|

Known to have exhibited as machine-tool manufacturers at the Great Exhibition at Crystal Palace, London, in 1851, the Hamann lathe was manufactured in Berlin, first by August Hamann Werkzeug-Maschinen-Fabrik (founded 1829) and then, according to a catalogue dated 1894 and held by the Deutsches Museum in Munich, by one H. Walz.

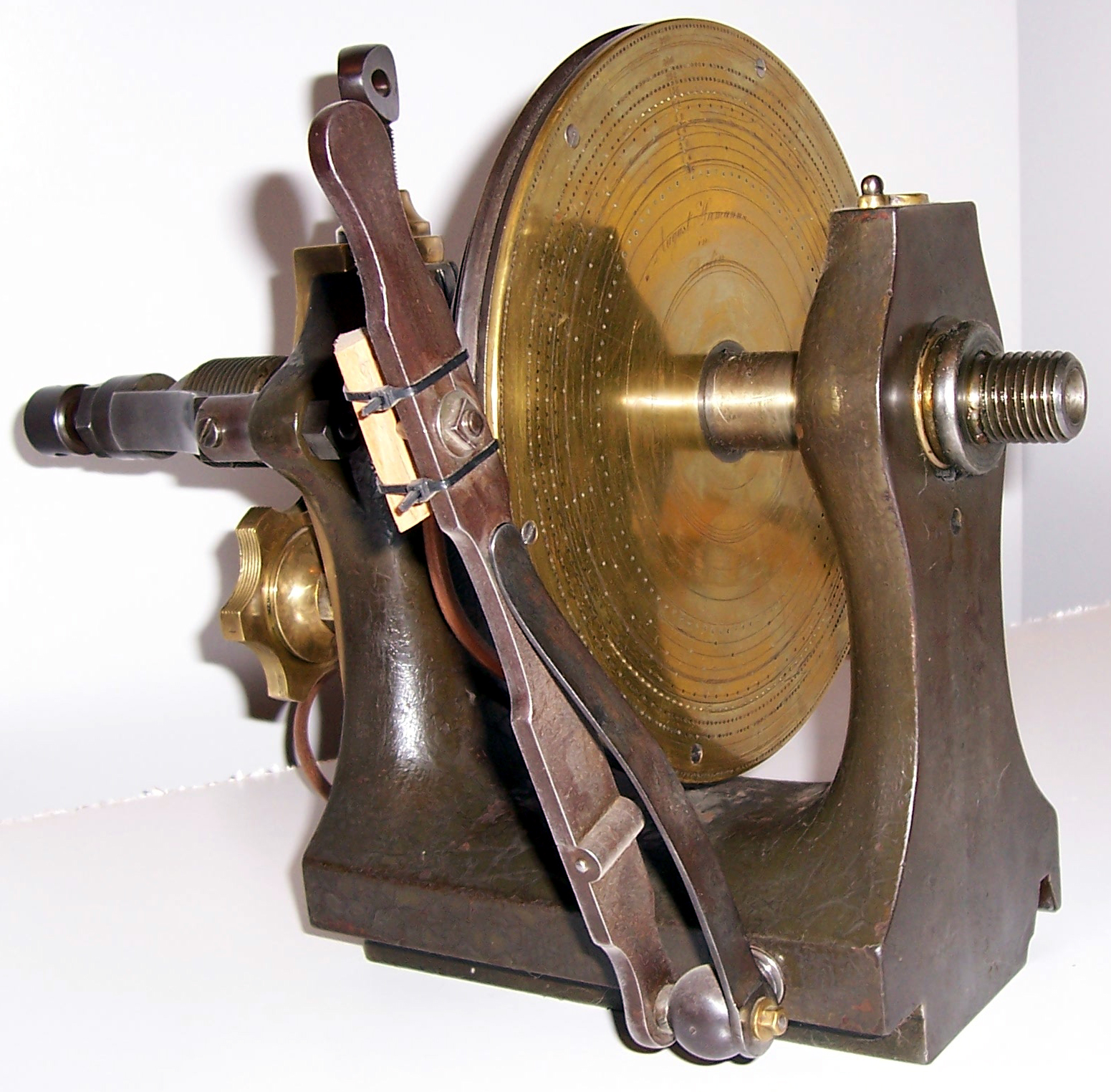

An original description of the lathe describes it as a plain type (i.e. non-screwcutting) with a drilling frame and eccentric and oval chucks. However, both the examples shown below (they reside in the United Kingdom), although lacking their ornamental-turning accessories, do have screwcutting of the "chase" type together with a sliding headstock-spindle and a master thread in the form a multi-faced star in bronze.

