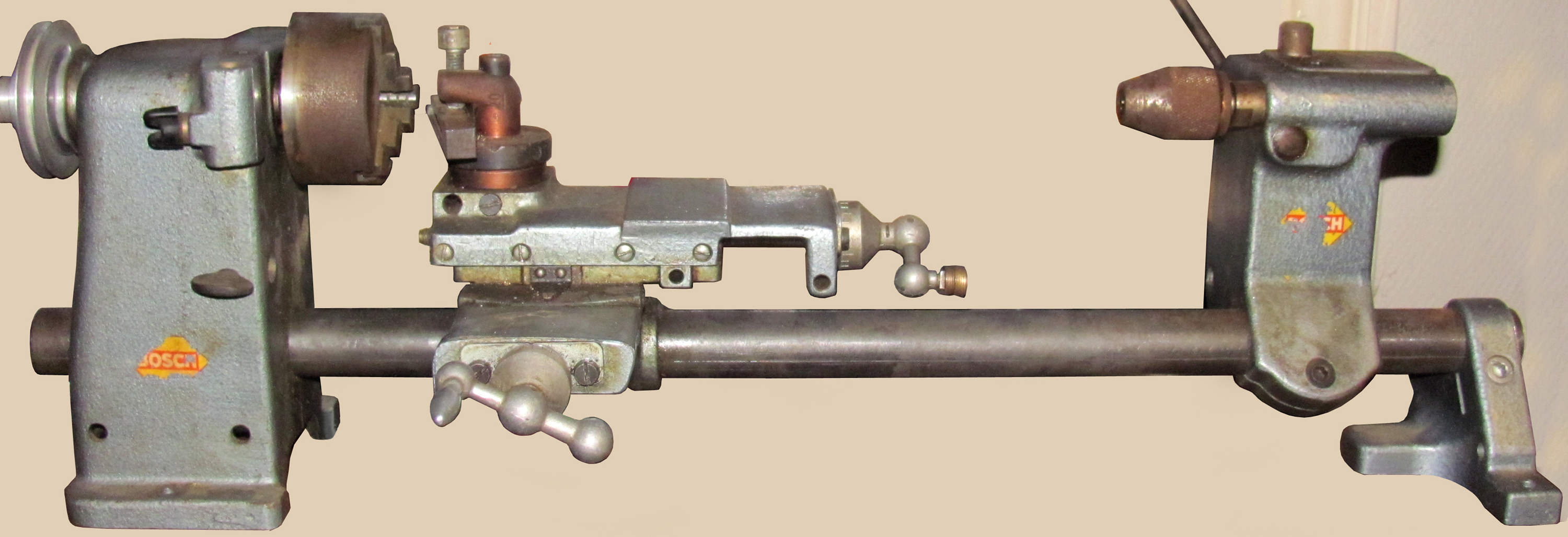

Restoration of a Bosch Wood Combi Type 500

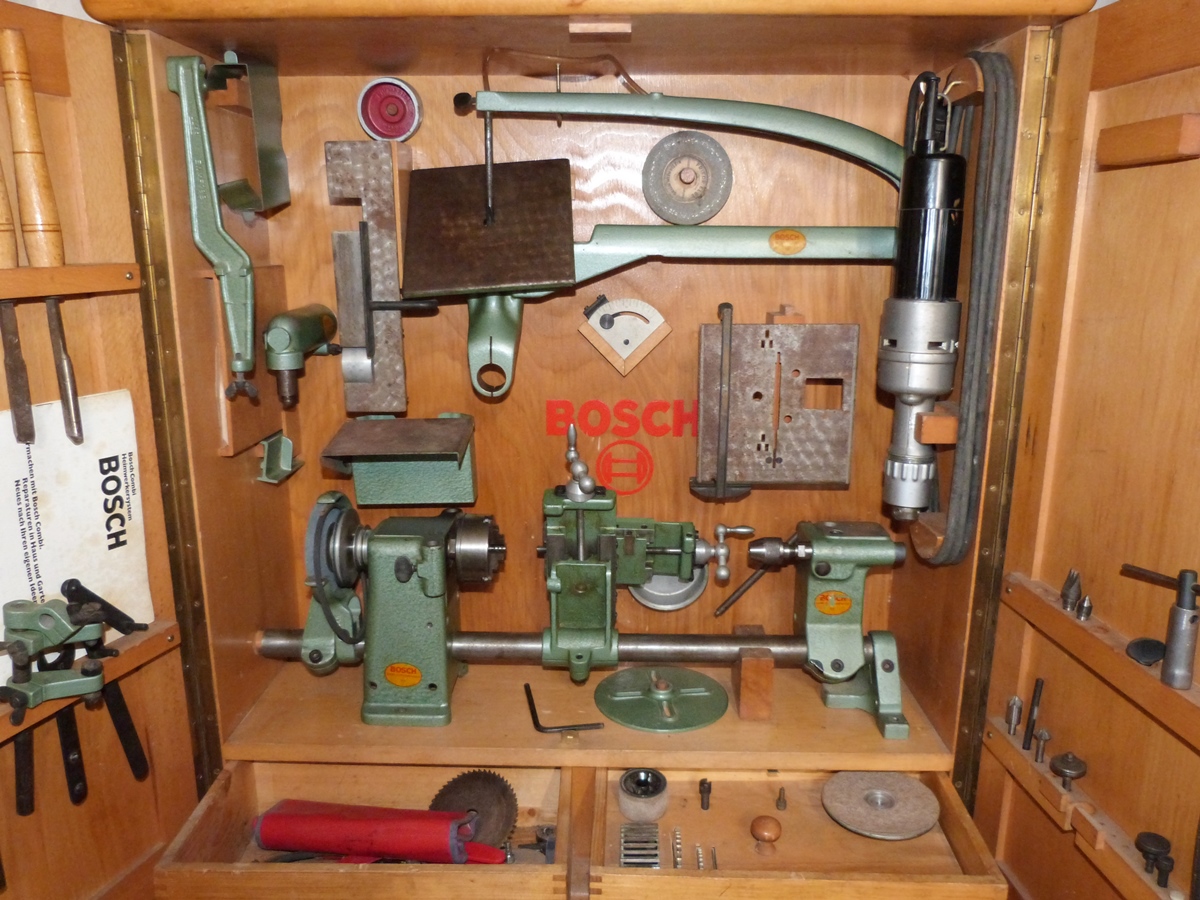

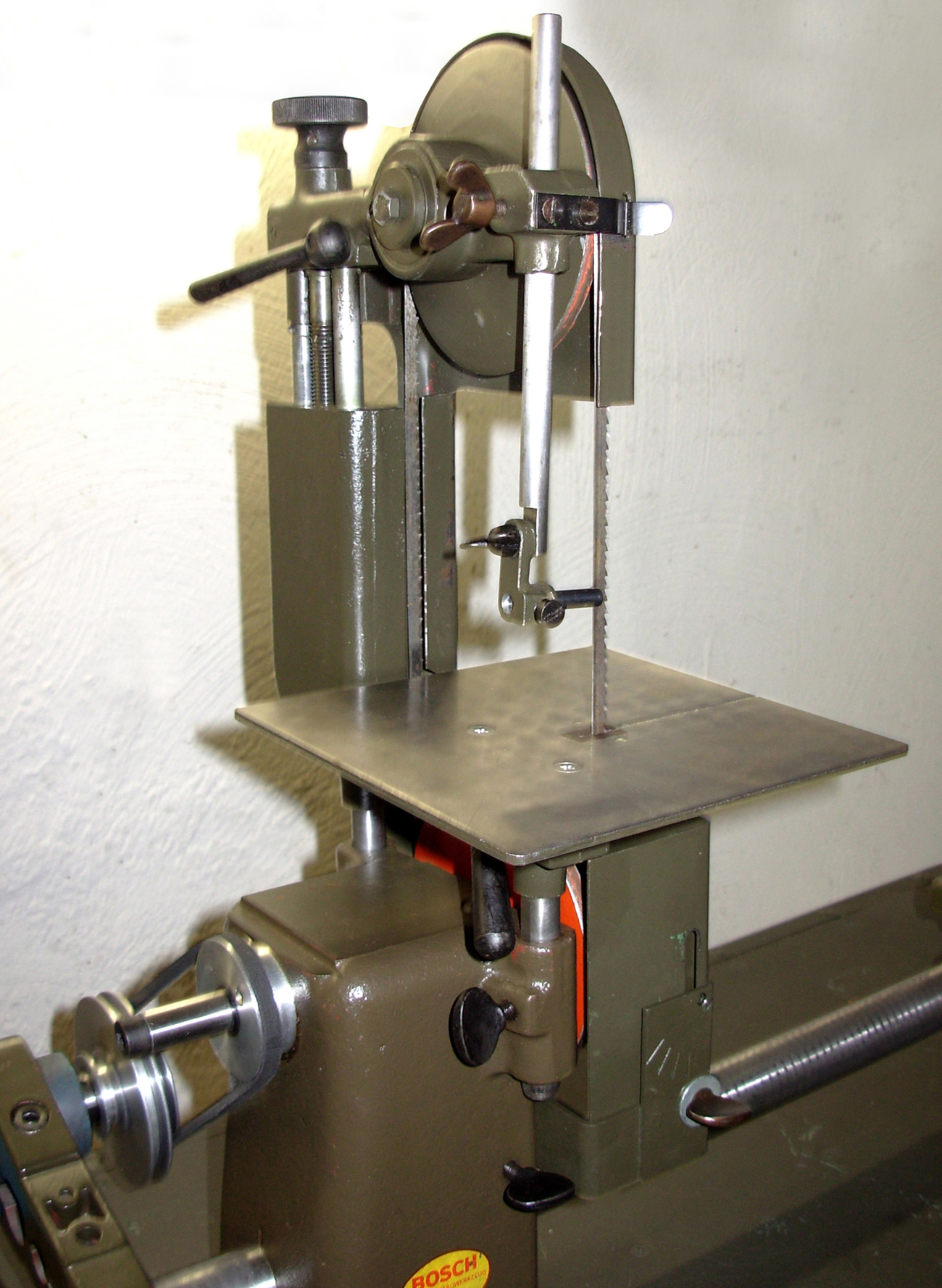

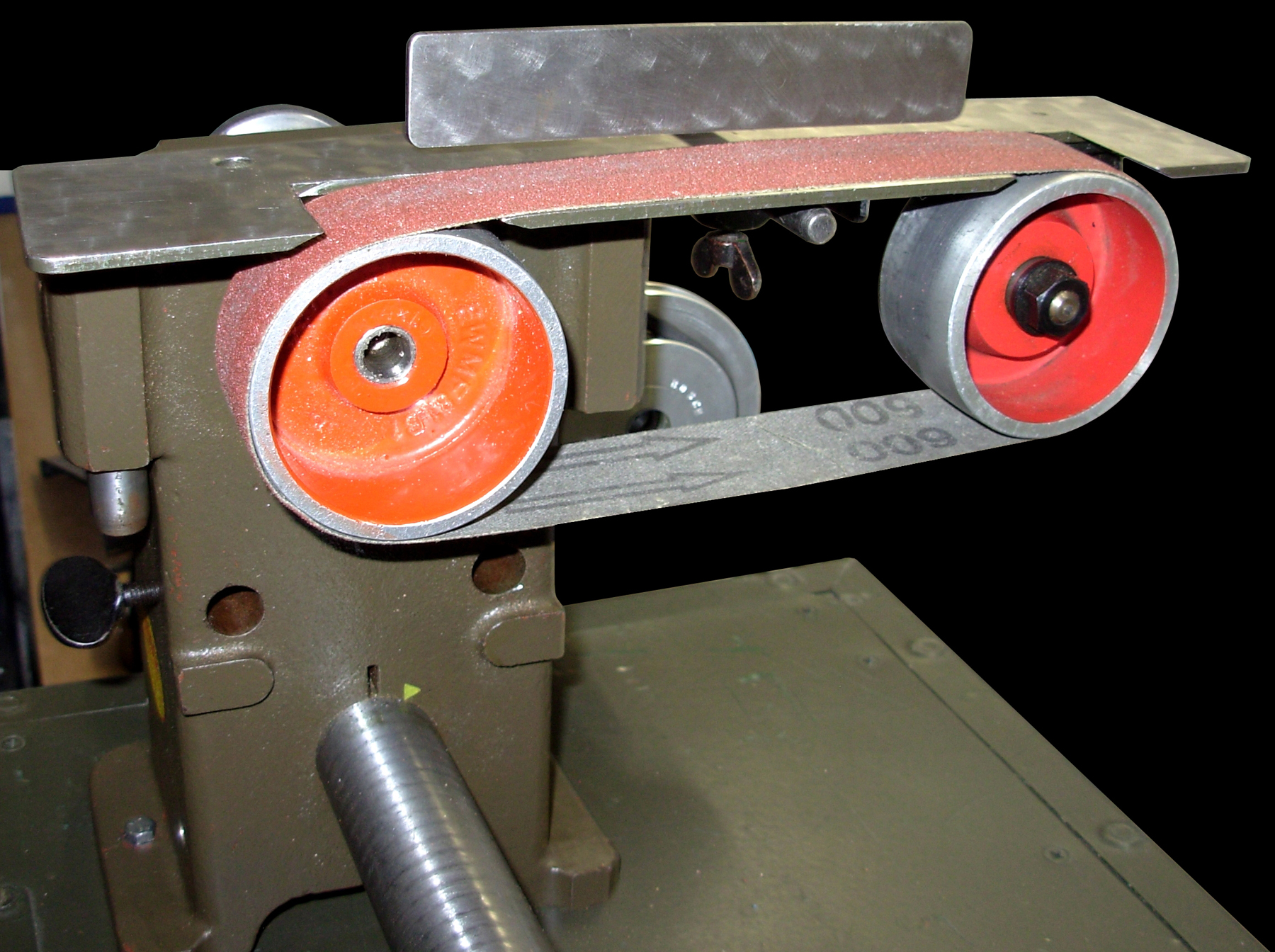

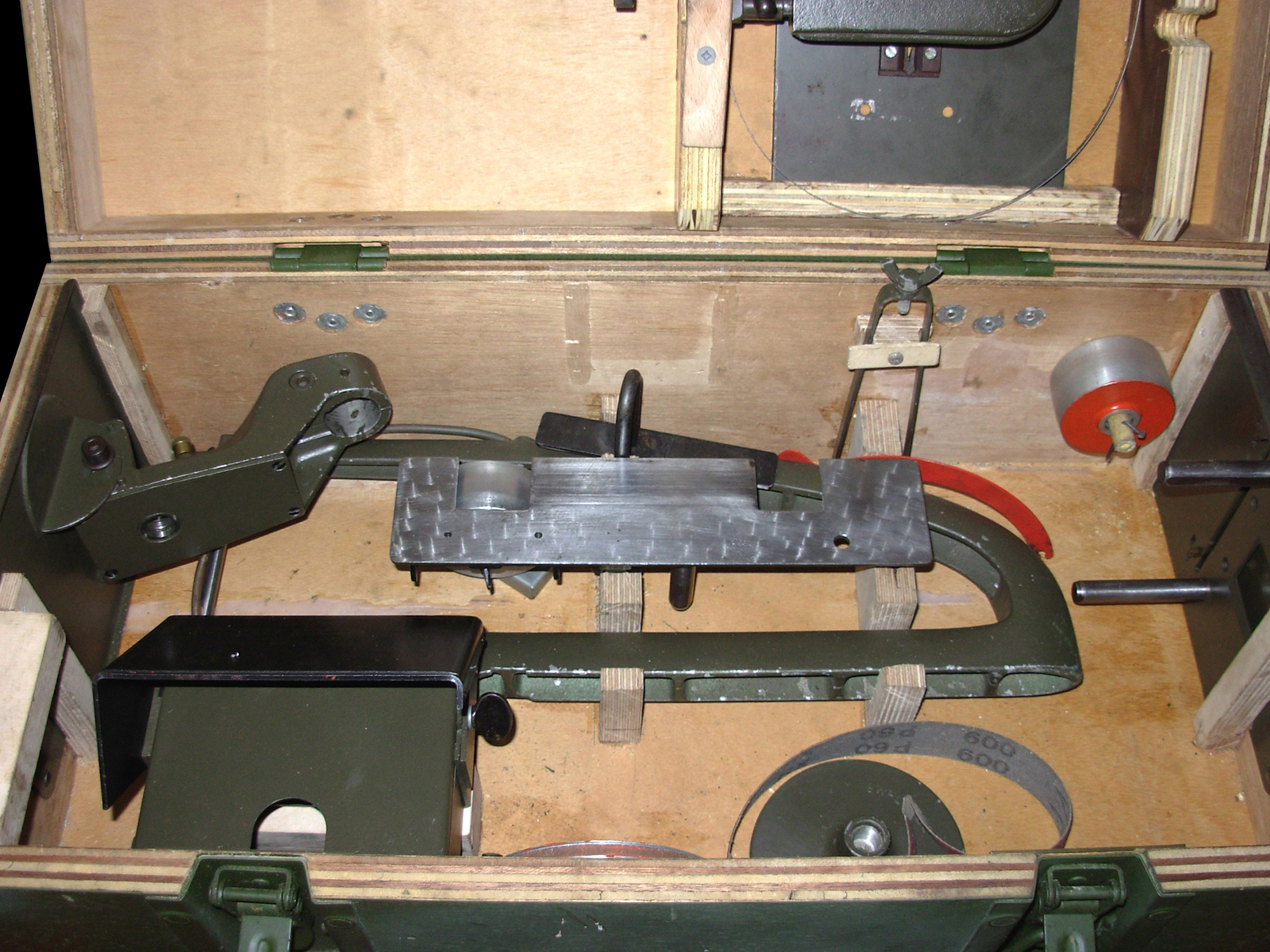

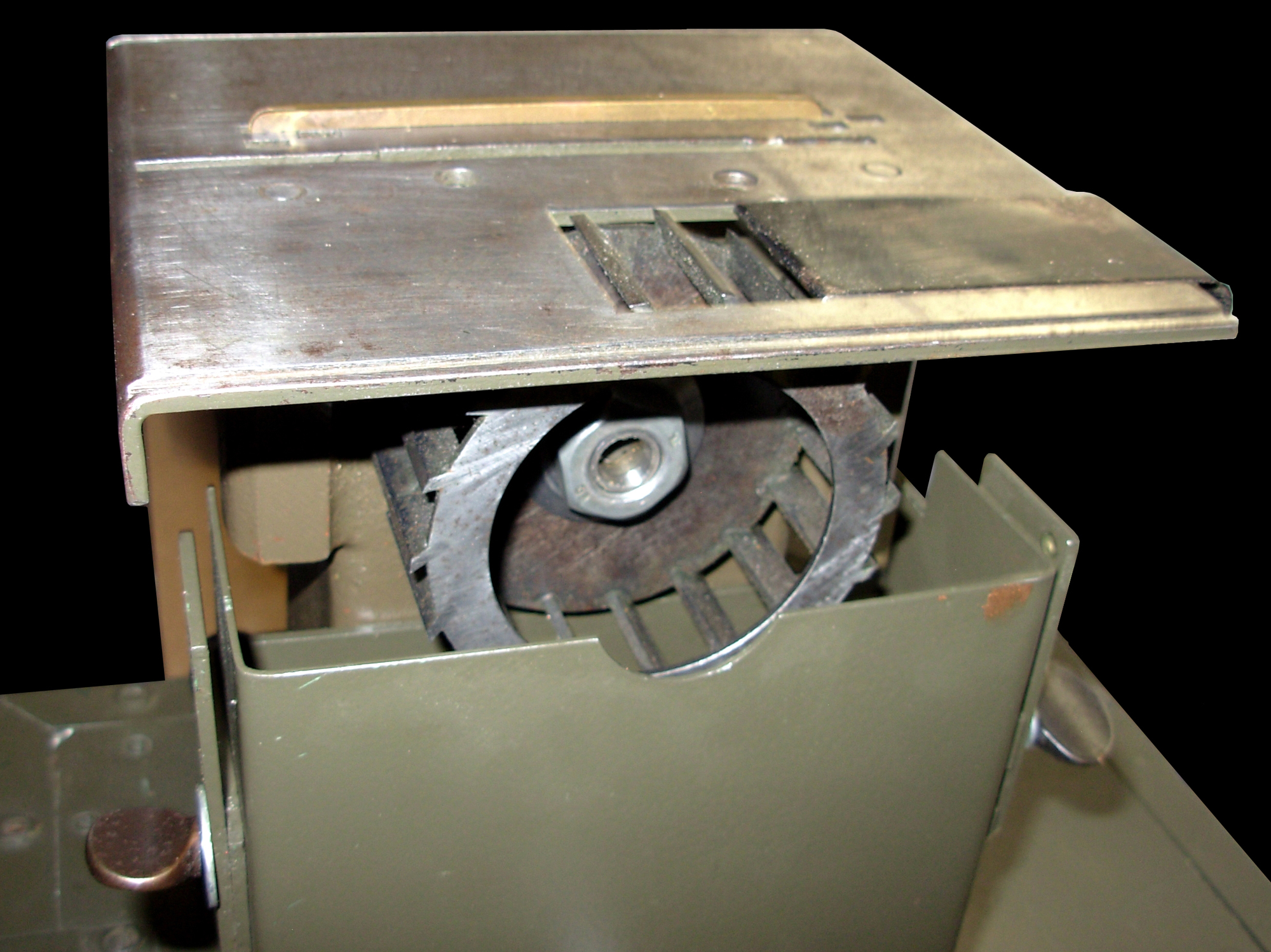

One of at least three basic lathes made for amateur use by Robert Bosh over the decades, the example shown below - the "Combi" -was not the usual ubiquitous and very simple wood-turning type intended to be driven by an electric drill - instead, it was built as a complete plain-turning lathe (that is, without backgear or screwcutting) and available with a wide range of well-made accessories. While not quite in the class of a "Eierlegende Wollmilchsäue" or, literally translated, "egg-laying wool-milk-pig", accessories included a proper screw-feed compound slide-rest assembly, saw bench, a large-capacity jig-saw, band-saw, band-sander, grindstone attachment, planer-thicknesser, spindle moulder, faceplate, sanding discs and drums, 3-jaw chuck, direct-fitting spindle collets, a large faceplate, tailstock chuck, tailstock rotating centre and plain and wood-drive Morse centres. More surprisingly, the makers even offered a copying attachment, though this is rare and seldom found - except in the fully-specified kits sold to the German army from the late 1950s into the 1960s. Quite what the army would have done with such a machine is open to debate, but, in typical taxpayer-funded, cost-is-no-object style, everything was included in a stout, metal-framed fitted wooden box. Doubtless many kits remain unopened and unused and would eventually have come onto the civilian market at auctions - and so offered something of a bargain to the canny buyer.

