|

Home Machine Tool Archive Machine-tools Sale & Wanted - South Bend 9-inch Copy - |

|

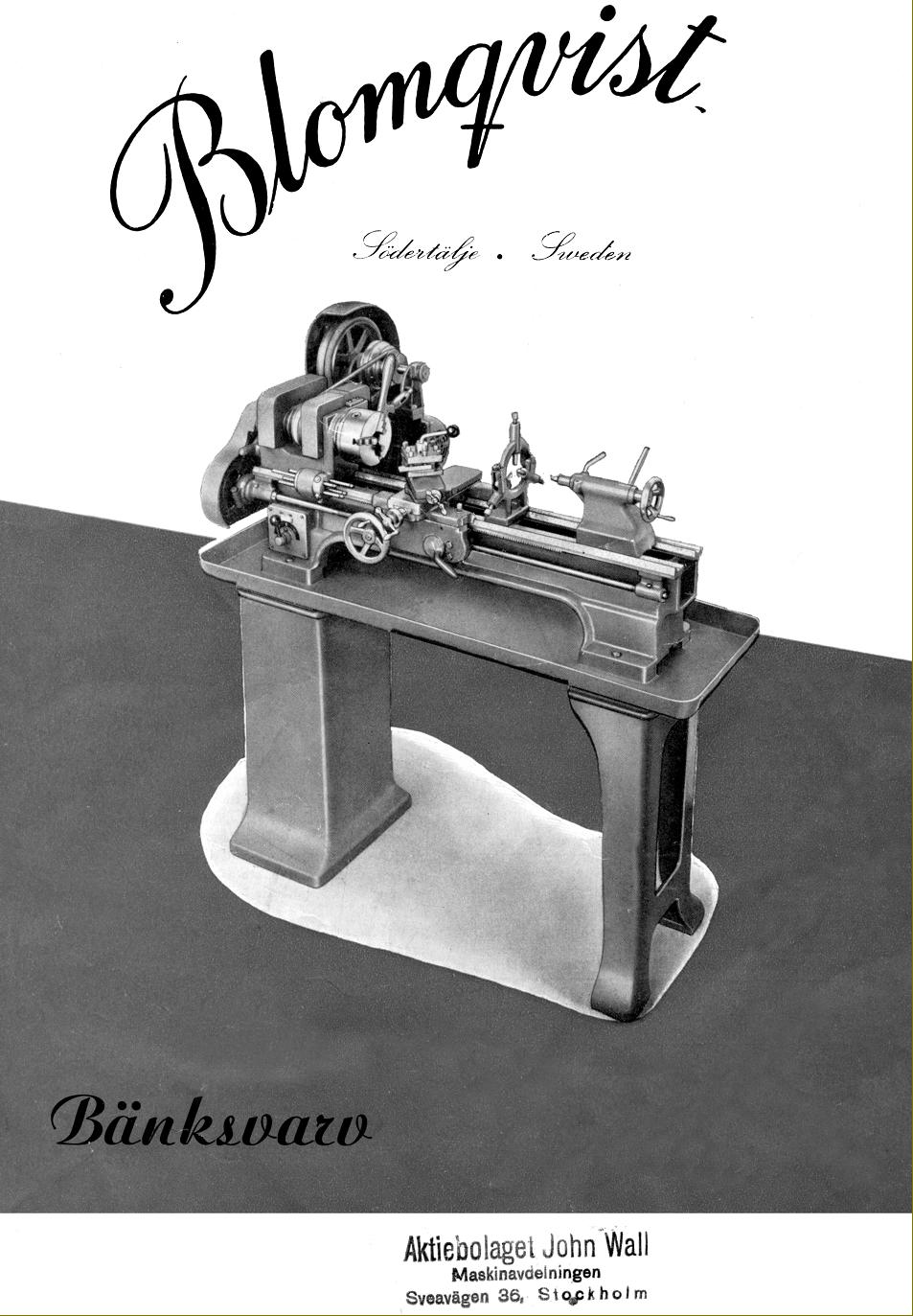

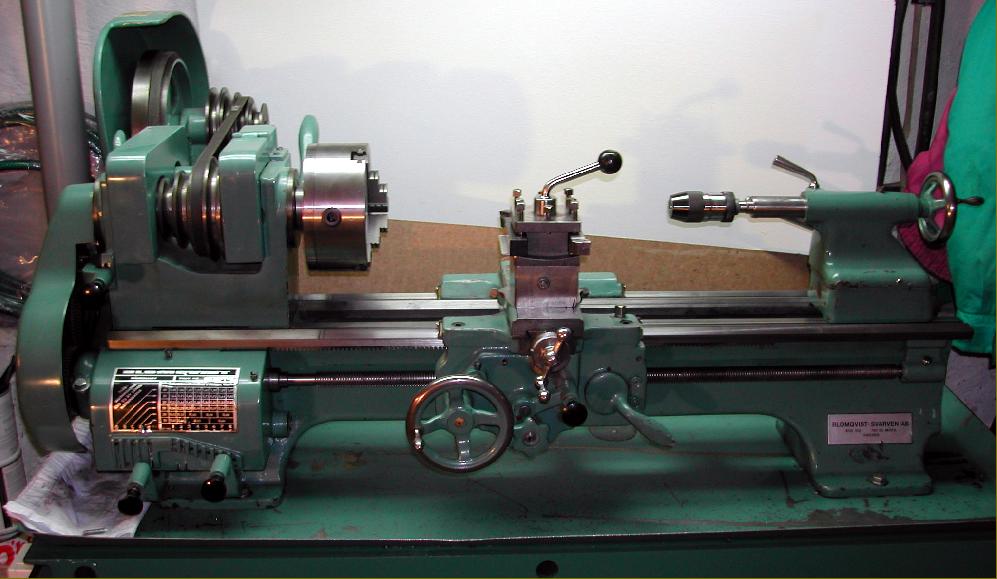

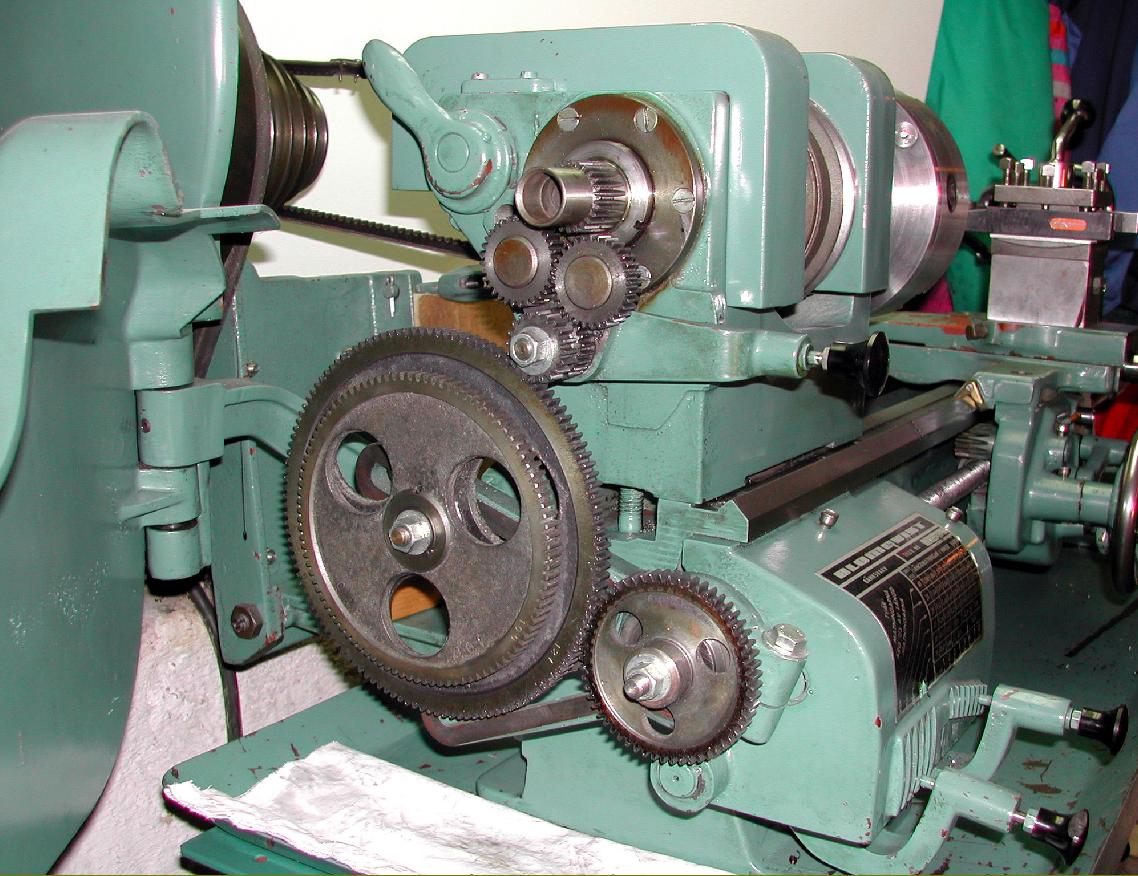

Even in Sweden, home to many makers of fine-quality machinery, the benefits of copying an established machine were recognised with both Storebro and the Blomqvist machine-tool companies producing their own lightly-modified version of the South Bend 9-inch "Workshop" lathe. Production of both would have spanned from the late 1940s until, it is believed, the early 1970s. Both plain and roller-bearing headstock models of the Blomqvist were made, the latter easily identified by the flat top to the headstock bearing area and the use of rectangular backgear guards. The maker's model designations varied; "BS" being the general type and BS-G used for the plain headstock bearing model and BS-K for the model with roller bearings - presumably after Swedish "Glidlager" for sliding bearing and "Kullager" for