|

Manufactured in Lyon, France, the plain-turning (i.e. non-screwcutting) "SF2-Lyon" was one of a number of French-built high-quality plain-turning, "bench precision" lathes with others including: Crouzet, Jenny, Precis, the very early triangular-bed Prudor, S.O.M.B.V. and the "JCH" that came from the Roanne, a small town to the northwest of Lyon (it's likely that they made a plain version of their unusual Type TG2).

The S2F, often found carrying badges proclaiming "Codima", the name of a machine-tool dealer, could be had as an ordinary centre lathe or one fitted for production use with capstan equipment. Heavily built, it incorporated a number of unusual design features - some of very dubious merit. Of the twin-bar type, the bed consisted of a main, 40 mm diameter tube, arranged centrally and spigoted into the headstock, with a second smaller-diameter tube placed in front. Incredibly, the tailstock end of the bed was unsupported - and the front tube carried on two brackets, one cantilevered out from the main tube at its tailstock end the other bolted to the outside face of the headstock - perhaps the designer had just returned from a night on the illegal Absinthe when he sketched out the design.. Between the bed ways was a leadscrew, turned by a handle at the tailstock end, that drove the carriage to and fro. The overhung bed tubes must have led to flexing under heavy loads and one can only assume that the machine was built for lighter work - yet designed to withstand continuous, day-in-and-day-out factory use (see below for a user's experience of bed flex).