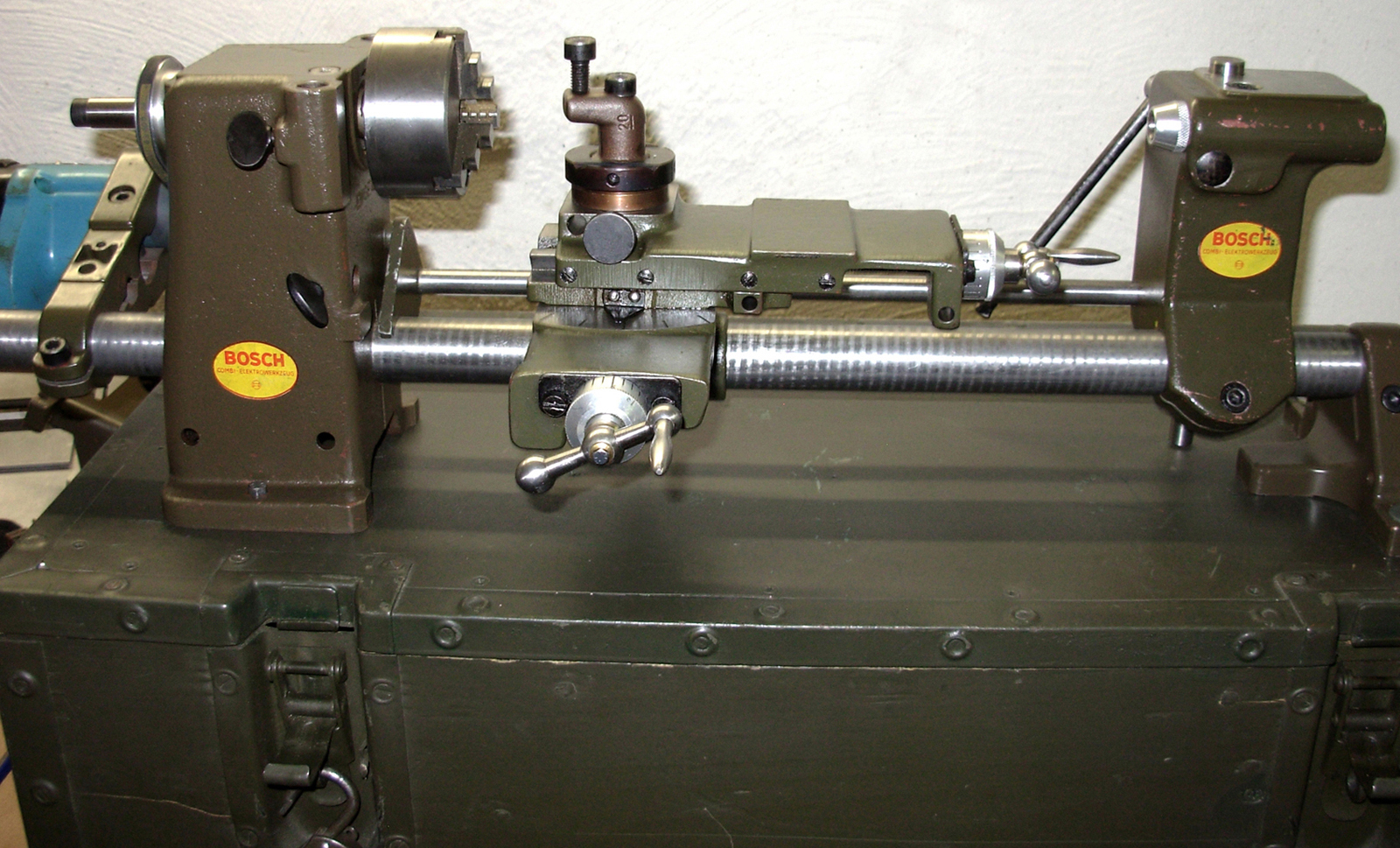

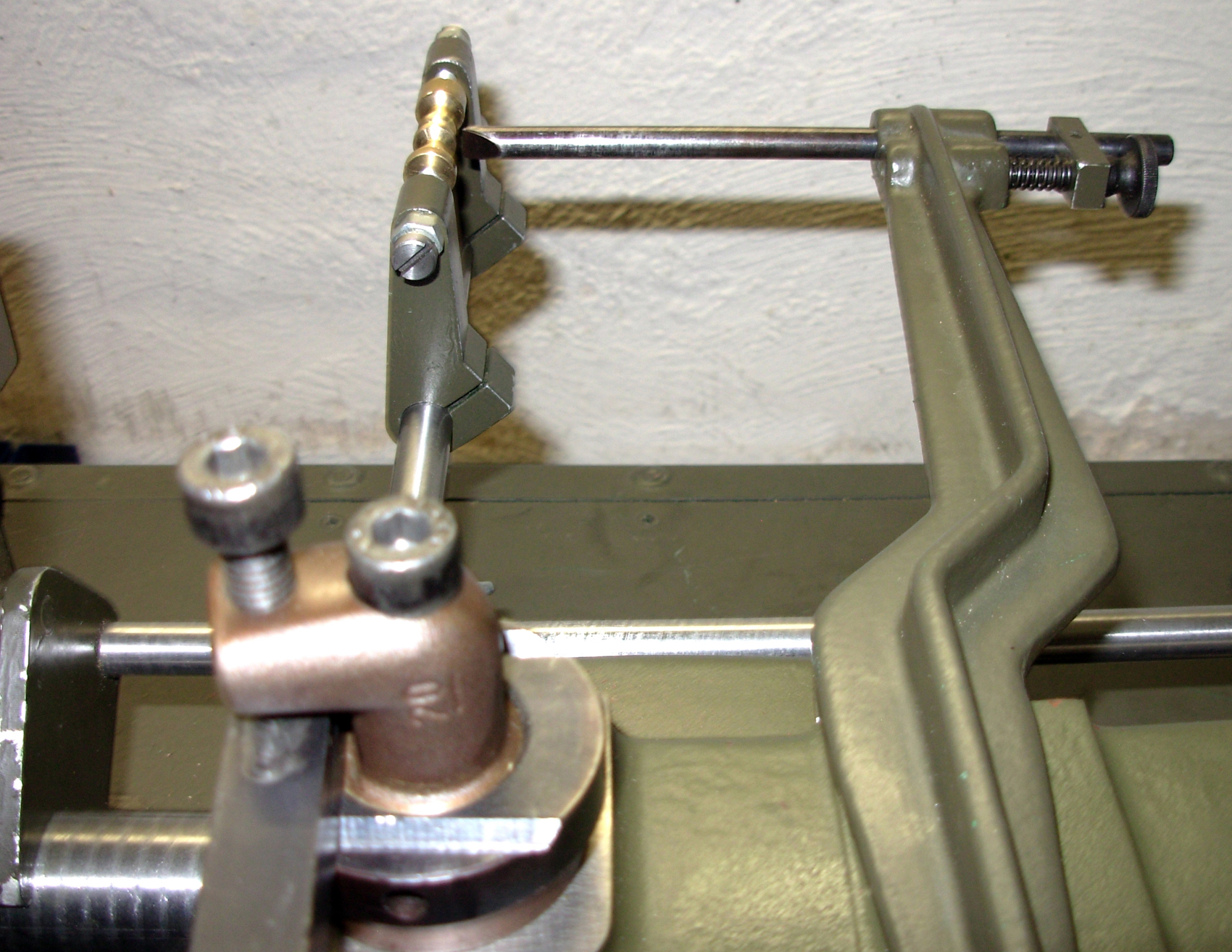

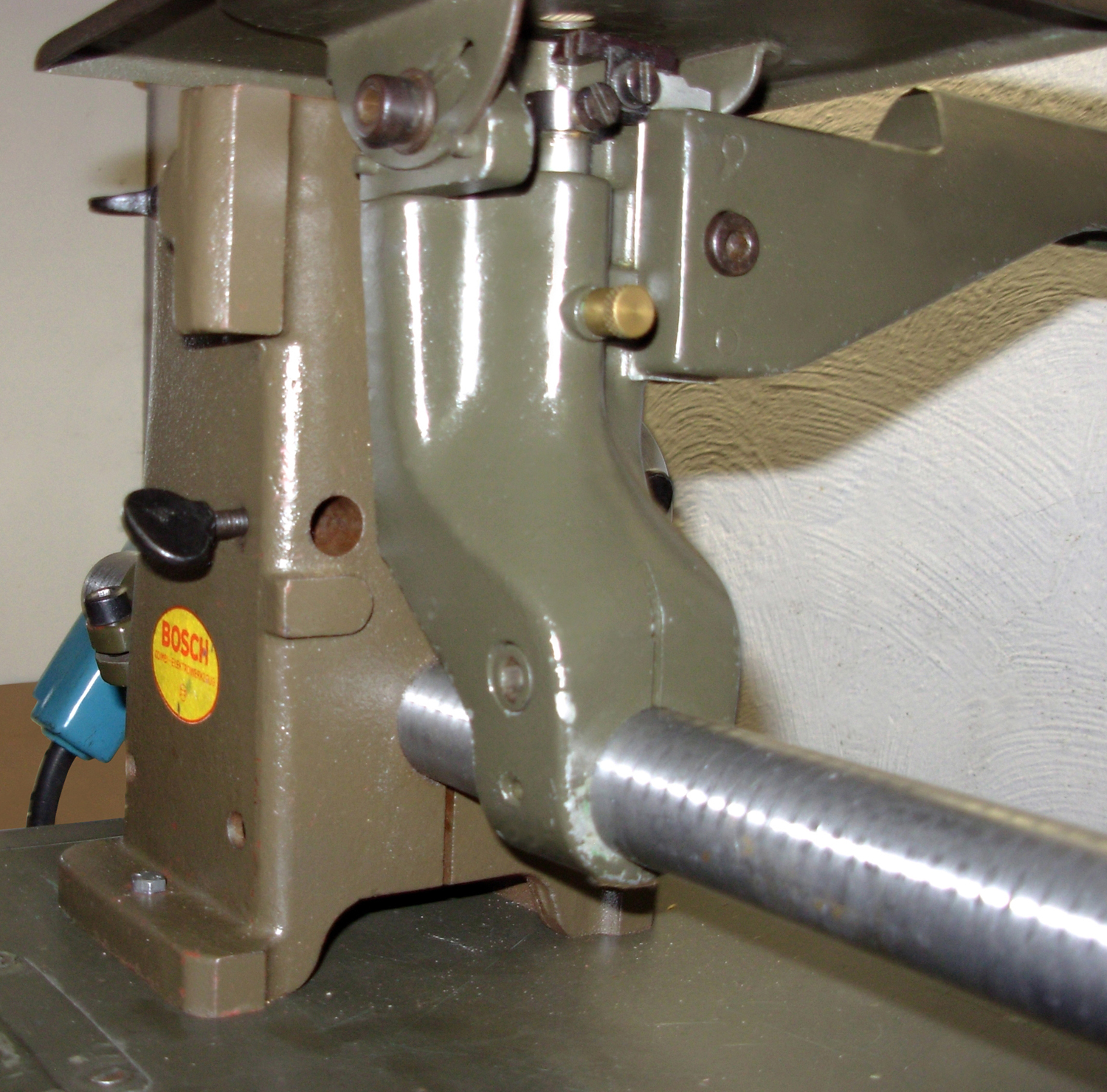

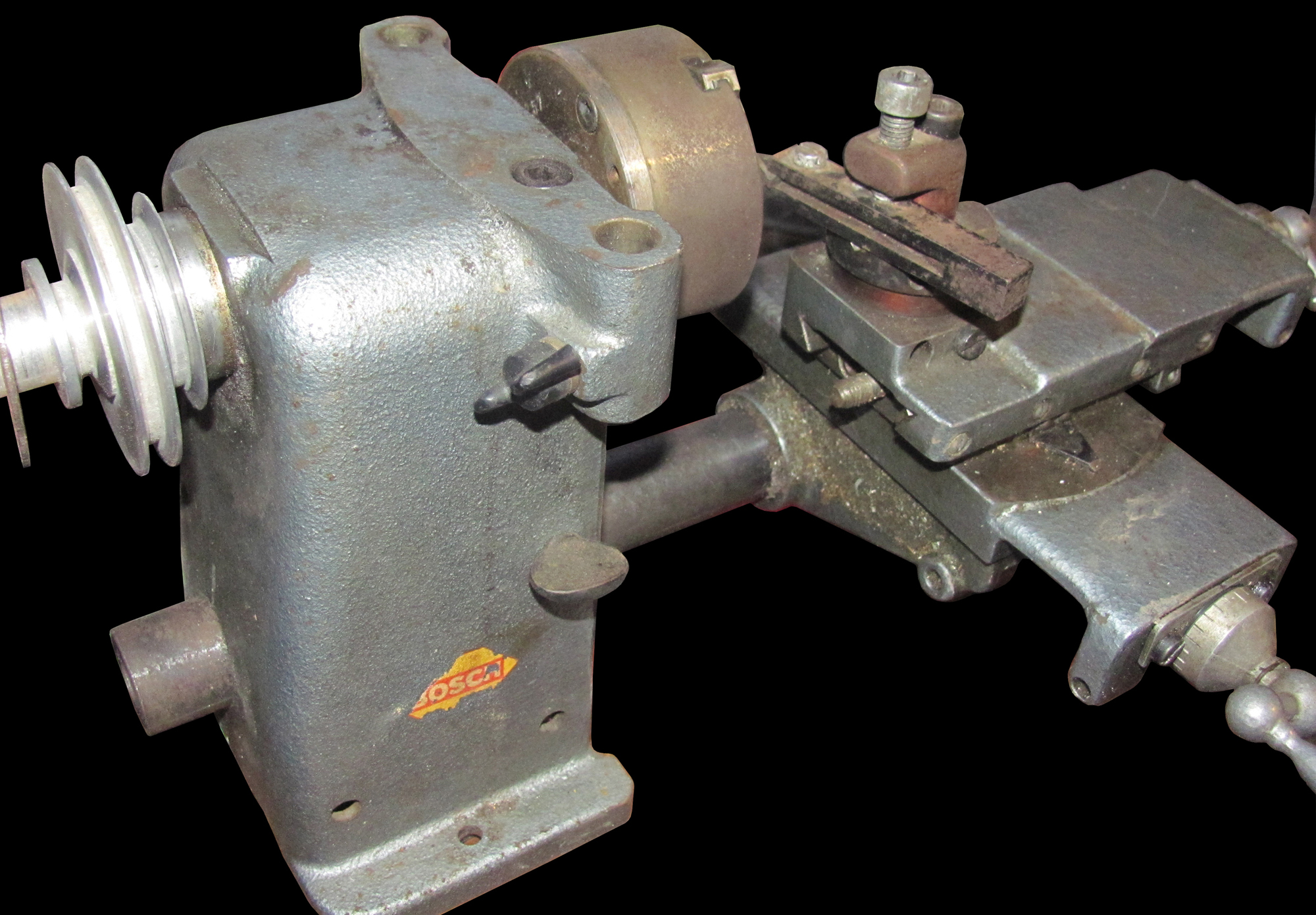

The lathe, with a centre height of around four inches (100 mm) and a capacity between centres approximately 13 inches (330 mm), was constructed around a steel tube with a smaller diameter, detachable "stabilising" bar running parallel to it at the back. From its appearance, all the main components appear to have been die cast, suggesting that the maker planned to manufacture a considerable number.