ball-bearing. The BS-G was always supplied with a 1400 rpm motor - giving a spindle-speed range from 52 to 1200 r.p.m. - whilst the BS-K could be had with the option of a 2800 r.p.m. unit that gave 105 to 2400 r.p.m. Also available, at extra cost, was a choice of three different 2-speed motors: 2800 & 1400 r.p.m.; 2800 & 700 r.p.m. and 1400 & 700 r.p.m. The full type designation for each model also included the distance between centres - which could be 600, 800, 1000 or 1500 mm - with, for example, a BS-1500-K being a long-bed machine with a roller-bearing headstock. However, very early models, being a more direct copy of the South Bend original, had flat belt drive and were known as the Type "SV" - and it may be that other (as yet unknown) versions were produced as well. However, precise catalogue specifications were not always adhered to with some (late) examples having a M38X3 spindle thread - instead of the 1.5" x 8 t.p.i. listed - and a screwcutting range (on the changewheel model) from 4 to 480 t.p.i. instead of the stated 4 to 112 t.p.i. Besides obvious cosmetic changes brought about by the use of new casting patterns, many other significant alterations were also incorporated: the bed was noticeably deeper with cast-in feet; the tumble-reverse lever fitted with an indexing plunger through its end instead of the side; the headstock spindle was increased in diameter to 17/8" and, although the bearings on early models were plain bronze bushes, roller races were employed on later machines. The plain bearings were, for a small lathe, relatively massive with the front being 58 mm long and with inner and outer diameters of 47.7 mm and 54 mm diameter respectively; the rear bearing was 34.6 mm long, 34.8 mm inside and 40 mm outside. Thrust was taken by an SKF JH4-107 ball bearing. Both bronze bearings had two axial (horizontally disposed) oil channels - and two radial channels set near the ends - with oil supplied through a pocket in the casting aligned to the horizontal channel and connected to it by a drilling through the bearing. |

