|

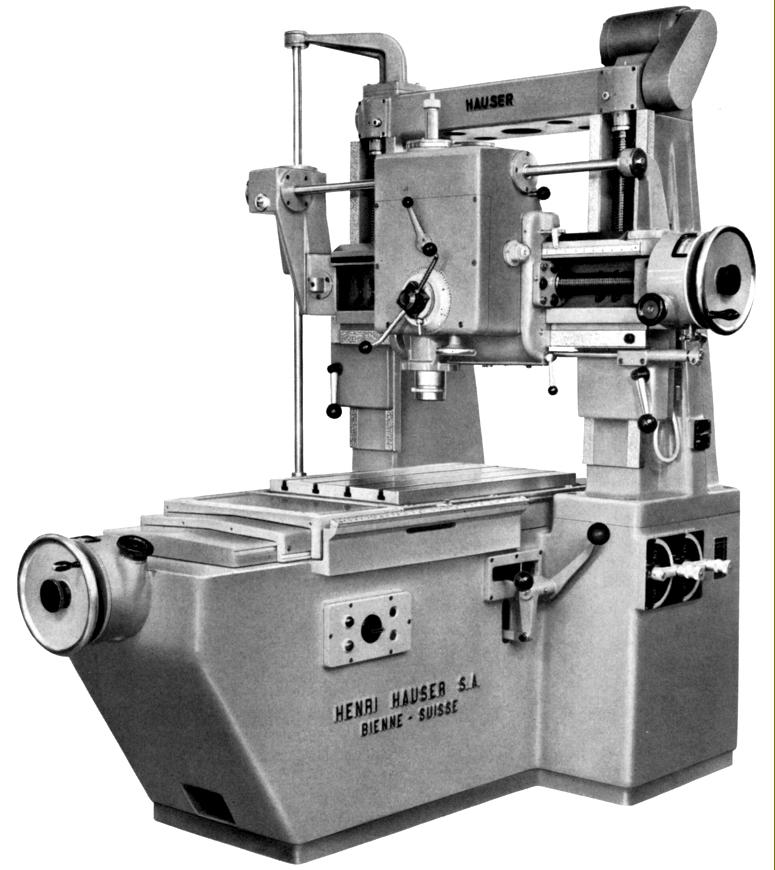

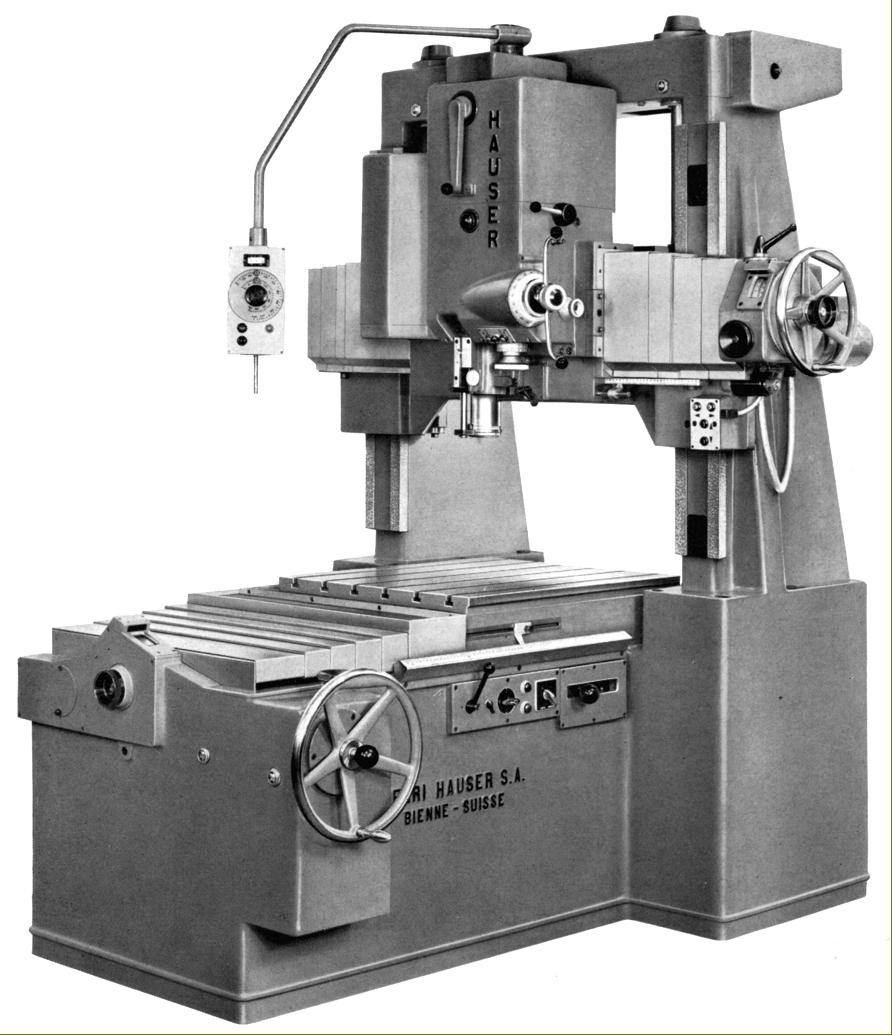

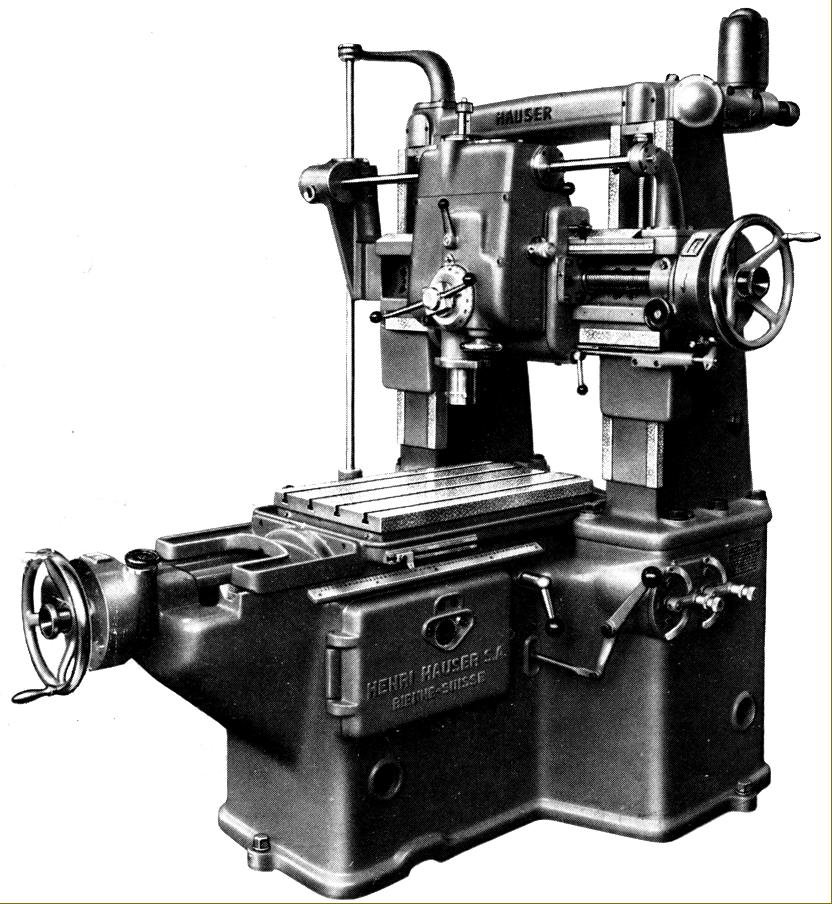

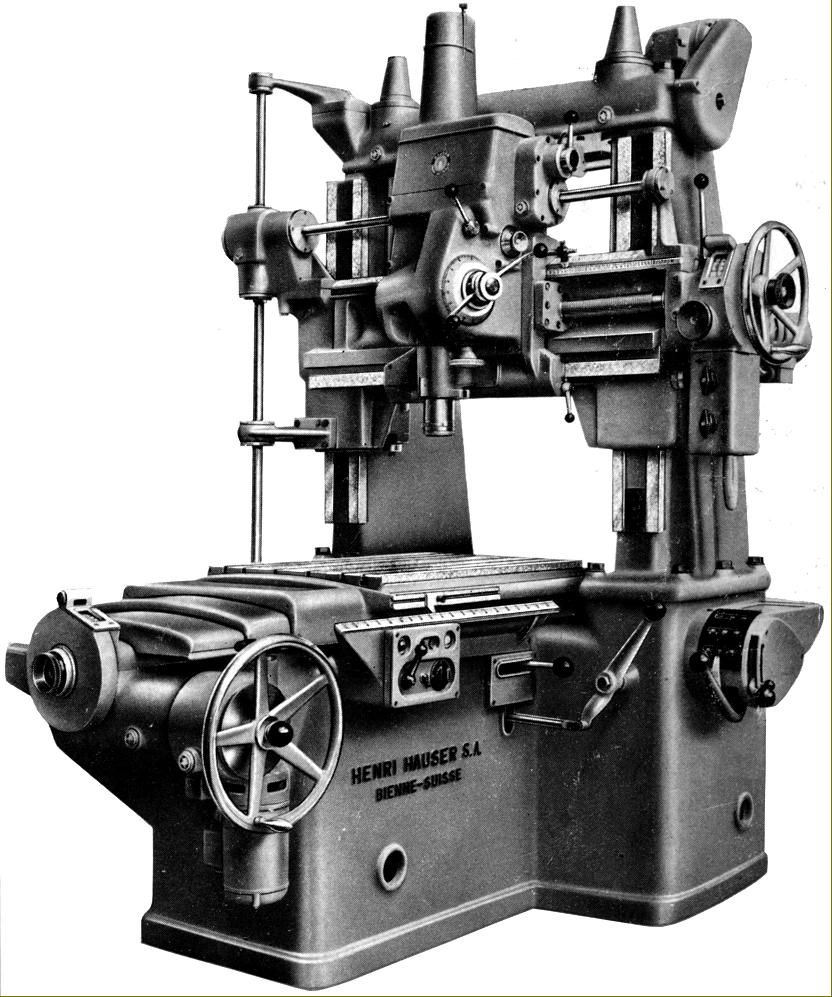

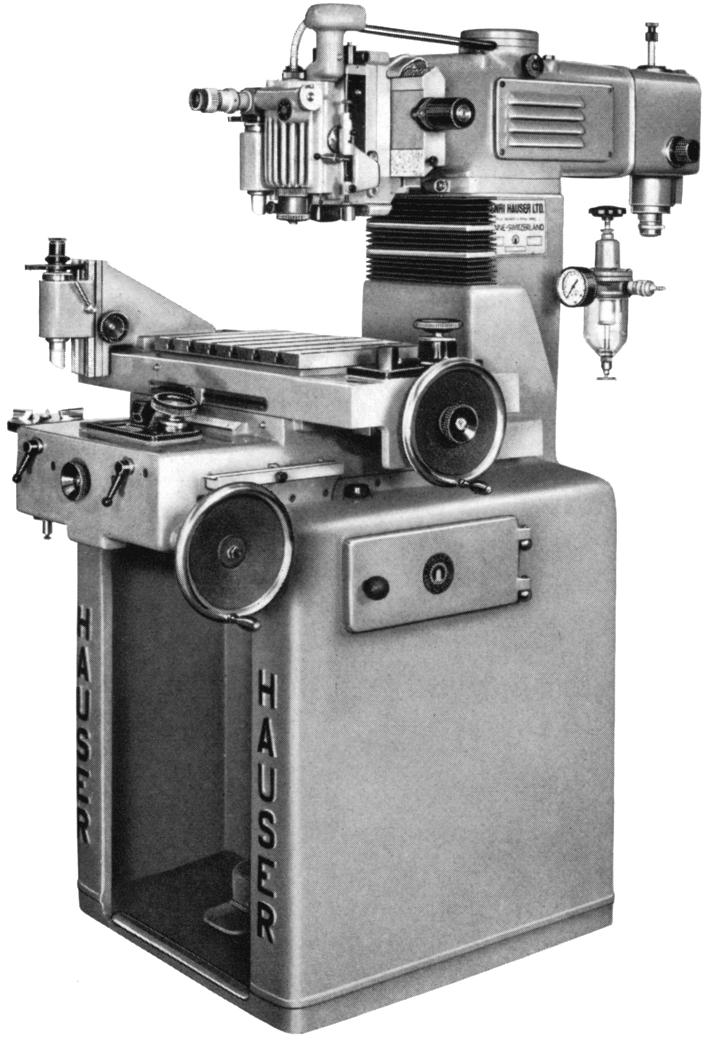

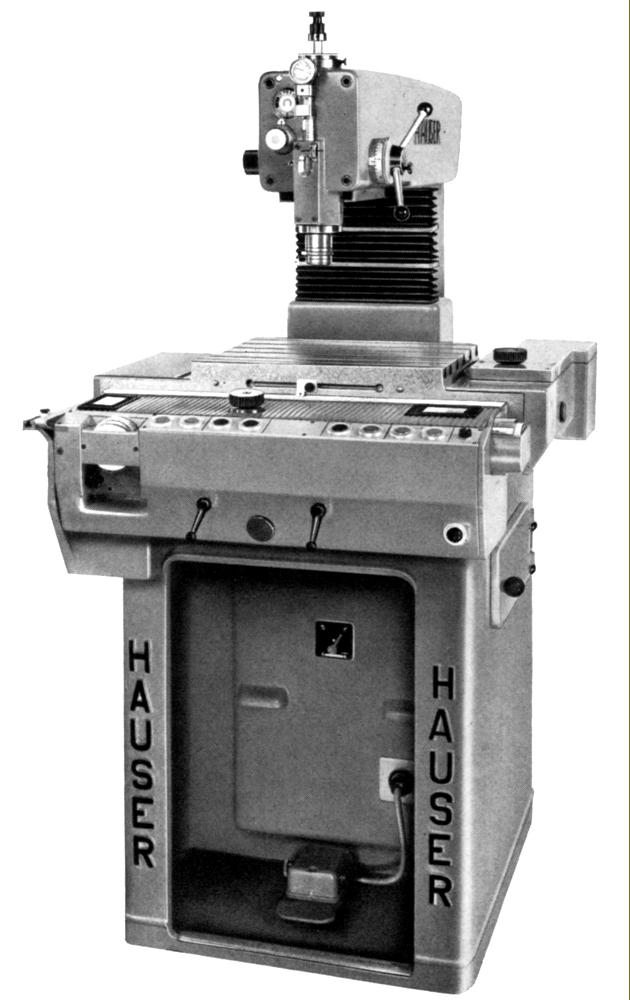

Hauser 2SB Combined Jig Borer and Jig Grinder

Makers of dies, press-tools, gauges, jigs and other precision components found that the small jig borer, as exemplified by the Hauser No. 2 and No. 3 ranges, were ideal toolroom machines able to turn out work of astounding accuracy in the right hands. Unfortunately, many of the smaller components produced on the jig borer required post-machining hardening, a process that could distort the part and require an amount of metal to be left for grinding. It was for this purpose that Hauser produced their jig grinding machines - a range that stretched from the heavy Type 5SM (based on the Type 5 jig borer) through the increasingly lighter and more accurate direct-leadscrew-reading 3SM, 2S, 2SB and the even more precise optical-reading 3SMO and 2SO. However, if