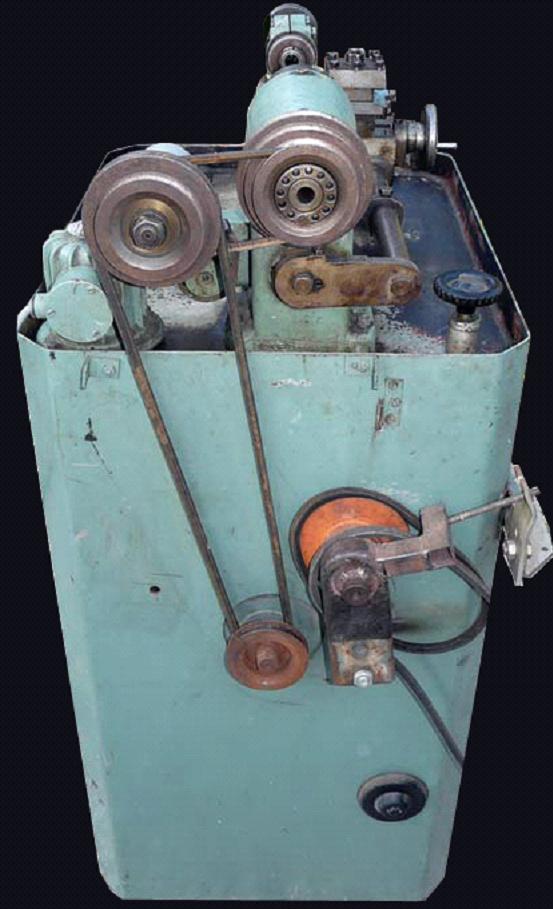

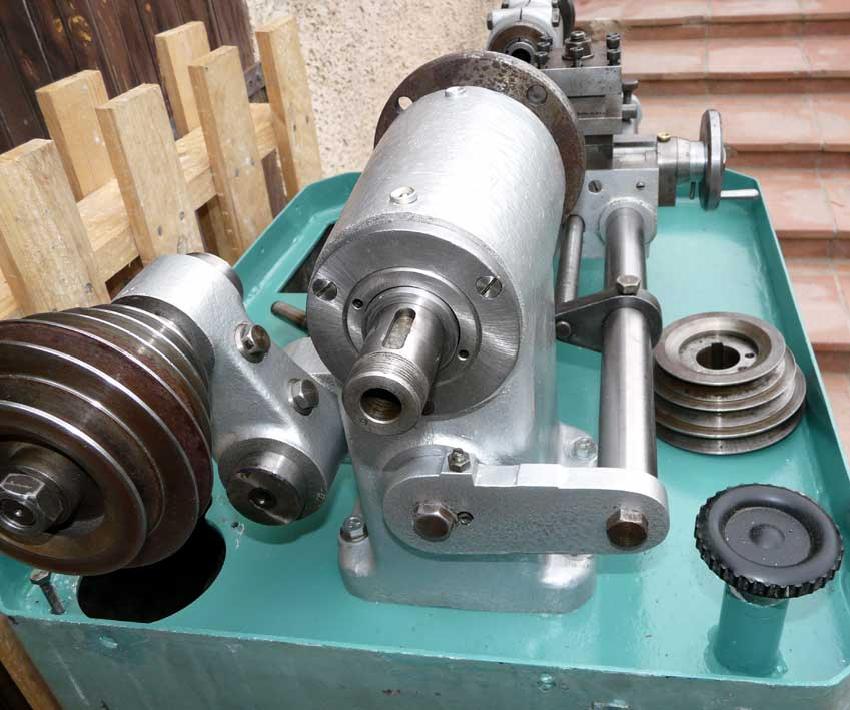

Massively built, the headstock was a rigid, enclosed assembly with a spindle supported in ball races driven from an overhung, 3-step pulley. Drive came by V-belt from a robust, rear-mounted countershaft that pivoted from a boss cast as part of the headstock's rear wall. Held within the cabinet stand, the motor's shaft (fitted with a 2-step pulley to give high and low speed ranges) protruded through the left-hand face, the drive rising to the countershaft by single V-belt. The arrangement gave six speeds that, from the size of the pulleys fitted, probably spanned 300 to 1000 r.p.m. or so.

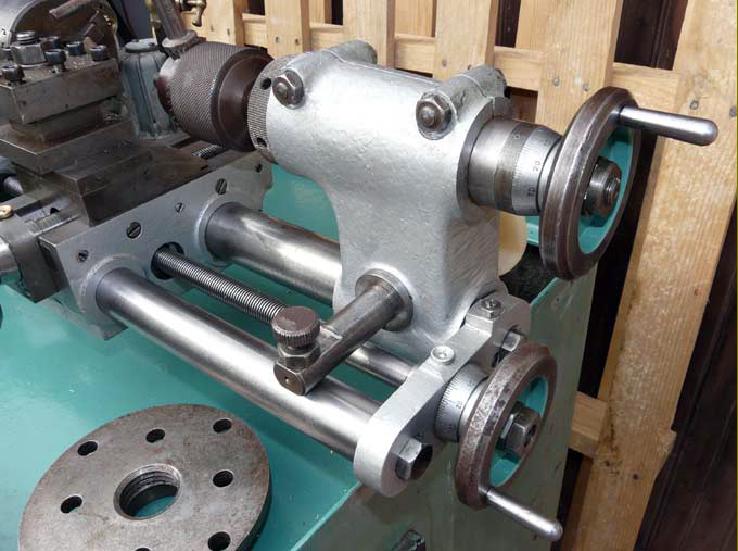

Only a single tool-slide was fitted and this, unable to be swivelled, indicates that the lathe really was probably intended for production purposes rather than general use. A further clue to the likelihood of repetition use can be found in the design of the tailstock were the top section of the casting was split and clamped by two through-bolts - thus allowing the complete barrel assembly to be removed and replaced by another - rather in the manner found on some "bench precision" lathes such as Pratt & Whitney and Ames.

Avez-vous un tour comme ça? Si c'est le cas, l'écrivain serait intéressé de vous entendre.

An owner reports:

My capstan version of the S2F had some interesting features including a small cross slide that was lever actuated and fitted with T slots with the forward and rear tables having different slot directions and only sensitive feeds with no scales only limit Stops. A big ship-style wheel the right was used to bring the capstan tailstock forward and backwards. I was told it was previously in use manufacturing buttons - which made perfect sense to me.

On my later (I presume) lathe, the main bar bed was still present, but instead of the second front tube, a rear-mounted cast iron bracket extended out and supported the rear of the captain table. It wasn't round in profile, but looked more like half a camelback or similar structure. In fact I still have it in use as a straight edge standard after fettling it flat on my surface grinder.

I tried to use the S2F as a manual lathe when I was having problems with my Harrison l5, but the small work envelope and lack of cross slide was a pain plus, when you started working away from the chuck, the unsupported bed started to droop significantly. I did a experiment one day and, with the operator leaning on the end, could alter the tailstock centre down by 0.10 mm. Deflection also happened when that big captain tailstock moved back and forth. I'm also puzzled as to why the makers didn't add even a small support to the outer end, maybe it really was only for close in button work to the chuck. For that it would have made sense with a cut off and facing tool mounted on the sensitive fed cross slide.

I know of someone else who owns one, and he too has reported the bed drooping under load. Second-hand value of these seem pretty low, as they are capstan lathes, yet tiny with it and cursed by the flex issue. I think I paid £100 for mine and bought it as a curiosity, and the other I'm aware of changed hands for a similar derisory amount..

|

|