|

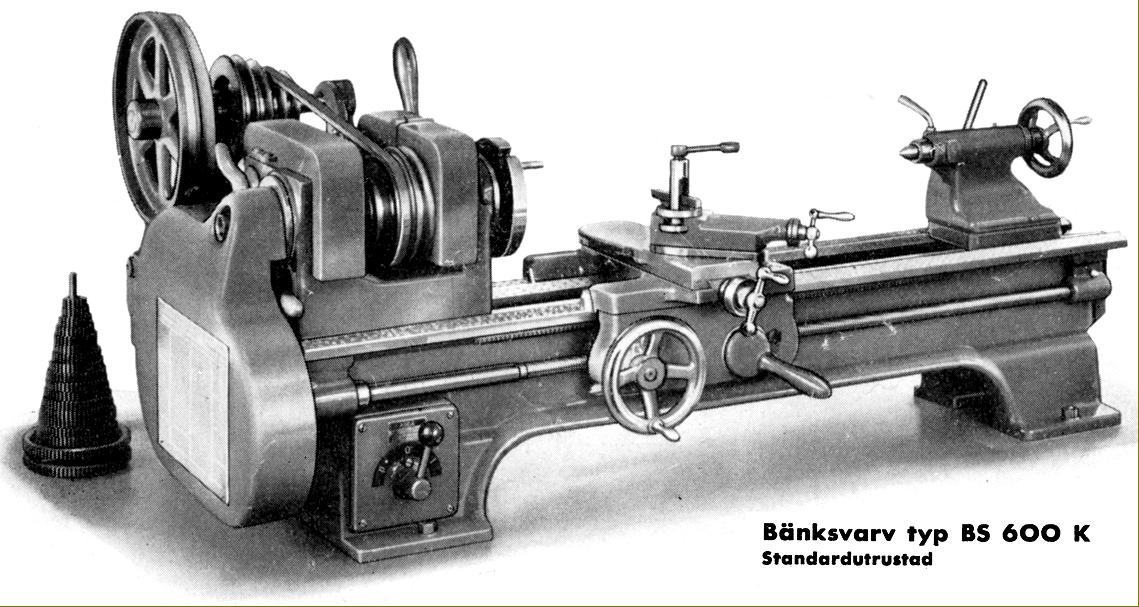

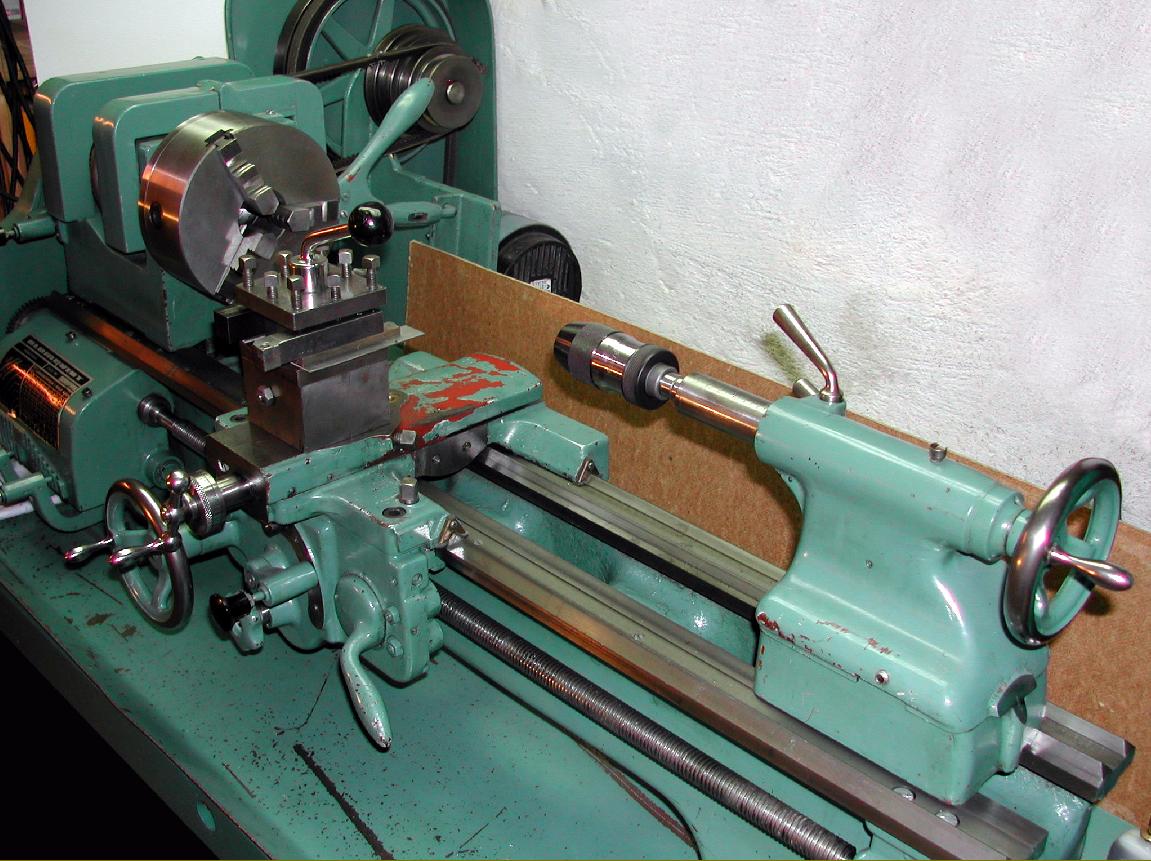

Blomqvist Type BS-600K. This was the least expensive version and equivalent to the South Bend Model C with screwcutting by changewheels and no power cross feed |

|

|

|

|

||

|

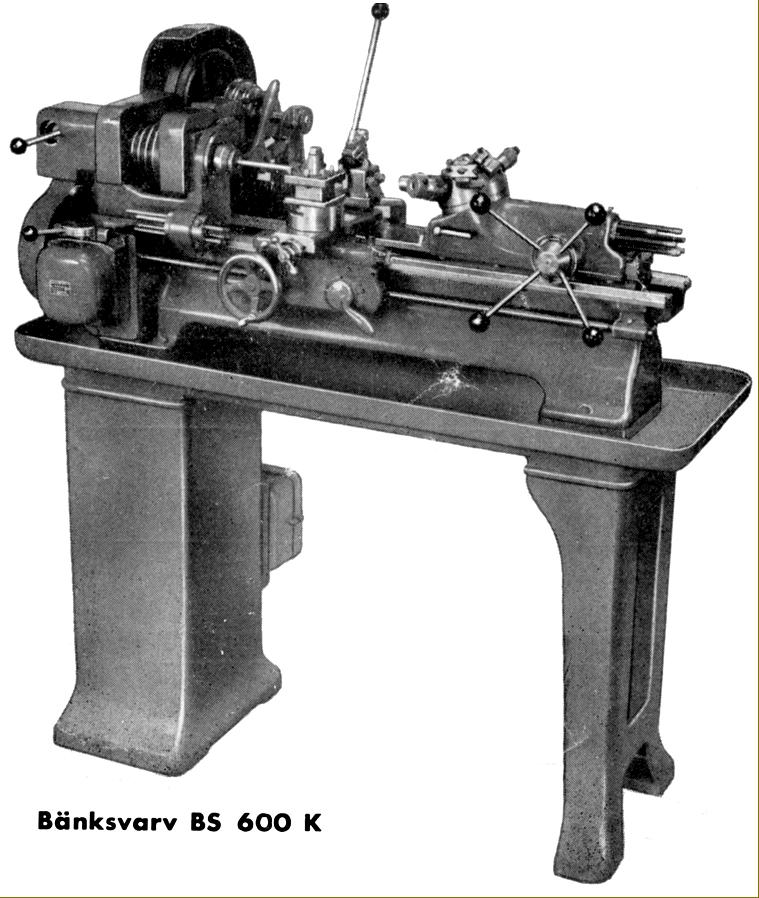

This Blomqvist appears to be fitted with a metric conversion changewheel set - thus, even for the home market, it would seem that the makers fitted an English-threads gearbox (the selection levers are disposed in the English-pitch fashion) and an inch-pitch leadscrew. |

