|

Home Machine Tool Archive Machine-tools Sale & Wanted GRINDERS - Page 2 - also branded "March", "Smart & Brown" & "DeVlieg" - models and the full accessory range is available |

||

|

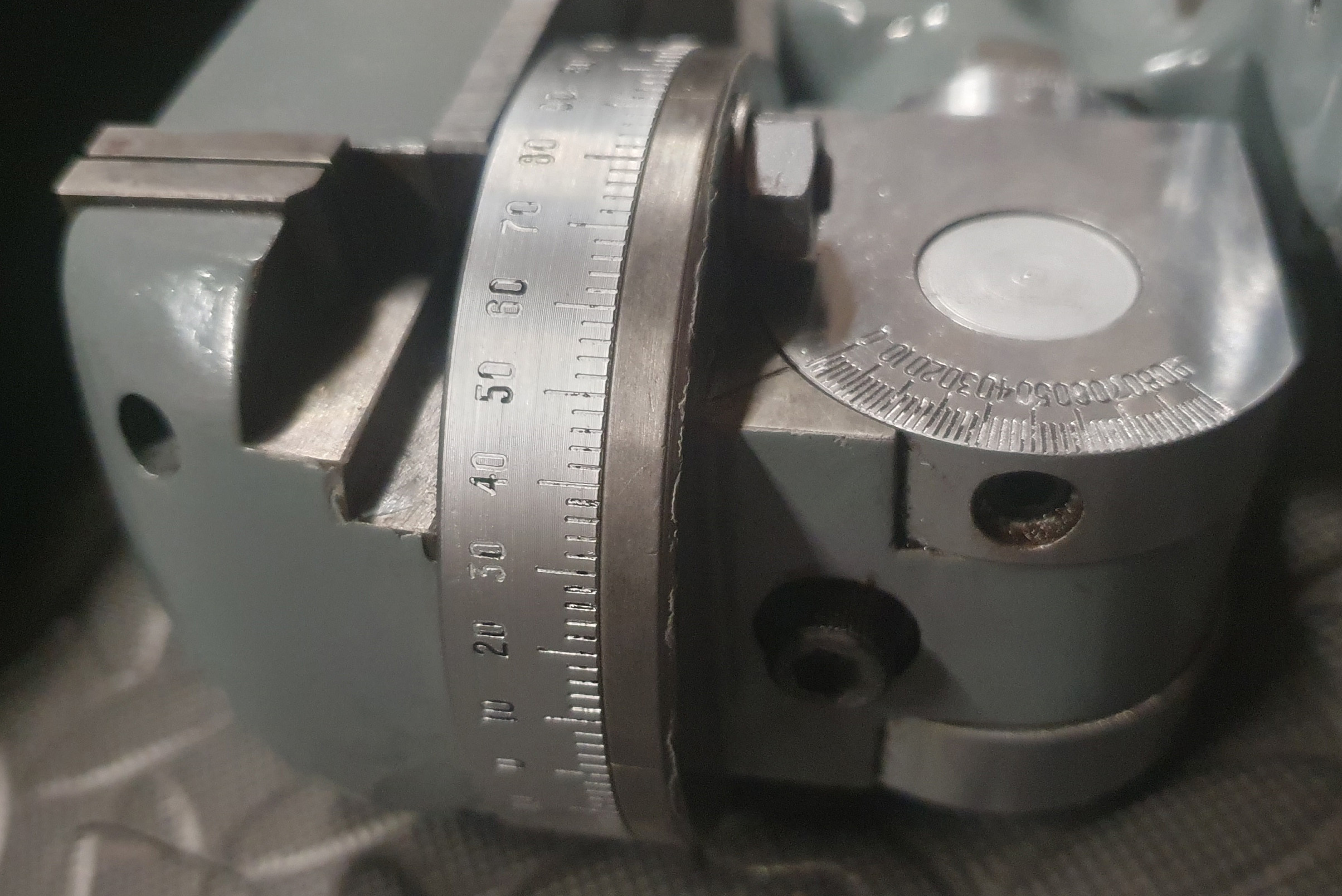

Drill Point Lead & Tap Grinding Attachment. For use on Mk. 2 and Mk. 3 models this unit was able to regrind drill points from 1/8" to 5/8" diameter (3 mm to 16MM), thin the web on drill points, produce a four-facet point and regrind the lead on taps from as small as 4BA to 1" diameter. |

