|

Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories Delta 10" lathe Delta 14" lathe Delta Wood Lathes An Operation and Parts Manual is available for this lathe see featured in the Archive, the writer would be interested to hear from you |

|

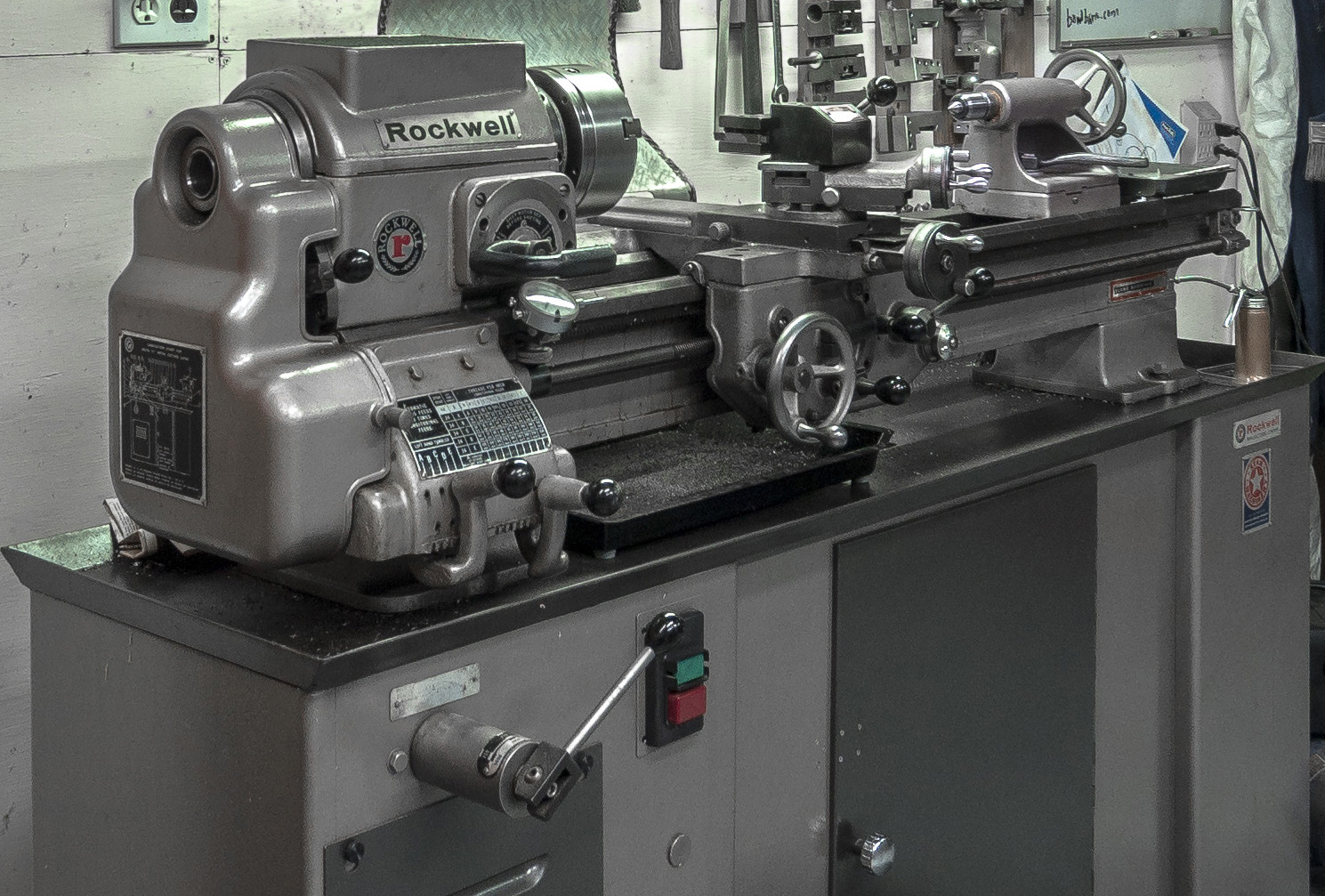

Very much more heavily built than the 10" model, the popular Rockwell Delta 11" underdrive lathe was available with a choice of three different spindle nose fittings: an ordinary thread (21/4" x 8 t.p.i), the much superior American long-nose taper in an L-00 size or (unfortunately for later private owners) a short-type "American Taper" with 6 retaining bolts. Two bed lengths were produced giving a capacity of either 25" or 37" between centres. |