||

|

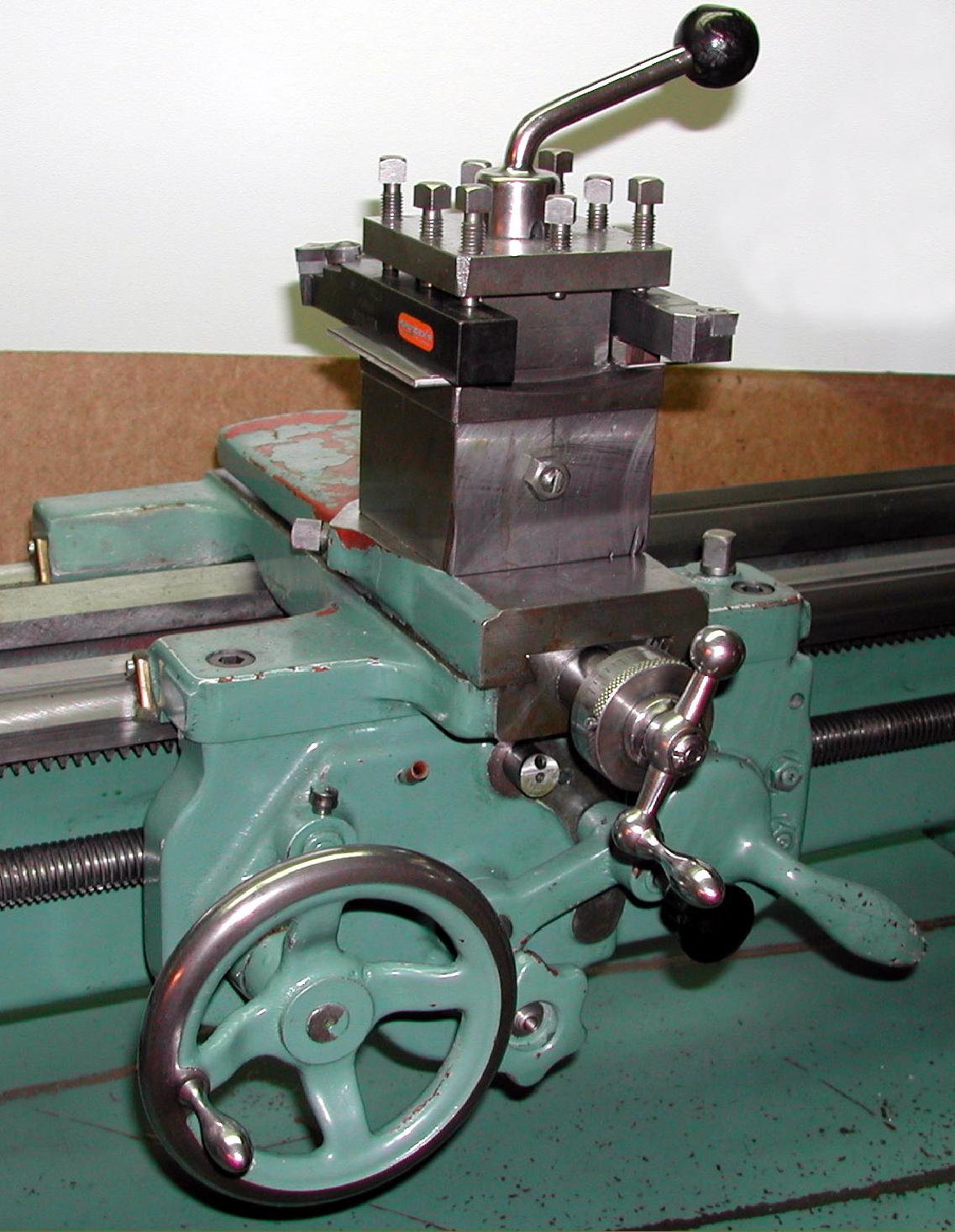

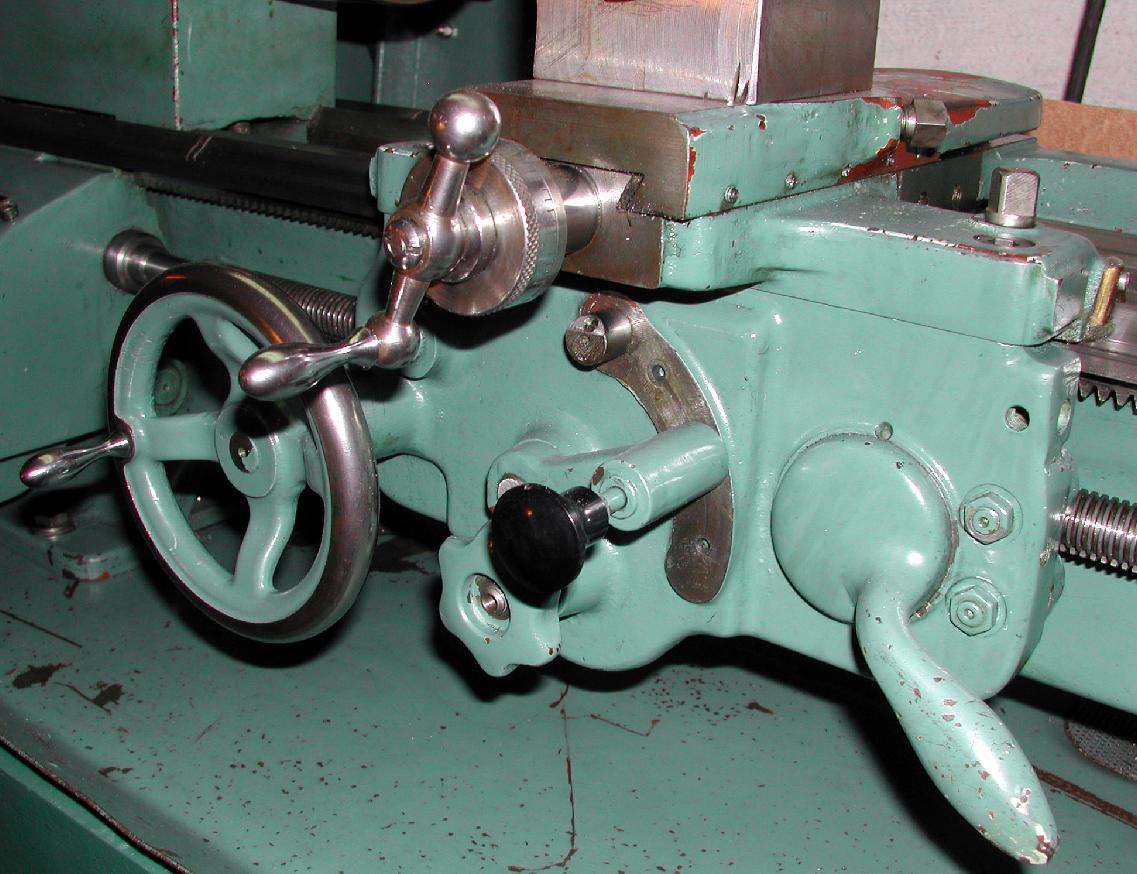

The same, but different. The apron, whilst following exactly the South Bend layout, had a section across the front raised proud from the front edge of the saddle - the latter being modelled on the heavier type fitted to the English Boxford |