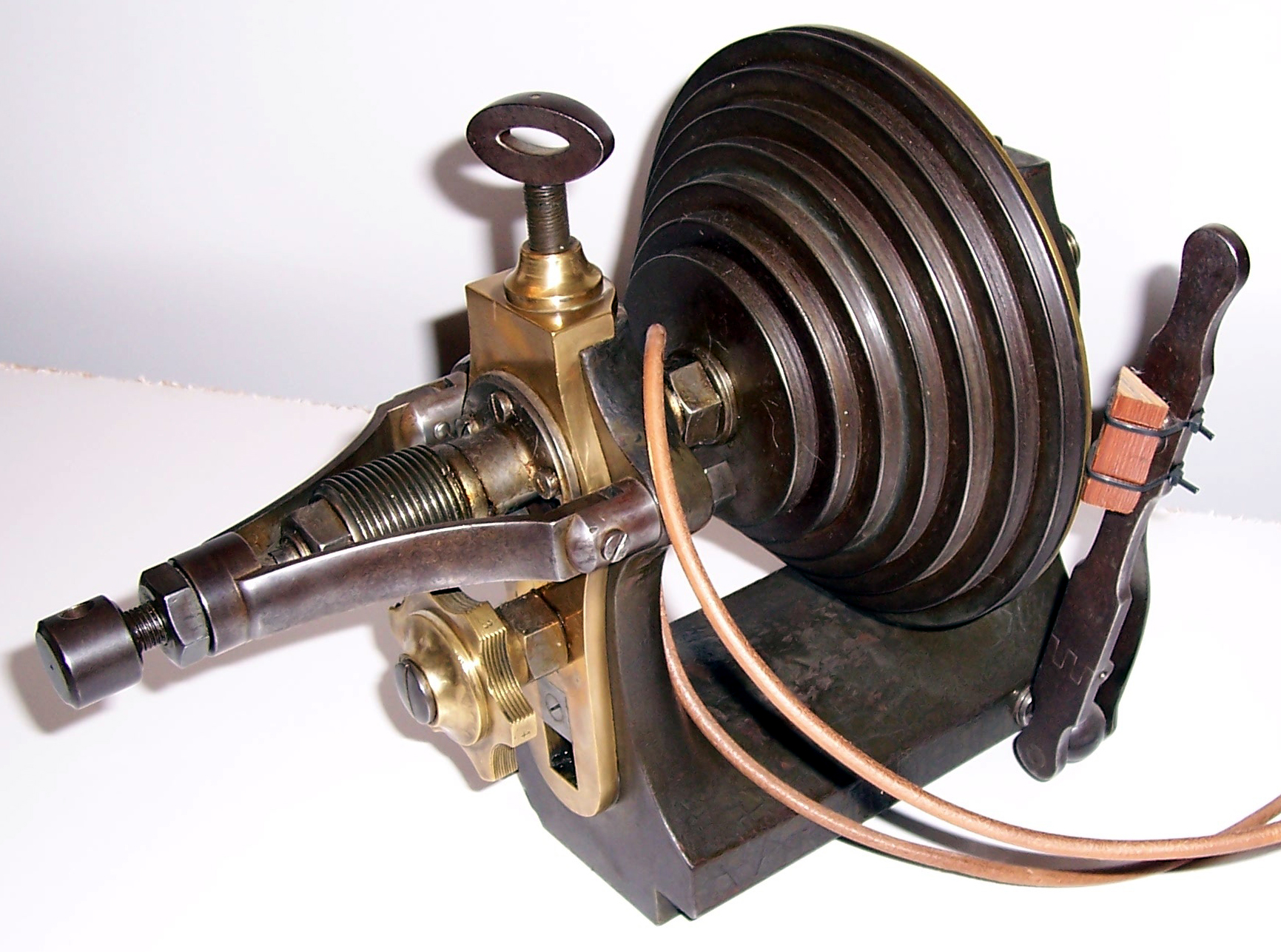

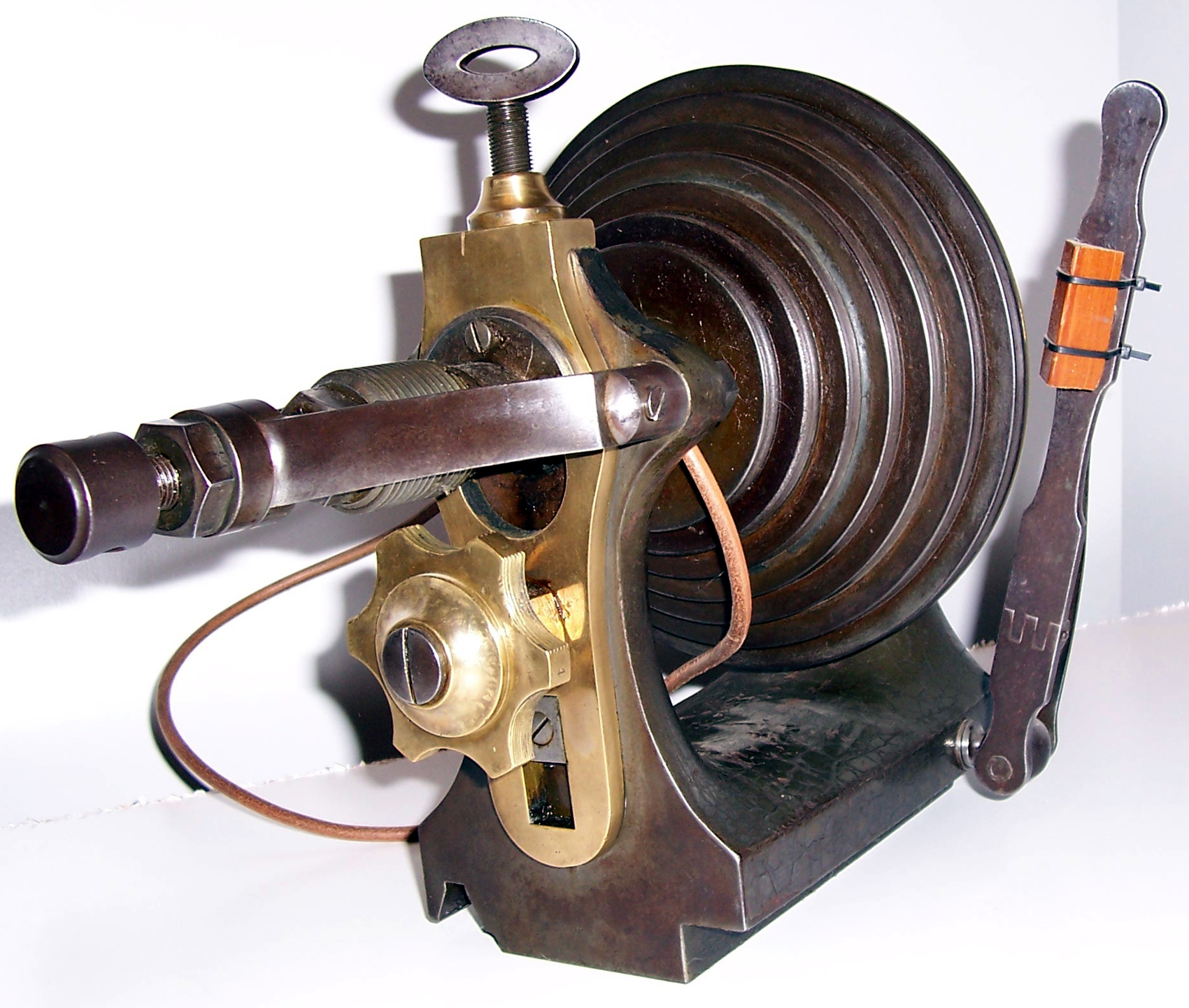

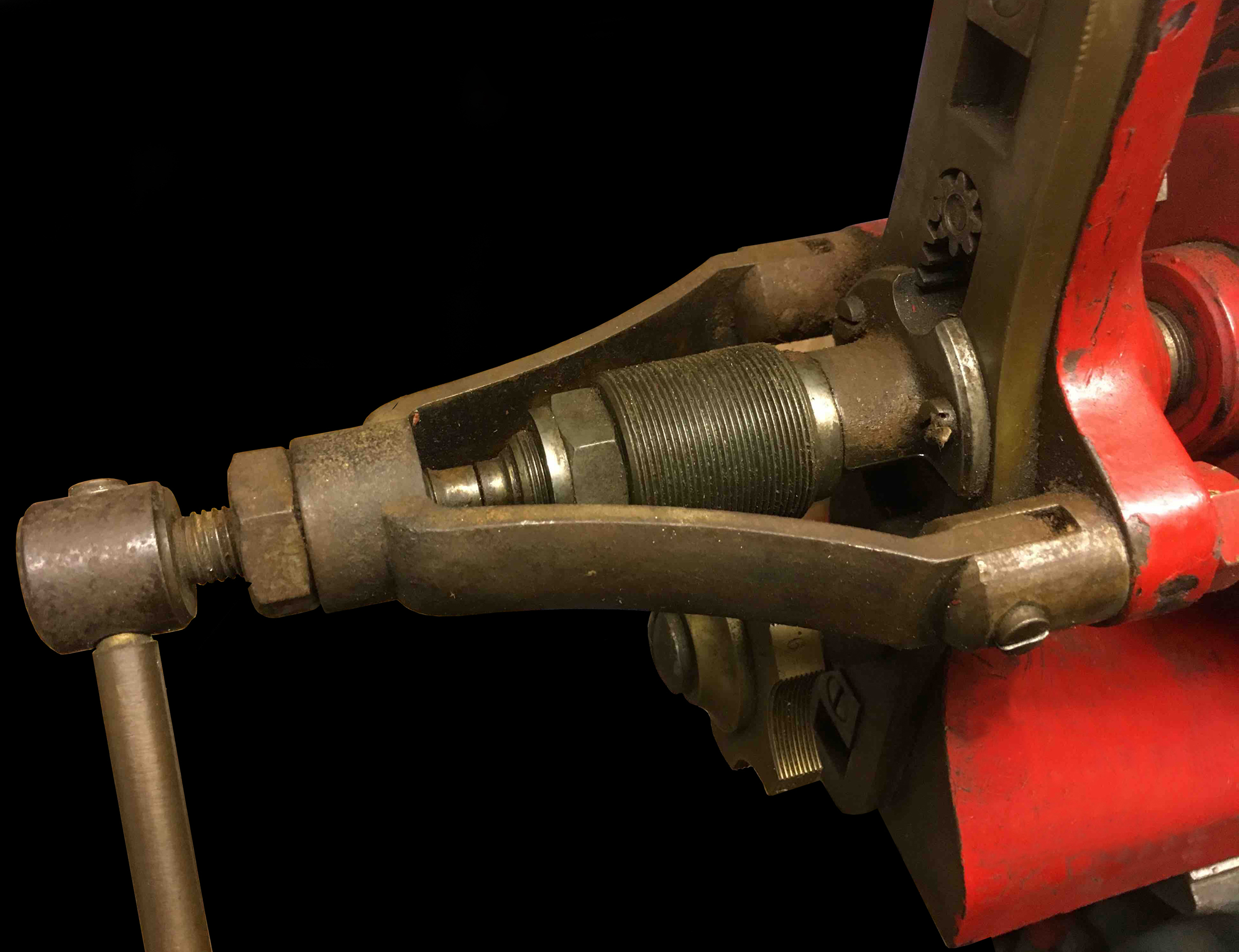

Instead of the threading tool being made to move along the job as with ordinary chase-type or changewheel-driven screwcutting, in the arrangement fitted to the Hamann, the headstock spindle was arranged to slide forwards and backwards in its bearings while the cutting tool remained stationary. Widely used on ornamental turning lathes in the 1800s, in more recent times it was adopted by such German firms as Lorch, Wolf Jahn, and Auerbach (the smallest model to incorporate it being the Wolf Jahn Model AA with a centre height of just 50 mm) and the Swiss-built Schaublin. The arrangement was also a feature of most "Swiss-Auto" mass-production lathes used for the manufacture of tiny parts - and is still in widespread use today on such machines, though these are now (of course) fitted with CNC controls. Examples of how the thread chasing system worked can be seen here and an explanation of how a sliding headstock spindle and star-shaped master functioned together (on a German Kärger lathe) here.

