|

Home Machine Tool Archive Machine-tools Sale & Wanted Midgetmill & Speedmill Manufactured by the Dalrae Tool Co. of Syracuse Building, Syracuse, New York, USA, the Dalrae "Midgetmill" and "Speedmill" were typical of attachments developed between the two World Wars that converted a simple horizontal miller into a much more a useful and versatile vertical type. The company were not alone in this market and, with machines available at various times from Bridgeport, Tree and Halco (amongst others), competition was keen. However, the Dalrae products must have been of particularly good quality for they were adopted by the very much larger Kearney and Trecker Corporation and sold by them branded as K & T products. |

|

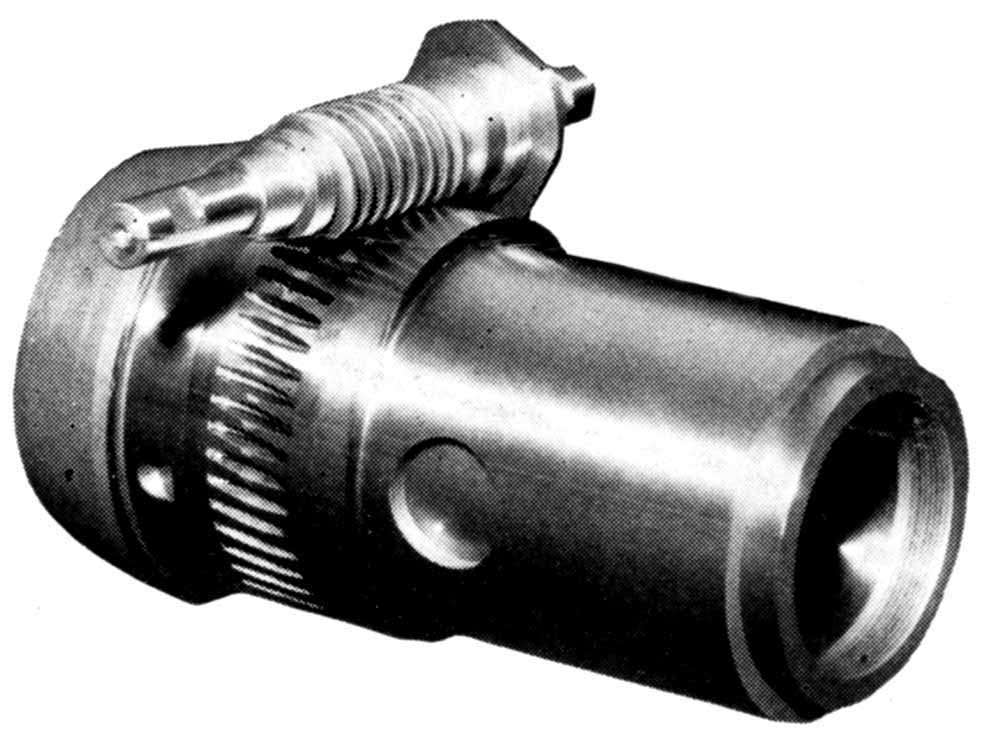

Dalrae "Midgetmill" with 2-speed 1/3 h.p. ball-bearing repulsion/induction reversing motor and 6 direct drive speeds of: 275, 400, 525, 800, 1675 and 2600 rpm on low range and: 350, 500, 700, 1200, 2200 and 3200 rpm on high range. The standard "Speedmill" shared the same speed range (though a special high-speed 5300 rpm model was also listed) and both had motor pulleys in aluminium and their balanced 7.5 lb spindle pulleys (to give a flywheel effect), in cast iron. Motors appeared to have varied with some having steel casings and others, like the main body of the unit, being in cast aluminium to keep the weight down. On the "Midgemill" the spindle sleeves, quill and worm and threads were all in hardened and ground steel and the worm wheel in bronze. The spindle ran in five ball races and the quill, with travel of 2.5 inches, could be ordered with either a fine-feed worm-and-wheel assembly (with a graduated handwheel), a quick-action rack feed - or both. The quill nose was fitted with the popular No. 7 Brown & Sharpe taper (equivalent in capacity to a No. 2 Morse taper) whilst that on the "Speedmill" was also furnished with a slot so that direct-fitting cutters could be knocked out with the usual type of slender wedge. Both machines benefited from a spindle lock that allowed cutters to be changed with ease. |

|

|

||

|

The separate cast-iron mounting cradle that attached to the overarm of the horizontal miller. Cradles se were available to fit arms with diameters of: 3.5", 4.25" and 4.5" with split bushes available (at extra cost) to accommodate intermediate sizes. For overarms larger in diameter than 4,5" a specially constructed "extension bracket" was supplied that positioned the milling unit below the centre line of the arm. The makers were also able to provide, to special order, adapters for rectangular or other unusual shapes of overarm. |

||

|

|

|

|

||

|

A picture that shows why horizontal miller conversion units were so popular - they immediately converted a simple machine into one capable of much great versatility and could, providing the operator was content to take delicate cuts, be manoeuvred into the most unlikely of positions. It was also possible to bring the unit into use after a workpiece had been machined "horizontally" so enabling a job to be finished, or progressed, without the time-wasting and profit absorbing exercise of dismounting, remounting and setting up on another machine. |

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted Midgetmill & Speedmill |