|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E-MAIL Tony@lathes.co.uk

Home Machine Tool Archive Machine-tools for Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues

Belts Books Accessories

Fritz Werner

Standard & Production Milling Machines of the Late 1940s and 1950s

Werner Production & Special Milling Machines

Operation Manuals and other literature is available for Fritz Werner machines

Founded in Berlin, in 1896, by Dr. e.h. Friedrich Carl Werner, the Fritz Werner company was named after his son, Fritz. Werner was a highly qualified mechanical engineer who had previously worked in the arsenal of the German emperor and had wide experience of military weapons and ammunition. Consequently, the company's first products were of this type and, as they required the highest standards of design and quality control, a sound reputation for top-class engineering was soon built up. The next stage was to design and manufacture high-grade machine tools with both toolroom and production examples of lathes, milling machines, tool and cutter grinders, cutting tools and machine-tool accessories of all kinds being offered.

After World War II, with little demand for their previously sought-after products, the company was nationalised and continued to make both machine tools and ammunition, production of the latter being moved (sensibly, given the political situation at the time) from Berlin to the scenic town of Geisenheim in the Rhine Valley. In 1957 Werner established a separate company, based in Nassau, Metallwerk Elisenhütte GmbH, to manufacture ammunition for German forces and other NATO defence forces. By 1990 Fritz Werner was back in private hands and continues to this day as a maker of ammunition, a builder of turn-key munitions' manufacturing plants and as world-wide technical advisors and development engineers concerning all manner of weapon production.

Over many decades Fritz Werner made a vast range of milling machines for toolroom, repair shop and production use - the ones shown on these pages are the regular production models from the late 1940s until the late 1950s. Millers were classified by size - these being, generally, from 0 through 1, 2, 3, 4, 5, etc. and also by category and function: Knee-Type Vertical and Horizontal, Bed-type, Unit-assembled Bed Type, Universal, Production Vertical, Production Horizontal, Production Universal, Surface Milling, Duplex (twin head), Combined, Automated, Semi-automatic, , Super Finish, Profile, Double Spindle Copying, and Special, etc. In addition Werner would construct special models and, to order, one-off machines to a customer's particular requirements, for example, the milling of jet-engine turbine blades or a machine able to form square of elliptical holes in long workpieces. A wide range of accessories was offered including slotting heads; vertical and universal double-swivel vertical heads; powered overarms with internal gearing to convert horizontal machines into fully-functional vertical, rotary tables; universal, semi-universal and hand-operated vertical horizontal dividing heads; an automatic indexing mechanism for the table feed; rack milling attachments; machine vices of all kinds; cutters and cutter holders Unlike the machines from many competitors, Werner always marked their machine tools with an exact model type - making it so much easier to determine exactly which version is which..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

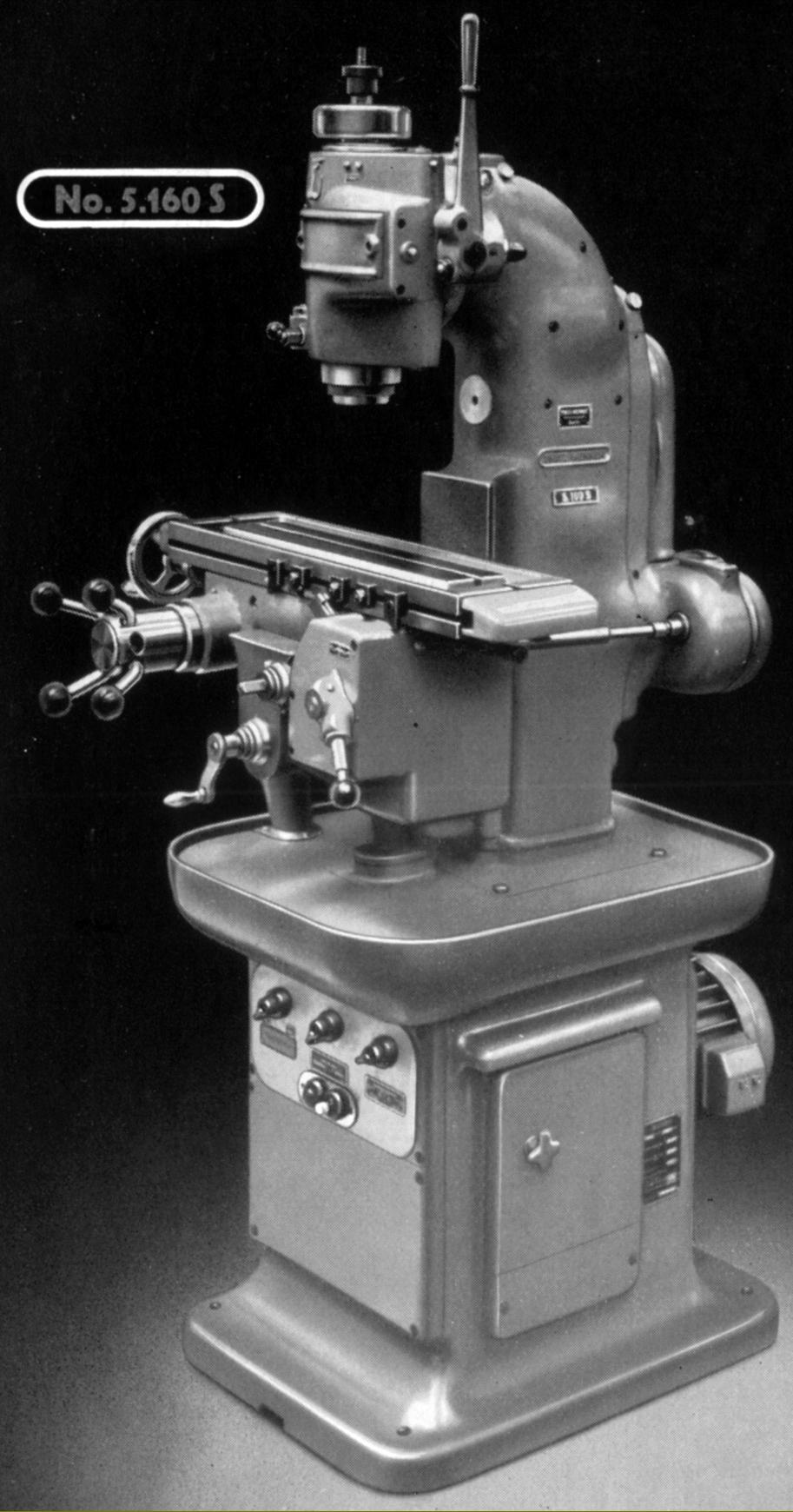

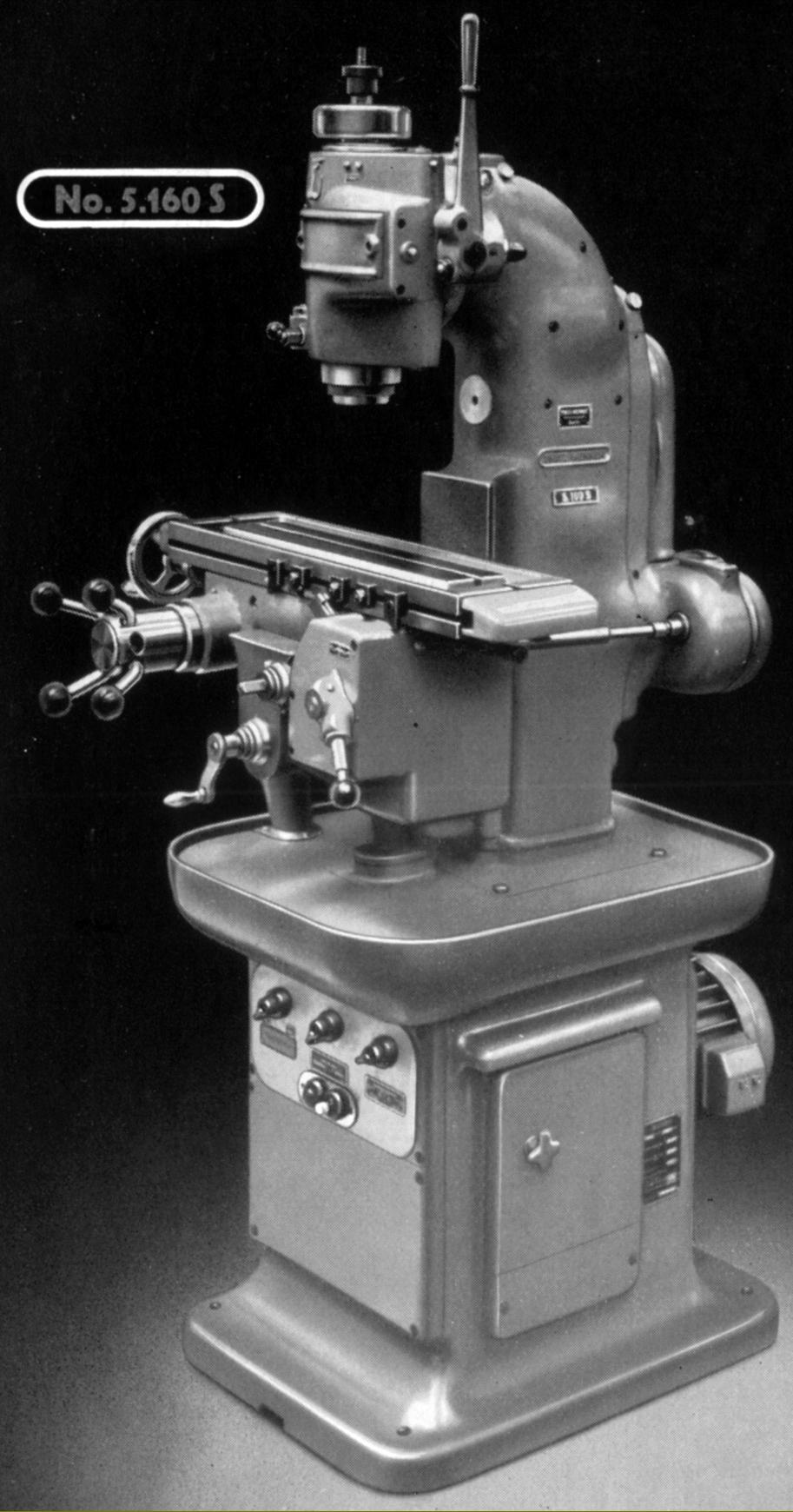

Fritz Werner Size 0 vertical milling machine No. 5.160S. This machine used the same knee and table assembly as the horizontal miller No. 5.160W and was listed as a "Production" type. When listed as the 5.160SW it was fitted with an integrated overarm and vertical head that transfomed it into a dual horizontal/vertical model sold as the "Combined Production" type.

Table 560 x 160 mm with, using power feed, 200 mm of longitudinal travel and, by hand only, 100 mm in traverse and 180 mm vertically. The standard 16 longitudinal feeds ranged from 4.8 to 150 mm per minute or, optionally, either 9.6 to 300 or 14.4 to 450 mm/min. 16 spindle speeds were available spanning 96 to 3000 r.p.m. Drive came from a 2.1 h.p. motor and the miller weighed around 500 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