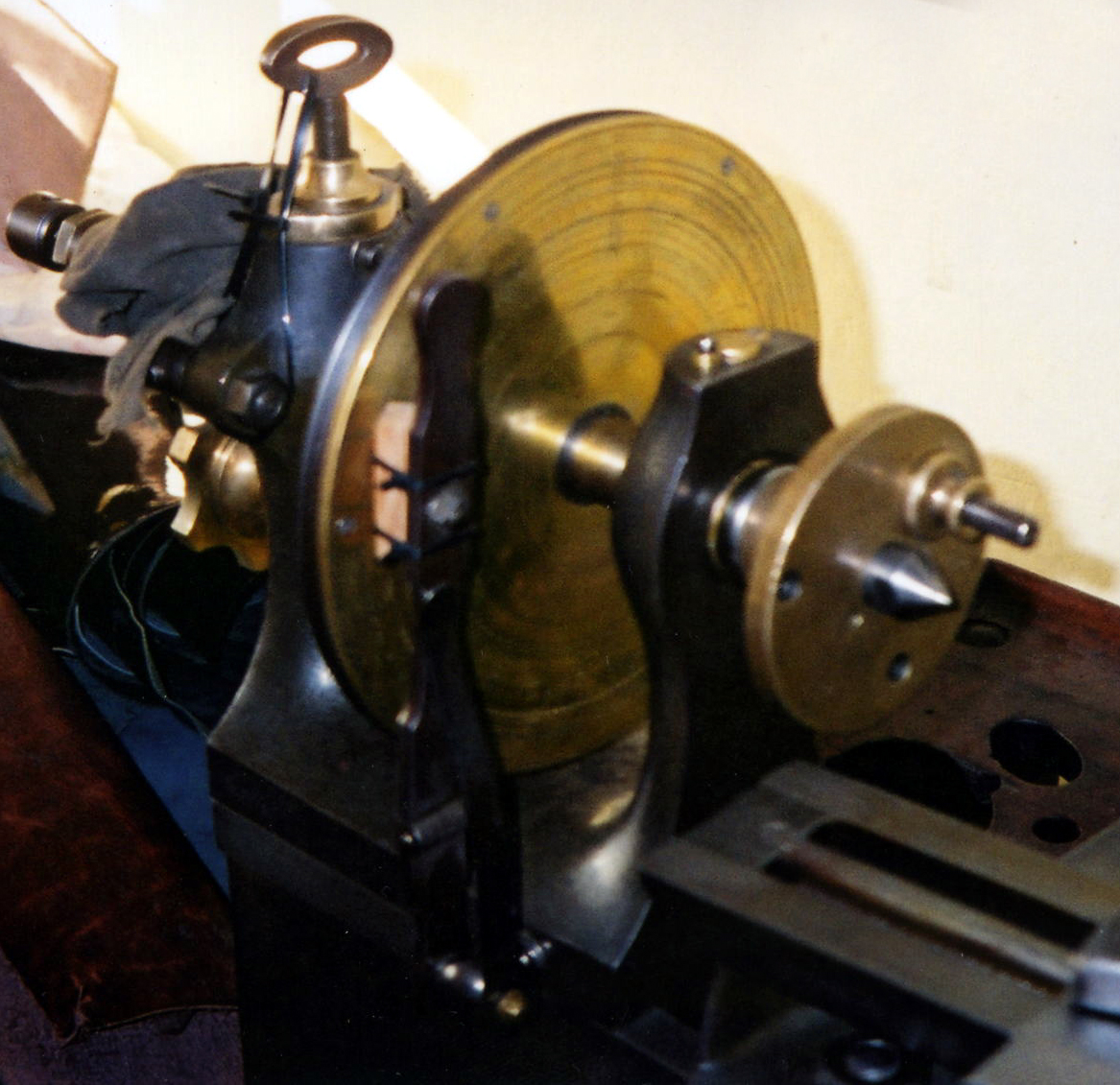

While the use of a spider with six threaded faces was not unusual - nor the fitting of a sliding spindle - the arrangement of these parts on the Hamann was beautifully engineered. The outside face of the headstock was machined flat and covered by a thick bronze plate that could be adjusted into an upper or lower position by the use of a screw that passed through a top-mounted flange to bear down against the top of the headstock casting. The plate was bored with a slot with, at the top, a semi-circular cap that prevented the spindle from moving endways - this position allowing the lathe to be used for conventional turning. When the plate was raised to bring the lower section of the slot into position, the star thread (carried on a stud fixed to the plate) engaged the spindle-mounted thread and, with the retention cap out of the way, allowed the screwcutting sliding action to take place. When set up for ordinary turning, spindle end thrust was taken by a hardened point at its left-hand end with the engagement pad carried at the junction of two converging arms mounted outboard of the bearing - their mountings being a pair of bosses, one at each side of the headstock casting.

