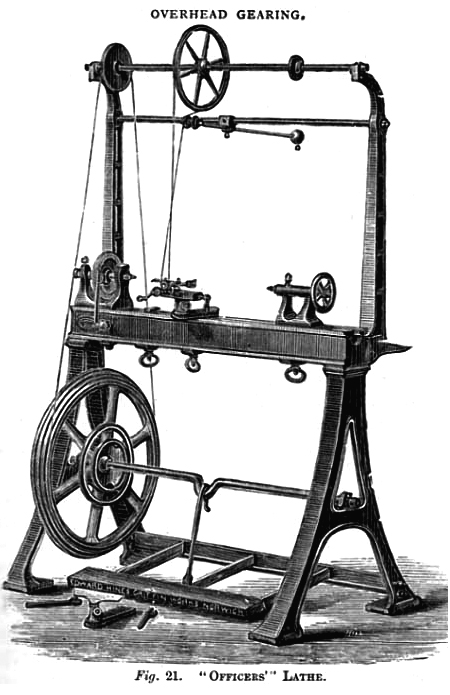

While Hines made a variety of lathe types, a sense of how the maker approached his business might be gauged from the details of the oddly-named "Officers'" model this being a plain-turning type without a speed-reducing backgear or screwcutting. It was described by Mr Edward Hines himself as: "Unquestionably the lathe for amateurs, and after long practical experience in suiting the requirements of gentlemen who make ornamental turning their chief indoor recreation. I advise in preference to any other where ornamental work in ivory and hard wood, or light metal turning is done, and it may be fitted with an E or F pattern Slide Rest for the heavier metal turning where necessary." In addition, a most important point was made: "When required for use in India, etc., a crank handle may be attached to the crankshaft outside the standards [legs] by which a coolie can easily drive the lathe sitting on the ground. This plan answers most admirably in hot climates" - by which means we can see how much the world has changed (possibly for the better) since 1900.

With a 4.5-inch centre height, the lathe could be also ordered with a one-half increase to 5 inches and a choice of bed lengths from 42 inches to right up to 72 inches. Beds were described by the makers as "planed and surfaced" - the former obvious (and probably "ganged up" on a large planer with several bed castings machined simultaneously) and the latter almost certainly meaning hand scraped.