||

|

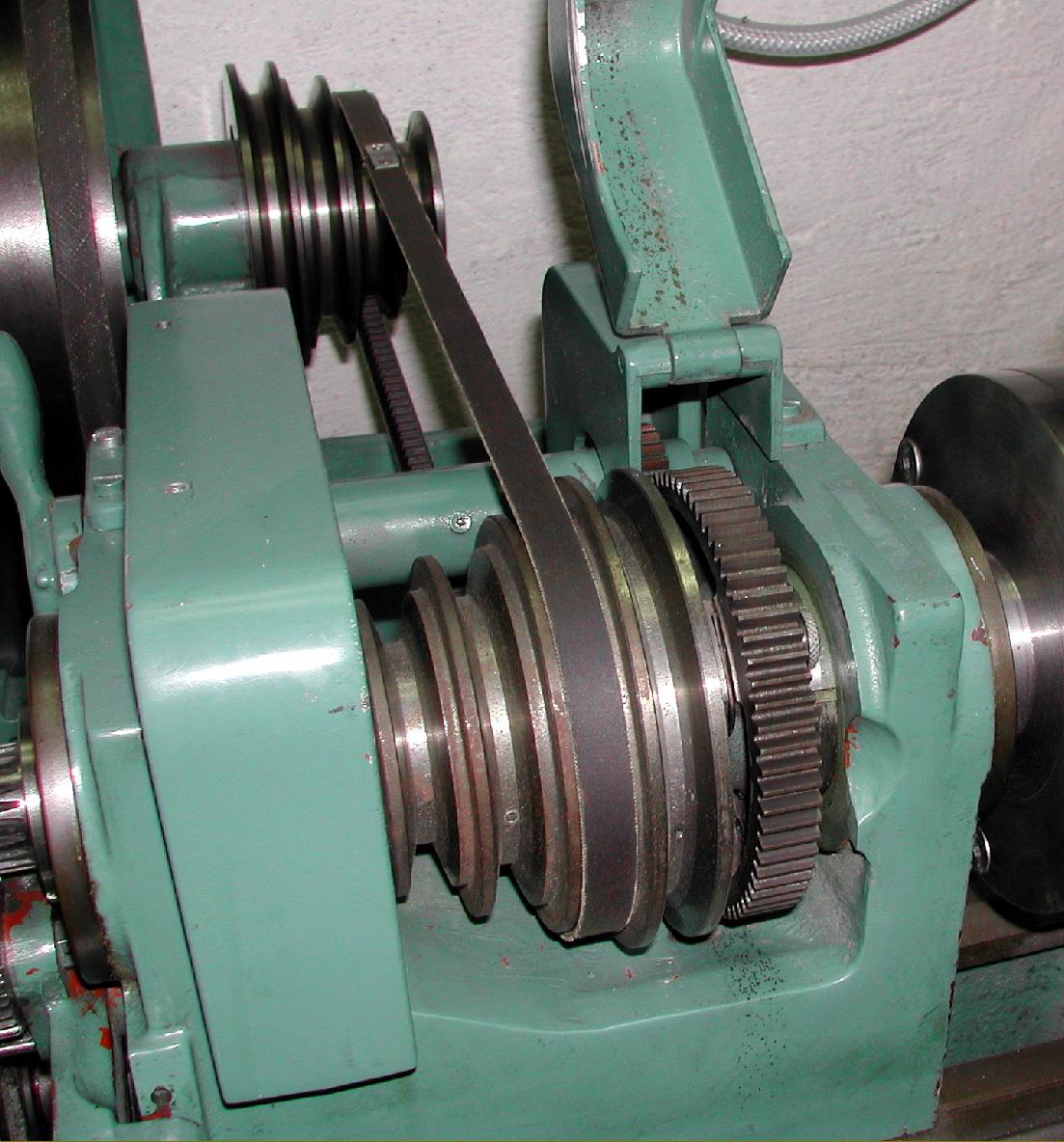

4-speed V-belt drive headstock. Before WW2 South Bend had also offered the option of a 4-speed V-belt drive headstock together with a hardened spindle, but their catalogs entry hardly inspired the owners to choose it, stating: "The flexibility of the flat leather belt and the ease with which the belt may be replaced are responsible for its wide popularity and use". However, in later editions they did concede: "The positive powerful drive of the V-belt makes it especially desirable for manufacturing operations and for use in shops handling work which requires volume in production". |

||

|

|

||

|

- South Bend 9-inch Copy - Home Machine Tool Archive Machine-tools Sale & Wanted |