|

Continued:

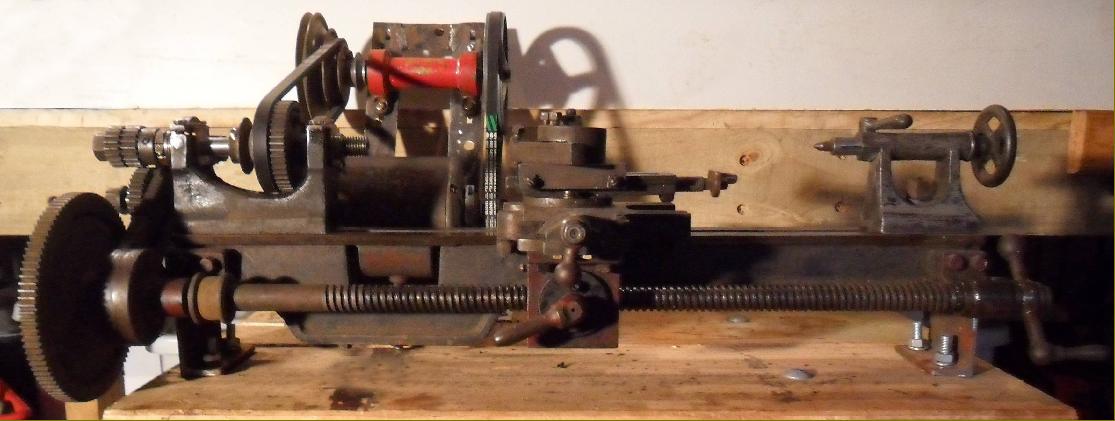

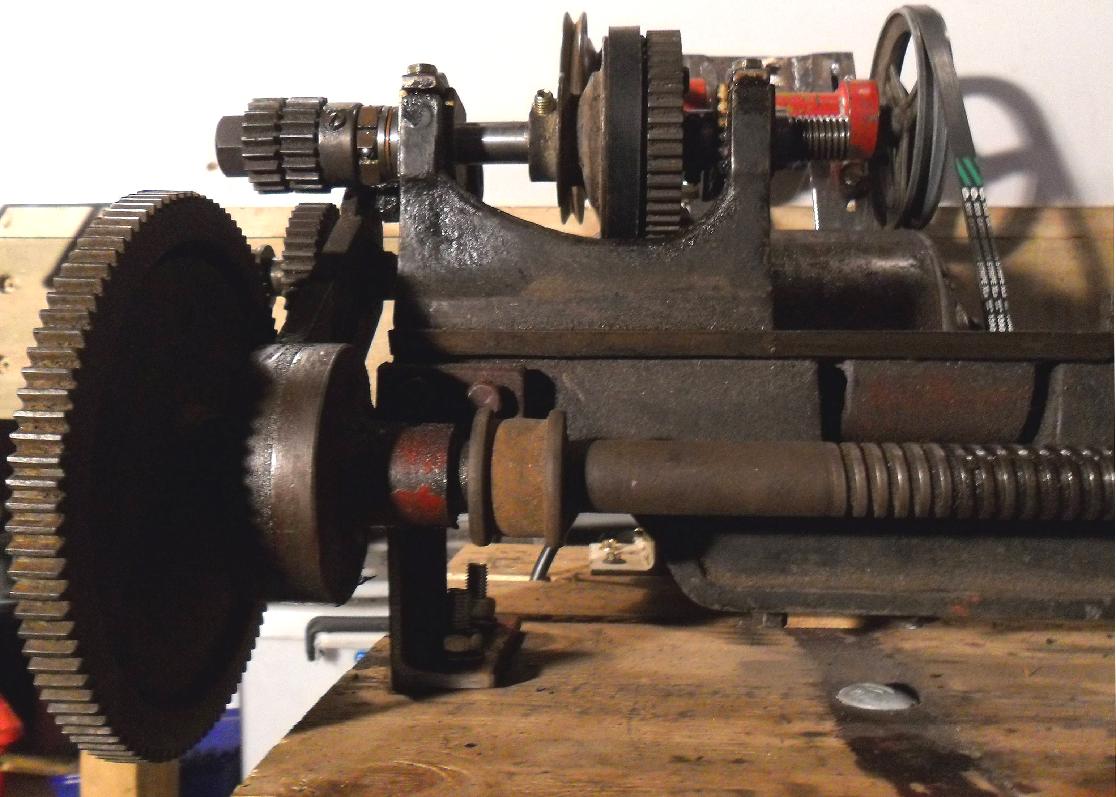

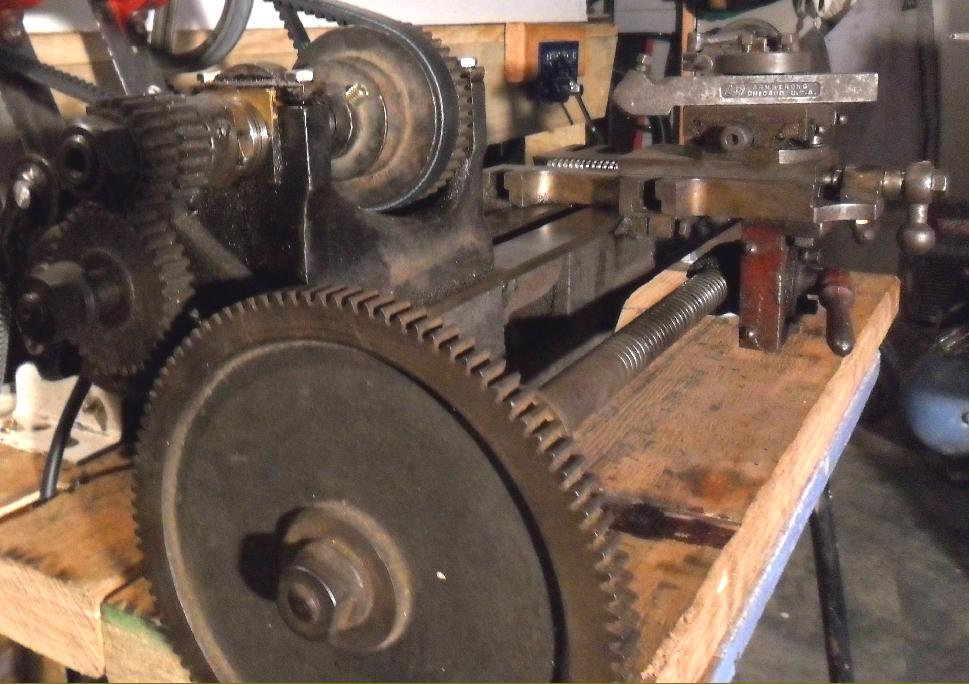

With two headstock bearings, and end thrust taken against an outrigger assembly bolted to the end face of the headstrock, the spindle of the "Progress" was solid, an indication that the design dated back until at least the late 1890s, the arrangement having largely died out on larger lathes by the start of the 20th century. The maker's claim that the gearing was: "of correct proportions such that a sweet and steady drive, without chatter or vibration" was pure hyperbolae, the one fault almost guaranteed with light lathes of this era being their uncanny ability to synchronise frequencies and "chatter" at the slightest provocation. Intended to take a round leather (gut) rope drive, both lathes had "nicely polished" 3-speed headstock pulleys in cast iron - though "polished" was almost certainly a euphemism for a part left as-cast. However, to be fair, this was at a time when it was not unusual to find the very cheapest lathes fitted with such components in wood.