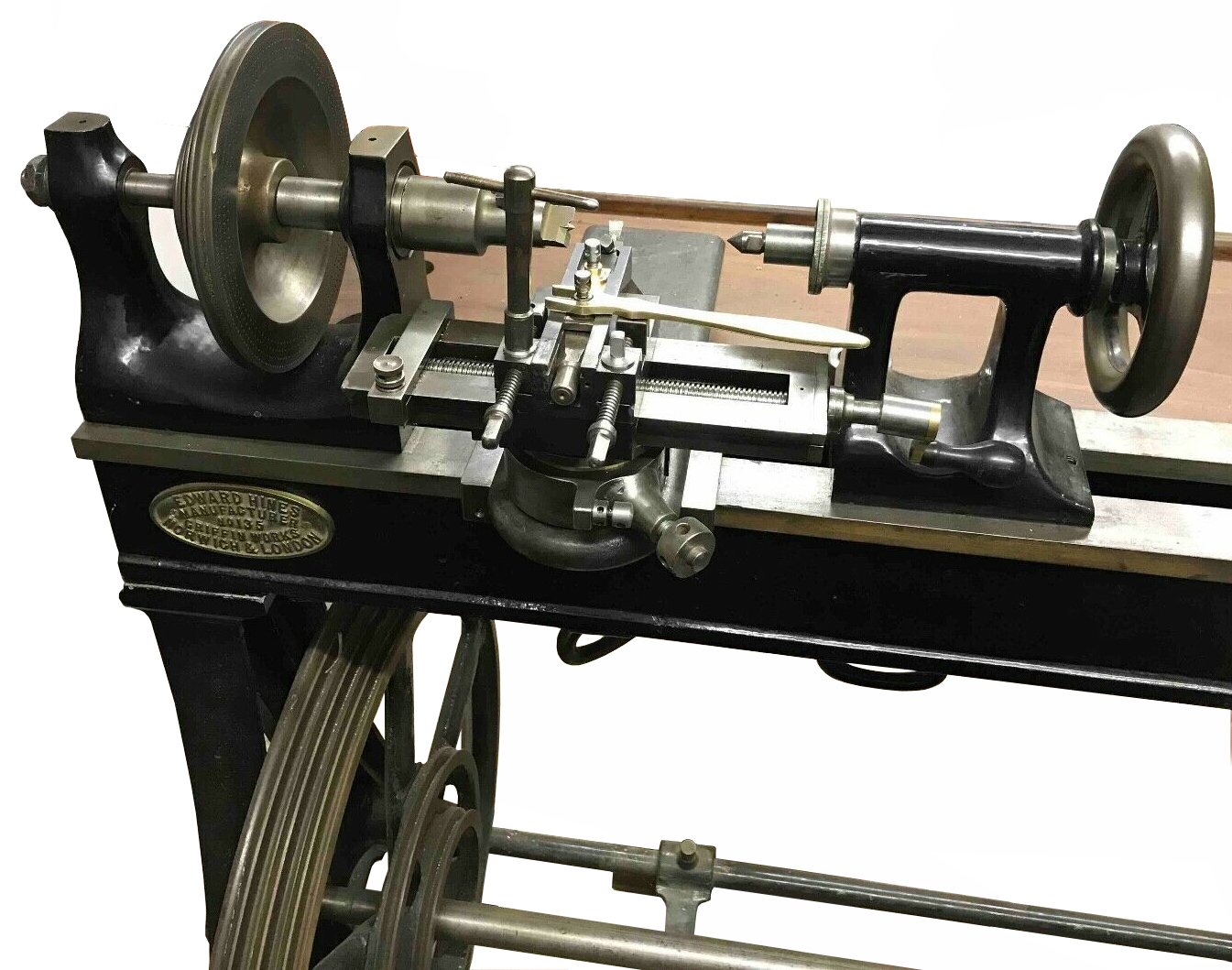

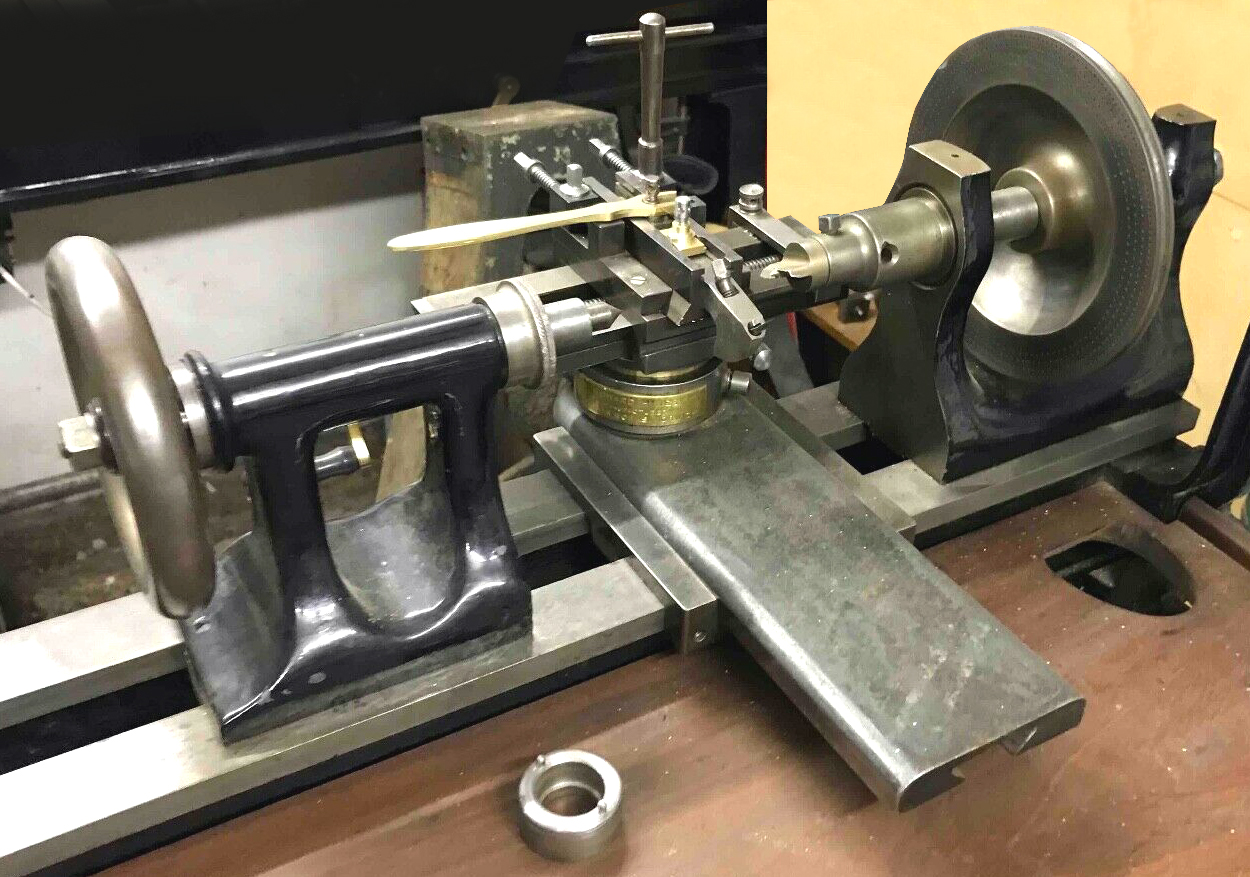

More than one version of the lathe was made, with some having a simple spindle with just a front bearing with the rear supported against a hardened and adjustable point. On others the headstock was far more complicated with an all-hard spindle that used a double-angle front bearing and a parallel long bearing to the rear - both bearings being in bronze. The entire headstock spindle assembly on these versions is impossible to dismantle without great care; the 3.5 kg pulley has a slight taper fit to the spindle of about 0.003" over its length and requires both warming up and a press to move it.

