|

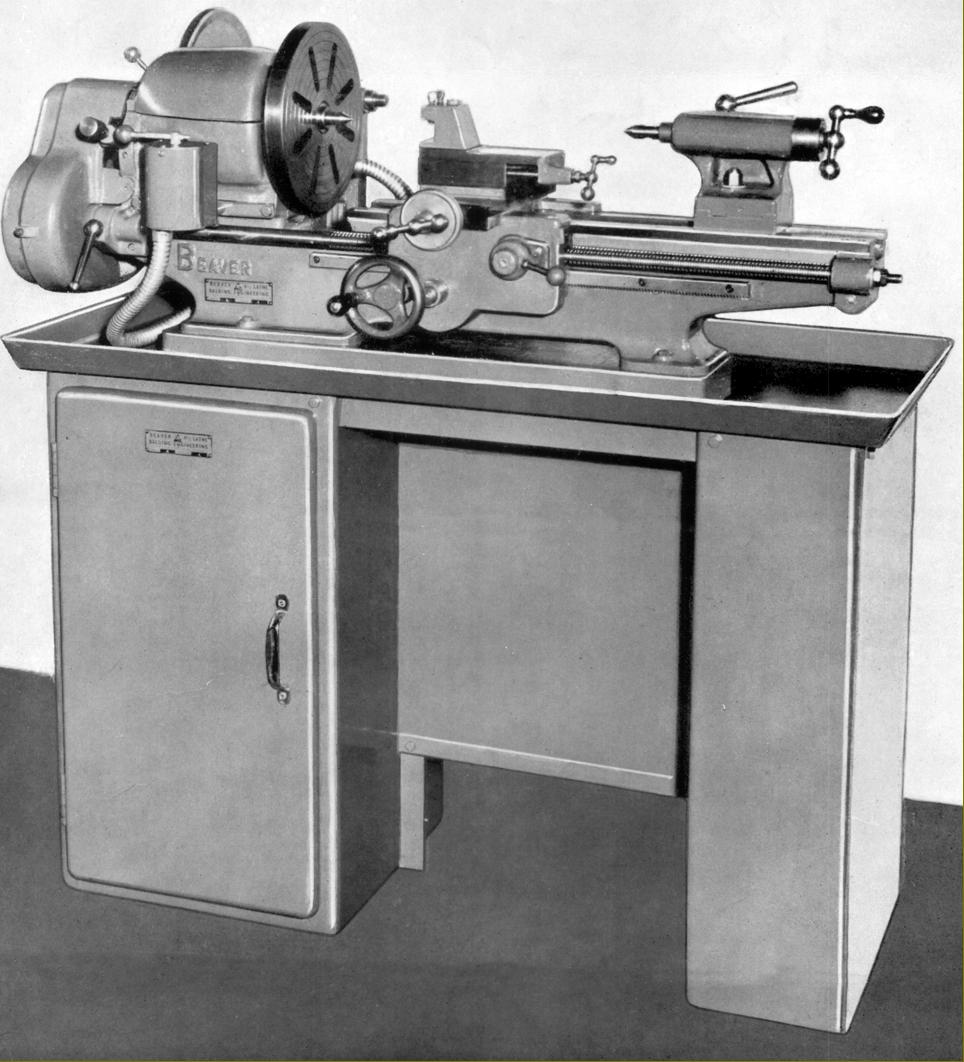

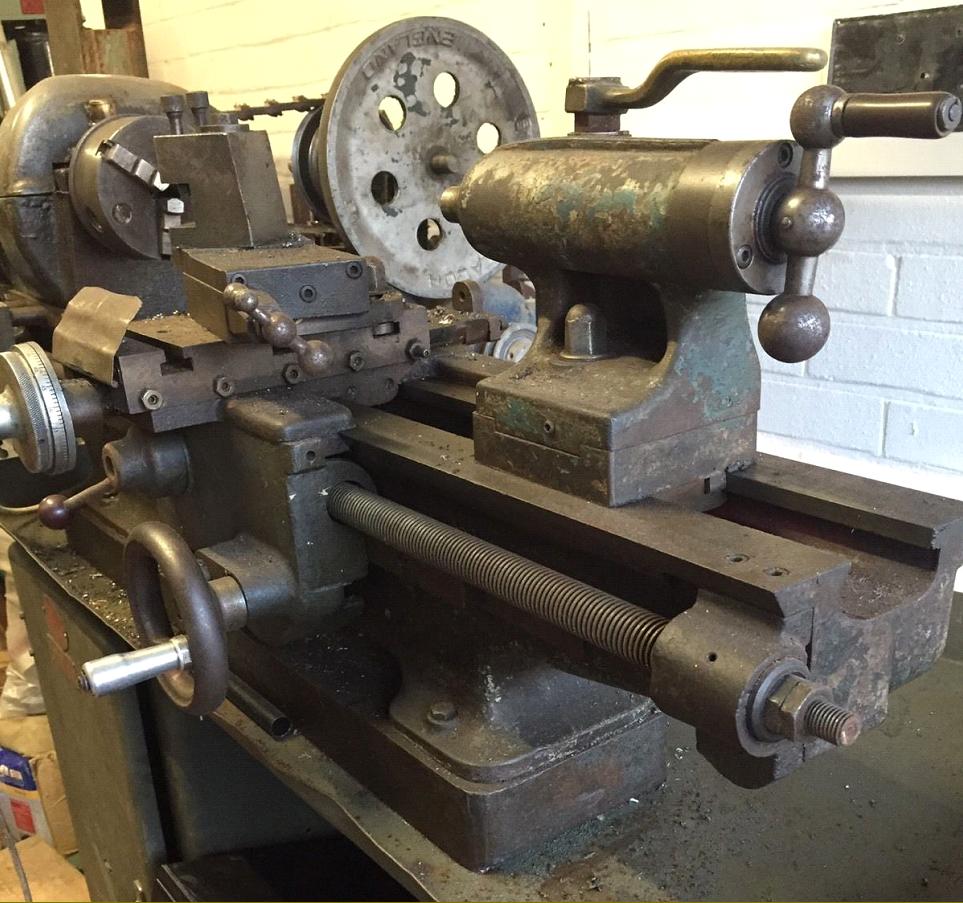

Only one conventional lathe was manufactured by Norfolk-based Balding Engineering - a company that became famous for their range of ram-head milling machines - the "Beaver Model A" Introduced during 1951 and made in very limited numbers (probably fewer than 50 being sold), this 4.5" x 20" lathe was a backgeared, screwcutting model of conventional design but very strong (260 lbs) construction, well specified and obviously designed to last.

Of robust proportions, the headstock spindle had a nose thread of 1.75" x 7 t.p.i., a No. 4 Morse taper socket and was able to pass a 1" diameter bar. Bearings were plain bronze, the front 1.875" in diameter and 2.25" long and the rear 1.37" x 1.375" with a ball-bearing race to take end thrust.

Flat-topped with 60° V-edged sides, the 40-inch long bed was 7 inches deep, 5 inches across the top and equipped with a rather narrow gap that allowed work up to 25" inches in diameter and 2.5 inches thick to be turned on the faceplate.