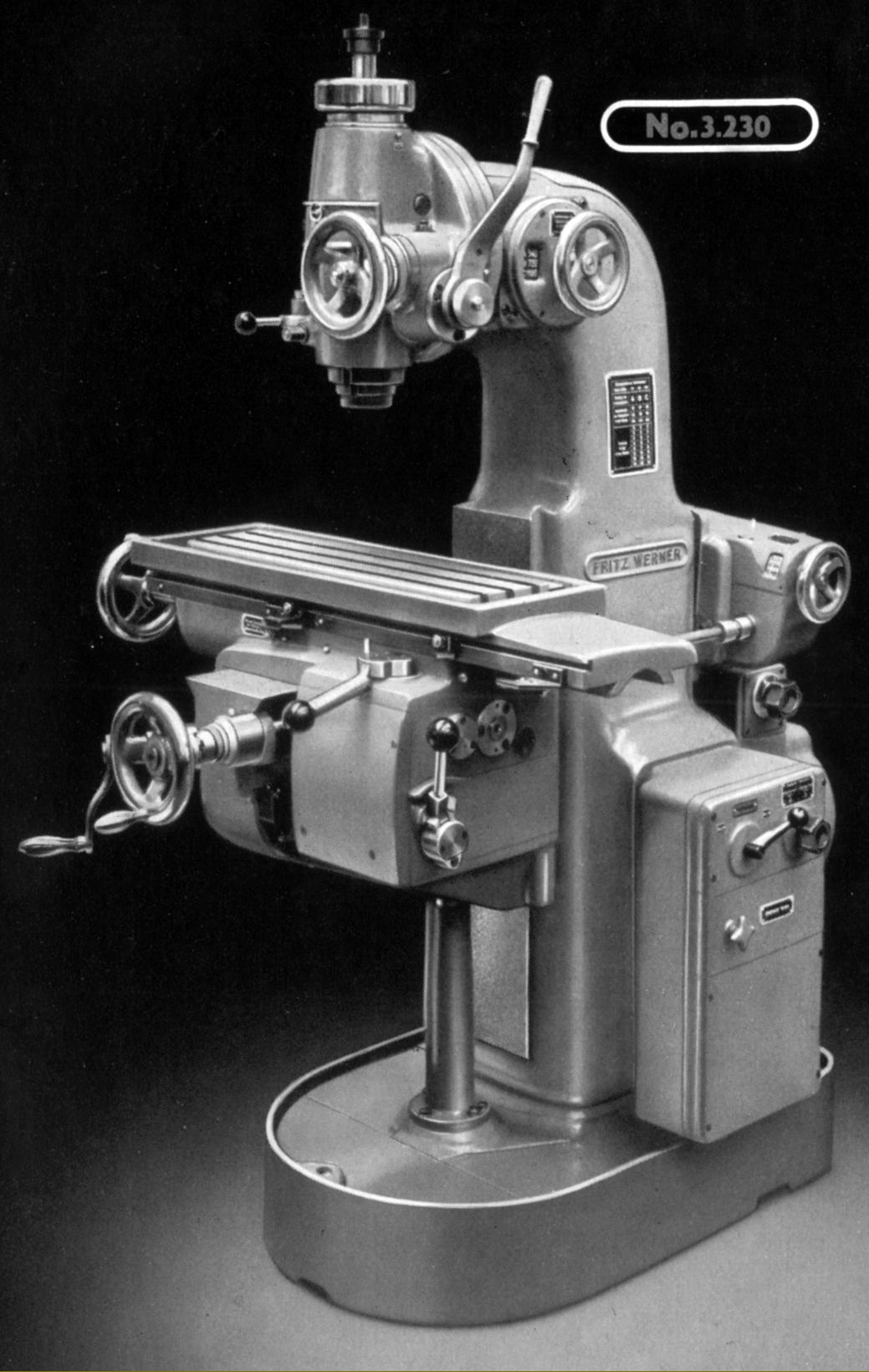

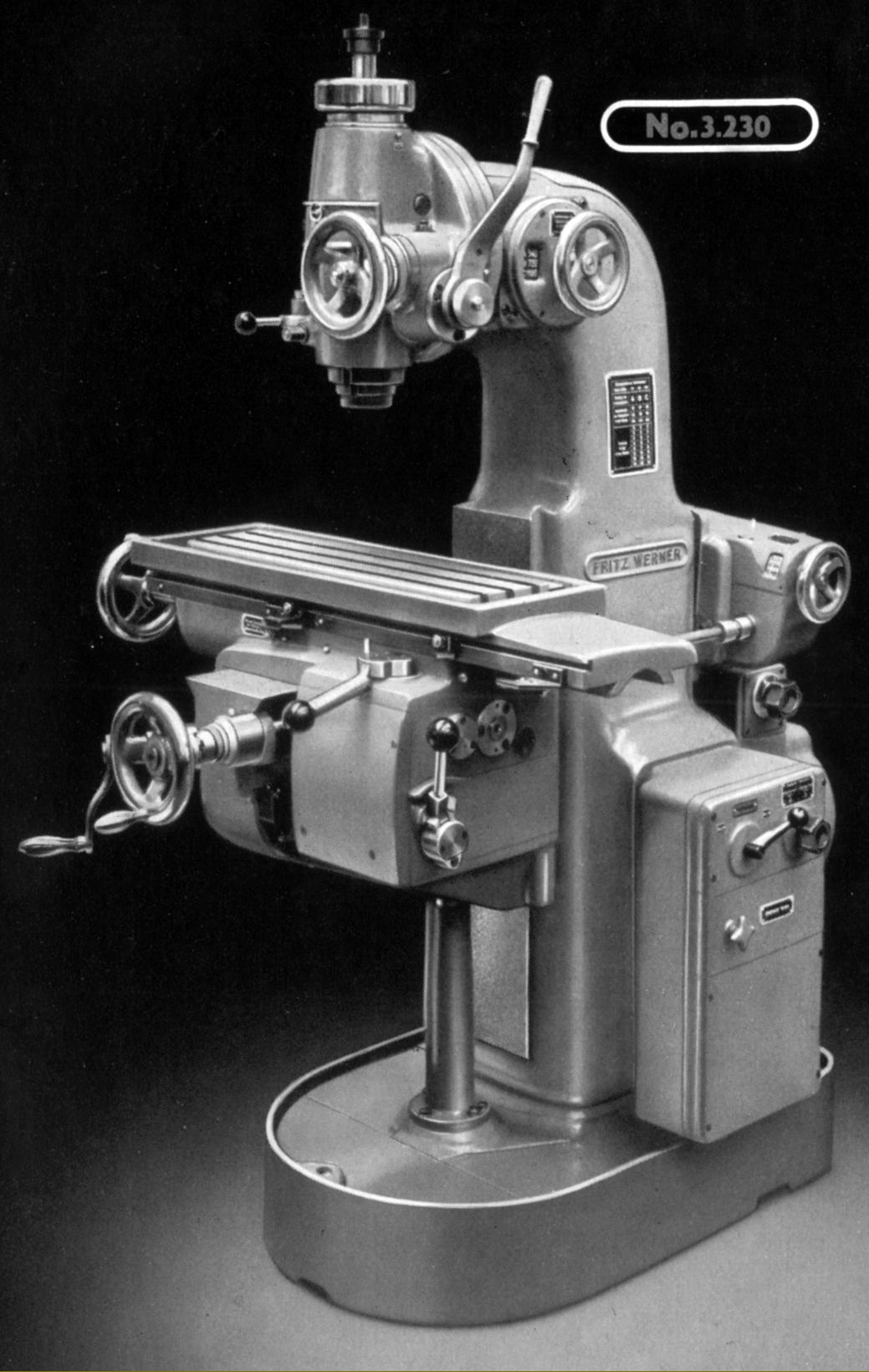

Fritz Werner Size 1 vertical milling machine No. 3.230. This machine used same knee and but slightly shorter table assembly from the horizontal type 4.100 Table 700 mm x 225 mm with, using power feeds, 400 mm of longitudinal travel and 220 mm in traverse. Vertical feed, at 400 mm, was by hand only. Each power feed had 8 ranges for each of the three motor speeds, these varying from 10 to 480 mm per minute. 9 spindle speeds were available spanning 96 to 1500 r.p.m. or, optionally, 192 to 3000 r.p.m. Drive came from a 2 h.p. motor and the miller weighted around 980 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

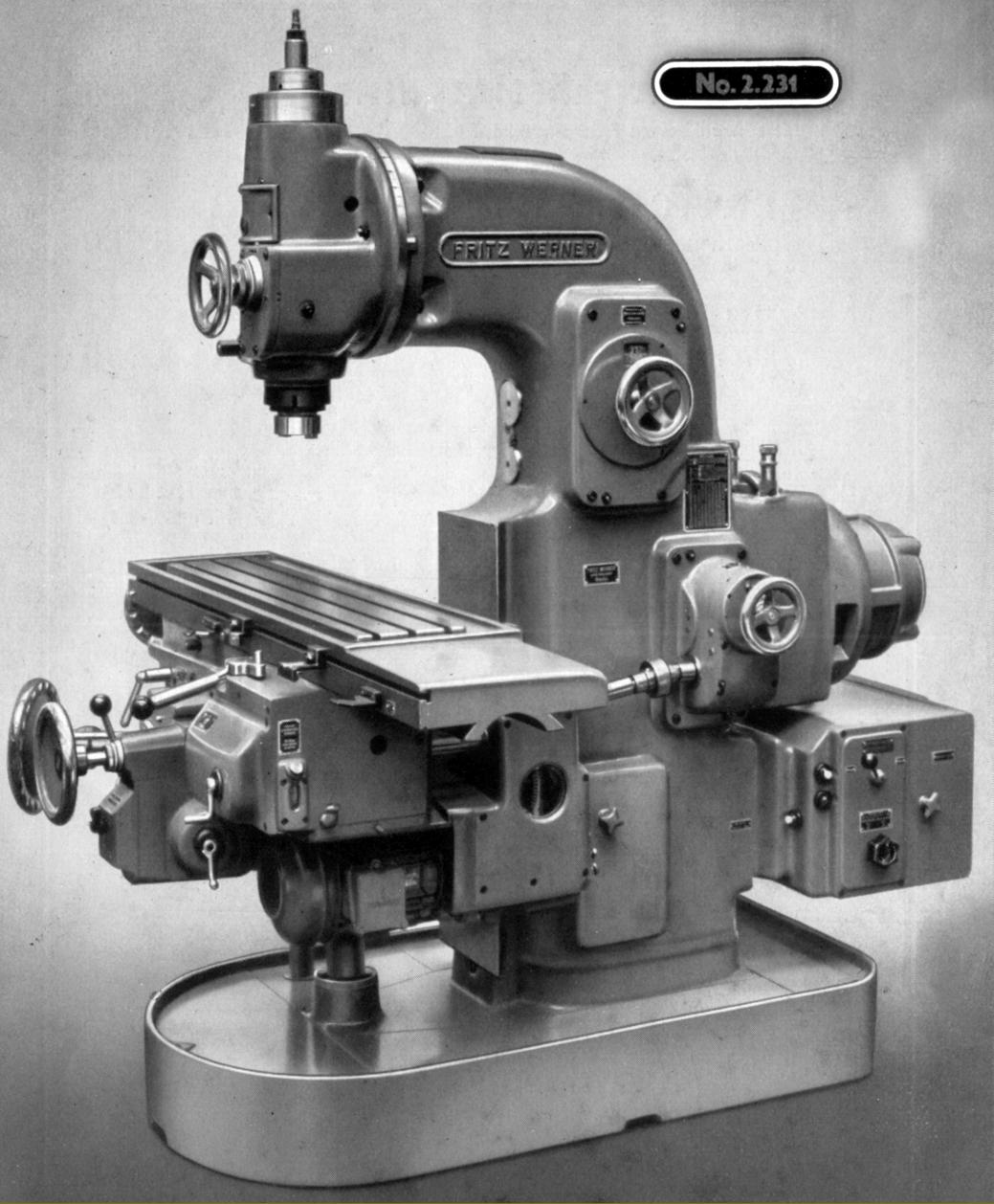

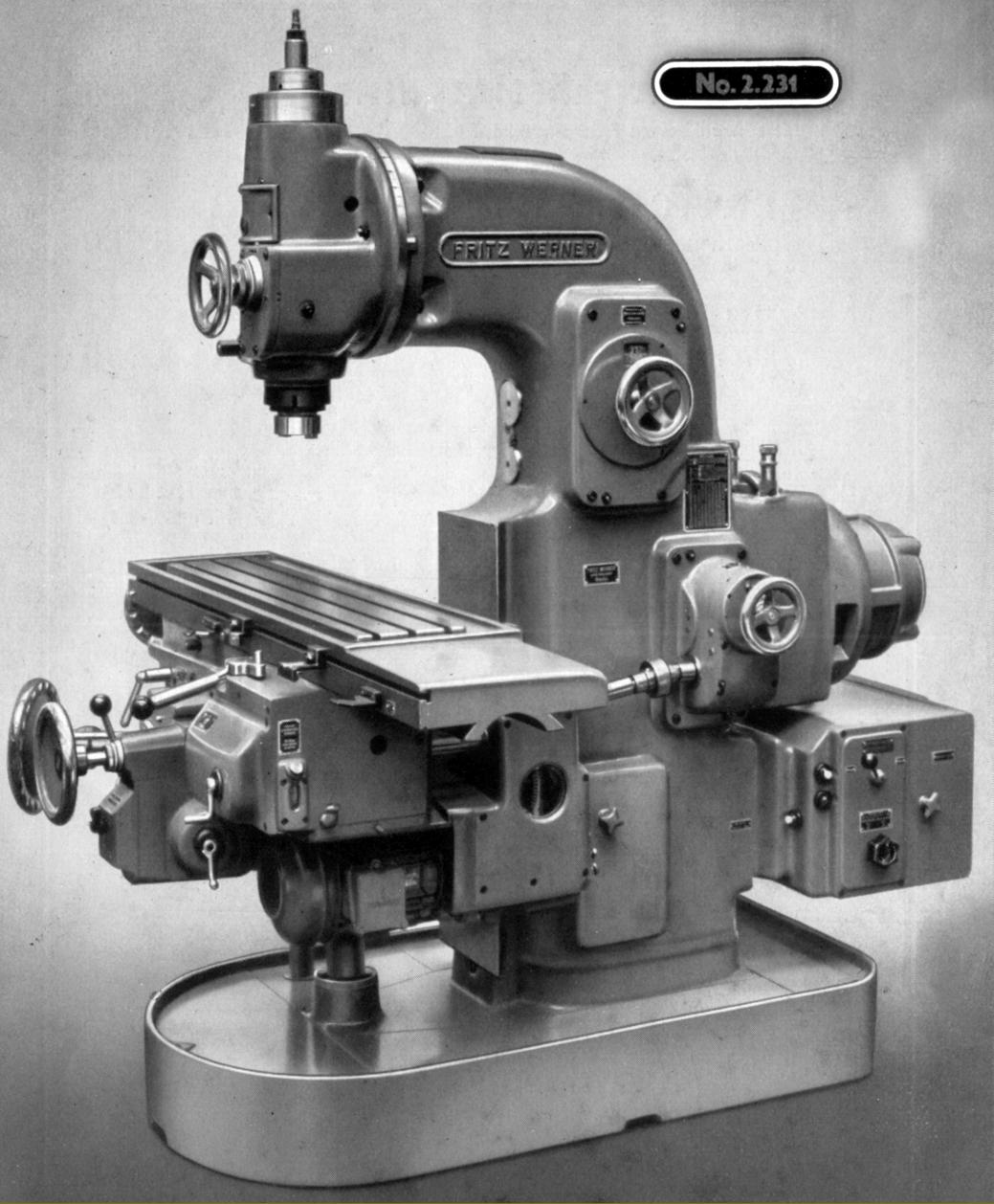

Fritz Werner Size 2 vertical milling machine No. 2.231 This machine used the same knee and table assembly as the horizontal type 2.201

Table 1100 mm x 310 mm with, using power feeds, travels of 650 mm longitudinally, 235 mm in traverse and 425 mm of vertically. The 16 longitudinal and cross feeds ranged from 10 to 300 mm per minute and vertical from 5 to 150 mm. 18 spindle speeds were available spanning 34 to 635 r.p.m. or, optionally, 80 to 1500 r.p.m. . Drive came from a 8.8 h.p. motor and the miller weighed around 2200 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

