|

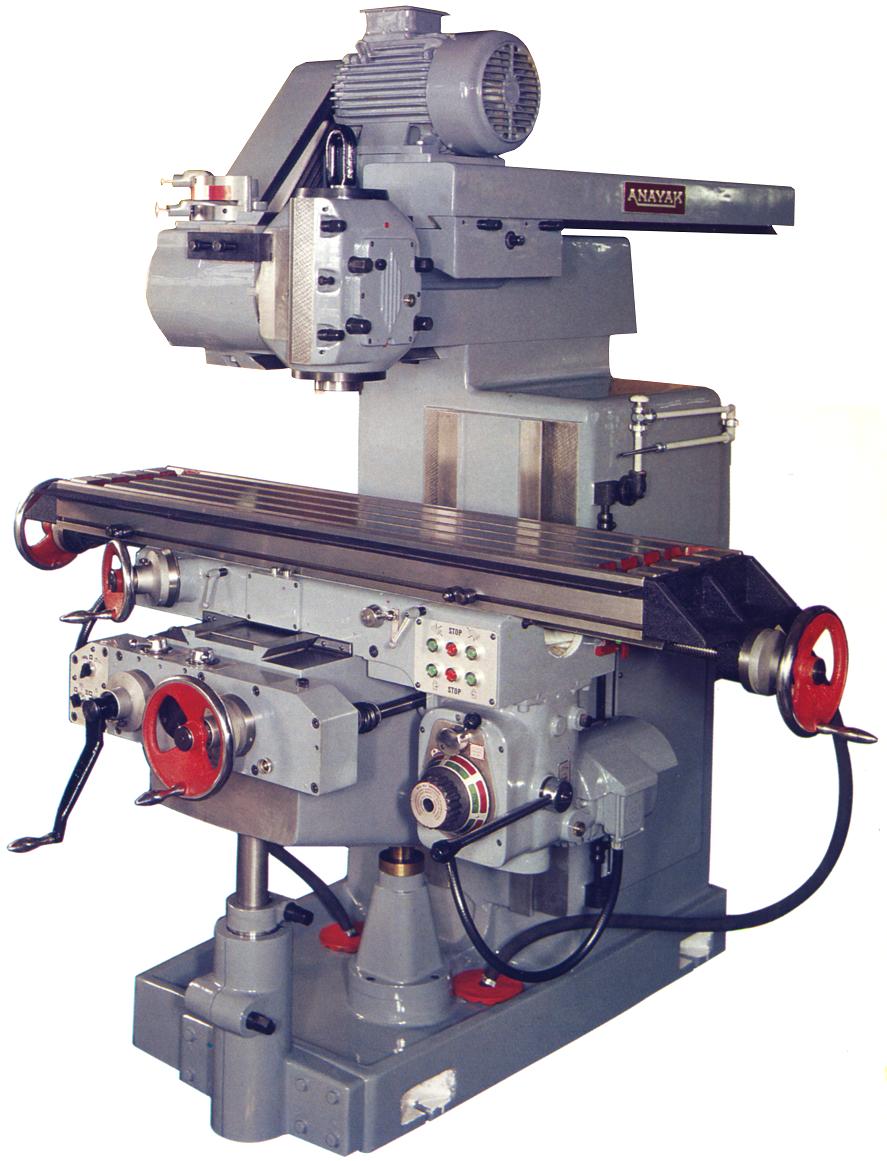

Machine Tool Manuals Machine Tool Catalogues Belts Milling Machines Anayak FV-1 & Fv-2 Anayak Fv-3 & FV-4 |

||

|

Anayak FU-205 arranged as a vertical machine |

|

|

|

Sold only as a vertical model, the ANAK-MILL-12 miller was a heavy (6 tonne), powerful, heavy-duty bed-type machine with a fixed table assembly and an elevating head - the whole arranged in the manner of a traditional jig borer - with the vertical ways protected by bellows at the top and sliding steel shutters at the bottom. Able to move through a vertical range of 560 mm (22") under hand-crank or power feed, the head assembly had a maximum clearance between spindle nose and table of 680 mm (26.7") with a throat of 560 mm (22"). |

|

Machine Tool Manuals Machine Tool Catalogues Belts Milling Machines Anayak FV-1 & Fv-2 Anayak Fv-3 & FV-4 |

||