a customer wished to save money, he could order a combined jig-borer-cum-jig grinder, the leadscrew-reading 2-SB or rather different optical 2-SBO. Made in Mk.1 and Mk.2 forms, the earlier 2SB had "round" styling typical of the 1940s and early 1950s and the later more modern, angular lines with the Hauser name picked out in large letters arranged vertically down each side of the stand's front face. Both models shared a very similar mechanical specification - based on that used by everything bar the head from the Type 2-A2 jig borer. A six-T-slot table with a working surface of 360 x 220 mm (14.5" x 9.5") had a longitudinal travel of 200 mm (8") and a cross-feed of 200 mm (8"). Carried on the back of the main body, the complete head assembly- a jig-boring head at one end and a jig-grinding at the other - together with the 0.75 h.p. spindle-drive motor and gearbox - could be elevated under power (using a 1/10 h. p. motor) through a distance of 250 mm (9.75"). Raised to its maximum height (electrical switches were fitted that cut power if either limit of up or down travel was reached) a clearance of 350 mm (13.75") was created between the jig and grinding spindle noses and table surface. However, on the Mk.1, this clearance was slightly less at 317 mm (12.5"). In order to employ the grinding spindle, the complete head assembly was simply rotated through 180°.

Fitted with an oil-mist lubrication system, the grinding head (as also fitted to the Hauser 2S jig grinder) was driven by a ½ h.p. motor that turned a built-in 30 to 45 p.s.i. air turbine to give speeds of up to 70,000 r.p.m. on the Mk.1 and 80,000 r.p.m. on the Mk.2 (by the year 2000 speeds available on CNC-controlled jig grinders had risen to 120,000 r.p.m.). The same motor also served to power two movements important for successful jig grinding - automatic reciprocating and vertical stroke of the spindle - the former being set in two ranges of 4 to 5 mm per second (0.16" to 0.20") and the latter adjustable between 5 and 35 mm (0.1875" to 1.4"). The maximum recommended diameter to grind as a bore was 19 mm (0.75") on the Mk.1 though on the Mk. 2 this had been reduced to a recommended maximum of 15 mm (0.625").