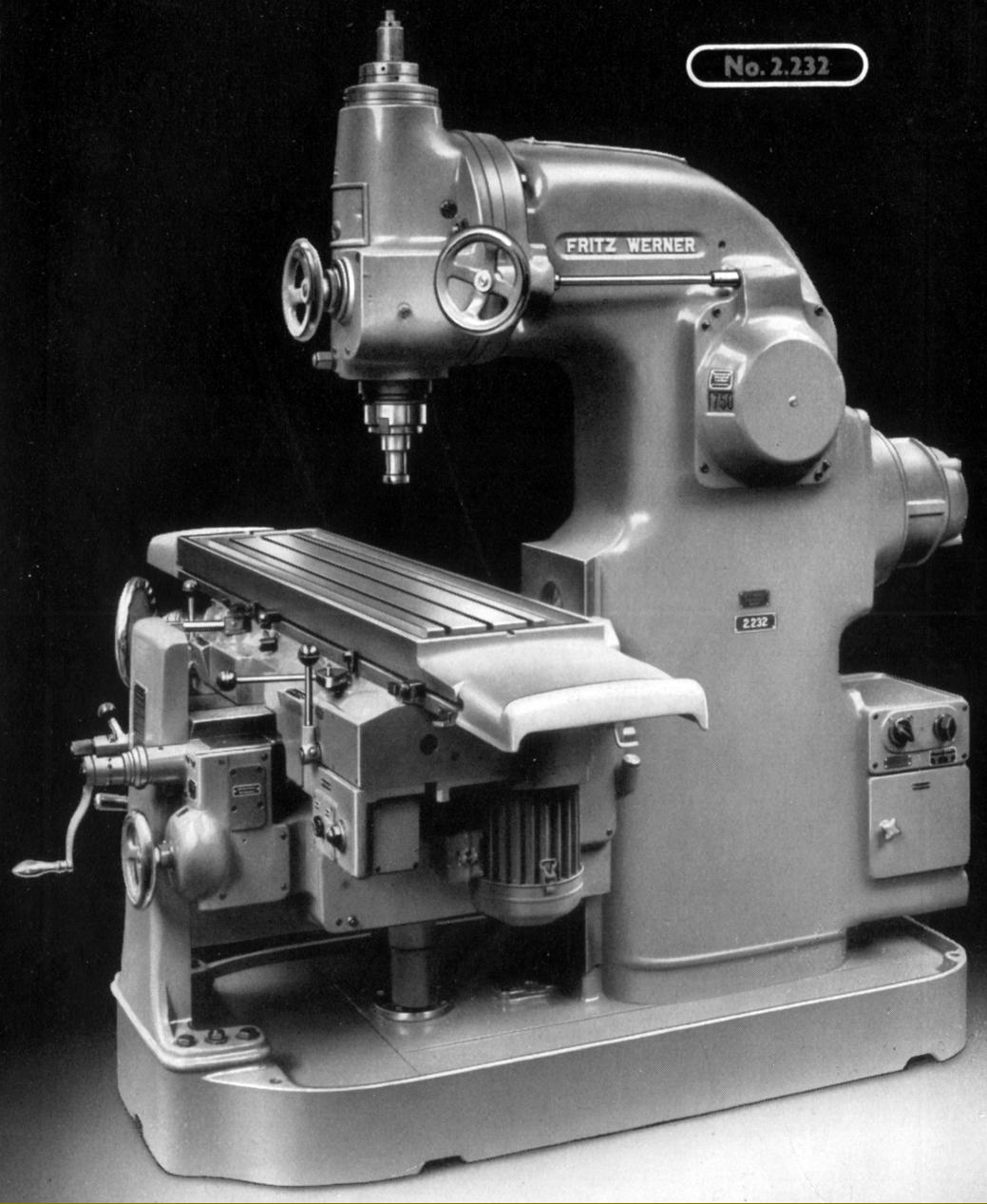

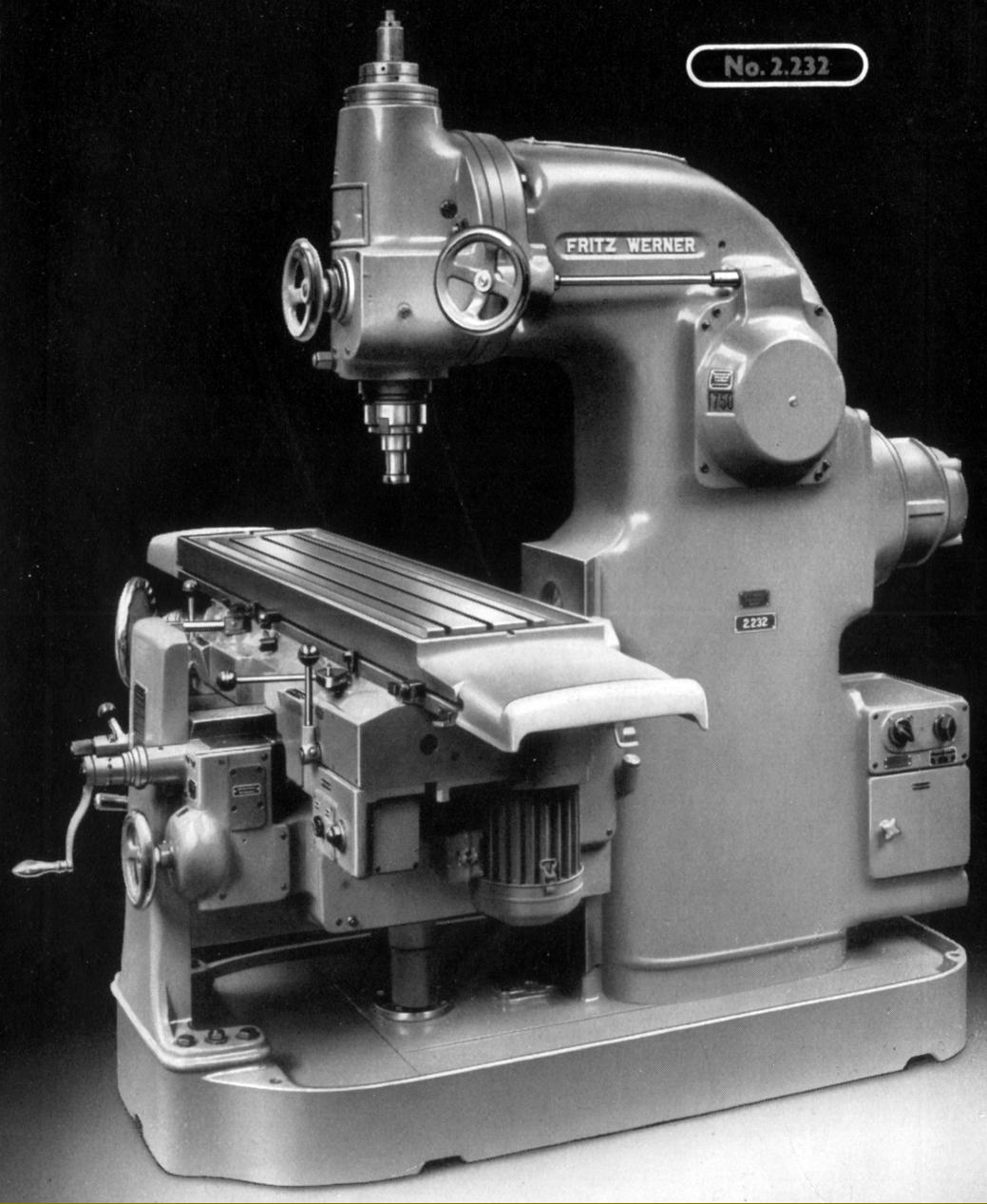

Fritz Werner Size 3 vertical milling machine No. 2.232. This machine used the same knee and table assembly as the horizontal type 2.202 Table 1600 mm x 360 mm with, using power feeds, travels of 1120 mm longitudinally, 315 mm in traverse and 405 mm vertically. The 18 longitudinal and cross feeds ranged from 10 to 480 mm per minute and vertical from 7.5 to 360 mm. 18 spindle speeds were available spanning 15 to 750 r.p.m. or, optionally, 24 to 1200 r.p.m. Drive came from a 11.4 h.p. motor and the miller weighed around 4000 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

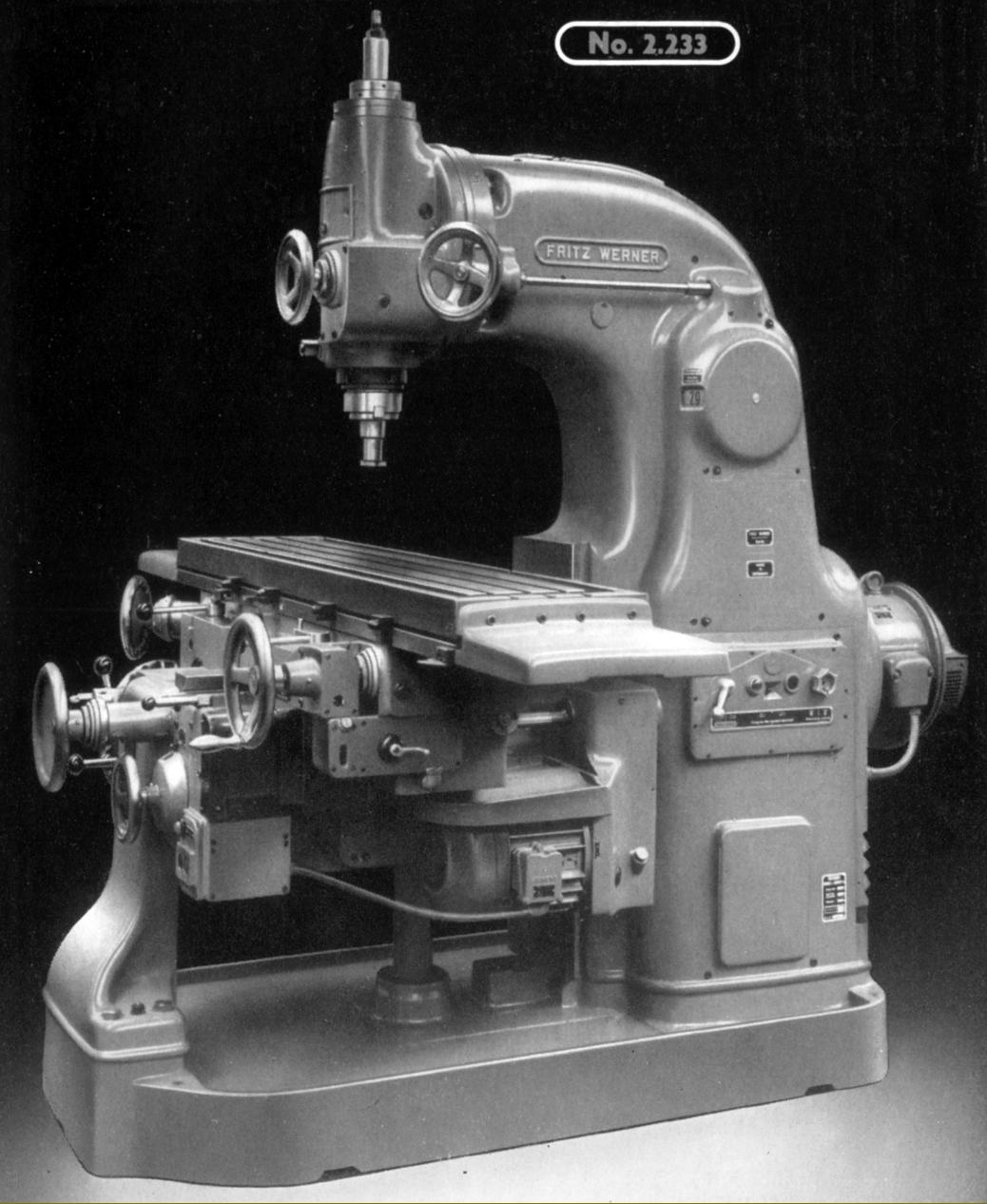

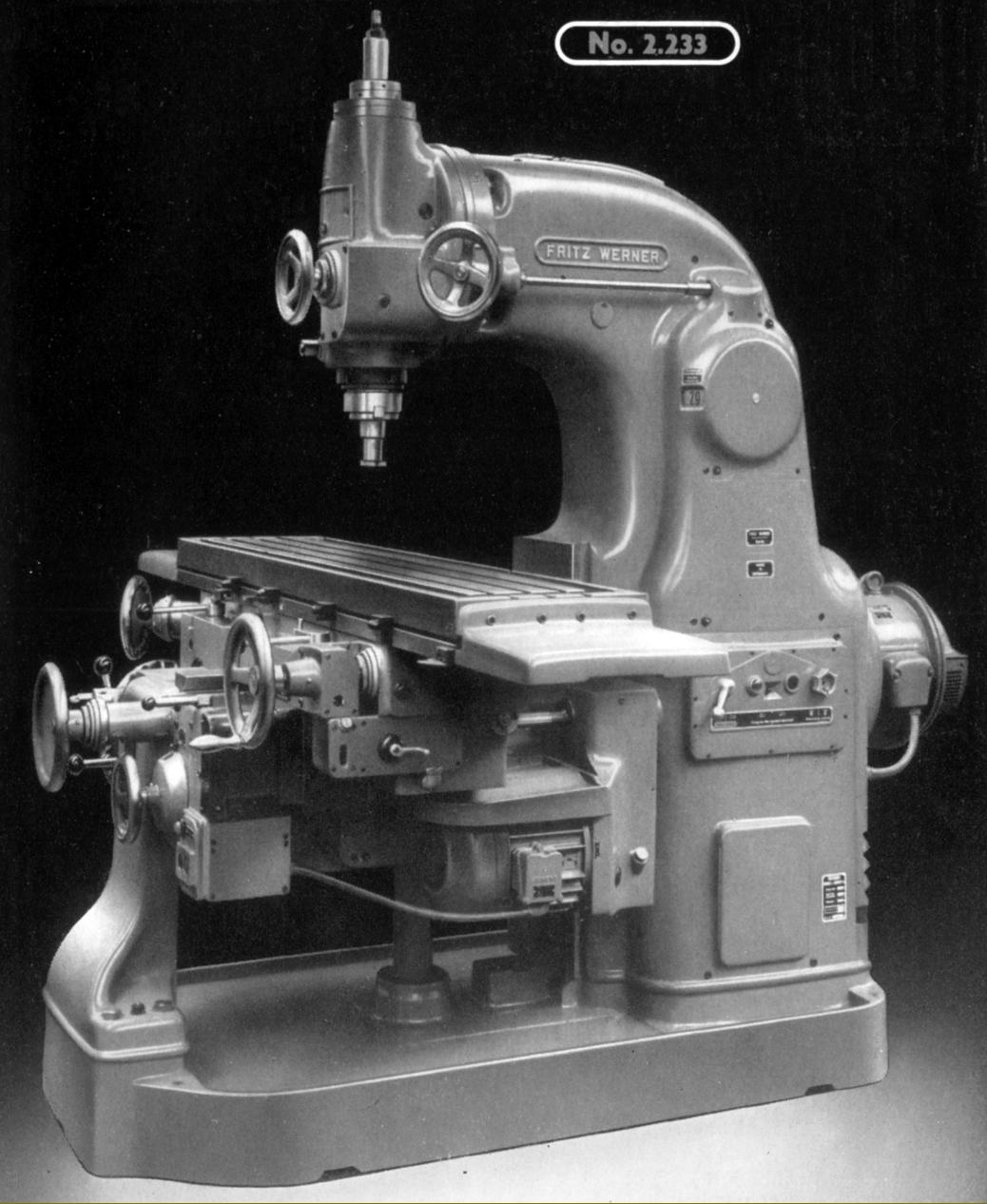

Fritz Werner Size 4 vertical milling machine No. 2.233. This miller used the same knee and table assembly as the horizontal Type 2.203

Table 1800 mm x 400 mm with, using power feeds, travels of 1200 mm longitudinally, 380 mm in traverse and 440 mm vertically. The 18 longitudinal and cross feeds ranged from 10 to 480 mm per minute and vertical from 5 to 240 mm. 18 spindle speeds were available spanning 15 to 750 r.p.m. or, optionally, 24 to 1200 r.p.m. Drive came from a 25 h.p. motor and the miller weighed around 5000 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

