|

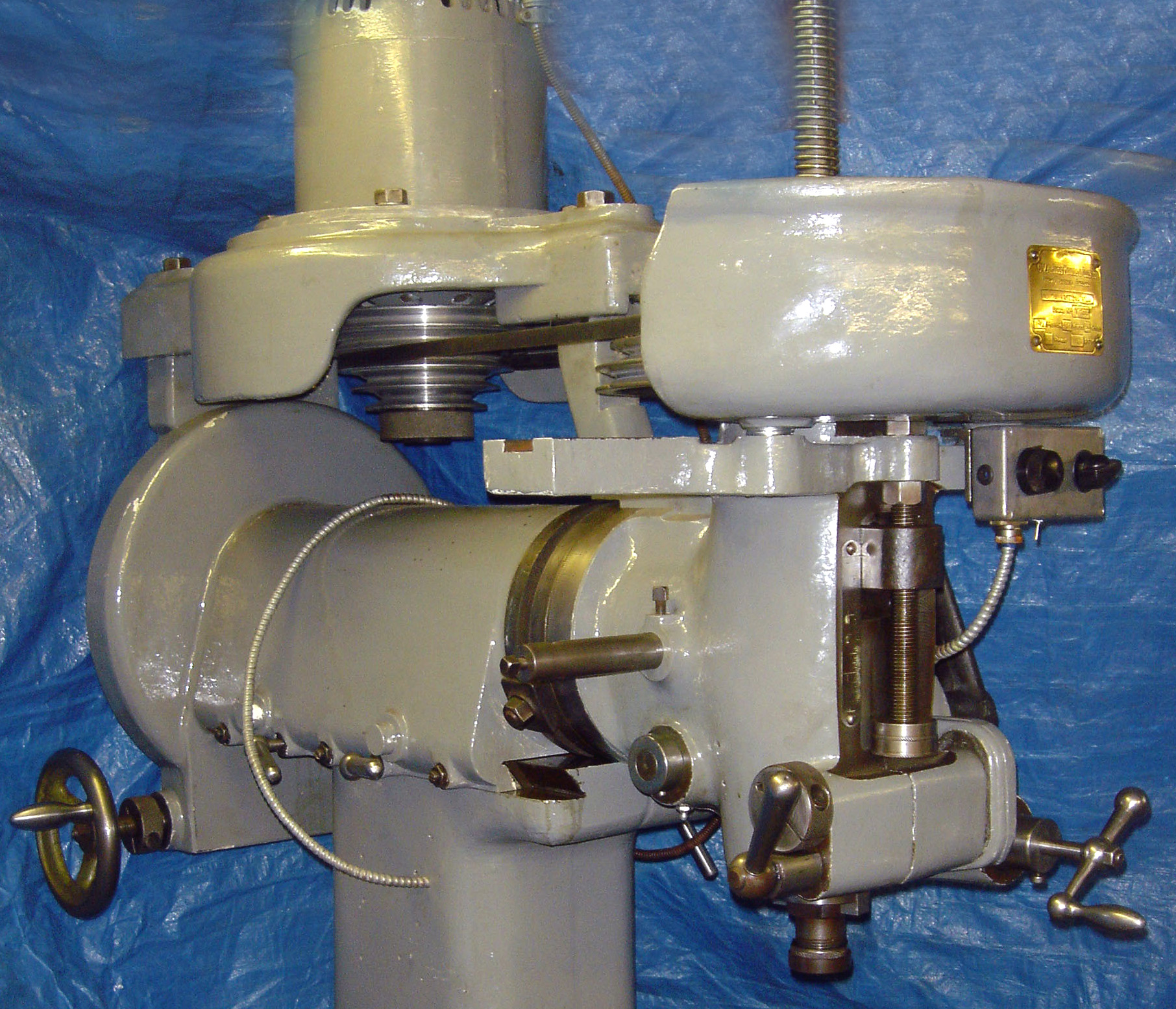

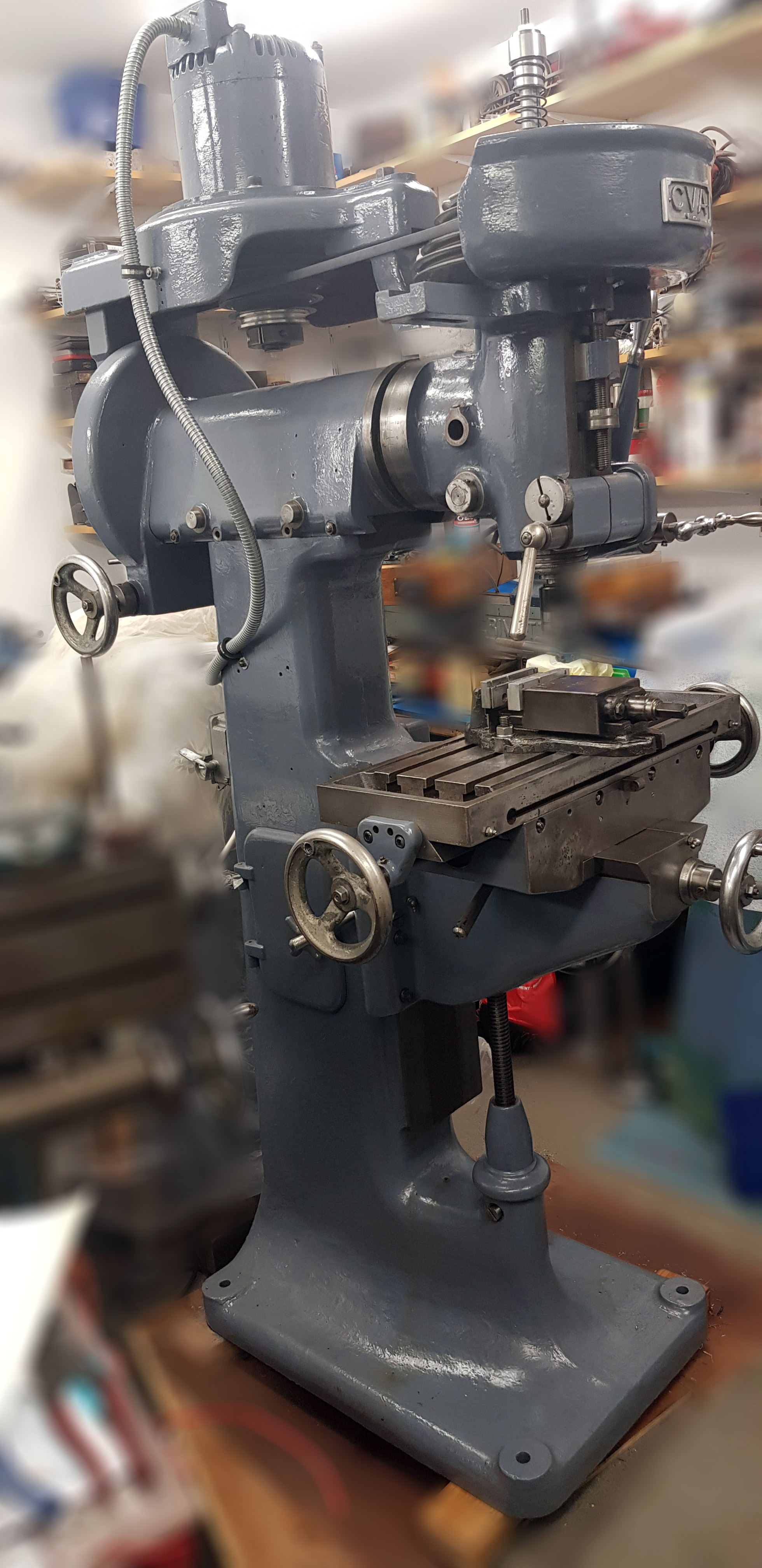

Another beautifully made product from CVA Jigs Moulds & Tools Ltd. of Hove, Sussex, the well-specified and versatile No. 79 was a toolroom-class machine and intended for precision milling and die-sinking. Advertised from the early 1930s until the early 1950s, as with some other CVA products, the sole selling agents were the well-known dealers E. H. Jones, Machine Tools Ltd. of Edgware Road, The Hyde. London. NW9.

Standing just over 81 inches high and with a compact footprint of just 20" x 30", the miller's 25.25" x 9.375" table had three T-slots and 14.5 inches of travel longitudinally and 7.5 inches in and out.