|

|

|

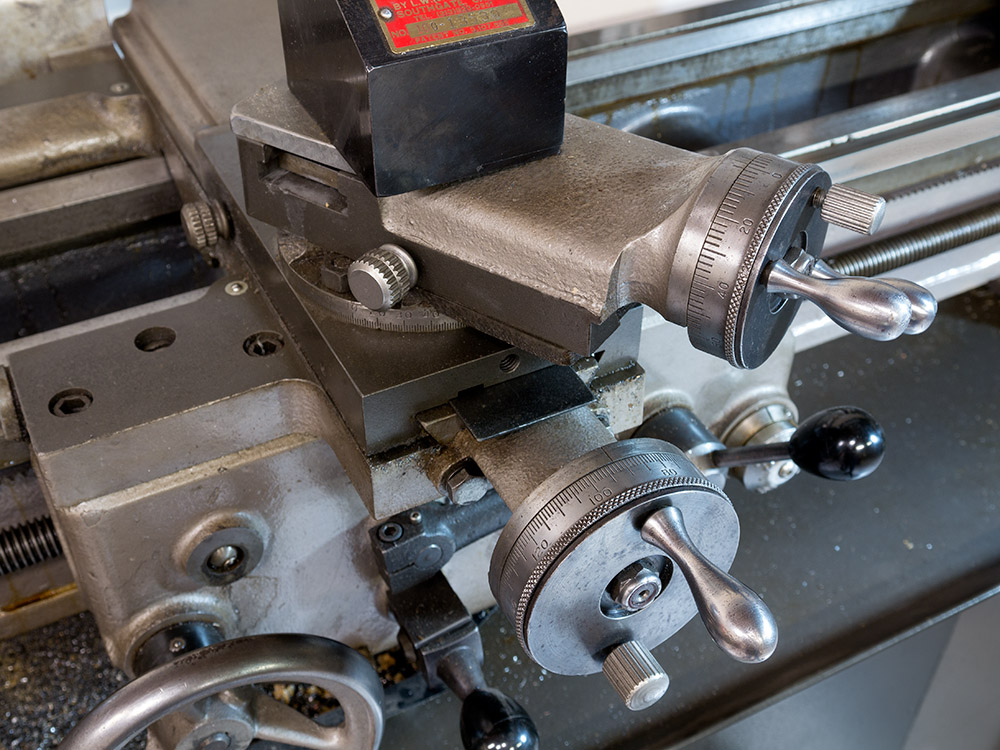

The compound slide-rest assembly. The zeroing micrometer dials are fitted with neat face locks - thus obviating any change is the reading when activated - and the top slide fitted with a knurled locking screw |

|

|

||

|

The thread on the leadscrew was used only for screwcutting, the power sliding and surfacing feeds driven from a slot running its full length; the slot as unique in have a "T" section, designed to prevent the edge of the sliding key from raising a burr along its edge. |