||

|

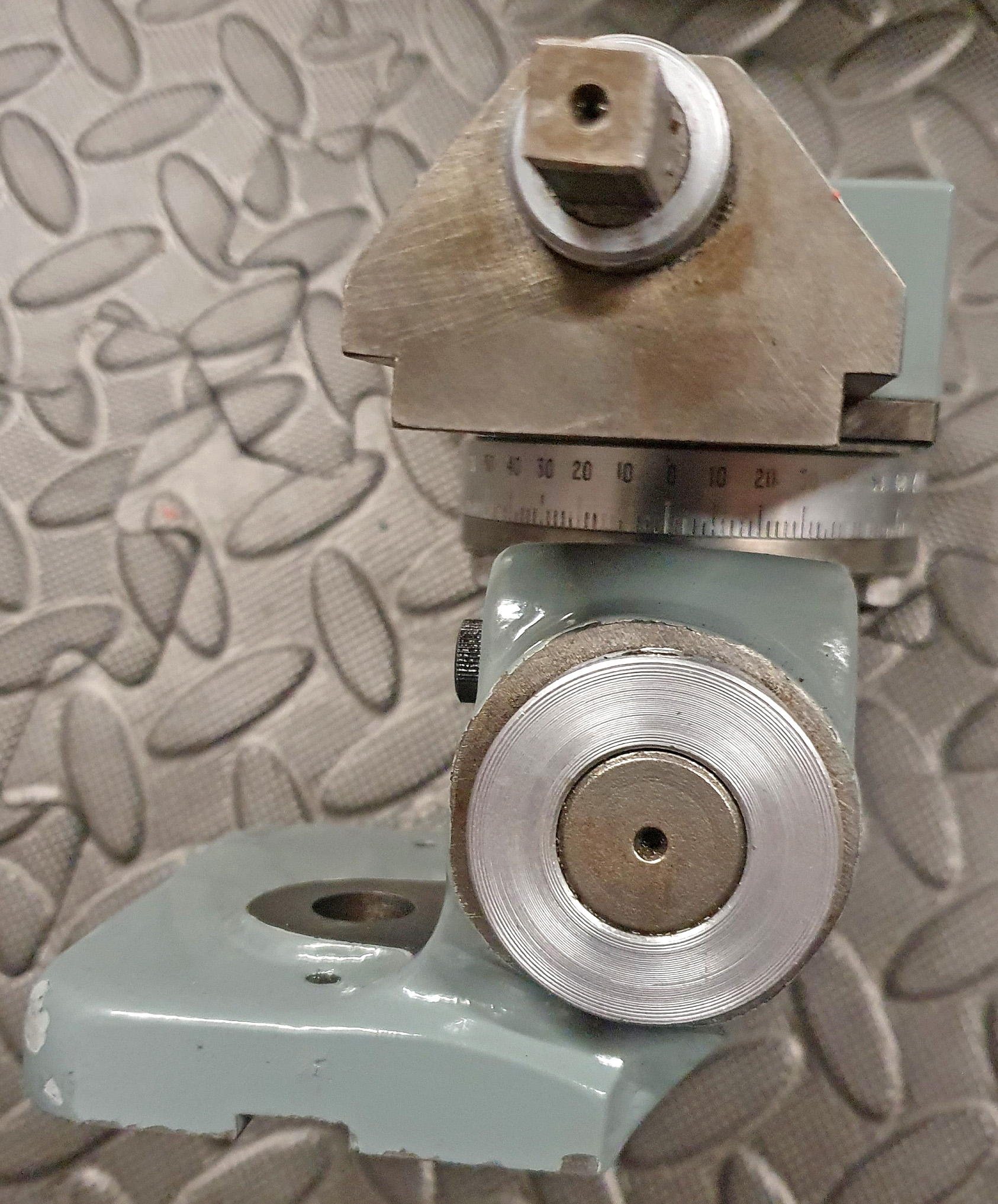

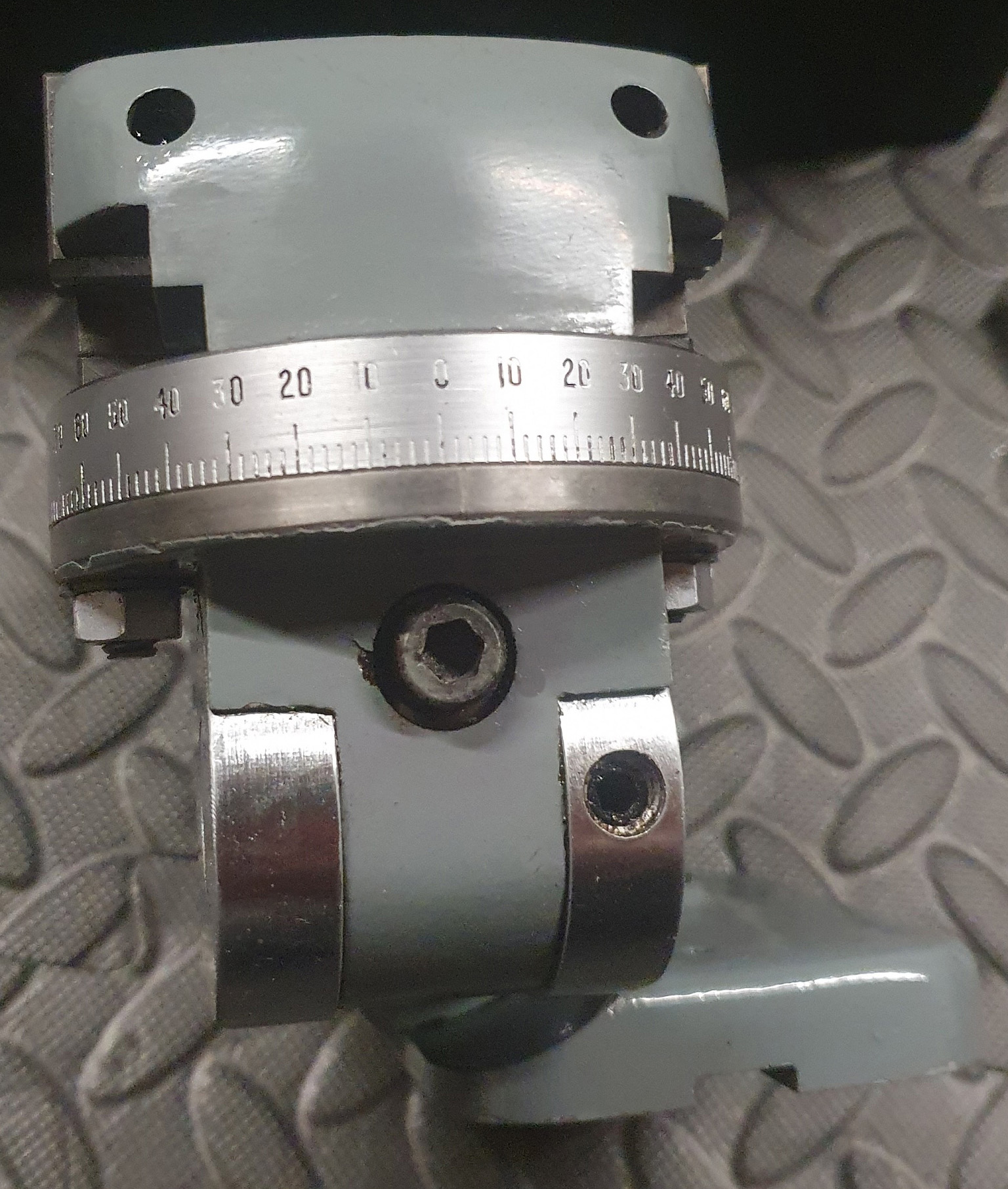

"Mk. 2" Radius Grinding Fixture for Mk. 2 and Mk. 3 models. This unit was designed to put a ball nosing on slot drills, grind radii on end mills, form and regrind corner-rounding cutters and (with extra attachments) grind radii on side-and-face cutters. |

||

|

Air bearing flute-grinding attachment. This unit consisted of a workhead able to mount various sizes of cutter-holder bodies that floated on a film of compressed air to give a virtually friction-free movement. The attachment allowed regrinding "up flute" and also on the relieving of flutes on cutters with right or left-hand spirals and without centre holes. One version was made for the Mk. 1 and 2 machines and with a modified unit supplied for the Mk. 3. |

|

Controlled Spiral Attachment. Produced in different versions to fit the Mk. 2 and Mk. 3 machines the unit was available with a range of index plates and designed to obviated the need for setting fingers when grinding spiral milling cutters such as the Clarkson "Rippa" and "Hyfeed" types. It could also be used for the regrinding of standard cutters up to 8-inches long on the Mk. 2 and 16-inches on the Mk. 3. By employing a collet-chuck system it was able to hold cutters without centre holes. |