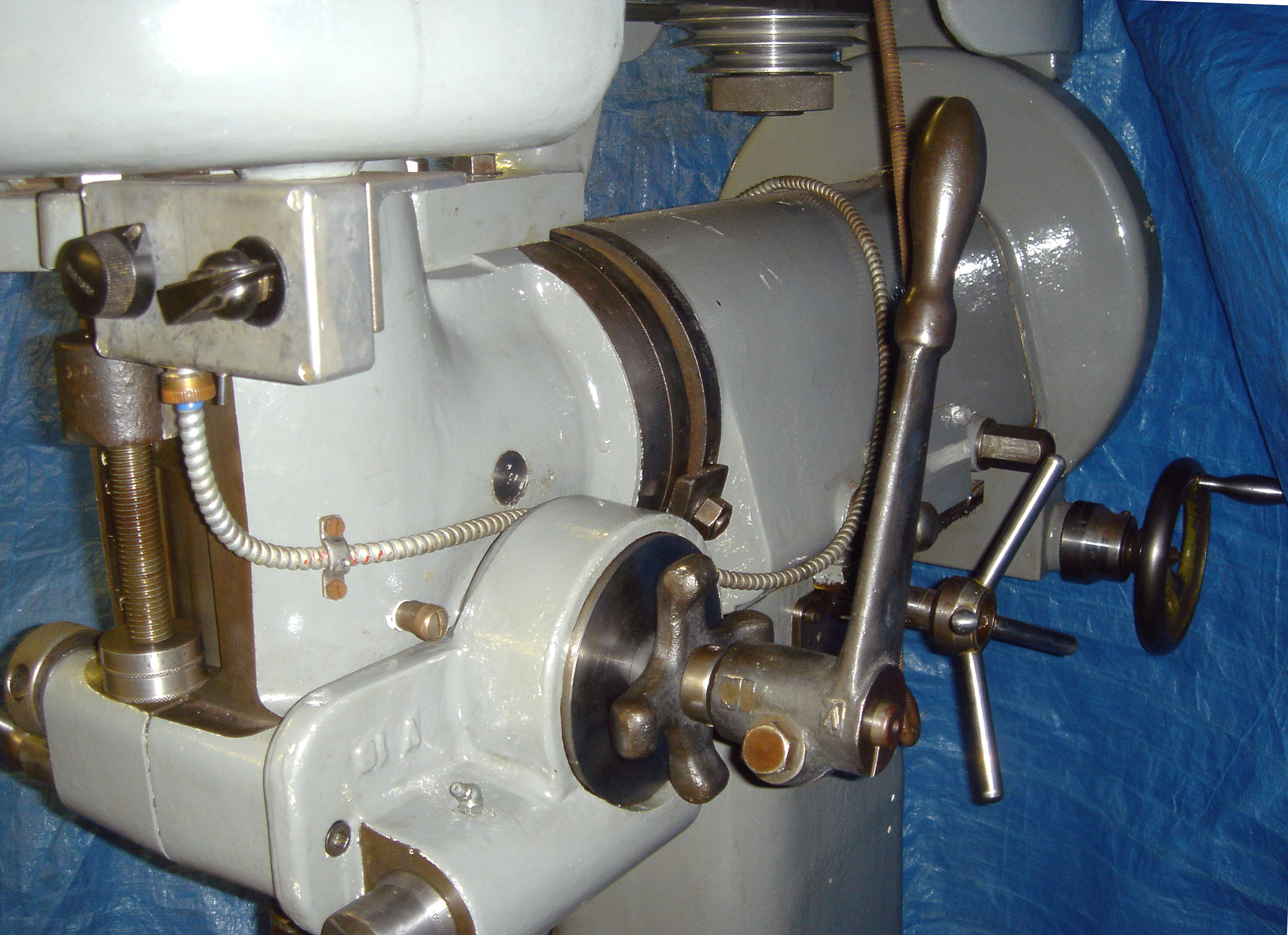

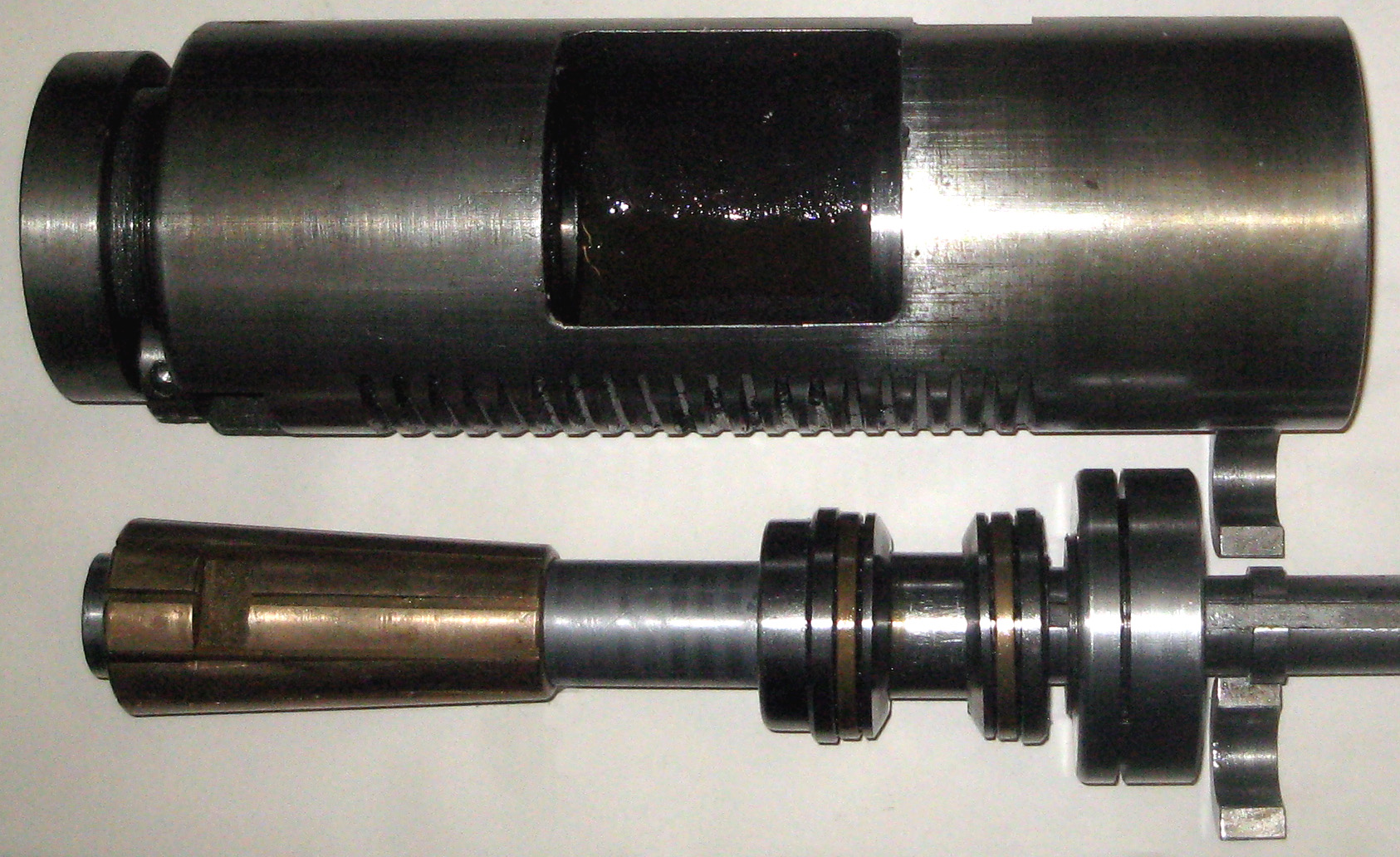

Powered by a standard-fit, flange-mounted 0.75 h.p. 3-phase motor, the four (later five) spindle speeds were driven by an "A" section V-belt and ran from 325 to 2900 r.p.m. Carried on the end of dovetail ram that could be moved forwards and backwards through six inches of travel, the head could be swivelled through 90° each side of vertical under the precise control of a handwheel set towards the rear of the ra, and working through worm-and-wheel gearing. Fitted with both a worm-and-wheel driven fine feed and a quick-action, lever-operated rack-and-pinion drilling quill, the spindle carried a No. 3 Morse taper nose and ran in an unusually long parallel-bore bronze bush gently tapered on its outside. In order to set the running clearance, the bush was machined longitudinally with a grooves and a slit right through and hence adjustable within its tapered housing. Lubrication was by a special design of wick feed that allowed oil to pass through the bearing and drip into a container - rather along the lines of an early IC engine's "constant-loss" system that ensured only clean oil was used. At the top of the spindle a pair of Hoffman W 13/8 ball thrust races used, these being provided with screw adjustment to take out end float. However, later spindles were considerably modified and fitted with adjustable taper roller bearings at the bottom and an angular contact ball bearing at the top - with threaded collars to adjust the axial preload.