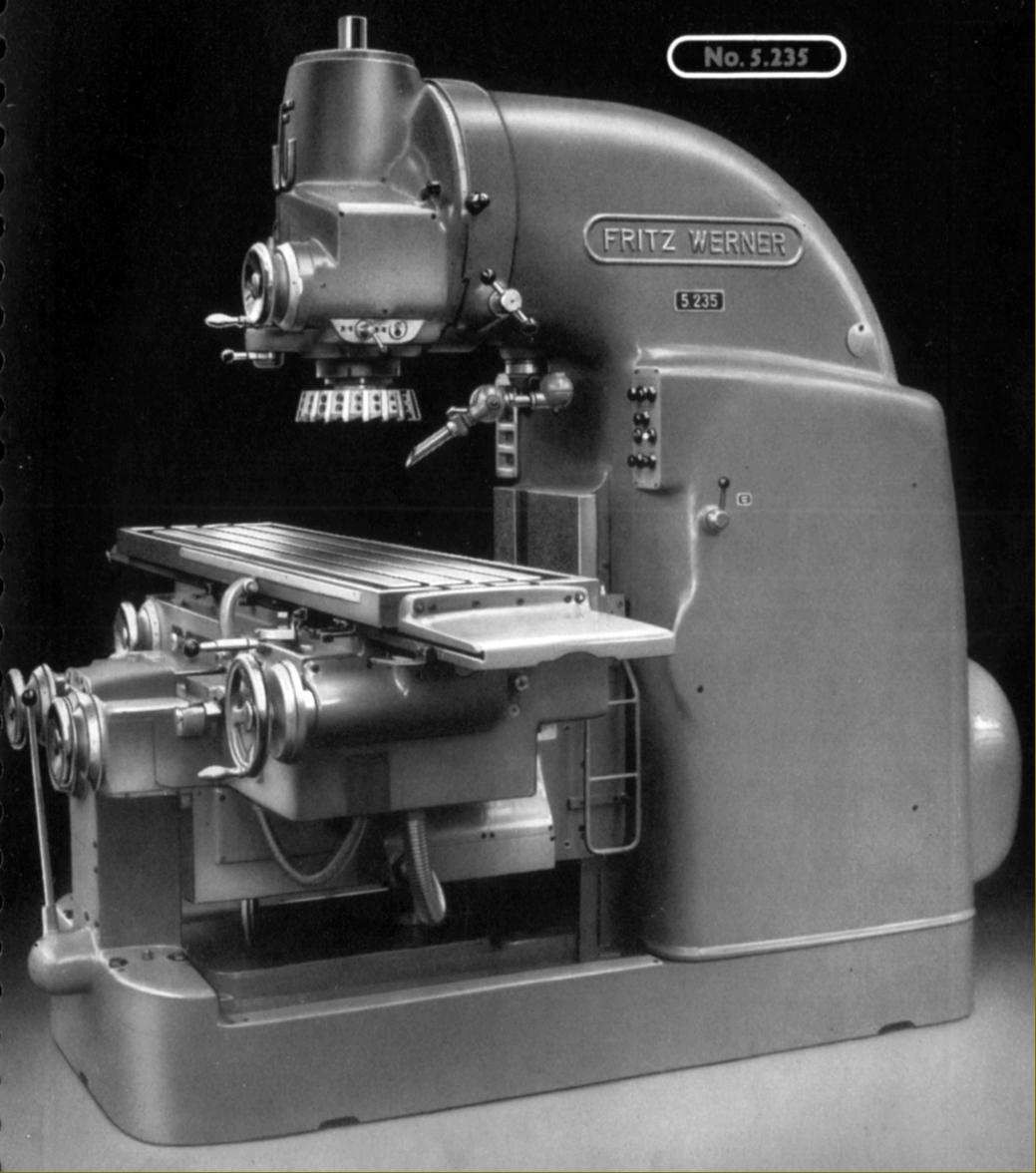

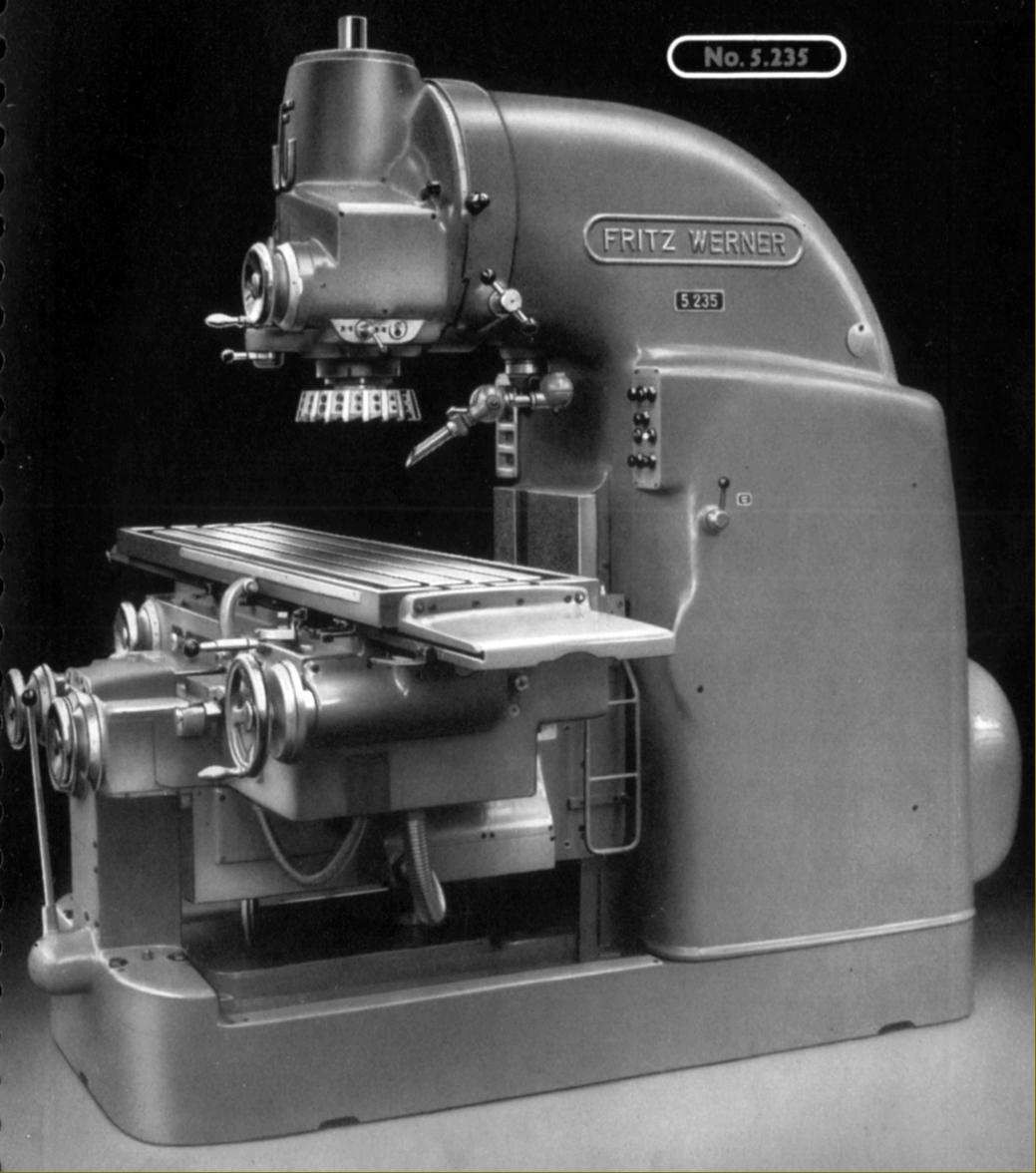

Fritz Werner Size 5 vertical milling machine No. 5.235. This miller used the same knee and table assembly as the horizontal Type 5.205

Table 2300 mm x 500 mm with, using power feeds, travels of 1400 mm of longitudinally, 400 mm in traverse and 510 mm vertically. The 50 longitudinal and cross feeds (including rapids) ranged from 7 to 2000 mm per minute and vertical from 3.5 to 1000 mm. 42 spindle speeds were available spanning 16 to 1800 r.p.m. Drive came from a 40 h.p. motor and the miller weighed around 11,000 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

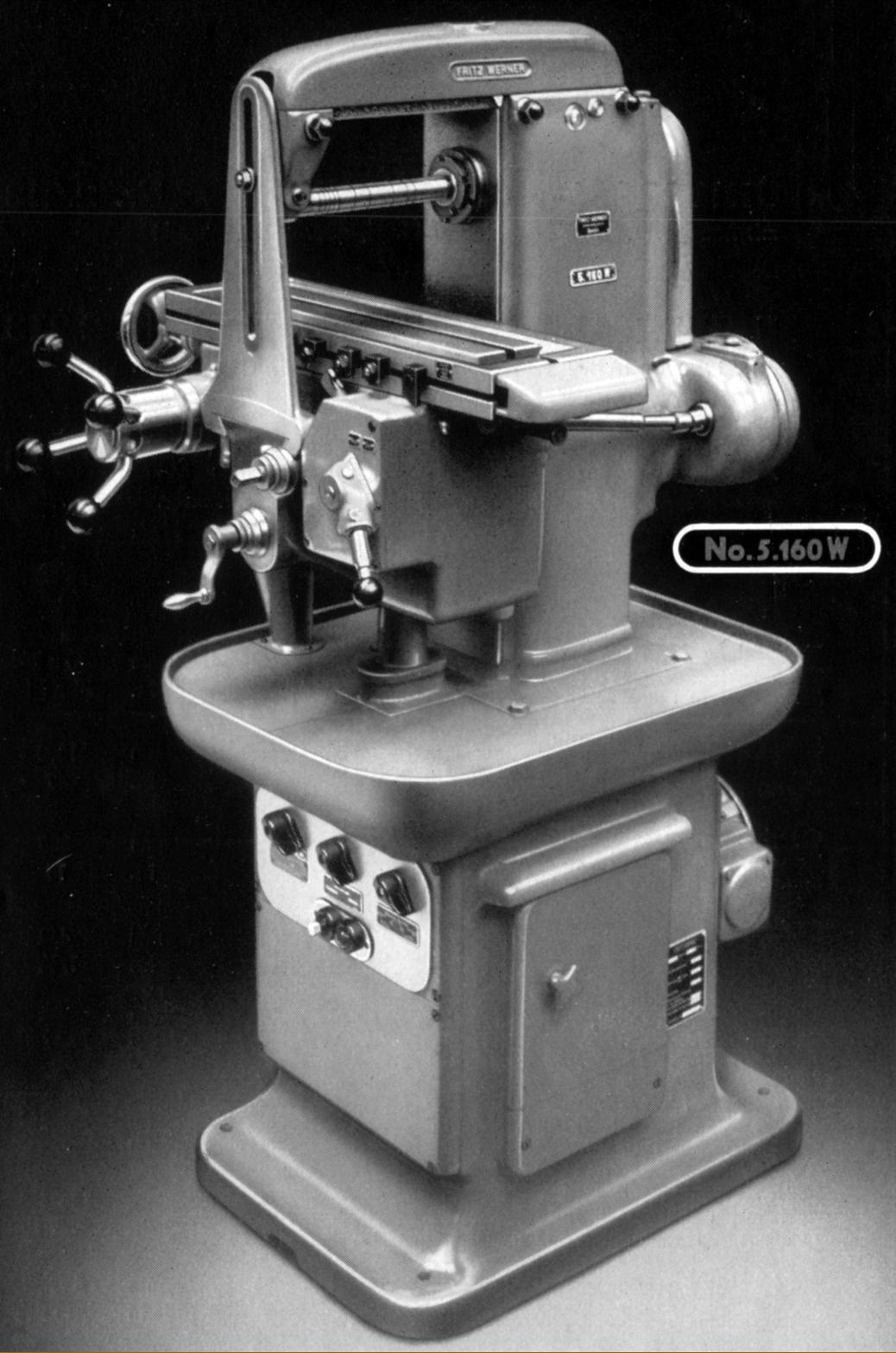

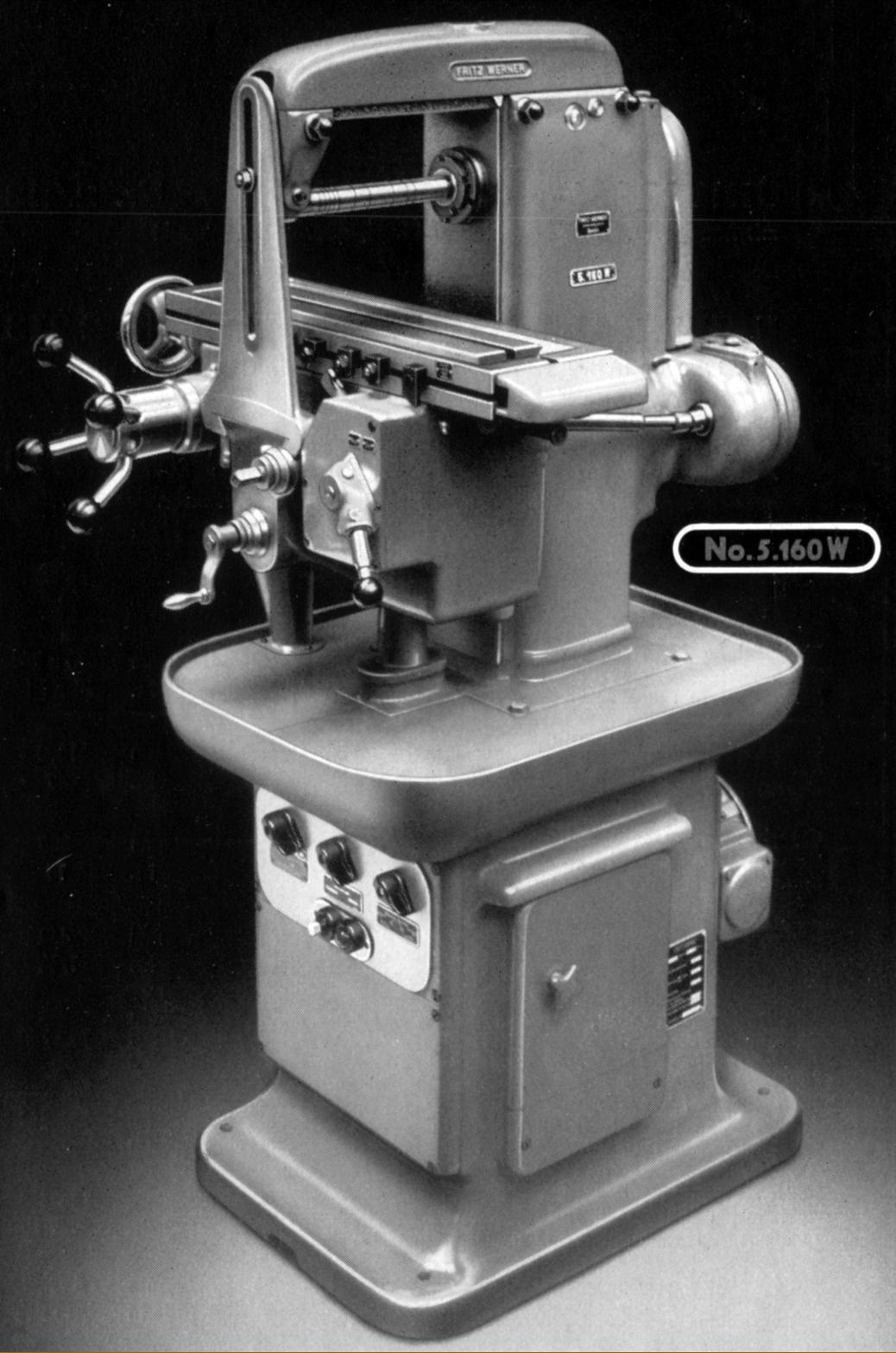

Fritz Werner Size 0 horizontal milling machine No. 5.160W When listed as the 5.160WS it was supplied with a vertical head driven from the horizontal spindle.

Table 560 x 160 mm with, using power feed, 200 mm of longitudinal travel and, by hand only, 100 mm in traverse and 180 mm vertically. The 16 longitudinal feeds ranged from 4.8 to 150 mm per minute or, optionally, either 9.6 to 300 or 14.4 to 450 mm/min. 16 spindle speeds were available spanning 96 to 3000 r.p.m.. Drive came from a 2.1 h.p. motor and the miller weighed around 500 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