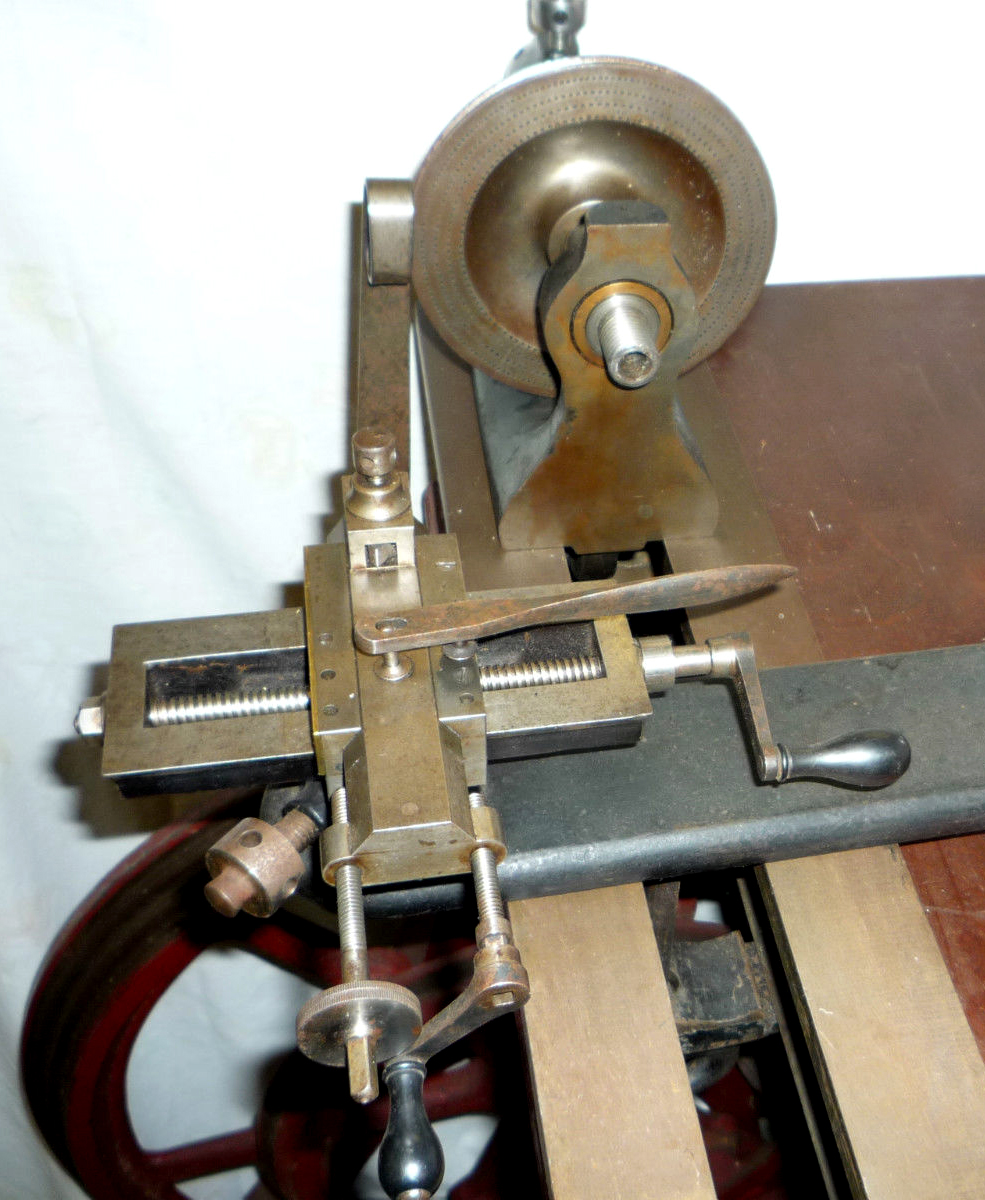

A 4-step pulley for drive by a round-leather "gut" drive was fitted - power coming from a foot-treaded flywheel fitted with four grooves for slow speeds and two, set nearer the centre, for high. To keep the belt aligned, the headstock could be slid along the bed - though it was often possible, with this arrangement, for a small amount of out-of-truth run to be tolerated.