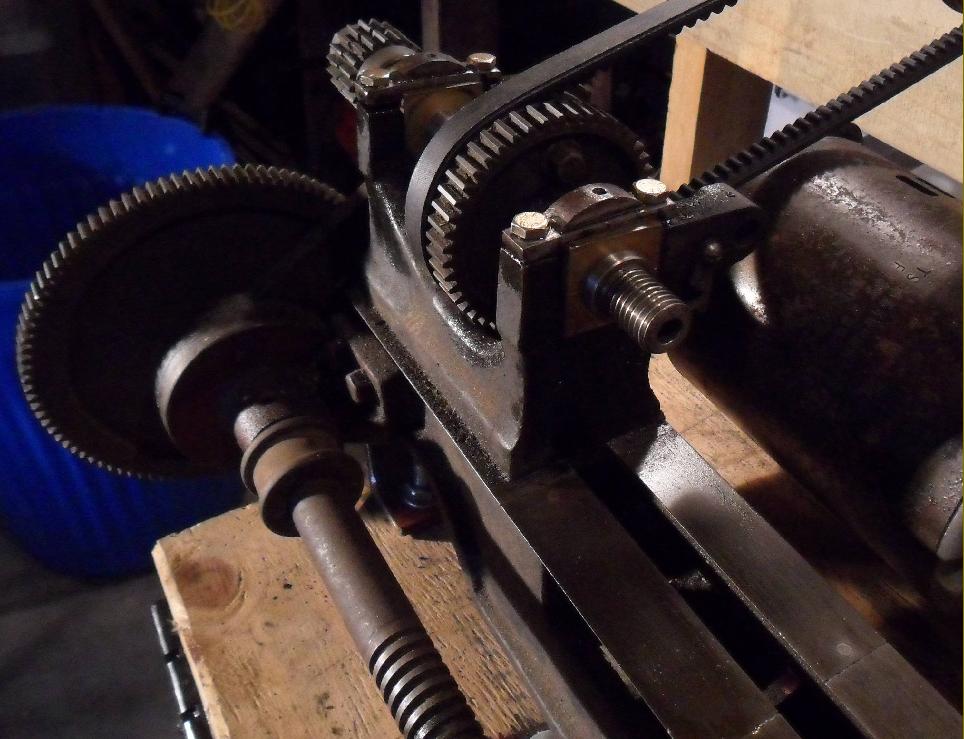

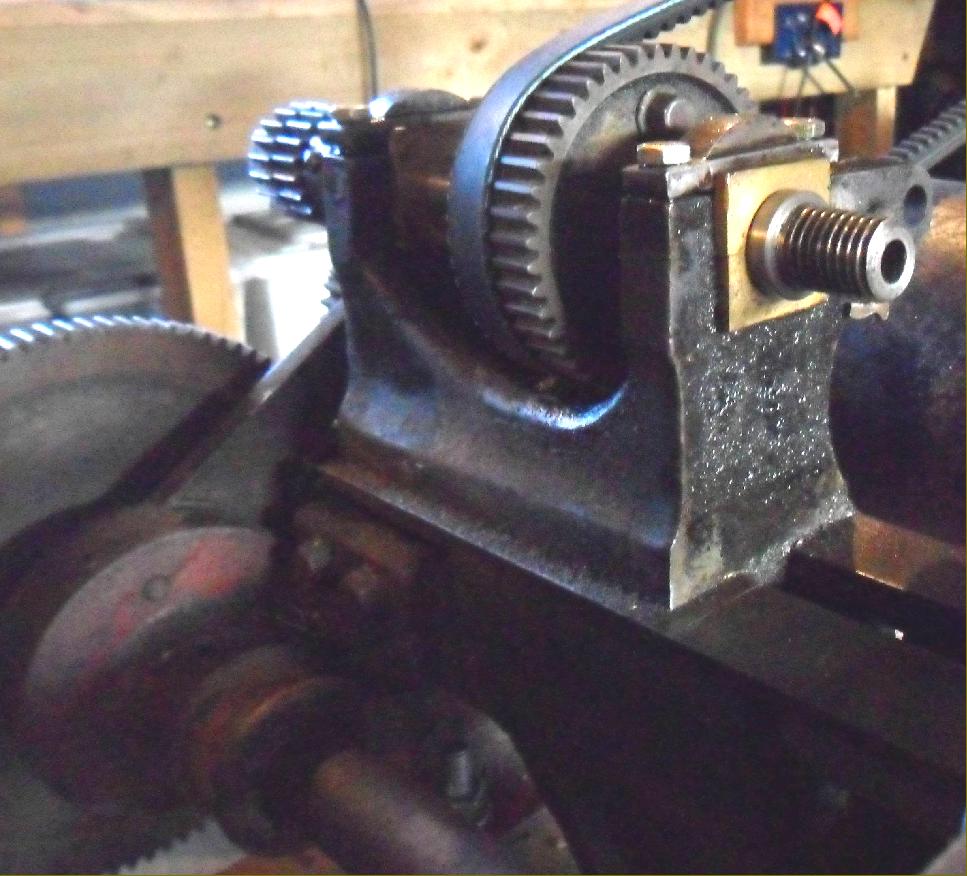

Bed ways were planed - no doubt several were ganged up on the table and machined together - and a hint given that hand finishing was employed to "fit them up". The tailstock, or loose headstock as it was then commonly referred to in the United Kingdom, was fitted with a polished cast-iron handwheel driving a (steel) feed screw and barrel, though the latter was locked by a simple pressure screw. No. 1 Morse centres were used in headstock and tailstock, both in Best Tool Steel. The backgears of the "Progress" were machined from a one-piece casting - the makers taking pains to point out the disadvantages of the cheaper construction used on competing machines with gears keyed to a shaft (or even gears left "as cast") - and slid into position. However, examination of one of the few surviving "Progress" models would seem to indicate that the screwcutting changewheels were of the much cheaper "as cast" variety

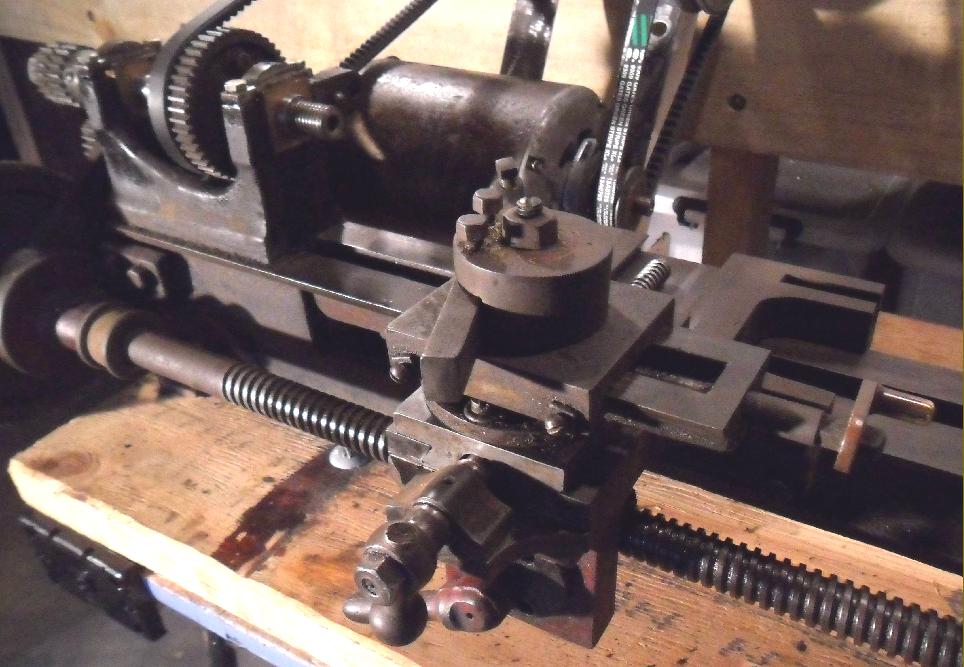

By 1913 the "Leader" had changed somewhat and was being described as: the cheapest Hollow Spindle lathe in the World. Price is only 21s). The hollow spindle (bored through 3/8") was possible because, fitted with two adjustable taper bronze bearings, end thrust could be taken against the inside of the lefty-hand bearing instead of on an old-fashioned style of outboard plate as previously. Fitted with a 5/8" Whitworth-thread nose the spindle carried a fully-machined 3-step gut rope pulley, the use of as-cast parts no doubt being abandoned due to their less-than-smooth running. The tailstock was also improved with a properly-made, square-thread "machine-cut" barrel feedscrew (the first model is likely to have had an ordinary Whitworth thread) and, most important of all, a split-clamp lock. A compound slide rest could be specified for an additional 18 shillings and sixpence as could a 3-inch ring-scroll 3-jaw chuck, though at £1 : 2s : 6d this cost more than the basic lathe.

Although in advertisements the maker's label says "Goodwins" some literature has the company as "Goodwin". However, in common with many other manufacturers, their name did not appear on the actual lathes. In addition to the then ubiquitous black enamel, Goodwin customers could choose from amongst finishes in dove, blue or green.If you have what appears to be a Goodwin lathe the writer would be interested to hear from you..

|

|