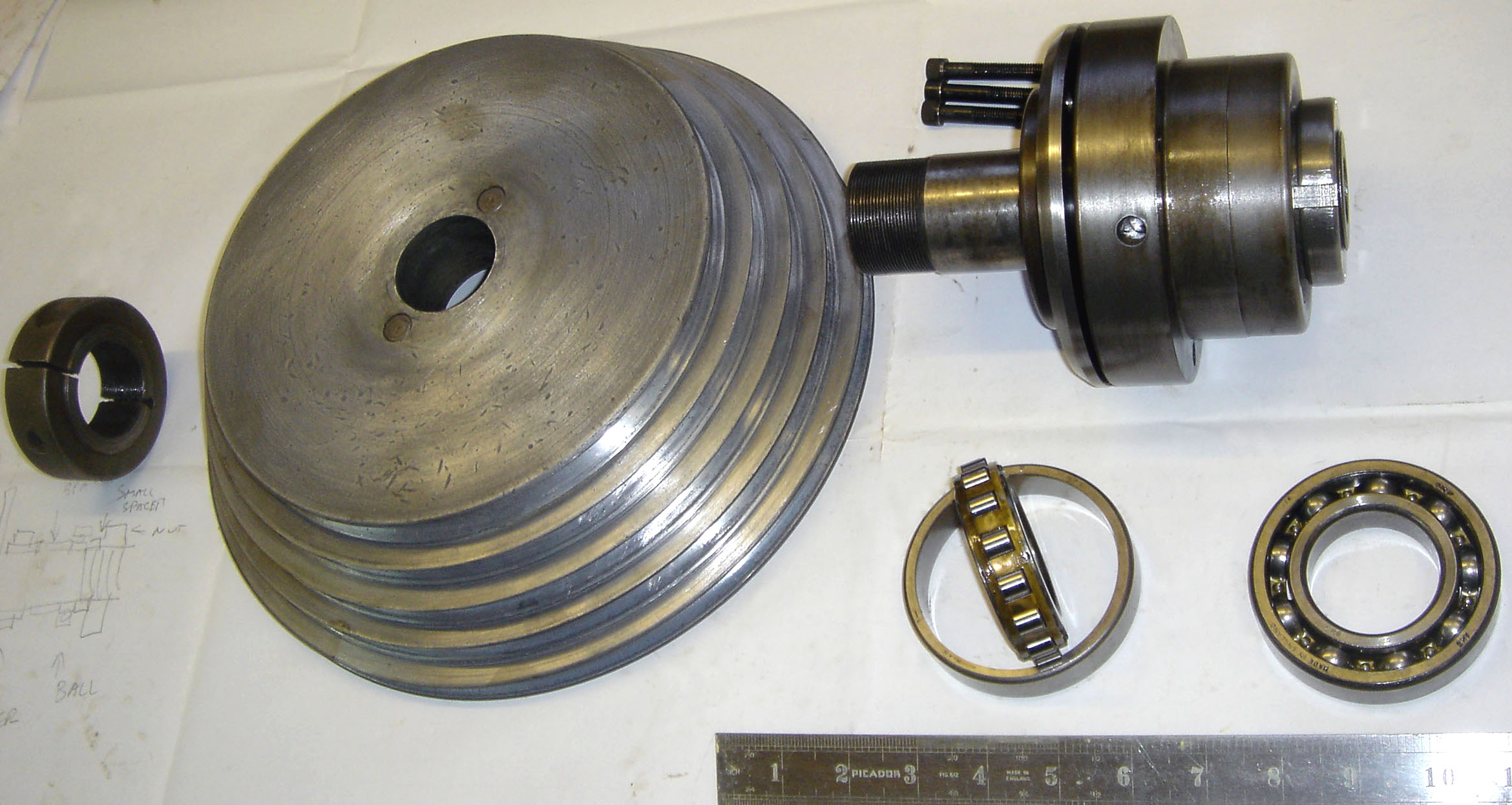

To avoid belt pull upsetting the spindle, the pulley (like those on high-class lathes) ran in its own bearings - one ball and one (expensive-to-replace) parallel roller - and drove the spindle through a long key. For the size of spindle the head was massively built, resulting in a very solid feel and a particularly smooth drive. Judging by the number surviving both in the UK and overseas, the No. 79 was a popular model and if any reader has a Type 79 miller, or any literature concerning them. the writer would be very interested to hear from you.

A reader responds:

" I am a regular user of your very useful machine tool archive, and wondered if you would be interested in some pictures of this other CVA vertical milling machine?