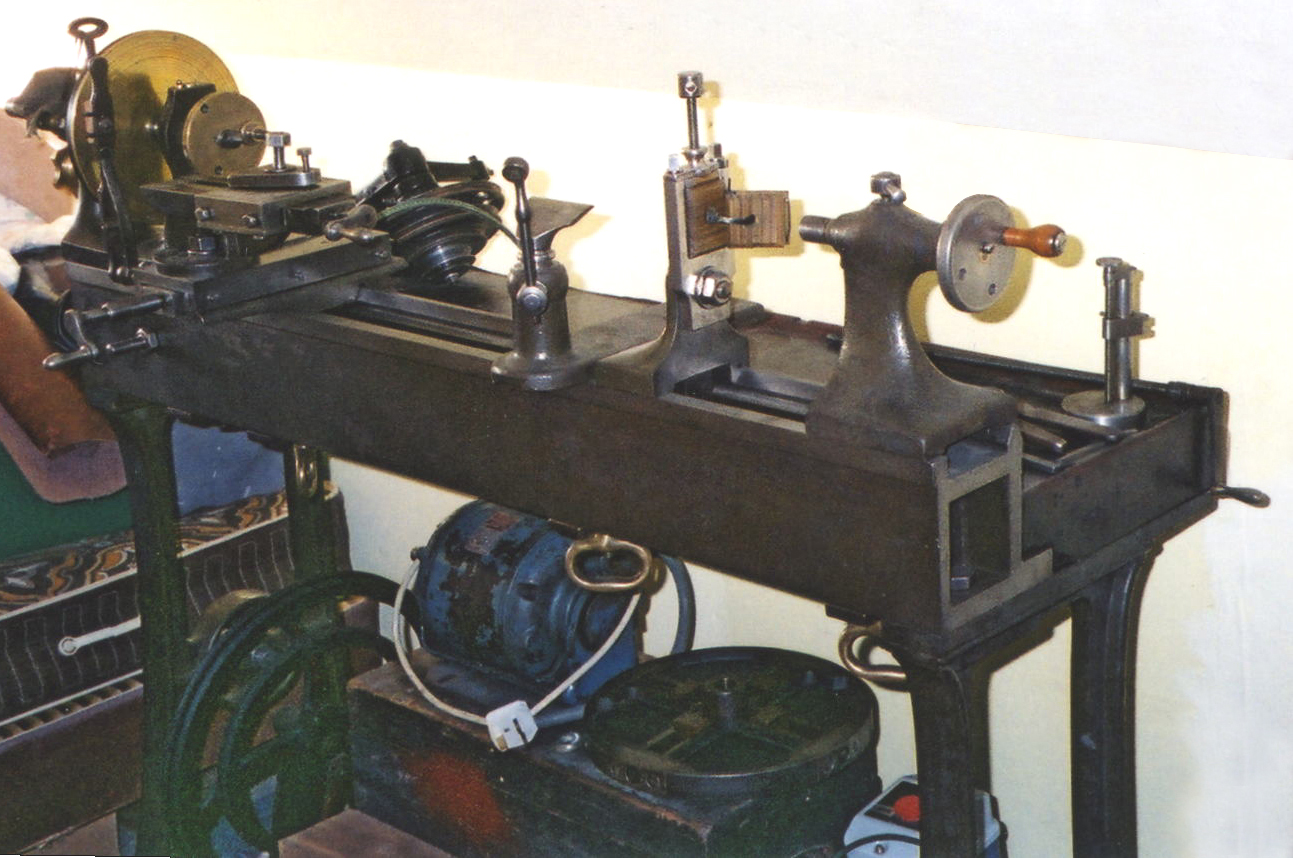

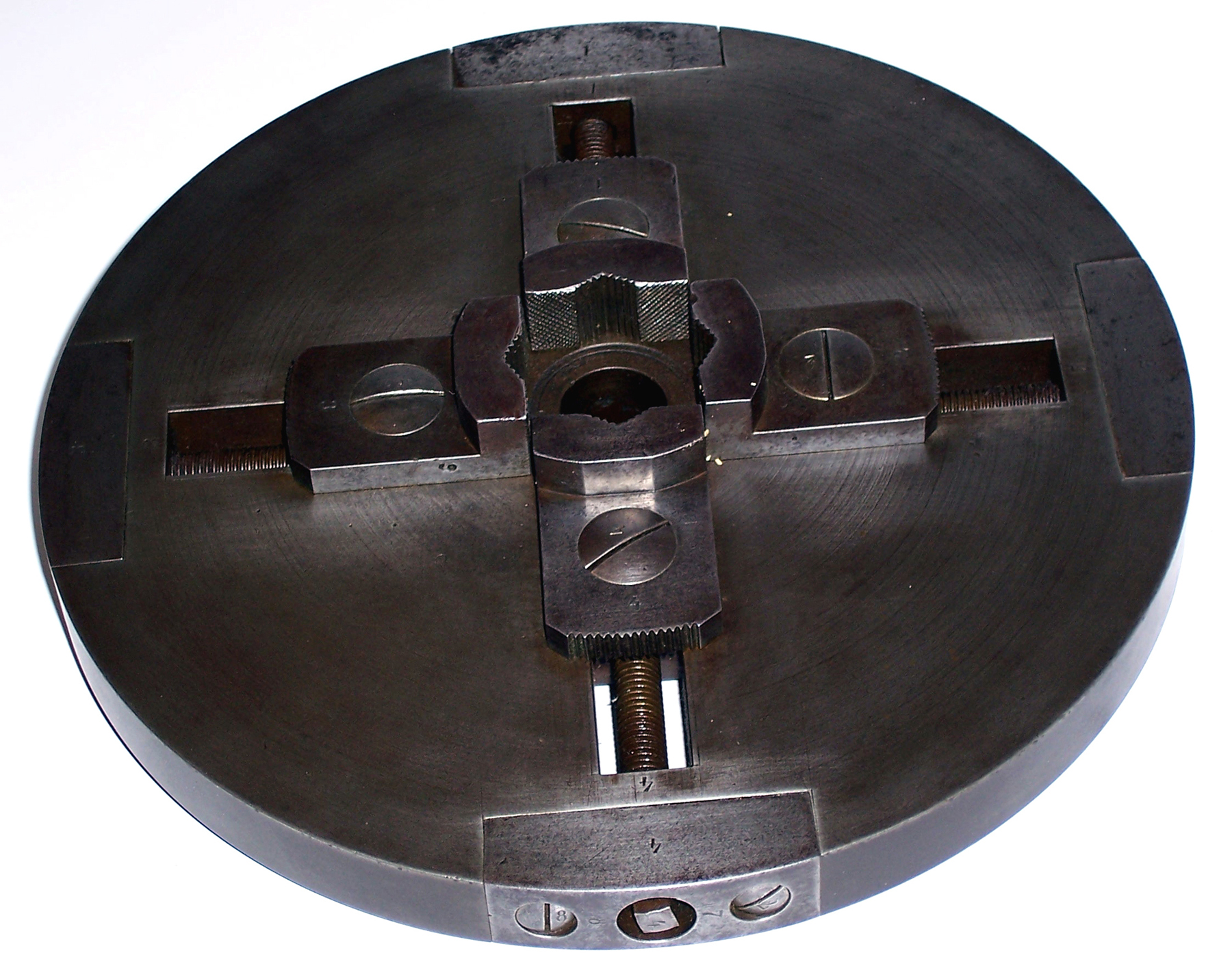

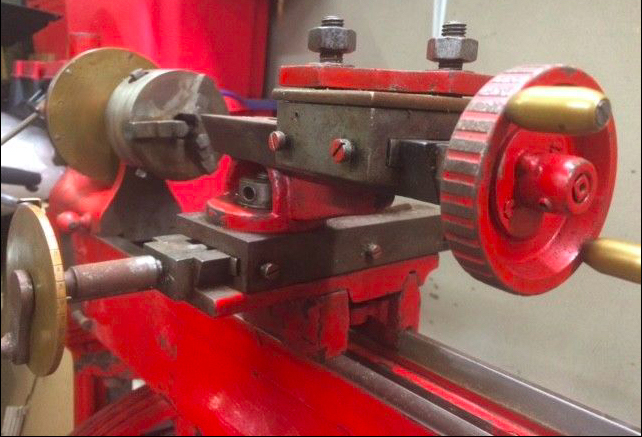

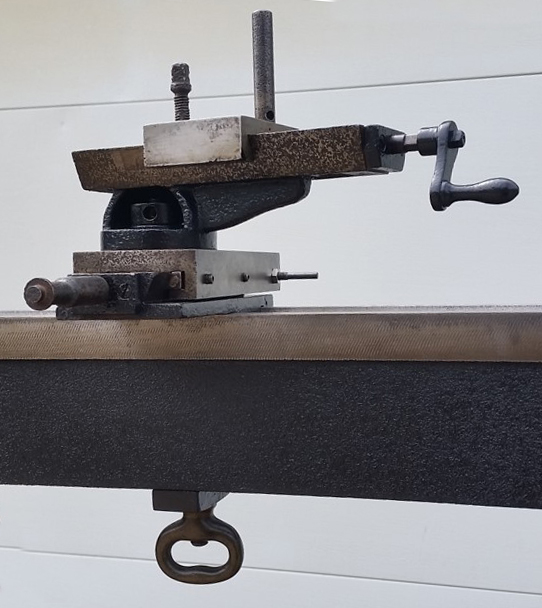

Unusually deep in section, the cast-iron bed carried just two ways, a V and a flat, these being shared by the carriage, hand T-rest and tailstock with all held in place by long through-studs fitted with rather fine-threaded hand rings in bronze. Driven by screws turned with the expected crank handles, the compound slide-rest was of almost modern appearance with a covered cross slide and 360° swivelling top slide, the latter with a simple triangular tool clamp.

Drive to the 7-step headstock spindle was by a foot-operated treadle turning a light flywheel machined with a pair of grooves, one for the higher speed and the other for the lower - the belt being allowed to angle sideways to pick up the required position on the headstock. Like most lighter lathes of its era, the stand was formed from cast-iron legs that extended rearwards to provide a platform on which was carried a handy wooden tool tray, this being pierced behind the headstock to allow the headstock drive belt to pass through.

Should you have a Hamann lathe, the writer would be interested to hear from you..

Some pictures are high-resolution and may be slow to open

|

|