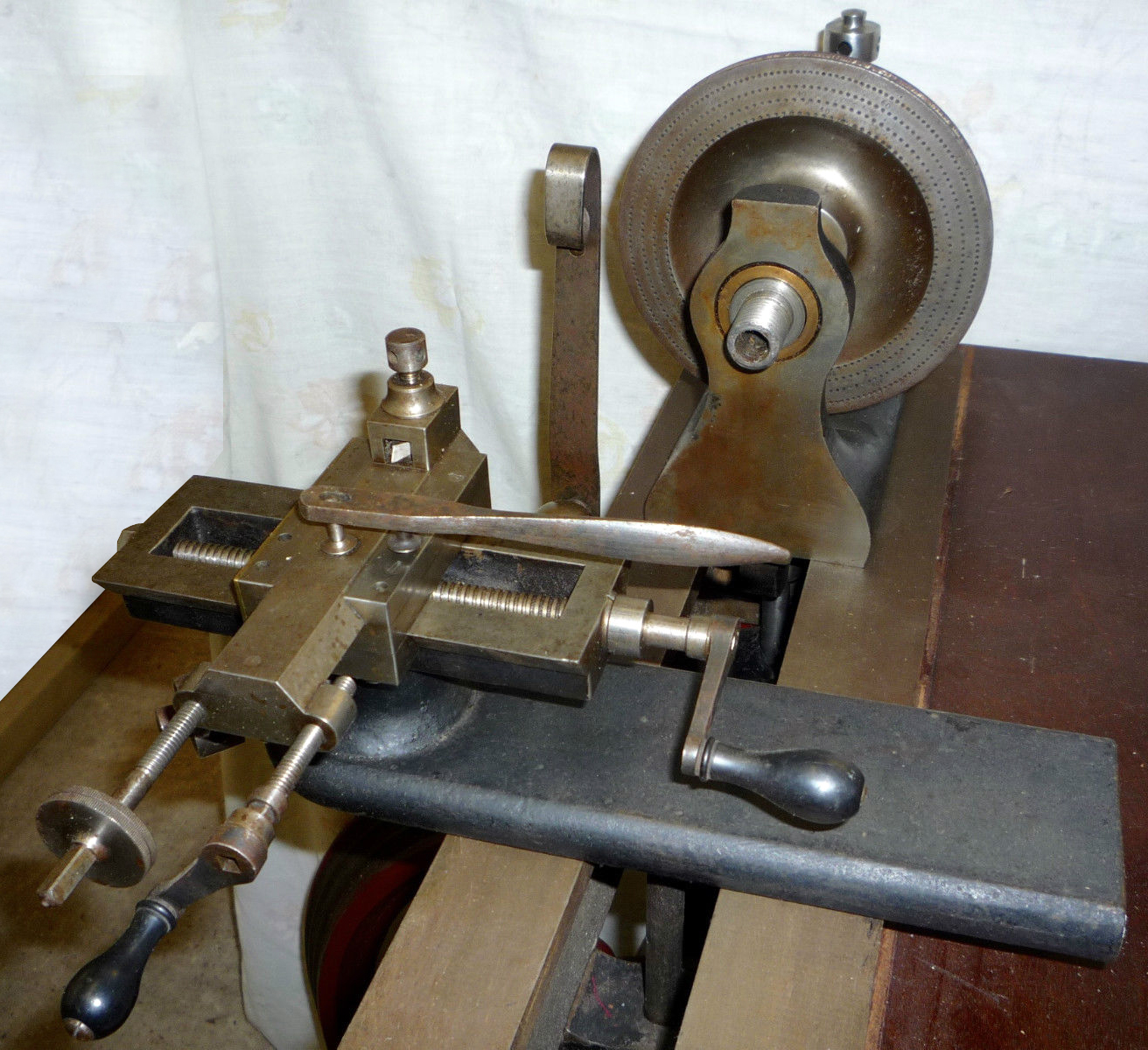

As usual with this type of lathe, the front face of the largest headstock pulley had circles of indexing holes - in this case five with holes giving 180, 144, 120 112 and 96 divisions - each of these, of course, having a large number of factors that allowed almost all but prime numbers to be used. Indexing was by means of a substantial arm in spring steel that pivoted from a large boss in polished brass mounted at a point mid-way down the front face of the bed.

Support by each of the bed legs (called "standards), the drive flywheel spindle ran in "fine gun-metal" (bronze) bearings fitted with dust covers and removable drip plates to catch the lubricating oil. The footplate was in a hardwood and connected to a wrought-iron frame.

Carrying a hardened centre, the tailstock was fitted with a 10 t.p.i. square-section thread to drive the spindle (called in those days a "poppet"). The tailstock casting was in one piece meaning no set-over was available for the turning of slight tapers.