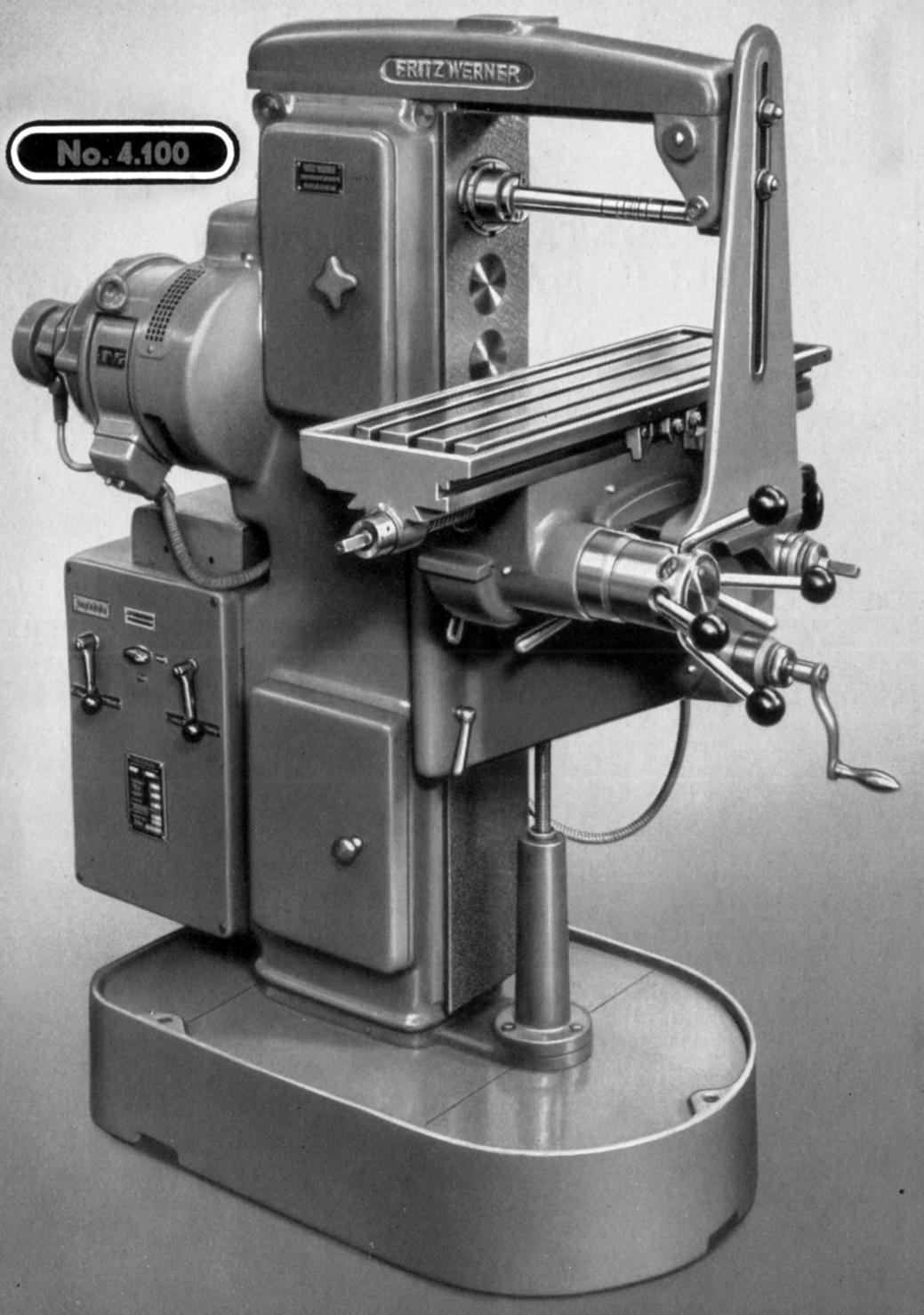

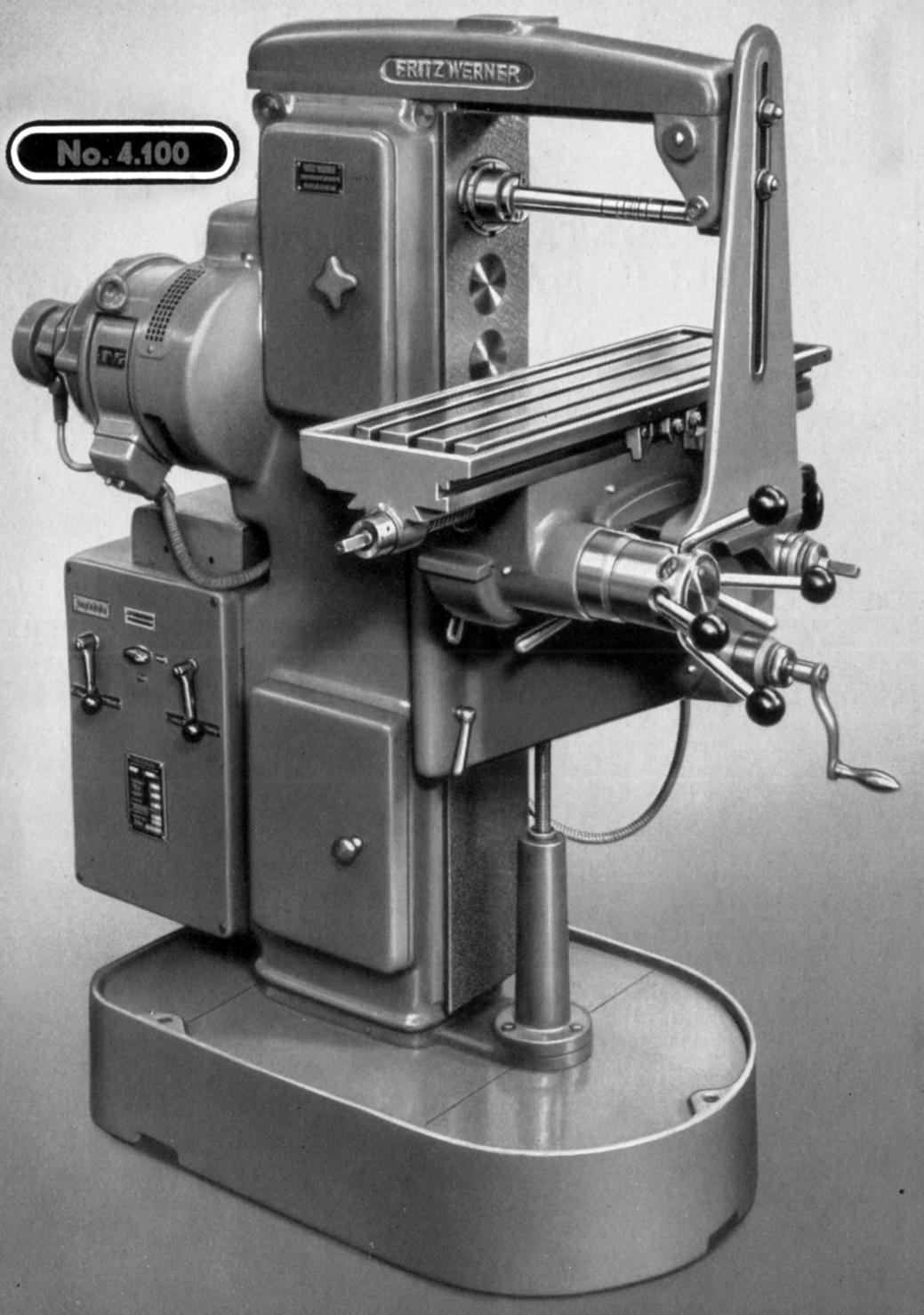

Fritz Werner Size 1 horizontal milling machine No. 4.100 listed as a "Production" type.Table 725 mm x 225 mm with, using power feed, 250 mm of longitudinal travel and, by hand only, 235 mm in traverse and 350 mm vertically. The 12 longitudinal feeds ranged from 12 to 380 mm per minute. 16 spindle speeds were available spanning 38 to 1900 r.p.m. Drive came from a 2 h.p. motor and the miller weighted around 600 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

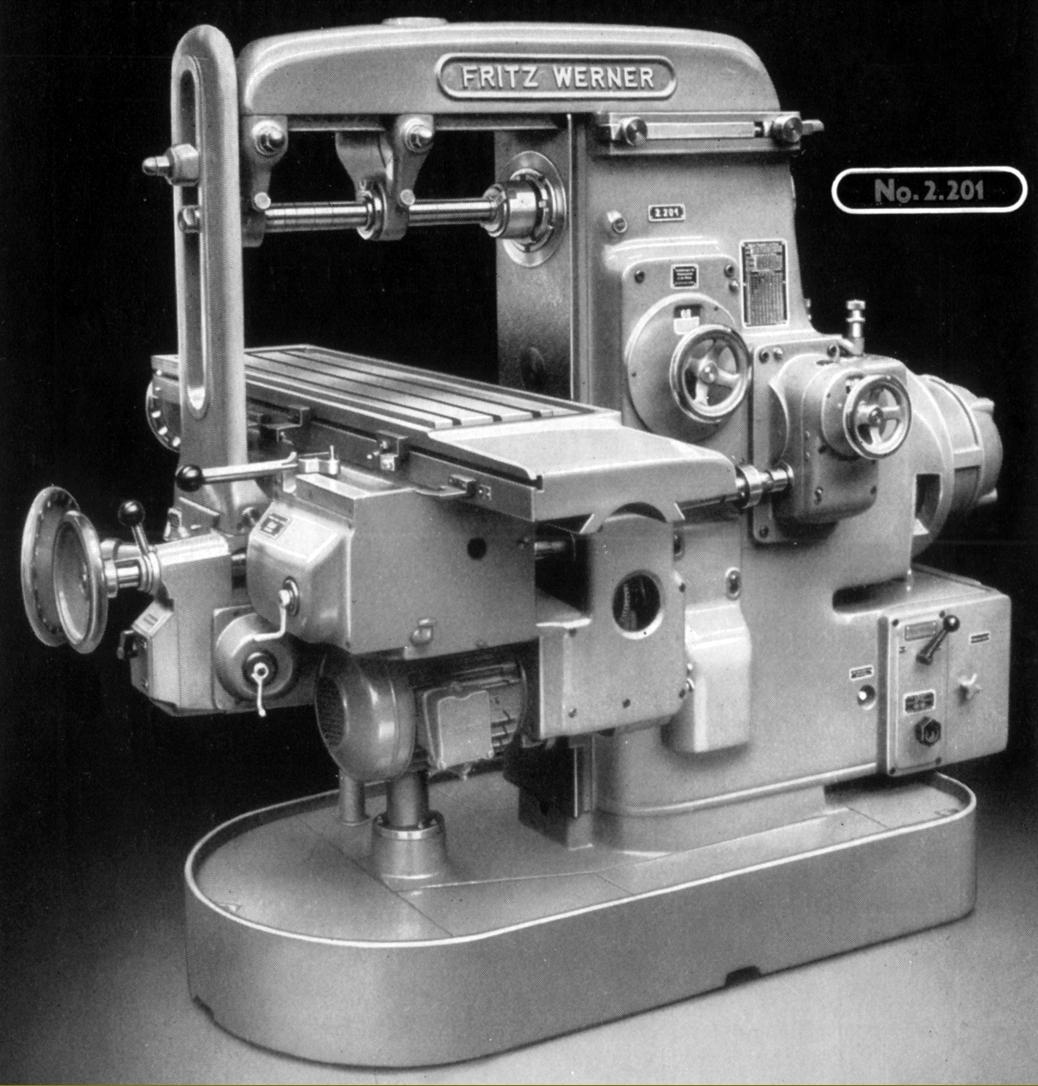

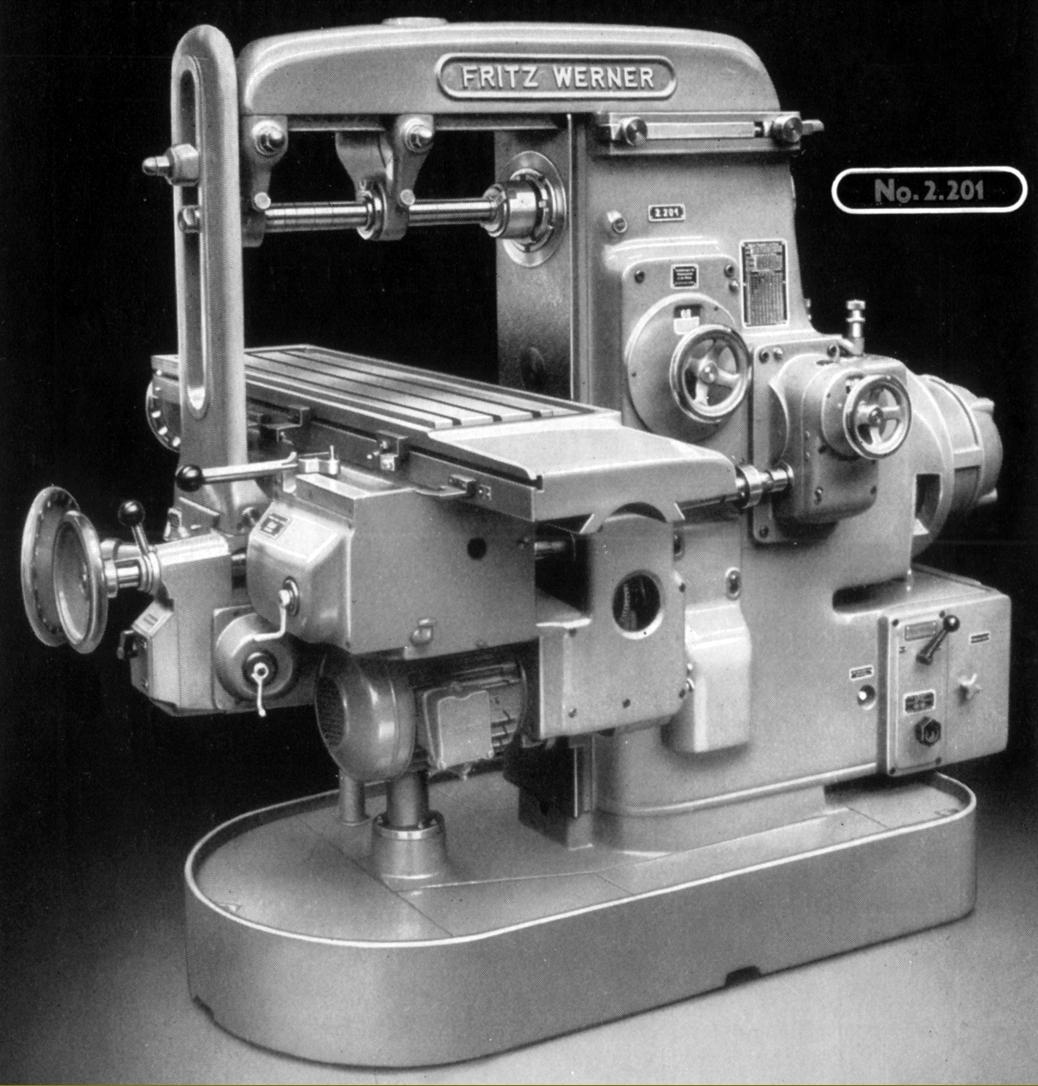

Fritz Werner Size 2 horizontal milling machine No. 2.201 listed as a "Production" type.

Table 1100 mm x 310 mm with, using power feeds, travels of 650 mm longitudinally, 235 mm in traverse and 420 mm of vertically. The 16 longitudinal and cross feeds ranged from 10 to 300 mm per minute and vertical from 5 to 150 mm. 18 spindle speeds were available spanning 34 to 635 r.p.m. or, optionally, 68 to 1270 r.p.m. . Drive came from a 9.5 h.p. motor and the miller weighed around 2100 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

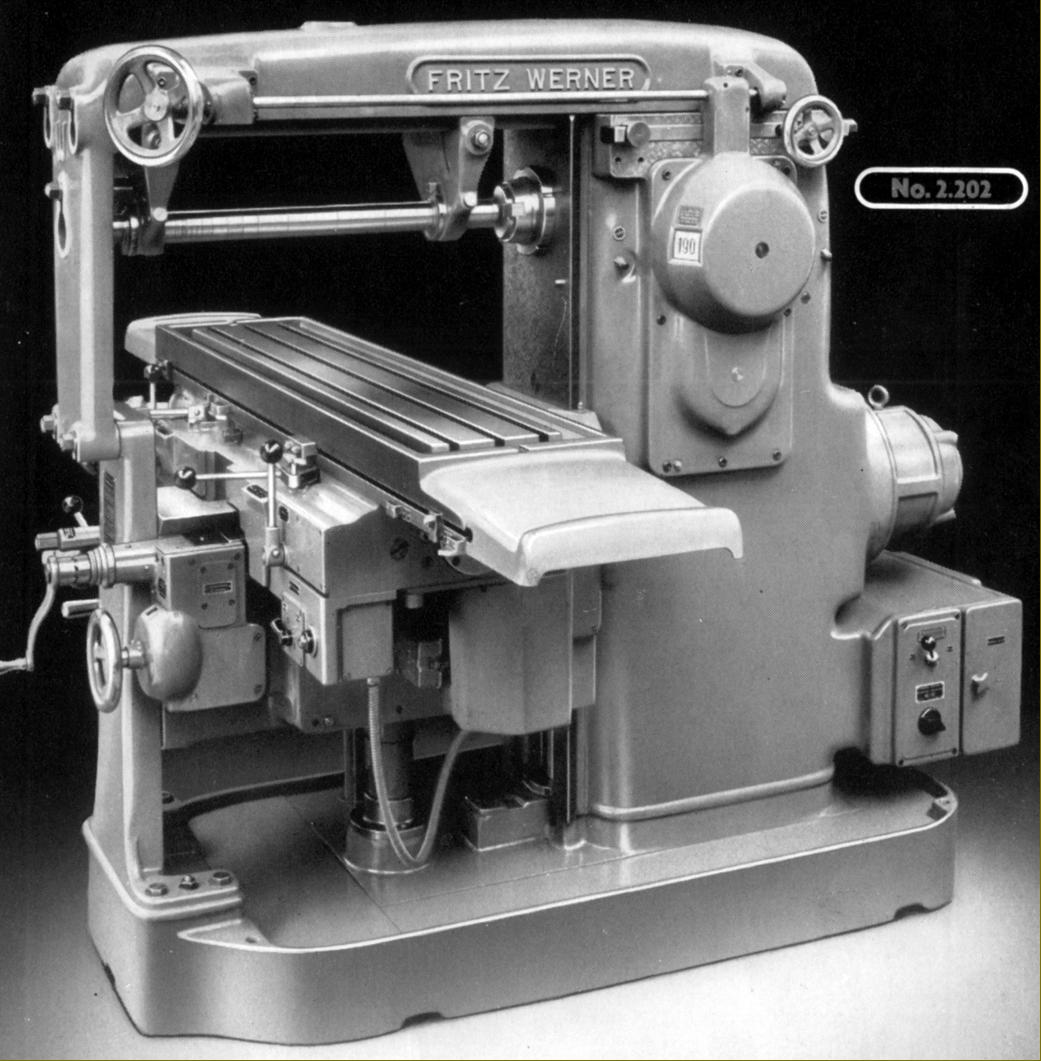

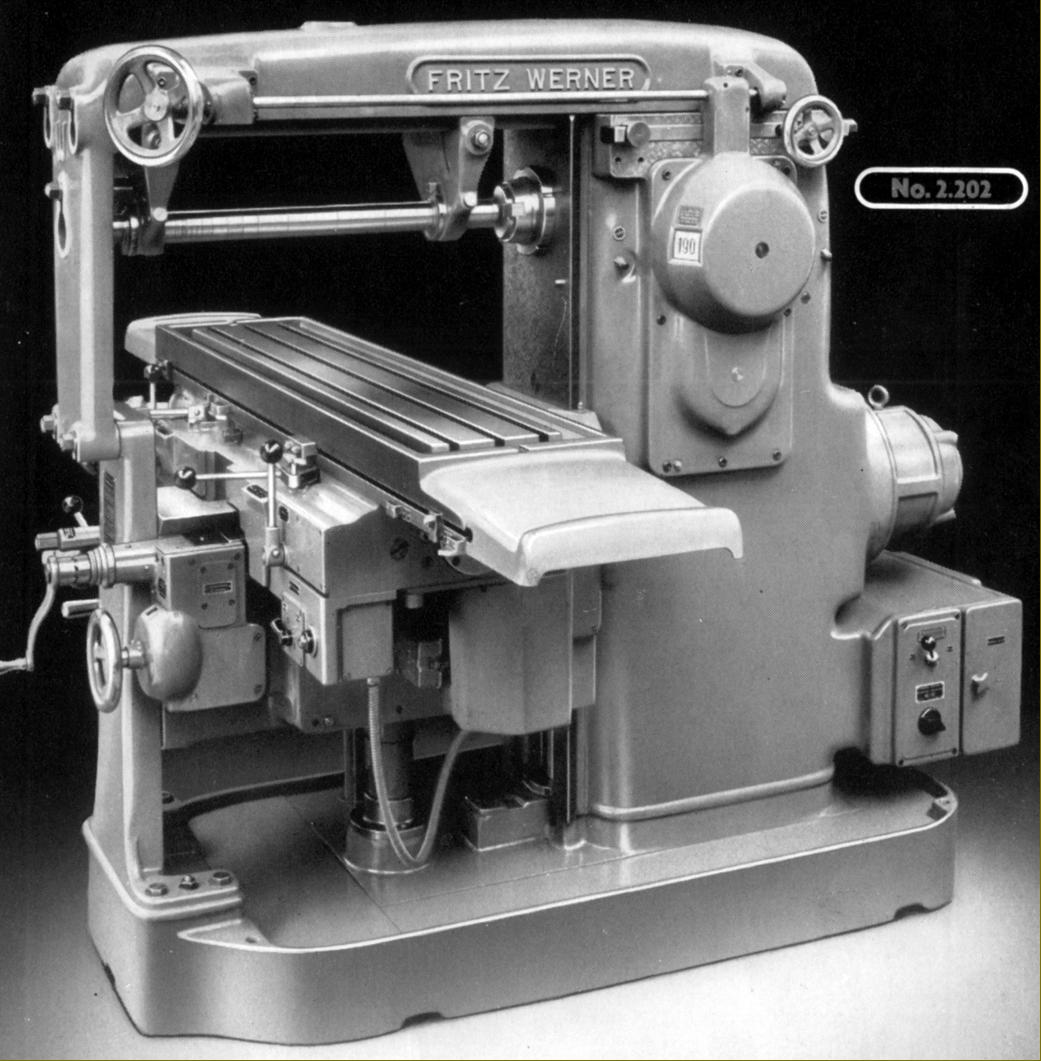

Fritz Werner Size 3 horizontal milling machine No. 2.202 Table 1600 mm x 360 mm with, using power feeds, travels of 1120 mm longitudinally, 315 mm in traverse and 425 mm vertically. The 18 longitudinal and cross feeds ranged from 10 to 480 mm per minute and vertical from 7.5 to 360 mm. 18 spindle speeds were available spanning 15 to 750 r.p.m. or, optionally, 19 to 960 r.p.m. Drive came from a 11.4 h.p. motor and the miller weighed around 4000 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