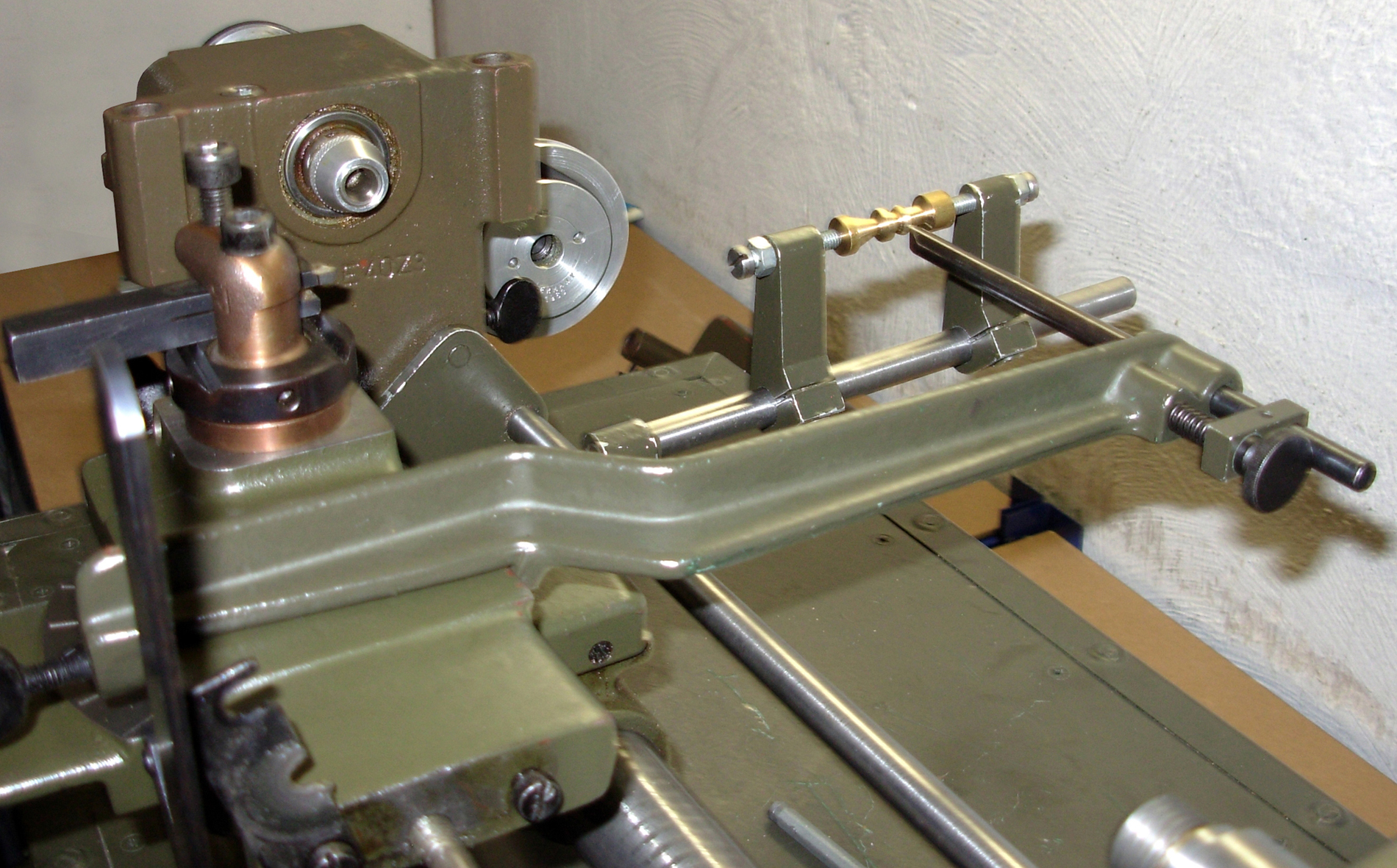

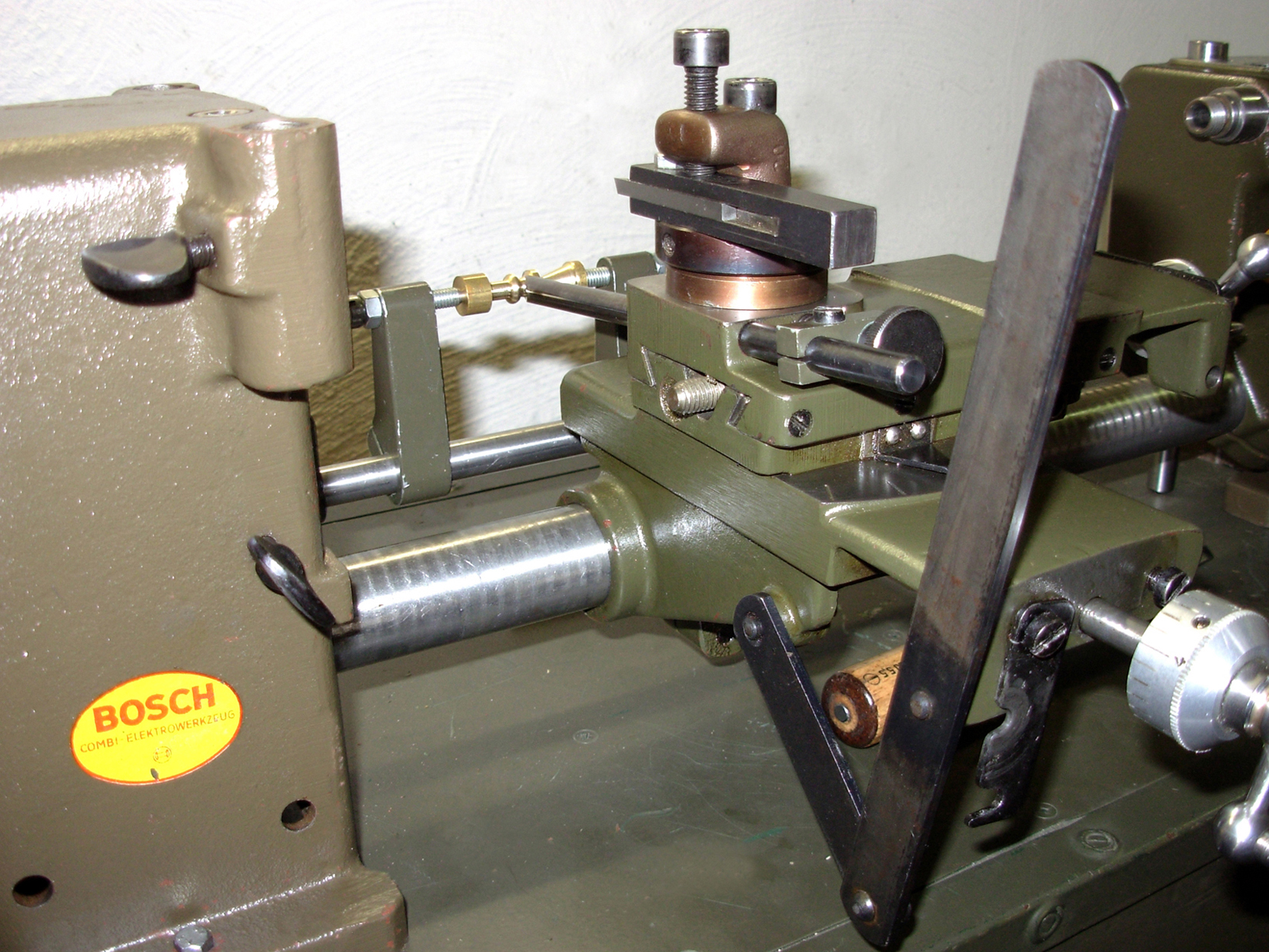

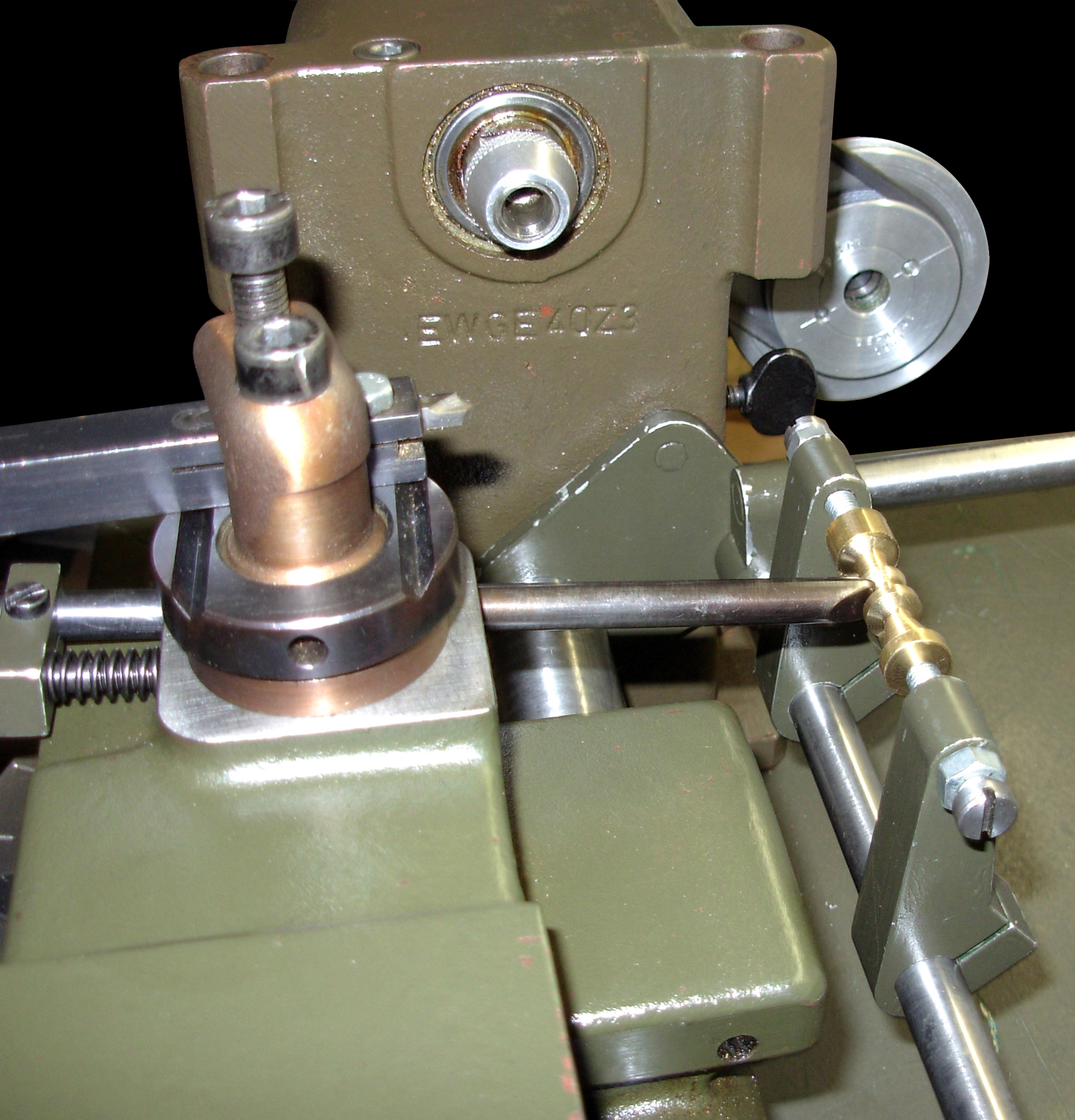

Although lathes with round beds have long been considered as suitable only for those of limited means - and specified accordingly - the Bosch was equipped with a proper screw-feed compound slide-rest unit complete with a swivelling, long-travel top slide (with an engraved degree scale), handles of the "balanced" kind and micrometer dials - it obviously being intended to be capable of light-duty metal as well as wood turning - rather like a larger version of the little English Wade-CAV lathe of the 1920s. However, apart from unlocking it and sliding by hand, there appears to have been no method of moving the carriage along the bed - all turning having to be done, as on a "precision bench lathe", by the top slide.

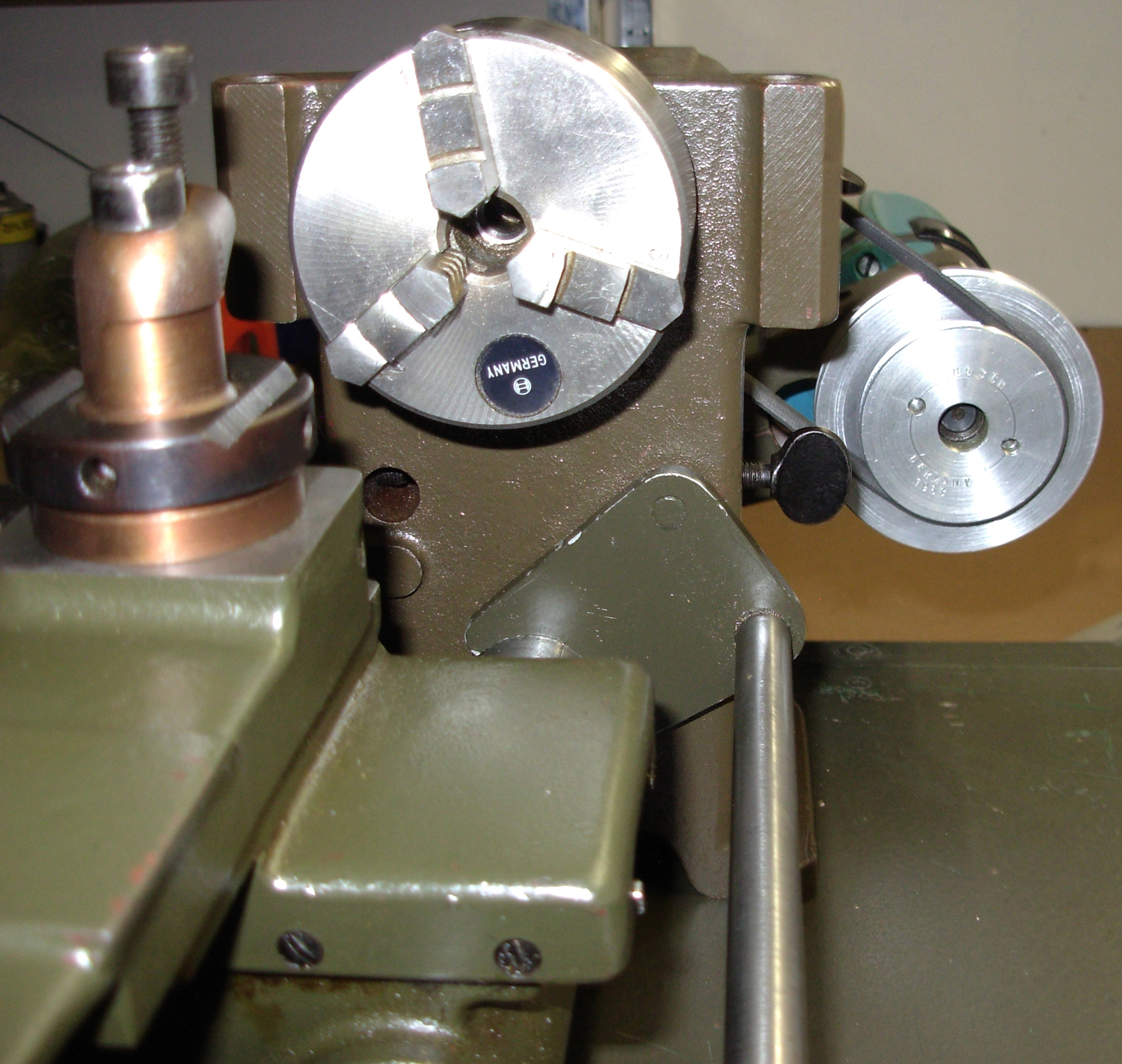