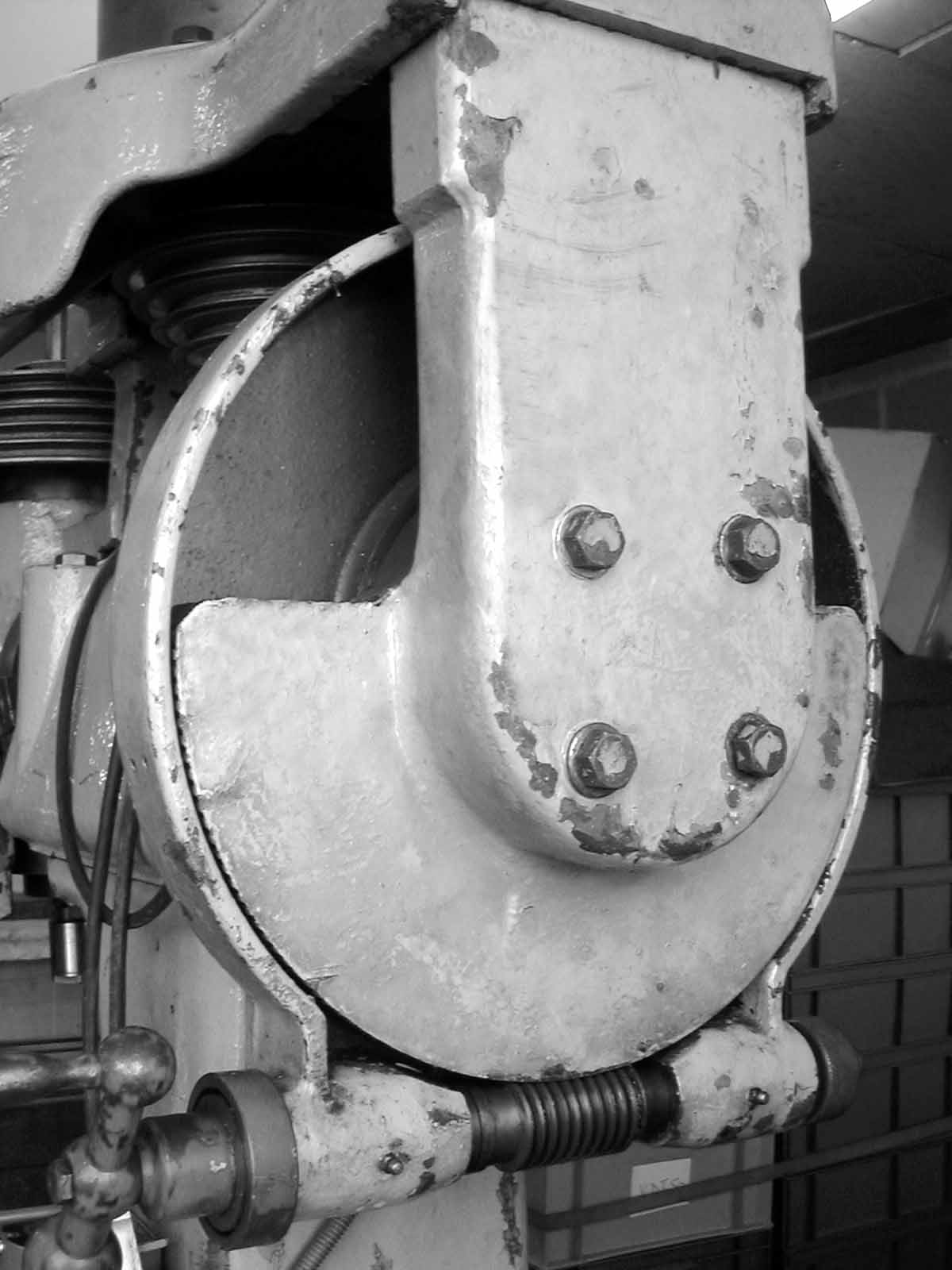

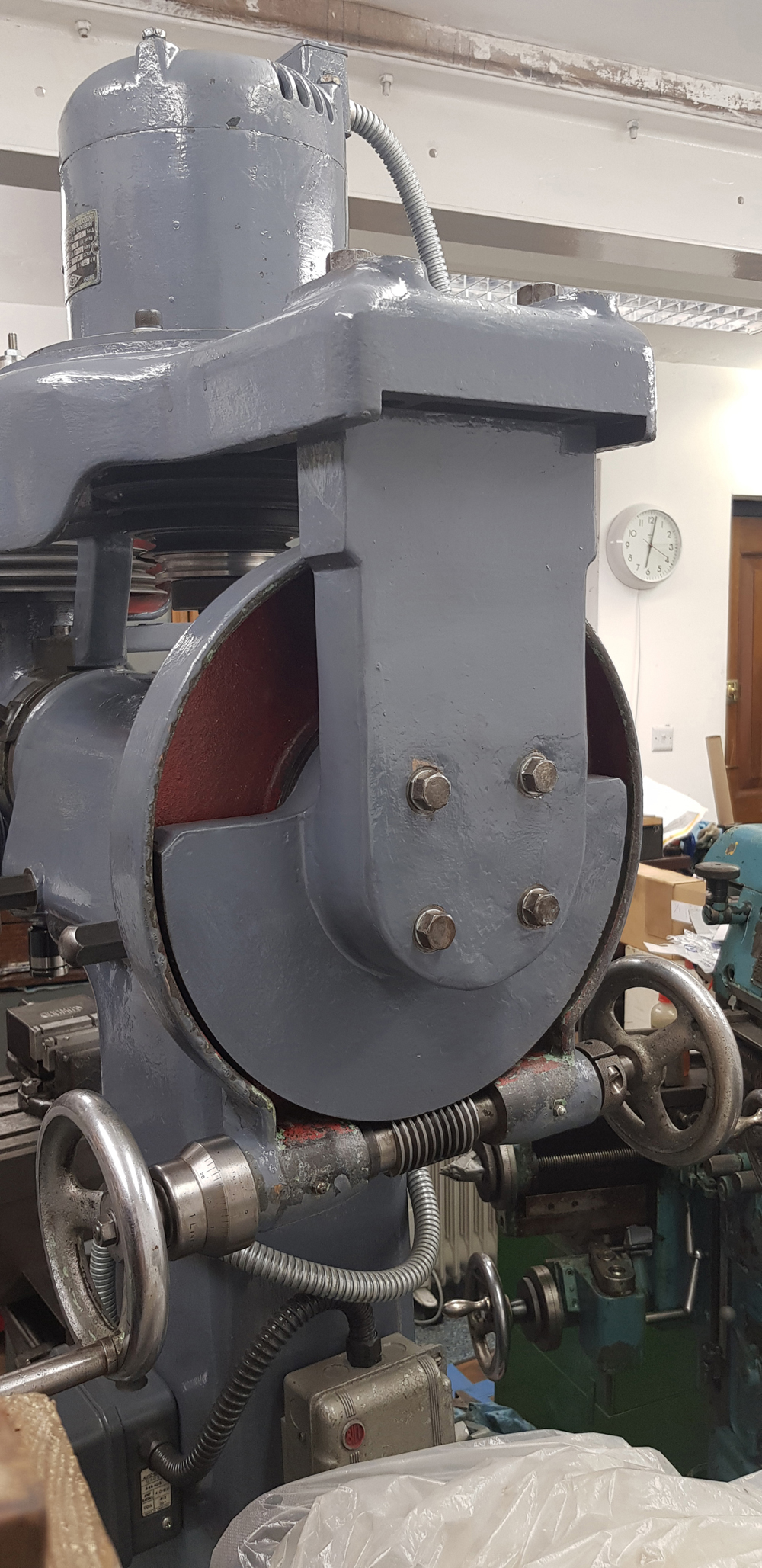

It appears to be, essentially, a bigger version of the well-known CVA No. 79 mill and was probably made by CVA, though it is badged 'E H Jones', including the cast 'EHJ 55' logo on the door in the side of the column - this Company once being a very well known trader who specialized in better-quality machine tool.

I bought the miller from a defunct brewery in Bristol, around 40 years ago, but have never seen another like it, nor a mention of the machine anywhere. Maybe you have?

The table is around 38" x 11", the column to spindle is 16.7" maximum throat and the spindle-to-table distance 20" maximum. I am not sure of the weight, but must be, judging by the difficulty of moving it, over a ton. The head slides back & forth on the column and rotates +/- 90 deg under worm & wheel control - just like the CVA No. 79.