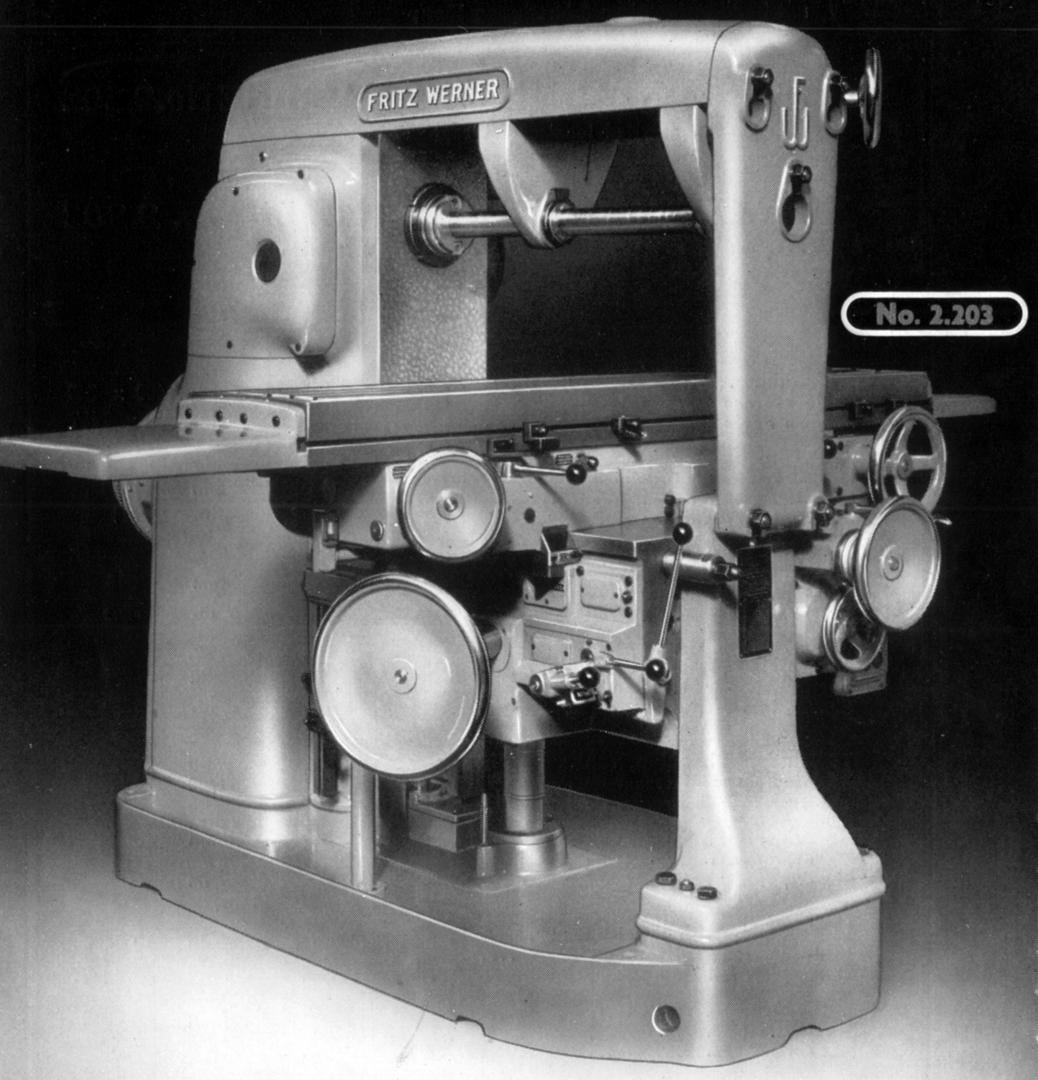

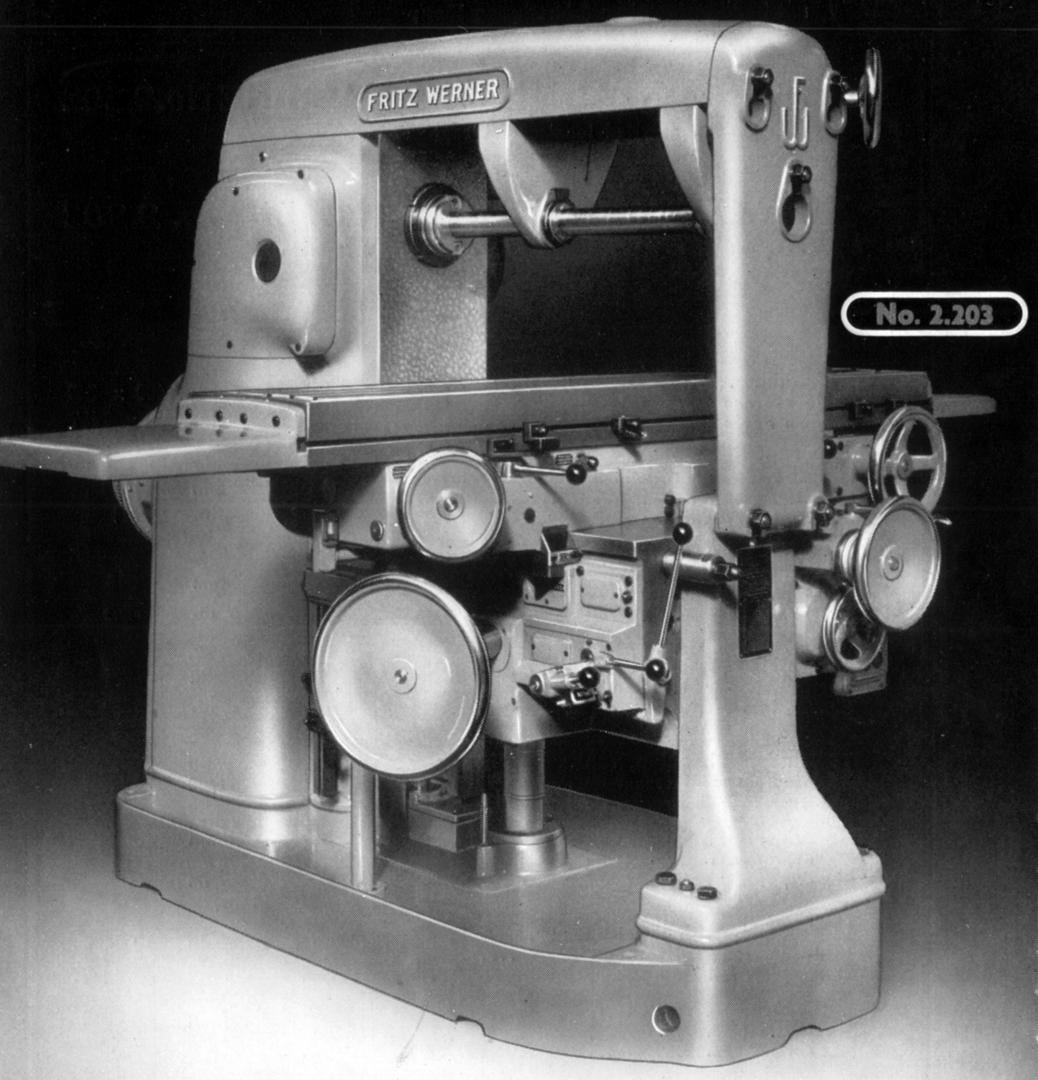

Fritz Werner Size 4 horizontal milling machine No. 2.203

Table 1800 mm x 400 mm with, using power feeds, travels of 1200 mm longitudinally, 380 mm in traverse and 410 mm vertically. The 18 longitudinal and cross feeds ranged from 10 to 480 mm per minute and vertical from 5 to 240 mm. 18 spindle speeds were available spanning 15 to 750 r.p.m. or, optionally, 19 to 960 r.p.m. Drive came from a 25 h.p. motor and the miller weighed around 5000 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

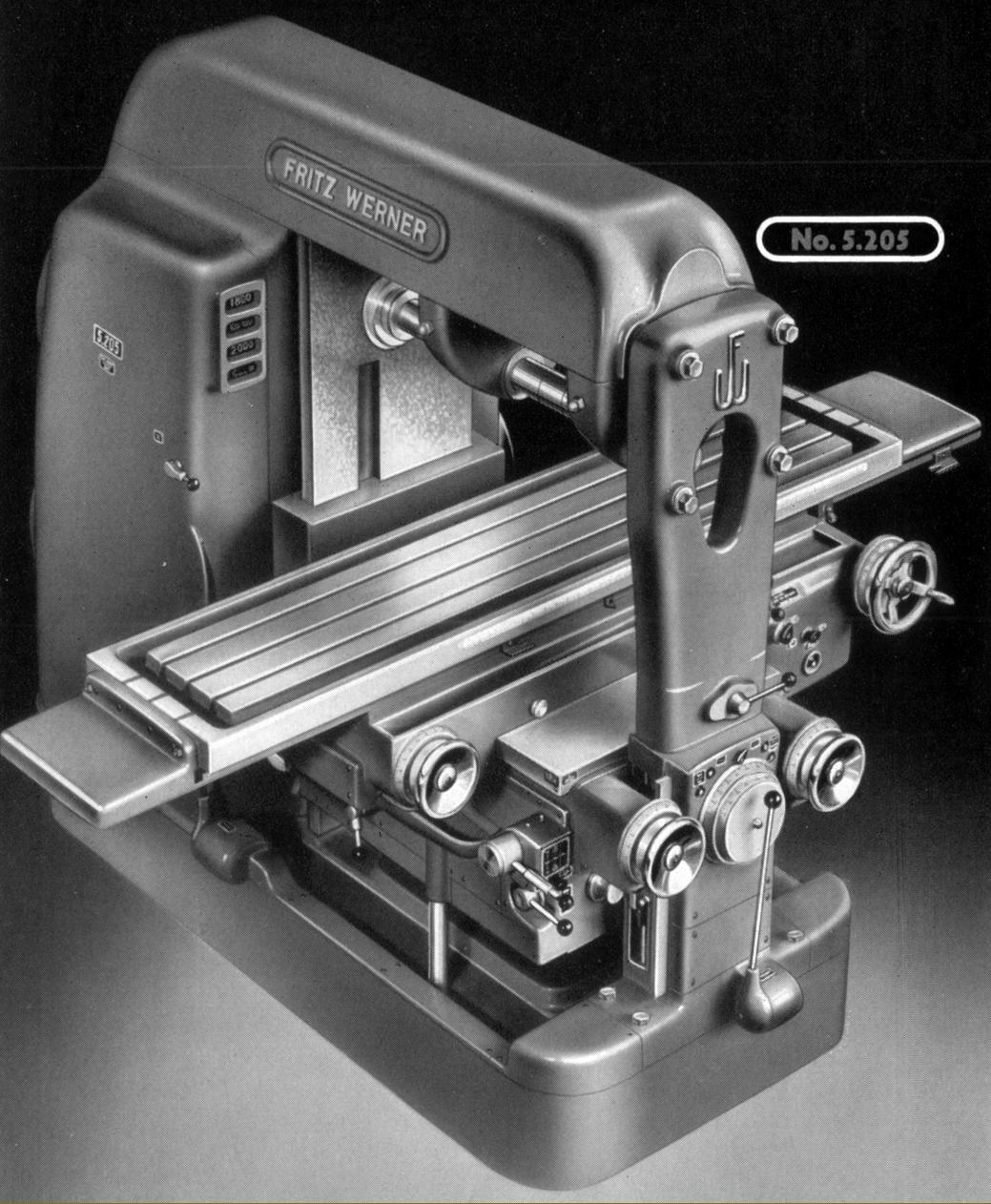

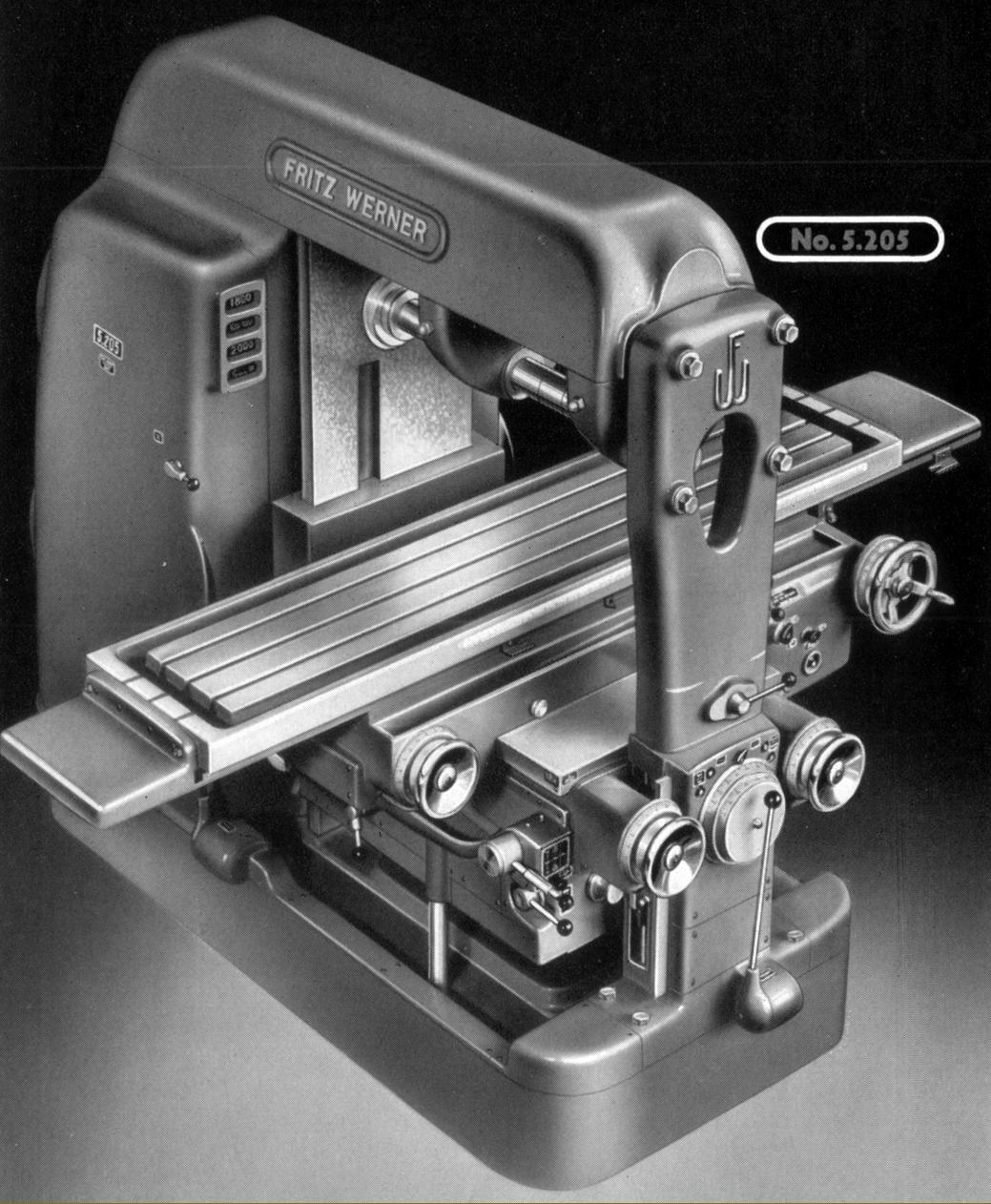

Fritz Werner Size 5 horizontal milling machine No. 5.205.

