Machine Tool Manuals Catalogues Belts Books Accessories

Henry Hind & Son Lathe

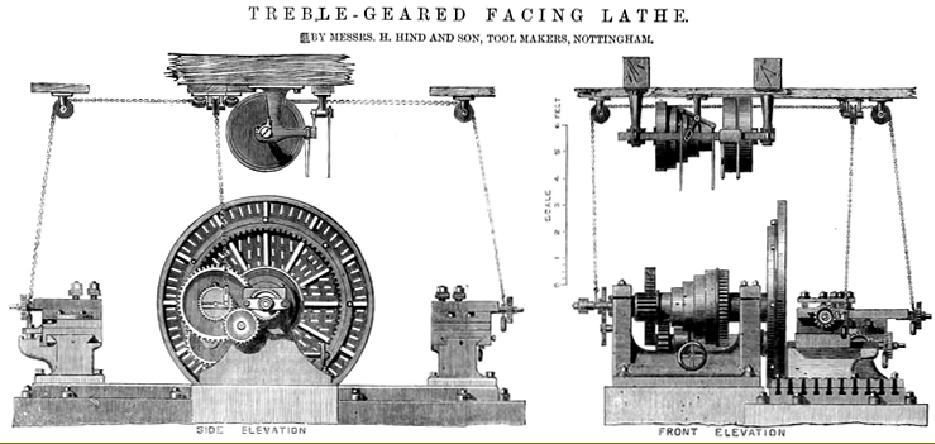

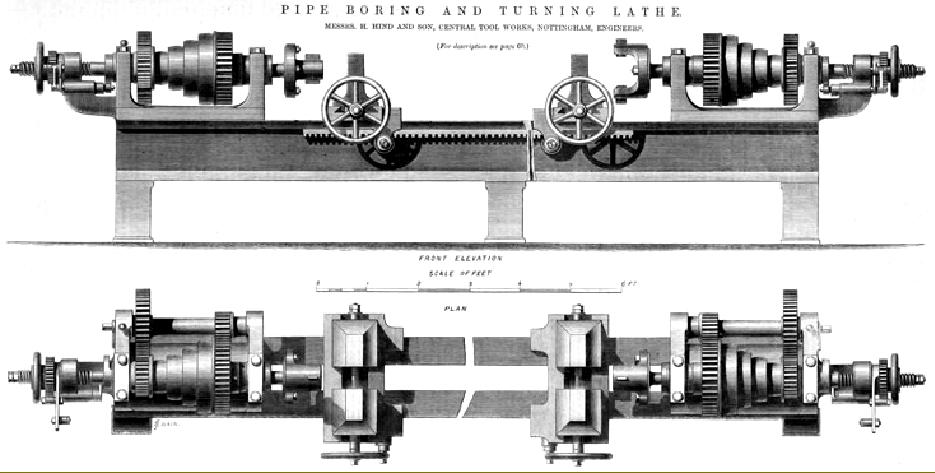

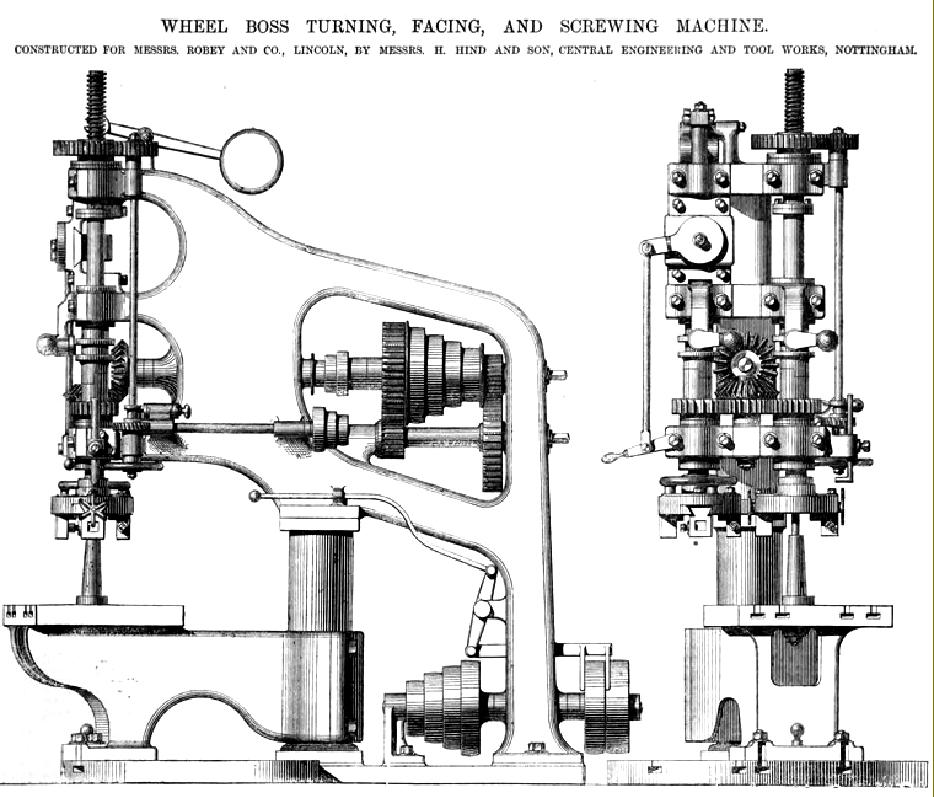

Mentioned occasionally in The Engineer magazine from 1869 to 1877 (as well recognised in Grace's Guide), it is believed that the little-known tool-making firm of Edward Hind & Son ceased trading around the beginning of 1888. Based at the Central Engineering Tool Works, Queen's Road, Nottingham and at 62 Blackfriars Road, London, Edward Hind worked with his son Thomas William Hind.