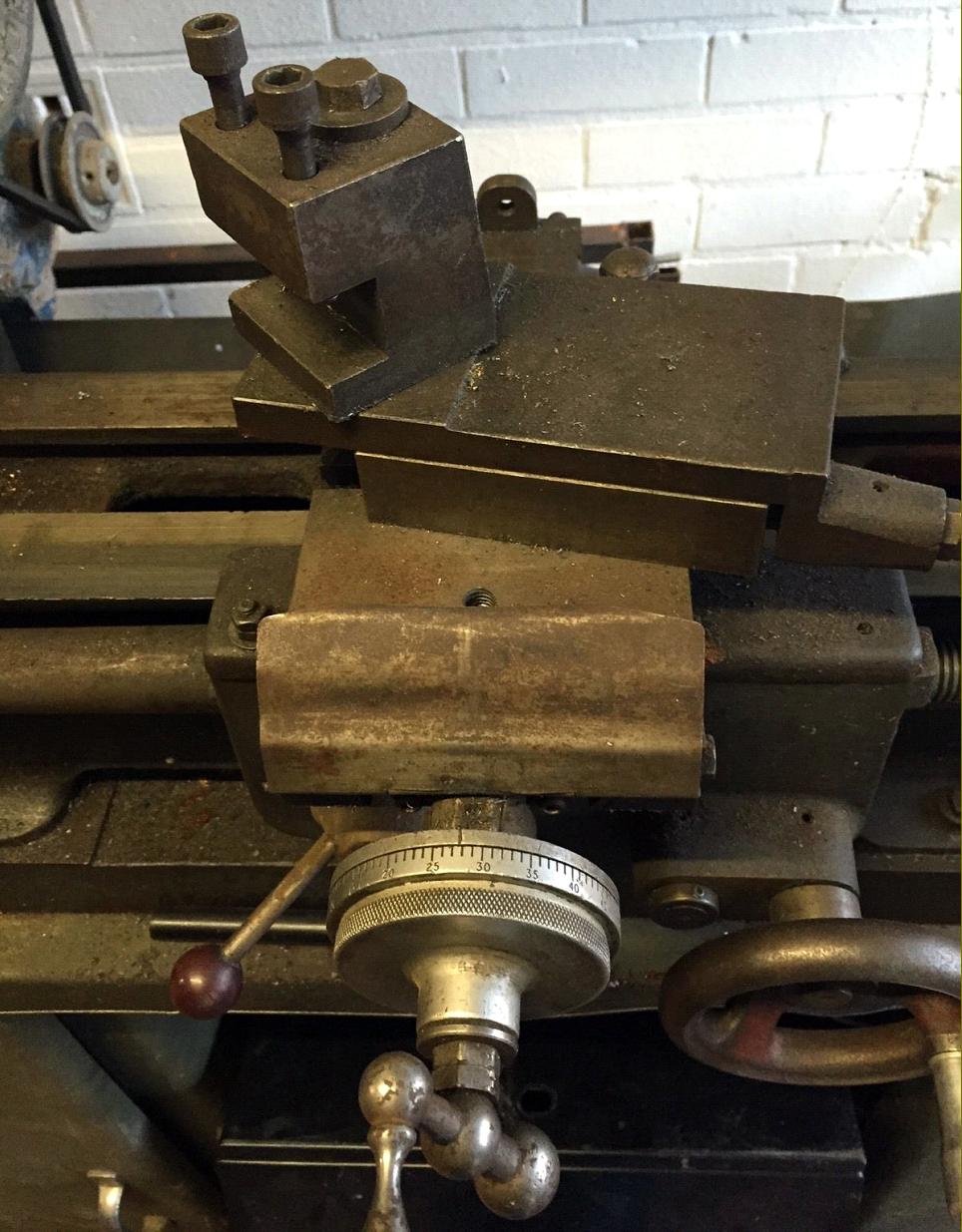

A 4.5" x 8.25" T-slotted cross slide was part of the standard specification, as was power cross-feed - this giving a travel of 5.75 inches. The cross-feed screw was of Acme form, 0.5" in diameter and equipped with thrust bearings for facing in either direction. The bronze nut was a generous 1.25" long and the satin-chrome plated 3-inch diameter micrometer dial (with a knurled rim for better grip) unusually large for this class of lathe. Although a generous travel of 4 inches was provided for the top slide, the 0.5" diameter feed-screw - very oddly - lacked a dial. Unfortunately, the apron power-feed mechanism was confined to the cross direction, the sliding feed being provided exclusively by the screwcutting mechanism, a design that ensured the clasp nuts would be worn out in ordinary work instead of being saved for screwcutting. Hand drive of the carriage was by a full-circle handwheel fitted with a rotating hand grip in horn; enclosed reduction gearing inside the apron, between wheel and bed rack, enabled the operator to give a slow and steady feed.

Drive came from a neat, all V-belt drive motor countershaft unit bolted to the stand behind the headstock. Eight speeds were provided: 220, 338, 490 and 685 r.p.m. in direct drive and 34, 56, 80 and 120 r.p.m. in the 6.5: 1 ratio backgear. Although no evidence can be found of what the standard motor specification might have been, it is likely to have been a 1 h.p., 3-phase running at 1425 r.p.m.

A set of 14 changewheels was provided for screwcutting (there was no gearbox option listed) these being encased within a neat, cast-aluminium cover and driving the 7/8" diameter, 8 t.p.i. leadscrew (fitted with a ball thrust race) through a conventional tumble-reverse mechanism to give a range of pitches that spanned 4 to 60 t.p.i. In order to provide an extra-fine feed, an 80t gear was provided, this giving a carriage-travel rate of 0.0021" per revolution of the spindle.

Bored No. 2 Morse taper, the 1.125-inch diameter tailstock spindle was driven by an Acme-form, 1/2-inch diameter feed screw equipped with a ball thrust race; the screw acting to self-eject the centre. A rather fine touch was the fitting of a rotating horn handgrip of the "balanced" drive wheel. The upper section of the tailstock could be set over 1/2" either way from central for the turning of slight tapers.

If you have a Beaver lathe, or any advertising or technical literature about them, the writer would be very interested to hear from you..

|

|