Table 2300 mm x 500 mm with, using power feeds, travels of 1400 mm of longitudinally, 400 mm in traverse and 510 mm vertically. The 50 longitudinal and cross feeds (including rapids) ranged from 7 to 2000 mm per minute and vertical from 3.5 to 1000 mm. 42 spindle speeds were available spanning 16 to 1800 r.p.m. Drive came from a 40 h.p. motor and the miller weighed around 11,000 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

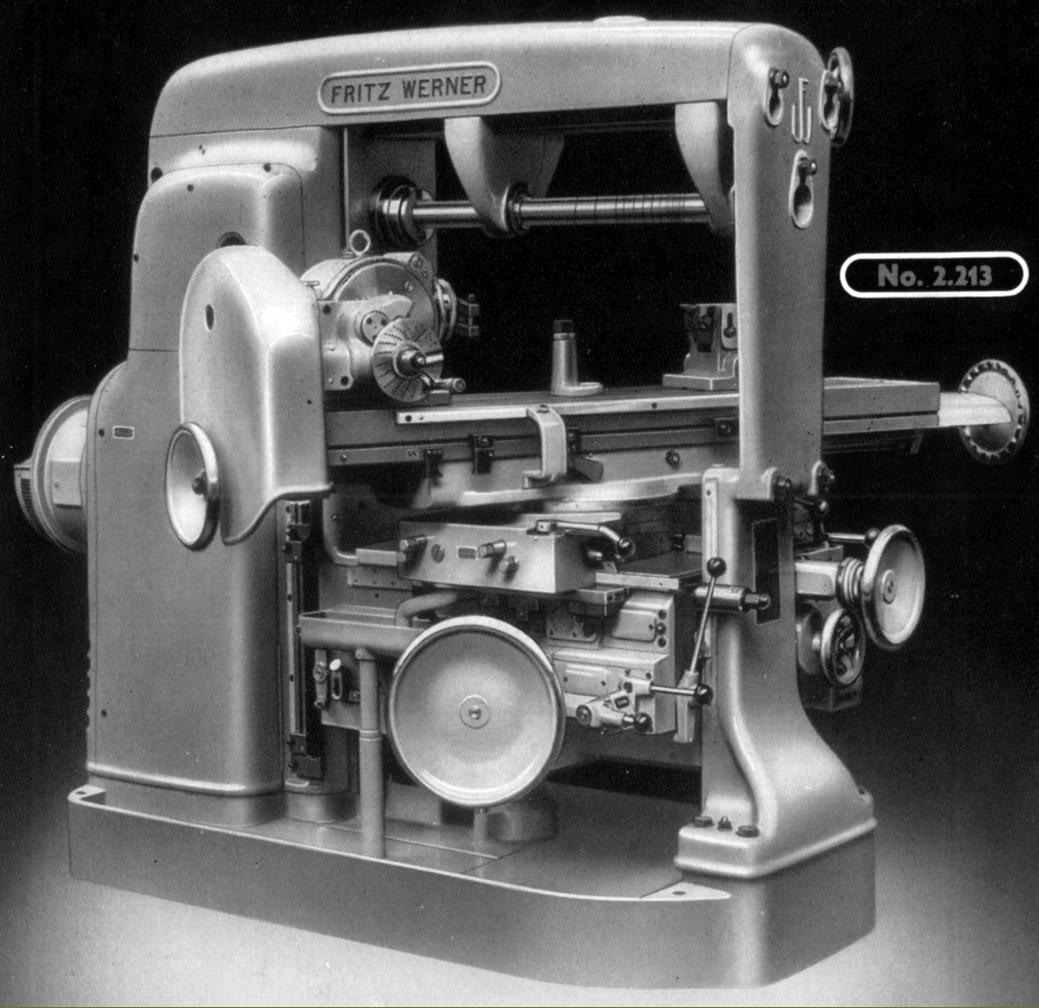

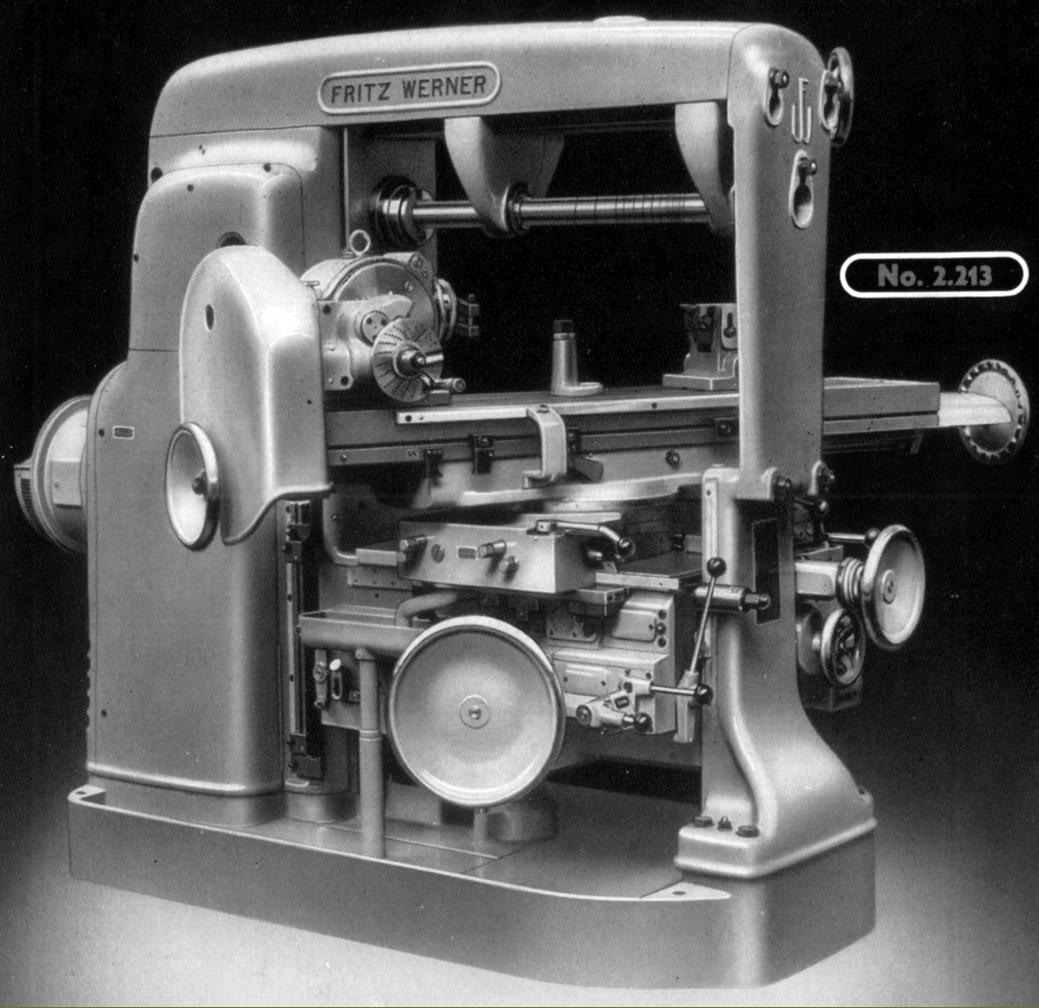

Fritz Werner Size 4 Universal milling machine - a horizontal type with a swing table Machine No. 2.213

Table 1800 mm x 355 mm with, using power feeds, a travel of 1000 mm of longitudinally, 380 mm in traverse and 440 mm vertically. The 18 longitudinal and cross feeds ranged from 10 to 480 mm per minute or, to choice, 5 to 240 mm per minute. The vertical power feed was set to run from 5 to 240 mm per minute.

18 spindle speeds were available that spanned 15 to 750 r.p.m. or, optionally, 19 to 960 r.p.m. Drive came from a 25 h.p. motor and the miller weighed around 5000 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

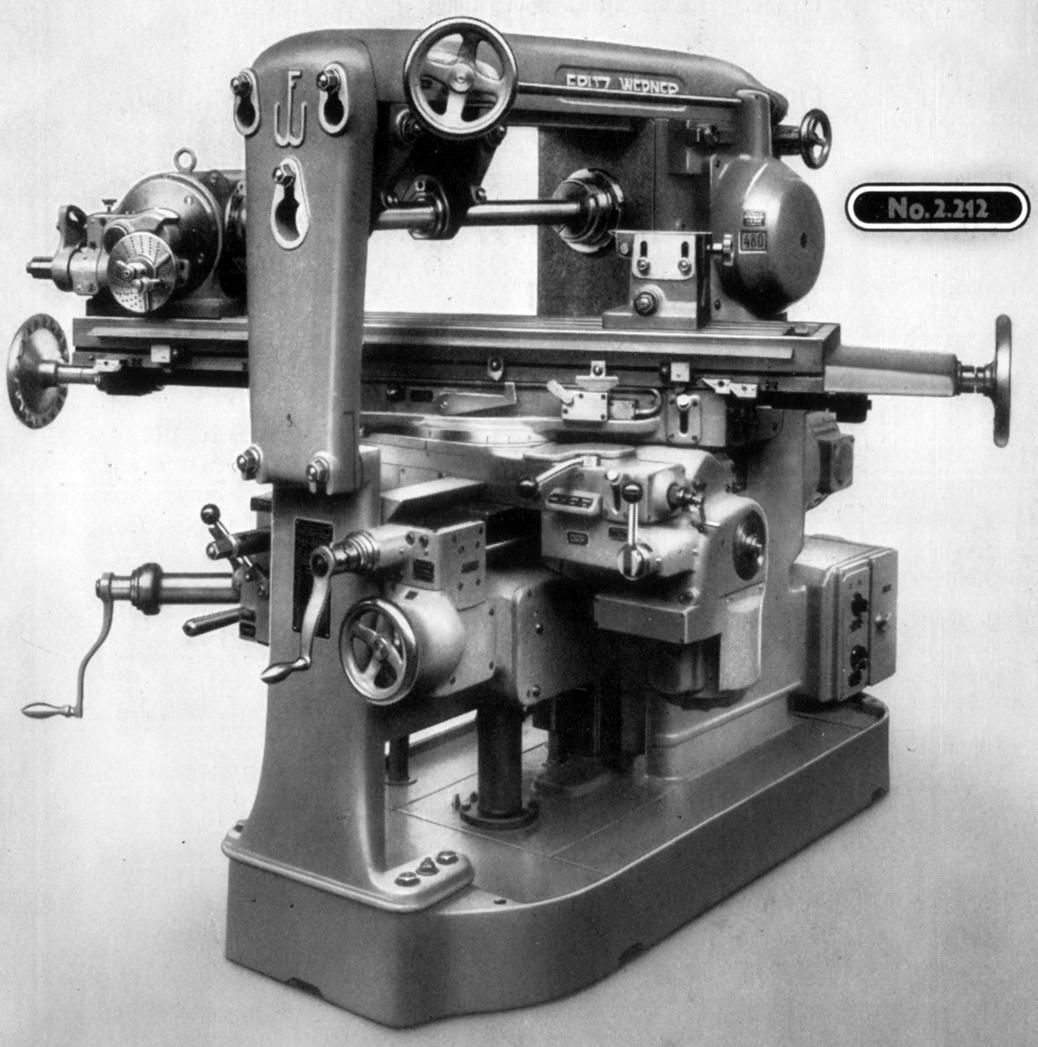

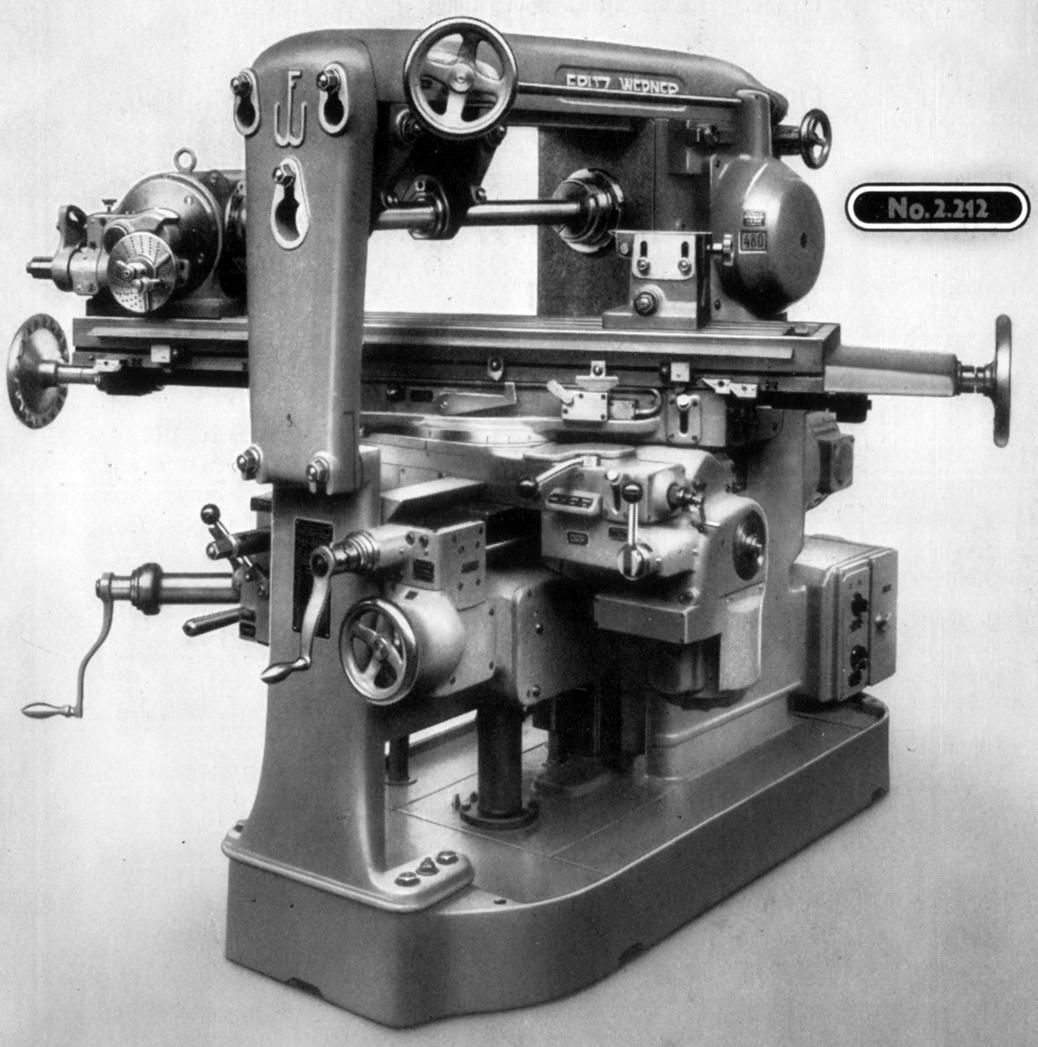

Fritz Werner Size 3 Universal milling machine - a horizontal type with a swing table Machine No. 2.212

Table 1600 mm x 355 mm with, using power feeds, a travel of 900 mm of longitudinally, 300 mm in traverse and 415 mm vertically. The 18 longitudinal and cross feeds were available in two ranges: 15 to 750 mm per minute or 19 to 960 mm per minute. The vertical power feed was set to run at the single rate of 5 to 240 mm per minute. 18 spindle speeds were available that spanned 15 to 750 r.p.m. or, optionally, 19 to 960 r.p.m. Drive came from a 25 h.p. motor and the miller weighed around 5000 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