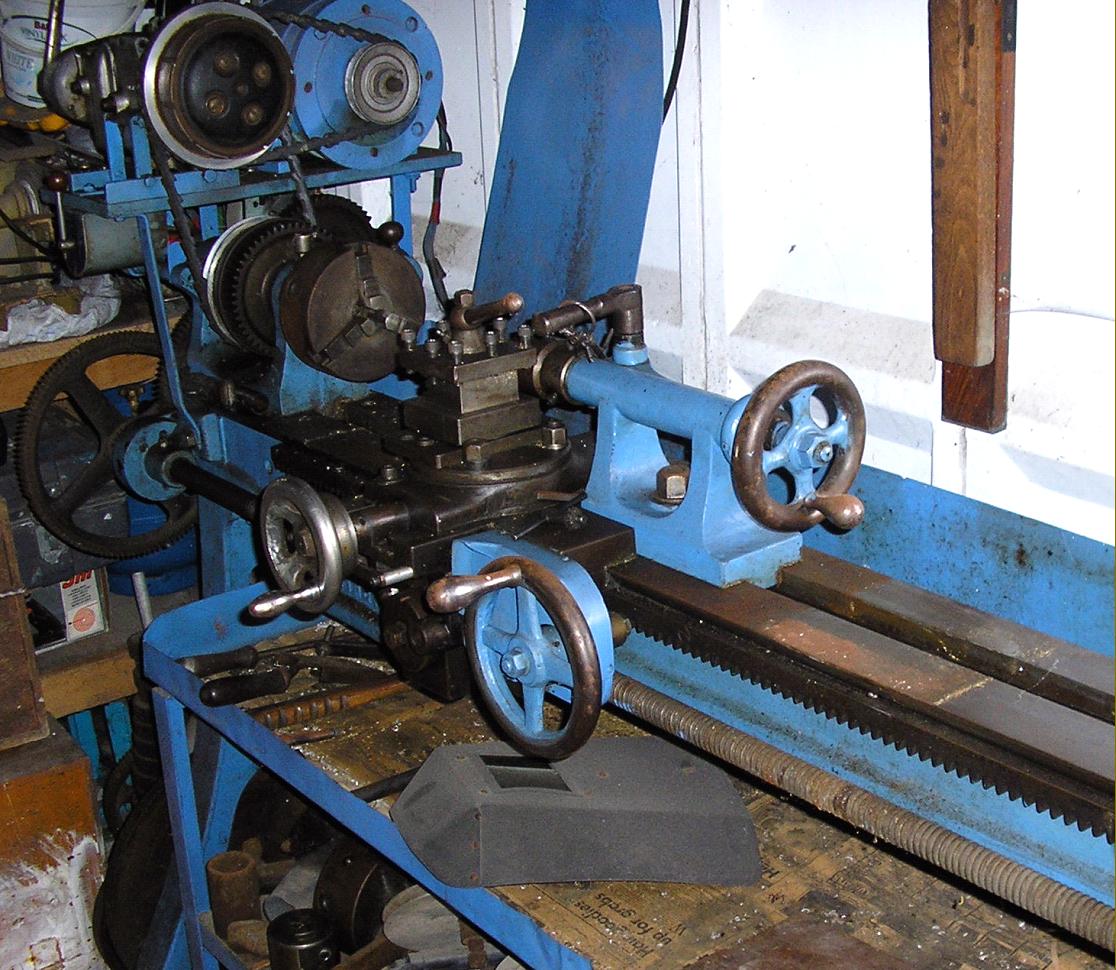

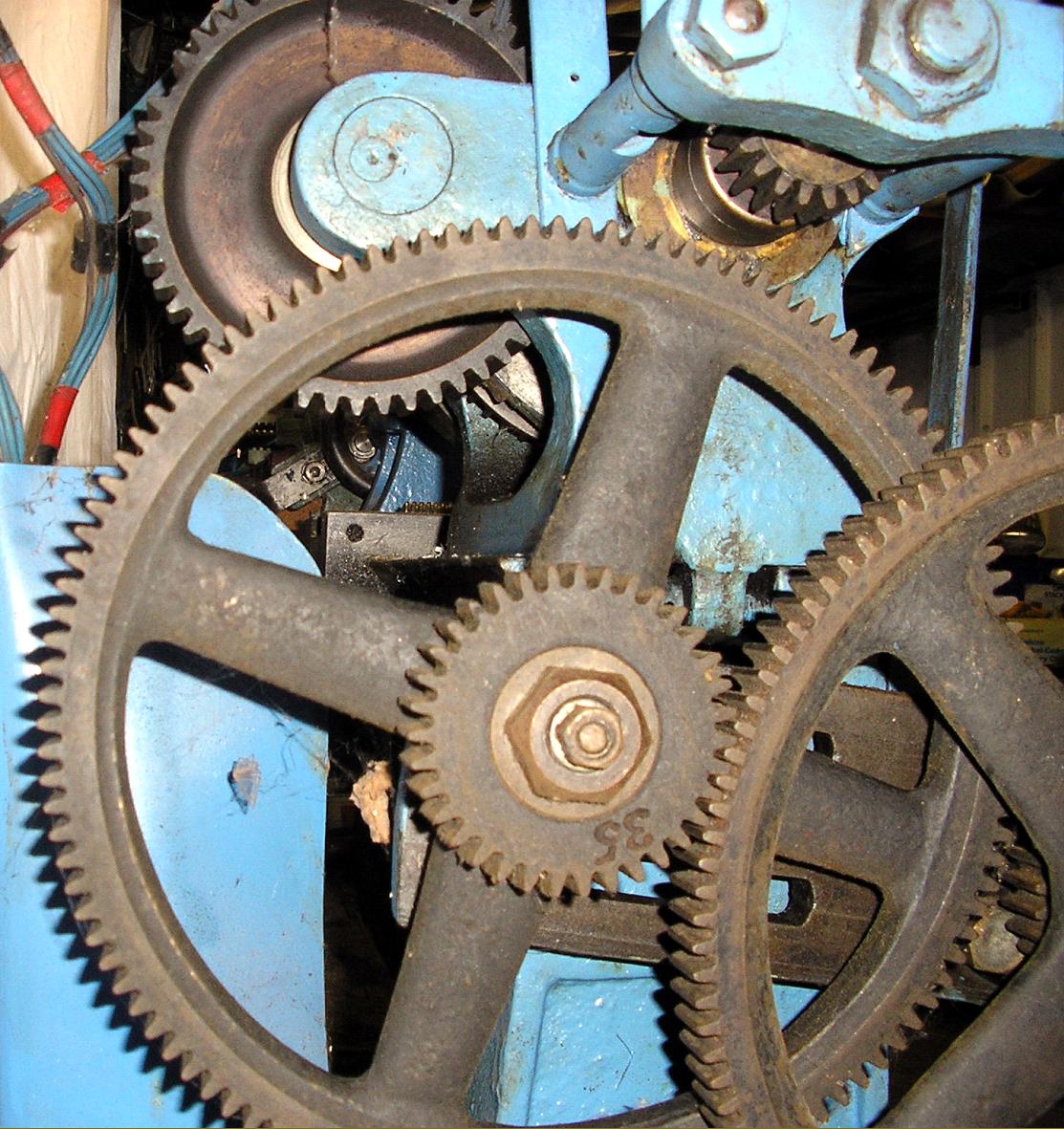

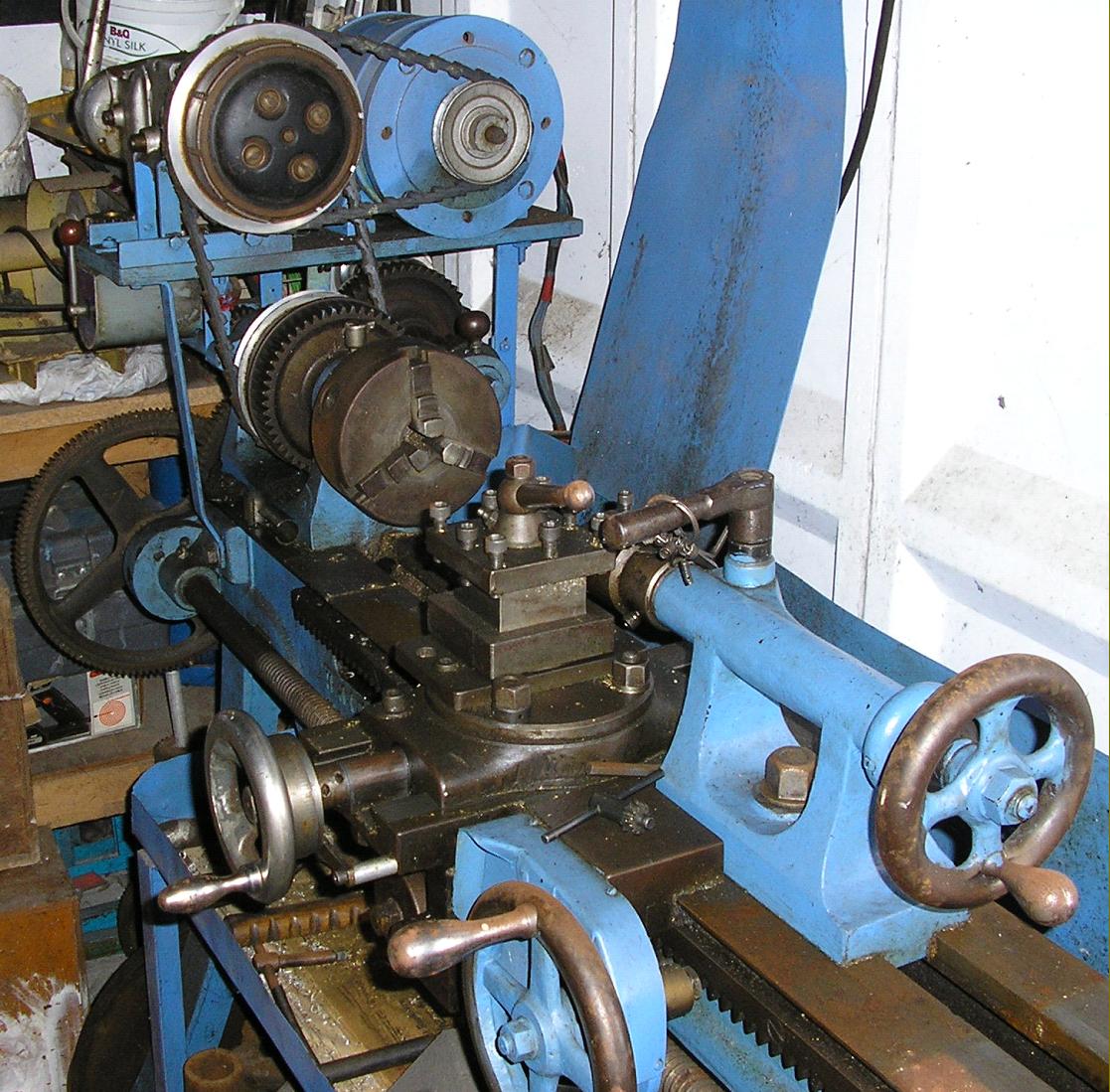

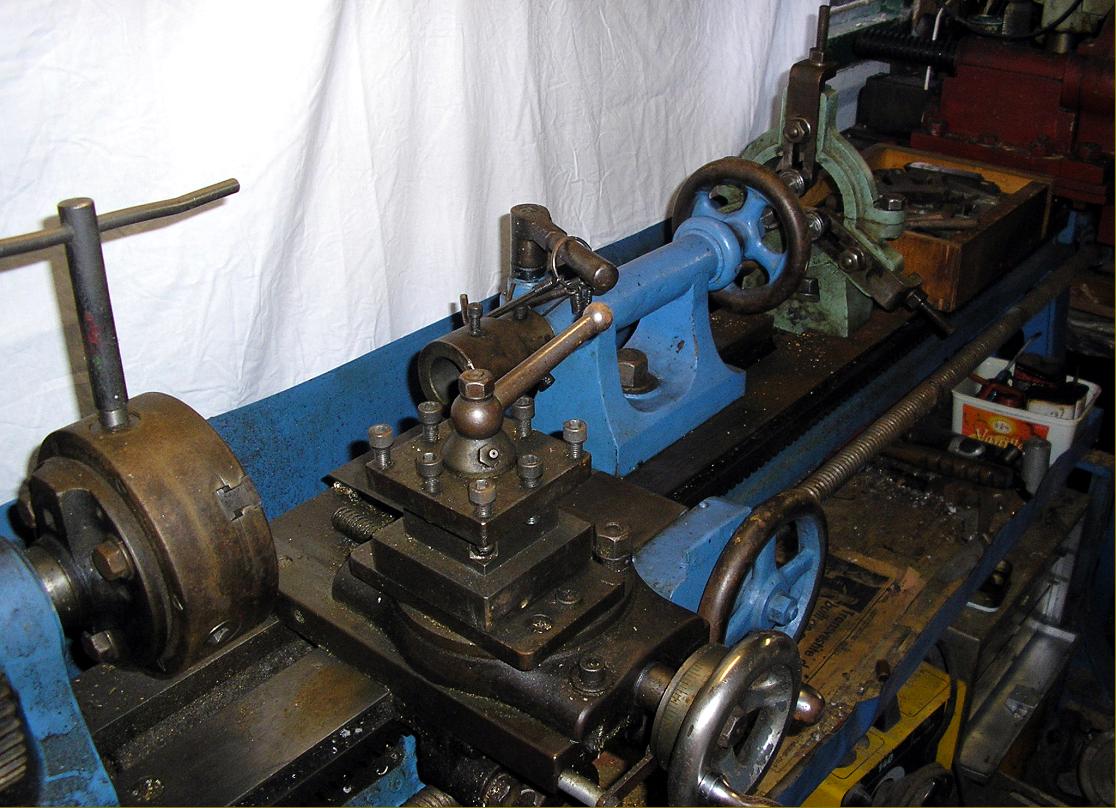

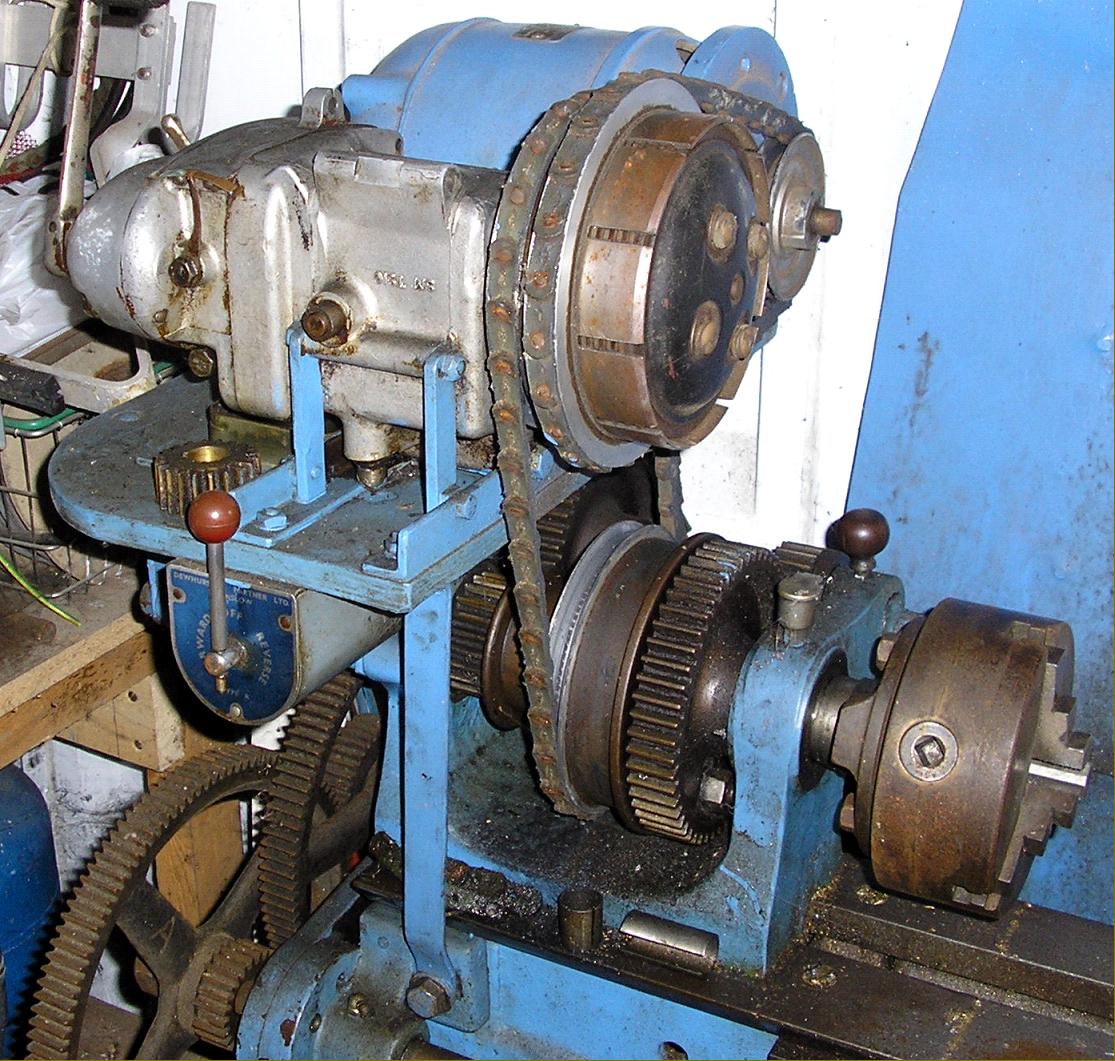

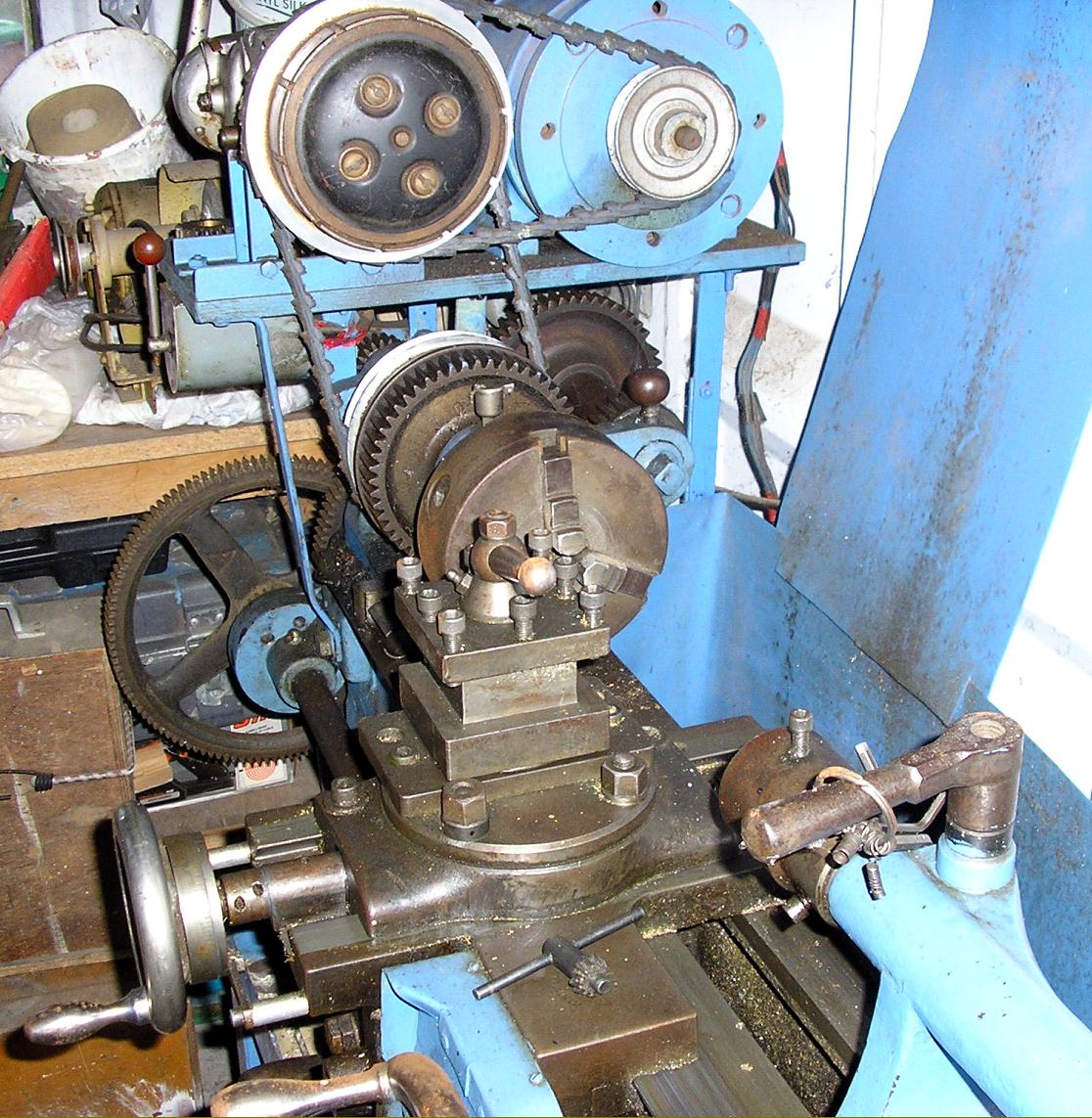

Absolutely typical of its era, the sole known surviving Hind lathe is of conventional, straightforward design with backgear and screwcutting by changewheels (the screwcutting and feeds gearbox having yet to be invented) with pointers to its antiquity including a generally light built, a deep gap in the bed created by forming the casting around it, a bracket outboard of the left-hand spindle bearing to take end thrust, relatively coarse-pitch backgears and changewheels, a narrow, lightweight apron - and a tailstock with daylight beneath the spindle. However, having been in almost constant use for many decades, some parts of the lathe shown below have been modified: instead of the original very long crank handle on the apron engaging a shaft with a gear direct against a bed-mounted rack (and the consequent over-quick and difficult-to-handle travel of the carriage) a previous owner has engineered in full-circle handwheel driving through a train of reduction gears to give a steady and much slower rate of feed. Instead of the cross-feed screw being turned by the usual small crank with a horn or wooden grip, an ordinary handwheel has been fitted together with a large micrometer dial and, finally, it looks as though the top slide (if originally fitted, and many such lathes did lack one) might be missing. The 4-way toolpost is also not original - the lathe being built well before that type came into regular use.

In plain bronze, the spindle bearings are tapered on their bore with the spindle drawn by adjusted nuts at the rear until the clearance is correctly set - and the end thrust taken on the previously mentioned external bar mounted on posts outboard of the left-hand bearing.

While the original cast-iron legs - standards in the nomenclature of