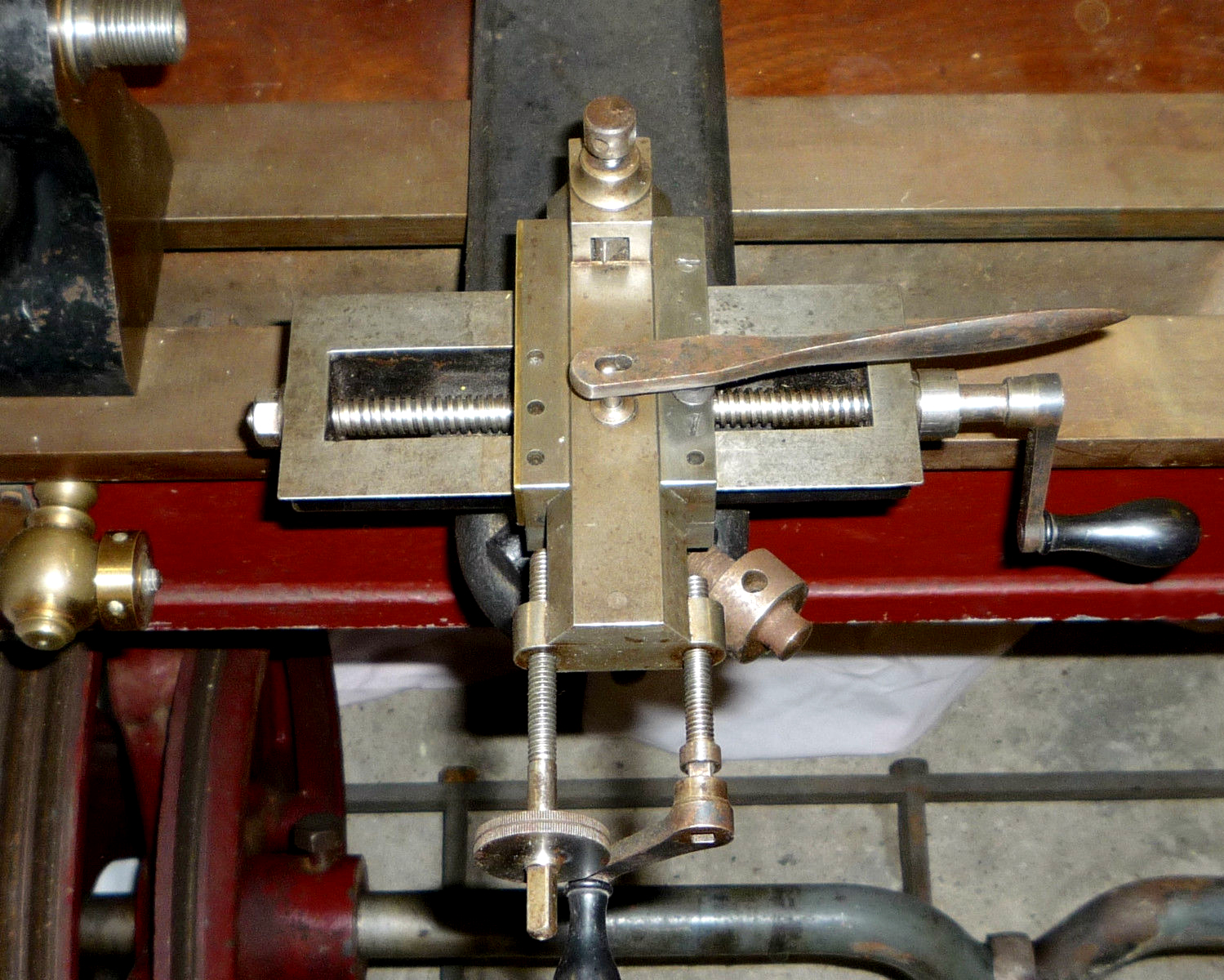

An interesting feature of the "Officers'" was the standard fitment of an overhead drive, this being held on substantial pillars in cast iron and consisting of a polished steel bar, running in dust-shielded bearings fitted with the usual removable oil-drip tray. The "overhead" was an essential part of both ornamental and some forms of ordinary work and was intended to drive a cutter or grinding wheel fitted in a high-speed spindle carried in the toolpost. The Types E and F pattern slide rests referred to above were, respectively, screw and lever operated and intended for both ornamental and ordinary turning; each was carried in the socket rest normally used to mount the three different lengths of T-rest supplied with each lathe. On early Hines lathes his type of mount meant that the slide, elevated well above the bed, was poorly supported - though for the light-duty turning envisaged was not a serious drawback. Later models were improved with the T-rest socket made far more robust and hence rigid enough to absorb the forces involved in turning hard materials

Costing in the late 1800s between £26 : 0s : 0d and £33 ; 0s : 0d for the two standard models with beds between three and four feet long, these were - for plain-turning precision lathes - relative bargains with inflation-adjusted prices to 2023 of between £3800 and £4700. English Hines lathes of the late 1800s make an interesting comparison with many of the "bench precision" lathes produced in the USA during the same period.

High-resolution pictures - may take time to open

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|