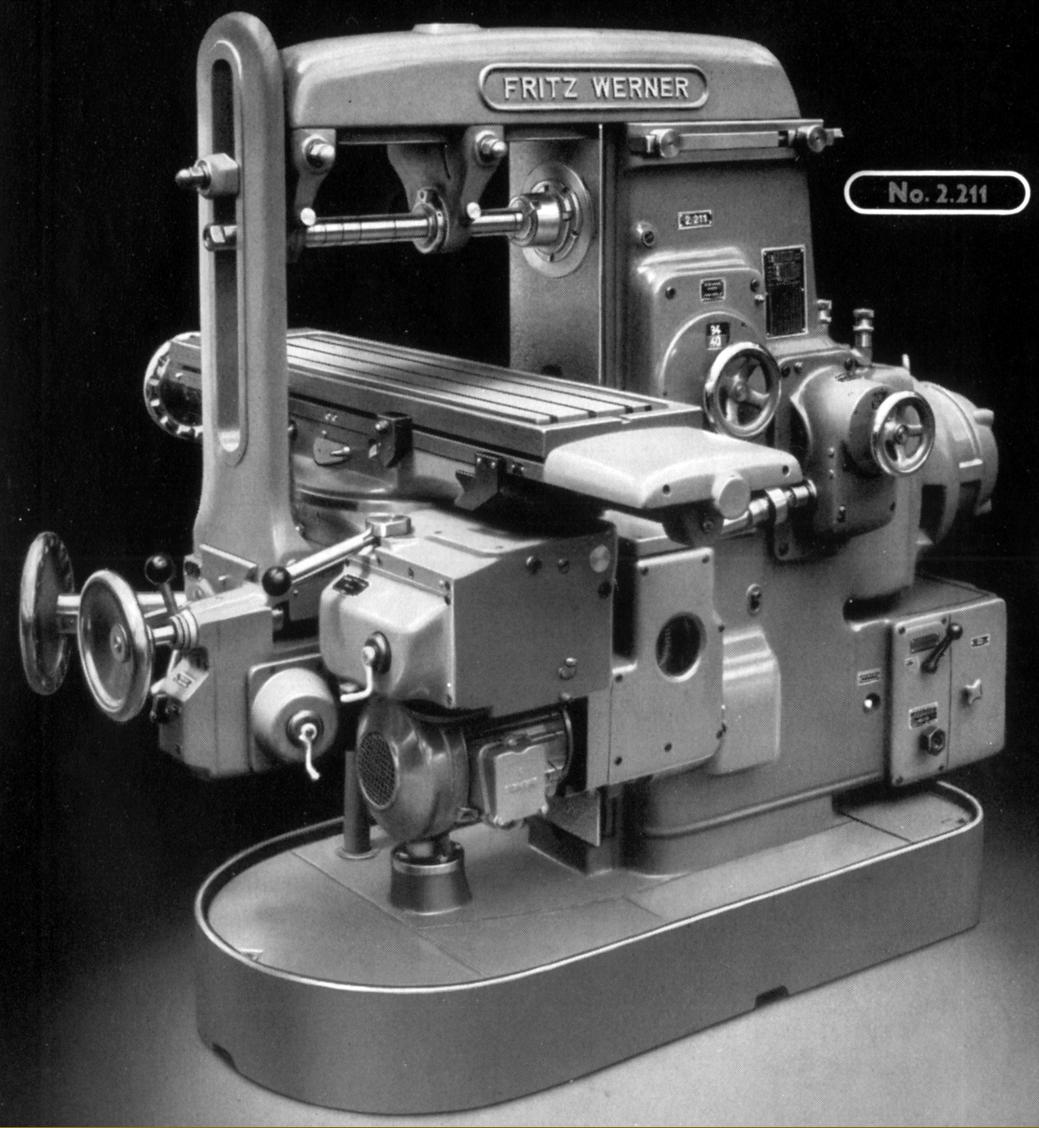

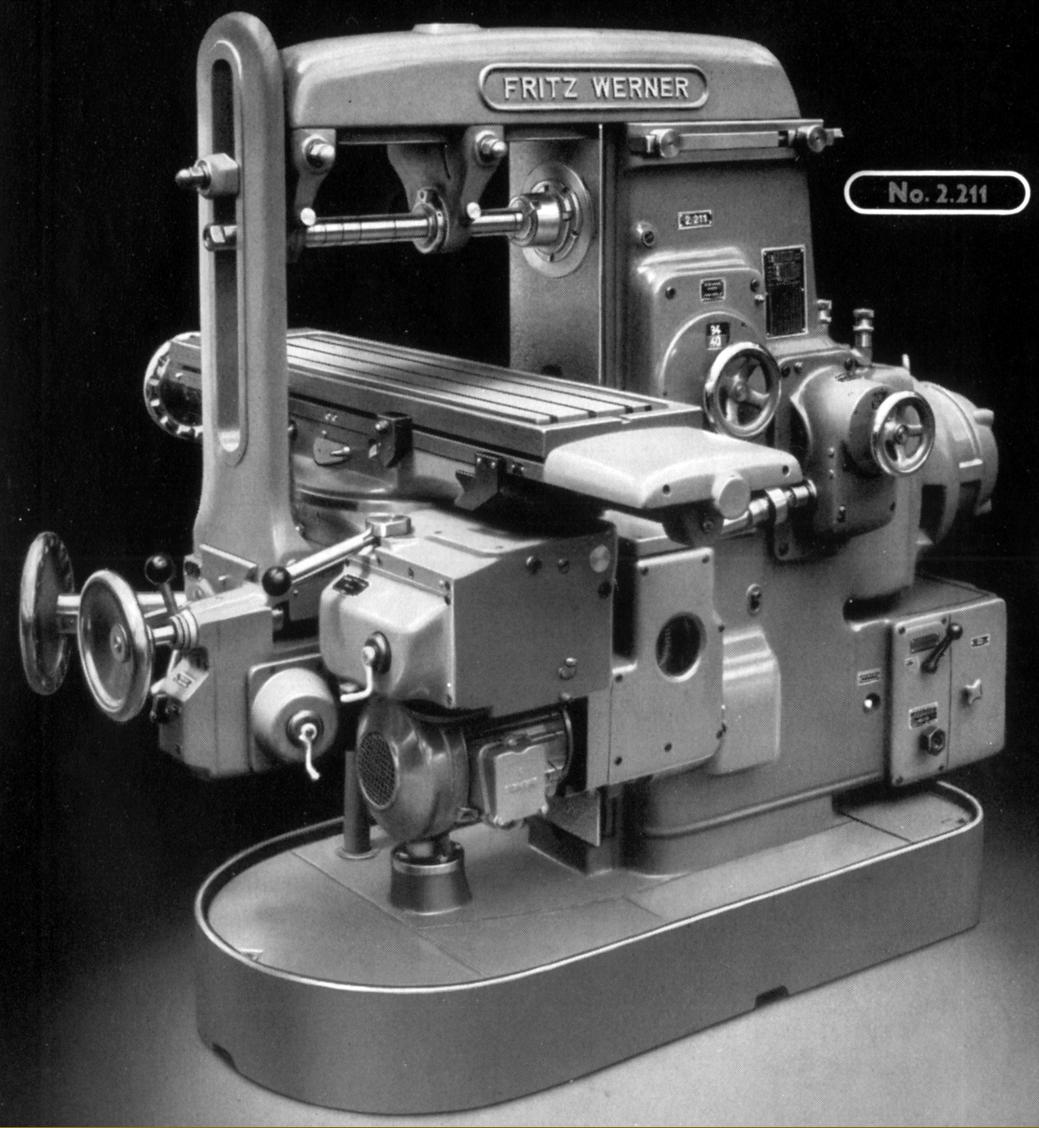

Fritz Werner Size 3 Universal milling machine - a horizontal type with a swing table Machine No. 2.211

Table 1100 mm x 275 mm with, using power feeds, a travel of 650 mm of longitudinally, 225 mm in traverse and 365 mm vertically. The 16 longitudinal and cross feeds were available in two ranges: 6 to 190 mm per minute or 3 to 95 mm per minute. The vertical power feed was set to run at the single rate of 3 to 95 mm per minute. 18 spindle speeds were available that spanned 34 to 635 r.p.m. or, optionally, 68 to 1270 r.p.m. . Drive came from a 9.5 h.p. motor and the miller weighed around 2200 kg.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

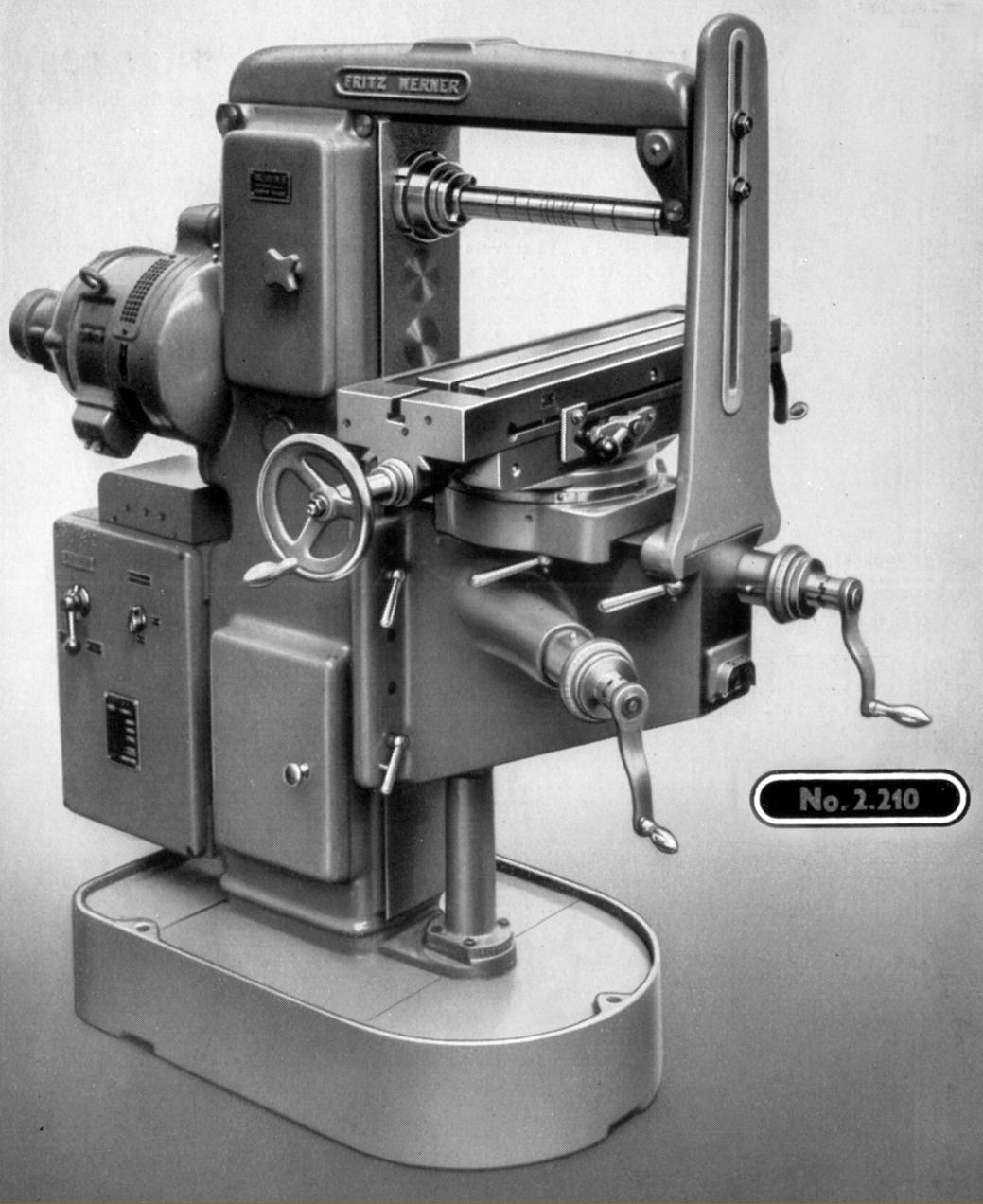

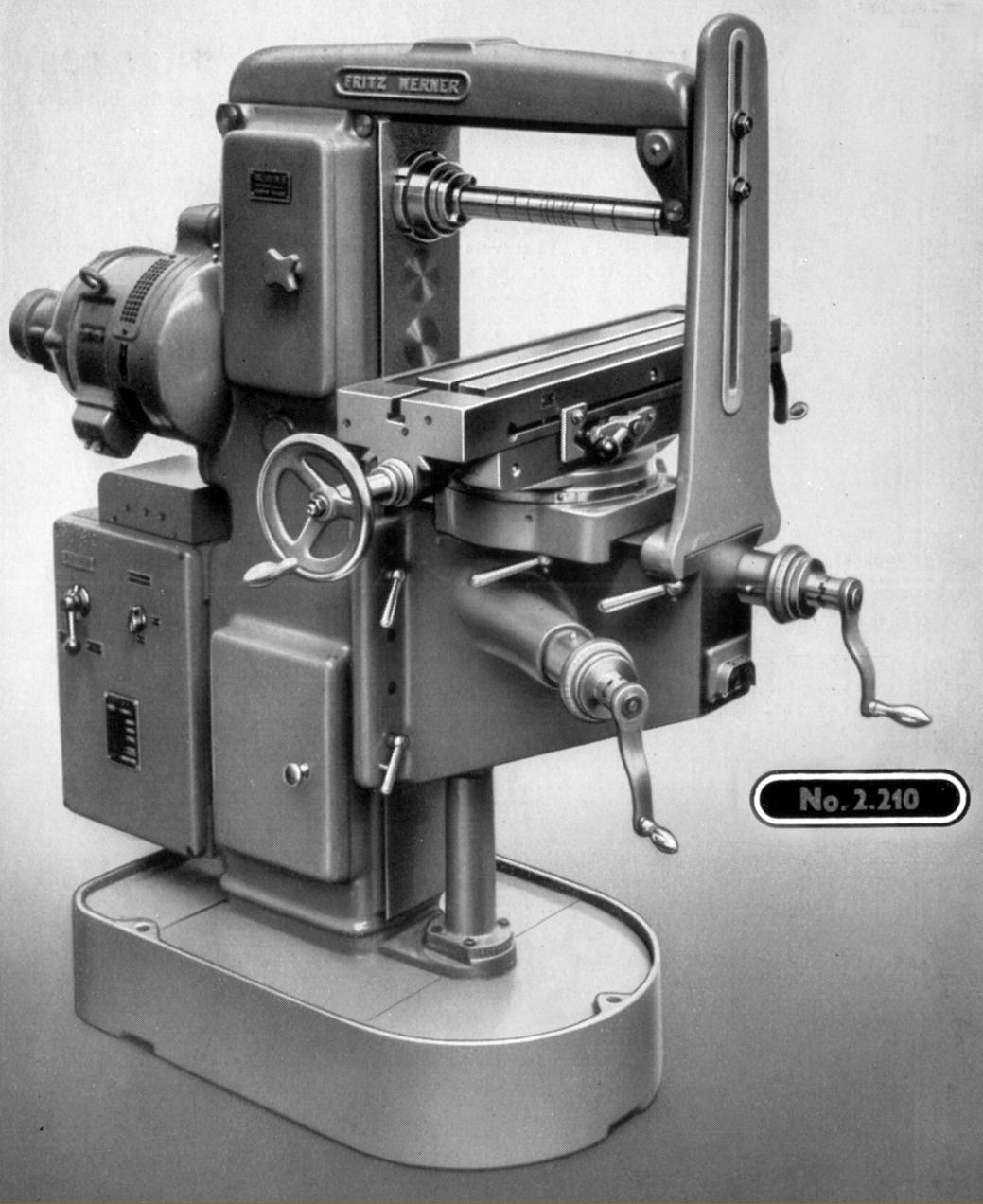

Fritz Werner Size 1 horizontal milling machine of the "Universal" type with a swing table Machine No. 2.210

Table 750 x 185 mm with, using power feed, 400 mm of longitudinal travel and, by hand only, 250 mm in traverse and 400 mm vertically. The 11 longitudinal feeds ranged from 6 to 190 mm per minute. 16 spindle speeds were available spanning 38 to 1900 r.p.m.. Drive came from a 2 h.p. motor and the miller weighed around 650 kg.

|

|

|

|

|

|

|

|

|