|

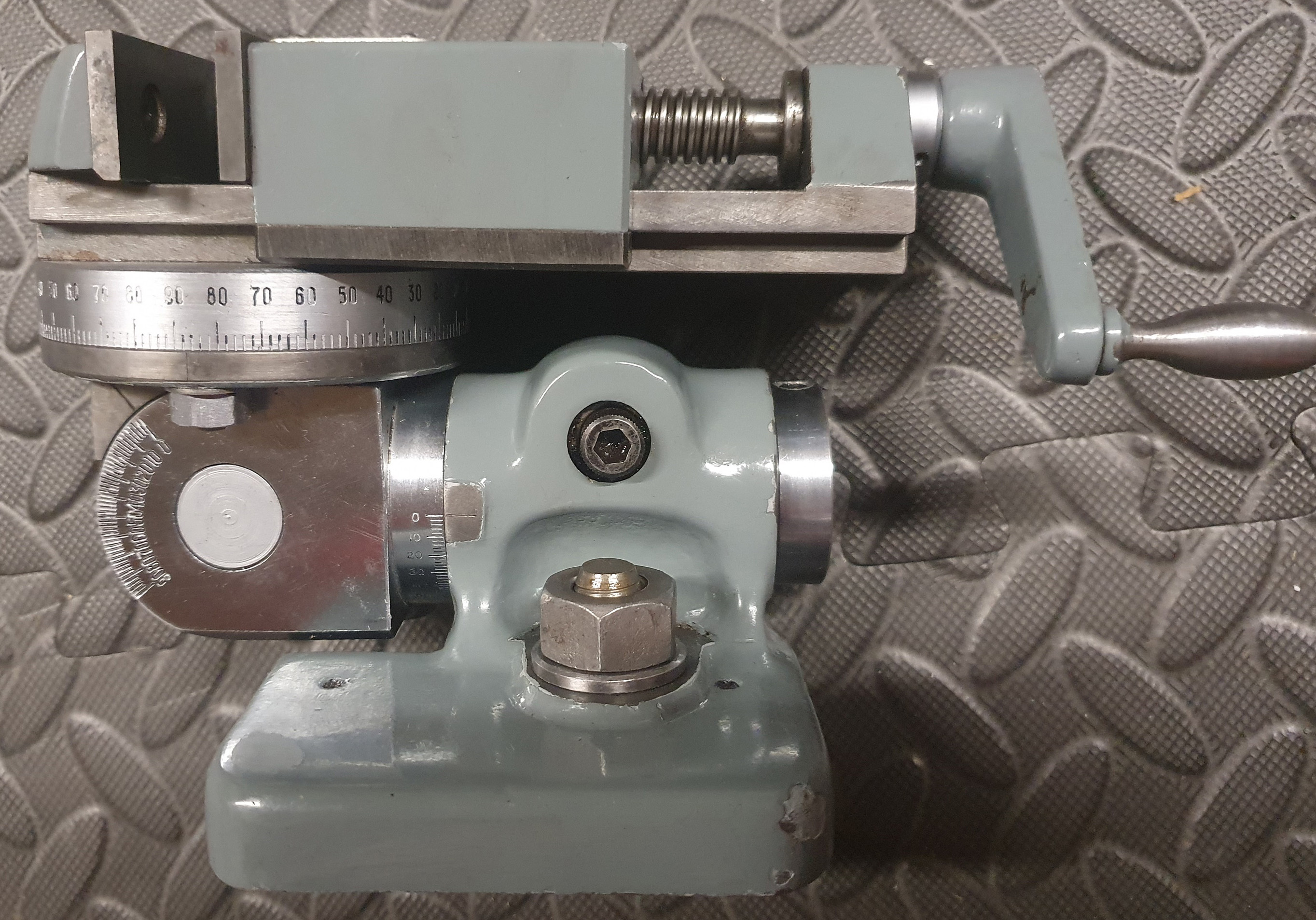

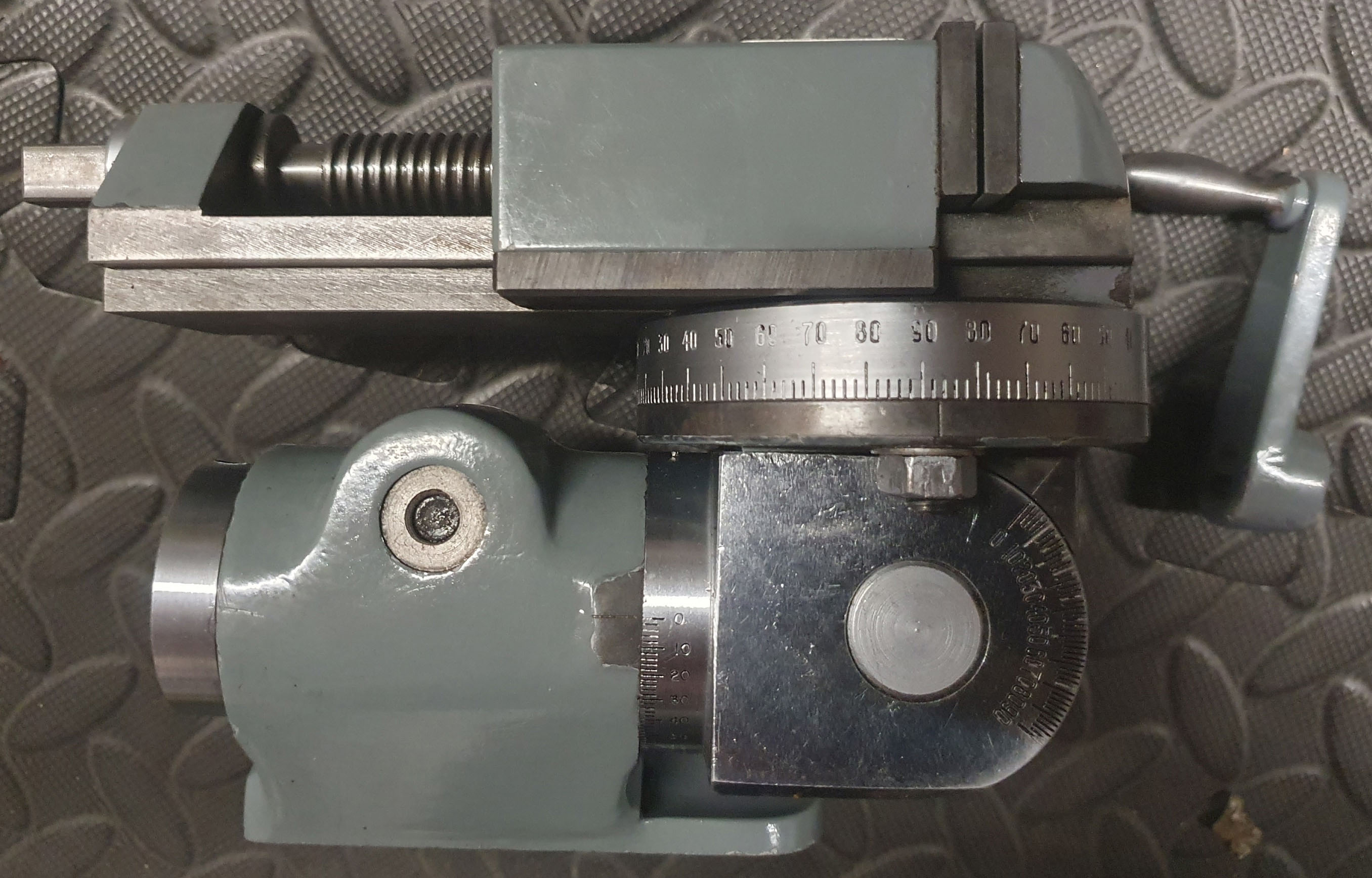

Clarkson Vice. This was available fitted to an expensive (and hence rarely-found) Universal 3-way Swivel Adapter or mounted on the swivel base (shown below). The vice had jaws 72 mm wide, 22 mm deep and capable of opening to accommodate a workpiece 41 mm wide. |

||

|

|

||

|

|

||

|

Relieving flutes on a slab mill with the use of the standard centre brackets, and a cranked toothrest of Type A or B (according to the flute depth). |

||

|

|

||

|

|

||

|

|

||

|

models and the full accessory range is available GRINDERS - Page 2 - also branded "March", "Smart & Brown" & "DeVlieg" - Home Machine Tool Archive Machine-tools Sale & Wanted |

||