|

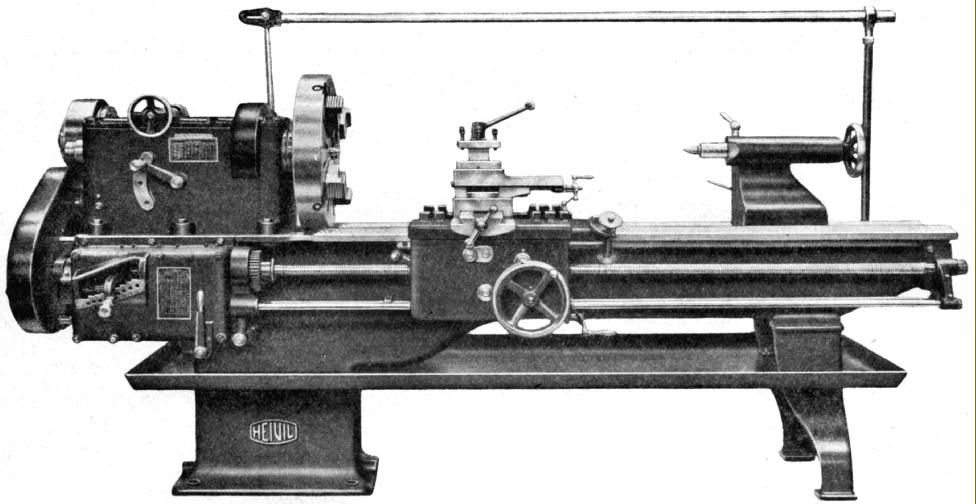

Above, a Heivil fitted with a very large faceplate-cum-4-jaw chuck. Note the exposed gear at the headstock-end of the leadscrew and unusual spindle-speed selector handwheel on the headstock

Continued:

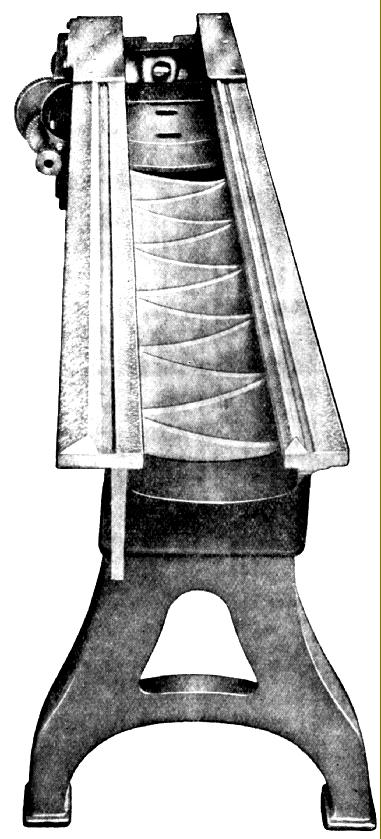

Employing a conventional backgeared headstock, the flat-belt drive models had a 1.5-inch bore spindle running in adjustable, parallel-bore, tapered-outside bronze bearings. A 4-step cone pulley was fitted to take 3-inch wide belt which, if driven from a 3 h.p. motor and the maker's 180 r.p.m countershaft gave 8 rather slow speeds (including backgear) of 10 to 392 r.p.m.

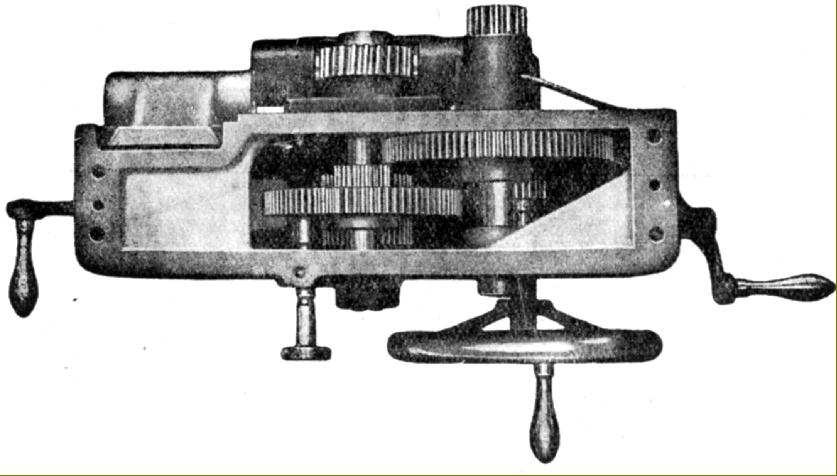

Built into the inside of the headstock, the leadscrew and powershaft reversing gears drove a conventional Norton-pattern quick-change screwcutting and feeds gearbox able to generate 36 English threads from 2 to 30 t.p.i. and 36 sliding and surfacing feeds from 0.08 to 1.22 mm. With one change of drive gear 21 metric threads could be obtained from 0.4 to 7mm pitch. The leadscrew was used only for screwcutting and engaged by a large sliding gear (unfortunately exposed when not in use) at its headstock end. The leadscrew gear meshed with one on the powershaft that drove the sliding and surfacing feeds through the usual worm-and-wheel arrangement within the apron. Surfacing and sliding feeds were selected by a push-pull knob on the face of the apron with the latter able to automatically disengaged by an adjustable collar on the shaft - a useful fitment and one omitted from far too many ordinary lathes of a similar size from the 1940s onwards. Besides the headstock-mounted gears, the carriage could also be instantly started, stopped and reversed by a third-shaft control system operated by a handle pivoting from the right-hand face of the apron and working a mechanism within a sub-box on the right-hand end of the screwcutting gearbox. Unusually, and breaking with established practice, this shaft was not below the feed shaft but forward and level with it and carried in a downward-pointing forked bracket at the tailstock end of the bed.

Entirely conventional in construction, the compound slide rest was fitted with taper-type gib strips and the usual (for the time) tiny and inadequate micrometer dials; a heavy cast-steel 4-way toolpost was fitted as standard as was a rather large, clear but ungainly-looking thread dial indicator.

Besides the items mentioned, supplied as standard with each lathe were: an oil tray, a light-duty 4-jaw independent chuck of the type then popular, a catchplate, fixed and travelling steadies, 2 hard centres, a set of 7 changewheels including a 127t metric translation wheel and 4 spanners.

Weights varied from approximately 2900 lbs for the shortest bed machine to 4150 lbs for the longest..

|

|