the time - have survived, the treadle gear and flywheel have not. Instead, a common conversion has been engineered in, a single V-belt drive to the headstock spindle but with the drive passing through a 2-speed motorcycle gearbox and clutch unit - though it appears that the latter component is not used and instead locked in the engaged position.

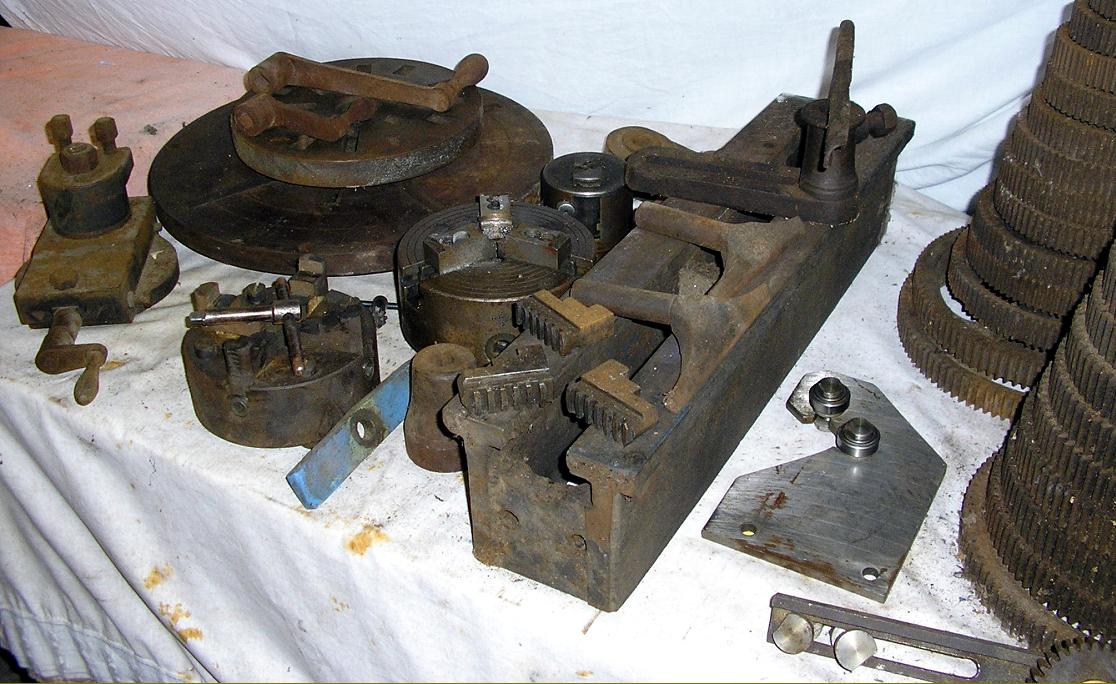

Surviving with the lathe is the original very large collection of changewheels, a lathe of this type often having around 20 ranging in size from a 20-tooth to a 120.

While many makers of machine tools from the Victorian failed to put any identifying marks on their products, the Hind is clearly marked and should any reader have another example, the writer would be interested to hear from you and see some photographs.