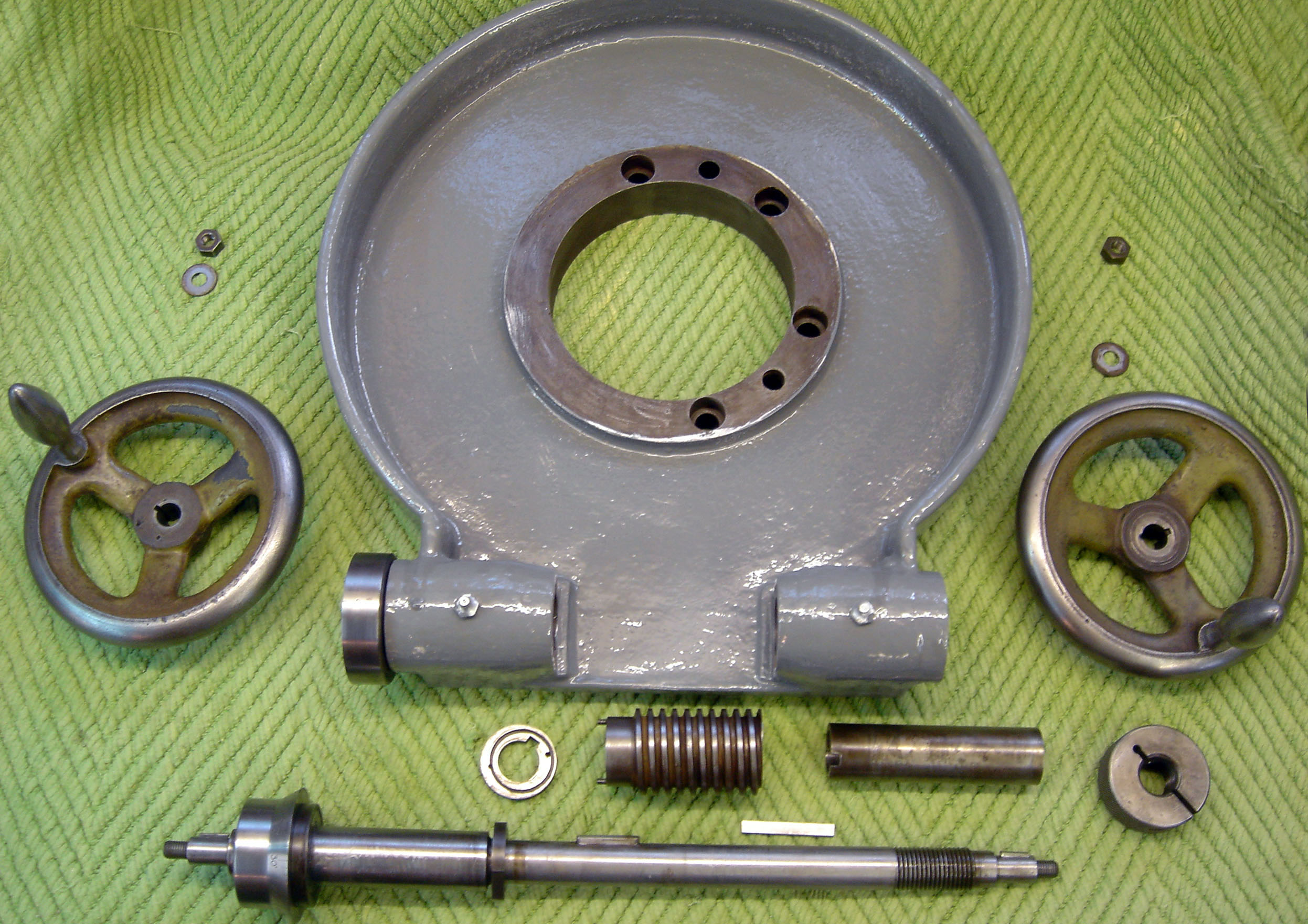

When I acquired the machine, there were quite a few 'dings' in the table, but I doubt it had seen a great deal of use , as it was otherwise in good condition - though pretty scruffy. The spindle originally ran in a split, tapered bronze bush and ball thrust bearings (like the earlier CVAs) and had a 4MT socket. I modified the quill to take taper-roller bearings and made a spindle to suit, retaining a 4MT socket. I initially fitted a single-phase motor to replace the original three-phase, but later went to a three-phase motor with a VFD and fitted a power feed unit to the table and DROs to all three axes.

This larger, unknown model of CVA is rigid and accurate, and can take large cuts in its stride - and is much better than a Bridgeport in this regard. It has done plenty of good work for me over the years. Pictures of the miller at the bottom of the page.

|

|