Drive to the headstock spindle was by a multi-step, Z-section V-pulley overhung on the outside face of the headstock, the arrangement allowing an owner to rig up a cheap and simple direct-drive system from whatever electric hand drill or other motor might have been to hand.

Mounting the accessories was made easier by the provision of various tapped holes with wing-nuts provided to secure whatever attachment was required. Securing points were formed into each side of both cross and top-slide end brackets, another into the headstock half-way down its inside face (with a locking wing nut on the outside) and a further pair drilled front to back through the front face.

Clamped to the bed by a split in the base of its casting (with the stabilising bar at the back keeping it in alignment) the tailstock carried a spindle driven by simple rack-and-pinion gearing - probably with a No. 1 Morse taper, though this is not confirmed.

Interestingly, a subsidiary of Bosch that still makes the Bosch "Blue" line of professional construction tools (drills, sanders, etc.), is a Swiss company, Scintilla SA - yes the very same one that used to manufacture a twin-bar bed metal-working lathe not dissimilar to the Combi.

A later Bosch wood-turning lathe, the Model S18, intended to take a drill as the power source is shown on this page - though an earlier version, contemporary with and similar to the Black and Decker type of the 1950s, is also believed to have been produced but, so far, none have come to light. Do you have one? If you have a Bosch lathe, or any literature about them, the writer would be interested to hear from you

Bruno Miller in Germany has amassed a great deal of data about the Bosch machines. His website is: http://www.bosch-combi.de

Pictures below are large files--and may take time to open