Fitted with a combination of super-precision roller and ball races, the boring head was lifted complete from the 2-A3 jig borer. This had a 70 mm (2.75") travel spindle with a No. 0 Morse taper, infinitely variable speeds from 150 to 3000 r.p.m. and a single rate of power downfeed of 0.015 mm (0.0006") per revolution - a rate so slow that it virtually guaranteed a superior surface finish on bored holes. The maximum drilling capacity in steel was 10 mm (3/8") with a suggested a boring limit of 50 mm (2").

Mounted at the left-hand side of the machine was what Hauser termed the Reproduction Attachment. This optical-reading device used elements of the Type M1 jig-borer-cum-spotting machine and consisted of two parts: an extension to the left-hand side of the main body that carried a vertical spindle topped by a 125 mm (5") diameter faceplate with three radial clamps arranged exactly like those fitted to a watchmaker's lathe. Above, but formed as part of the table, was a 100 mm (4") travel vertical slide fitted with an alignment microscope that allowed the direct duplication of workpieces - and of course without having to know their dimensions. In operation, the original part was placed on the faceplate - with the material to be machined on the main table - and the various required positions on the original observed through the microscope. It was also possible, of course, to use the unit for checking and measuring workpieces.

Quipped ready for immediate use, the 2SB was fitted as standard with a three-point suspended locating microscope, a setting attachment with dial indicator and a reduction spindle sleeve to take collets. As with all Hauser machine tools, a range of beautifully-made accessories was available to further expand the machine's capabilities and included: a 300 mm (12") diameter rotary table, a 160 mm (6.25') tilting rotary table, an indexing attachment with tailstock and a quite superb screw-feed compound slide topped by a 135mm (5.3") rotary table with 5 radial T-slots.

Hauser Jig Grinders here

|

|