||

|

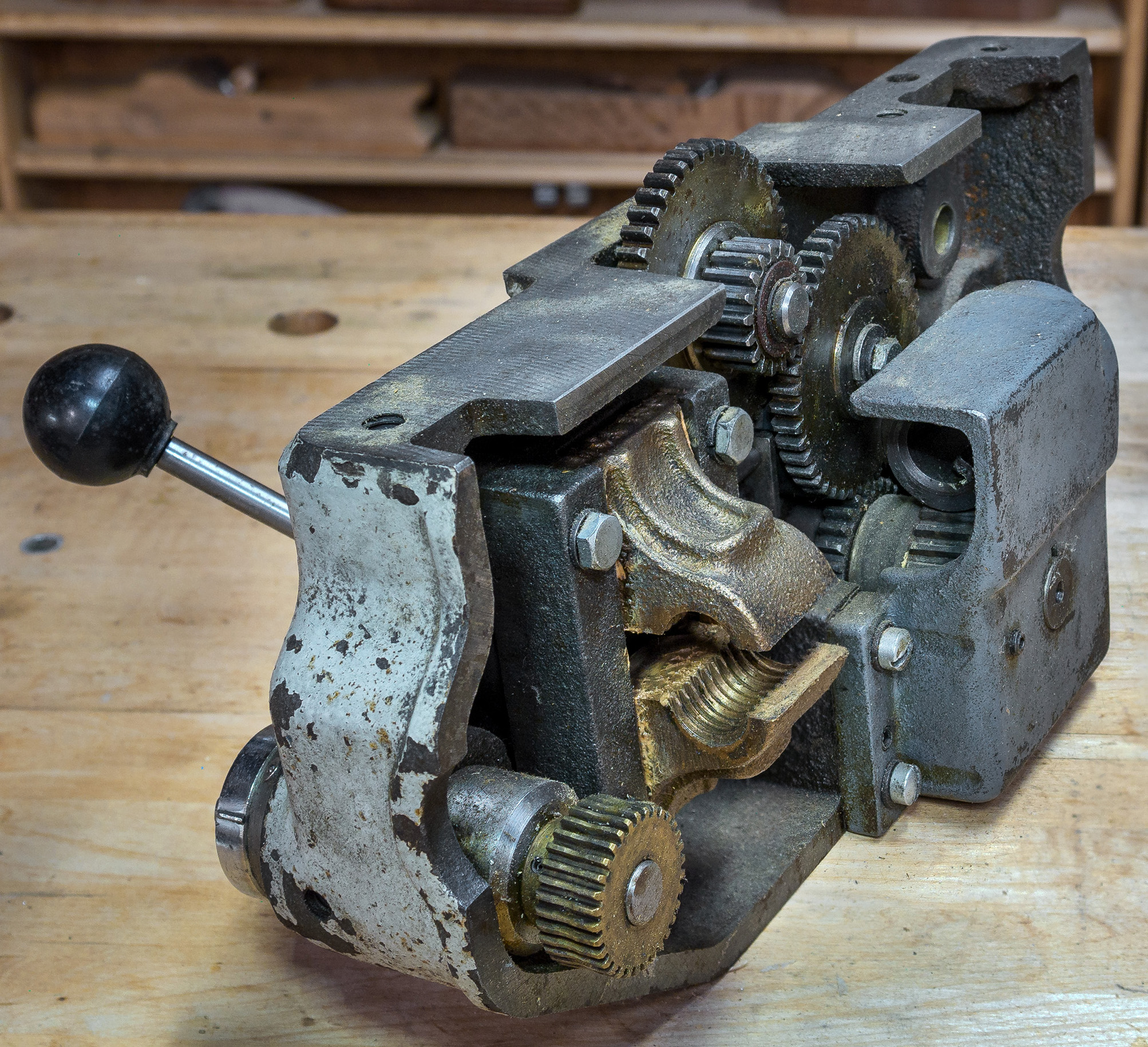

adjustable-engagement leadscrew clasp nuts |

||

|

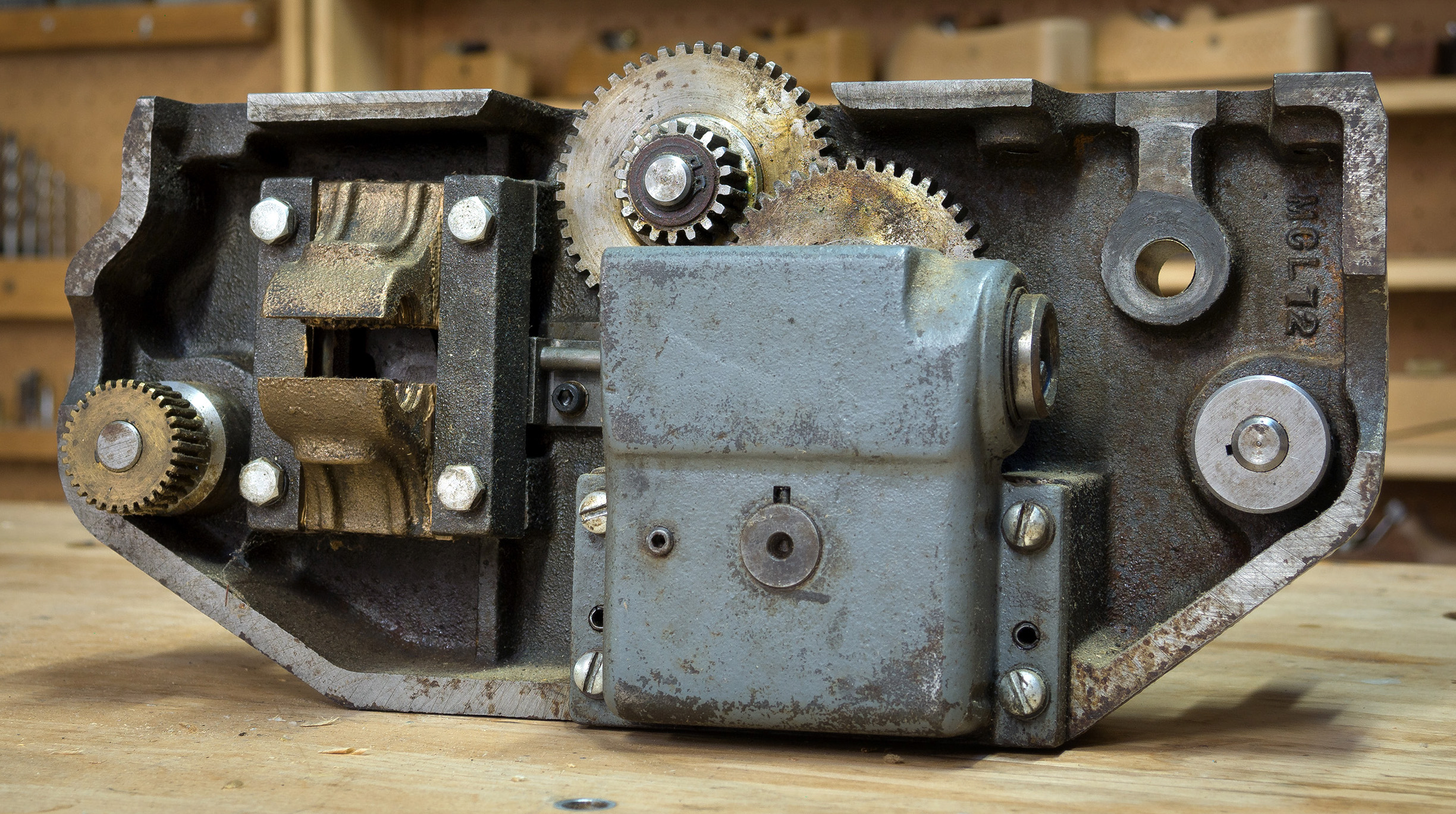

Cut-away view of the Delta 11" headstock showing the massive double tapered roller bearing and heavy-duty 21/2" diameter spindle. The headstock is illustrated turned through 90 degrees, in its operating position the backgear engagement and spindle locking handle on the "top" was situated on the headstock's front face - and shown in close-up below. |

|

|

|

Home Machine Tool Archive Machine-tools for Sale & Wanted Books Accessories |

||