|

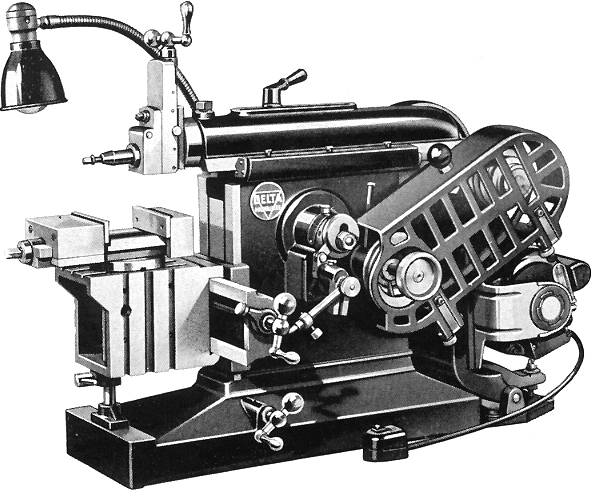

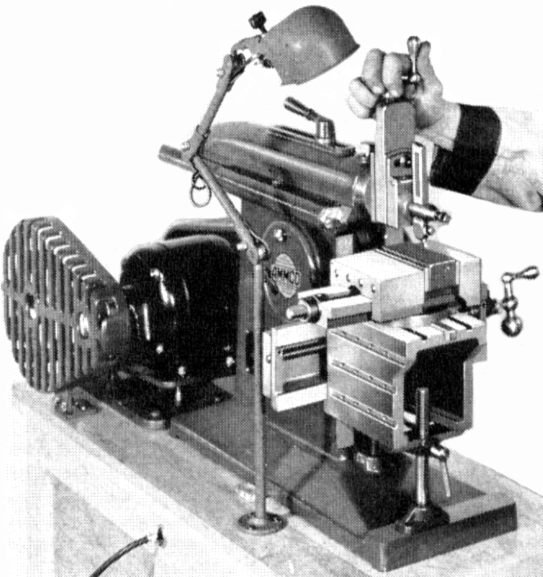

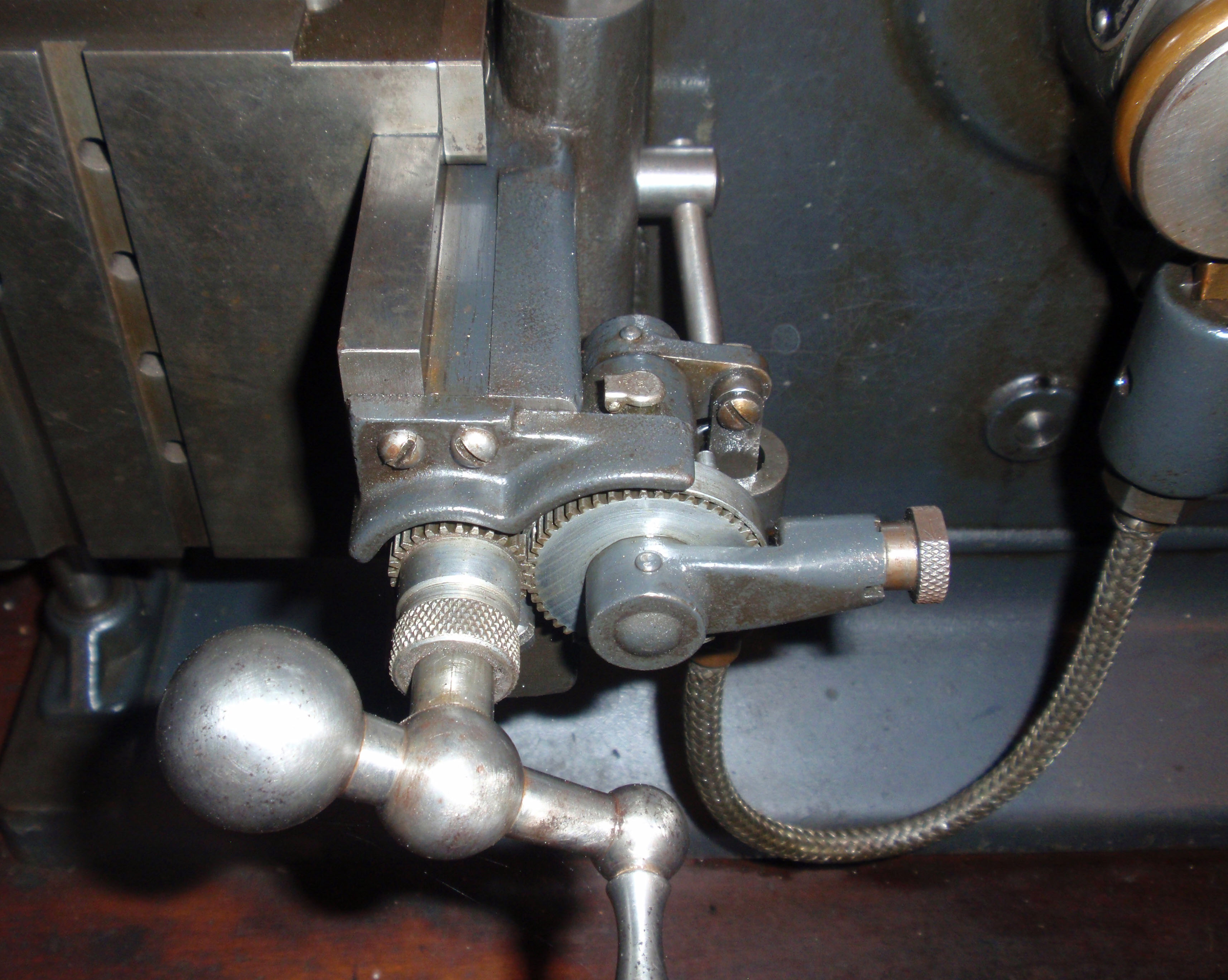

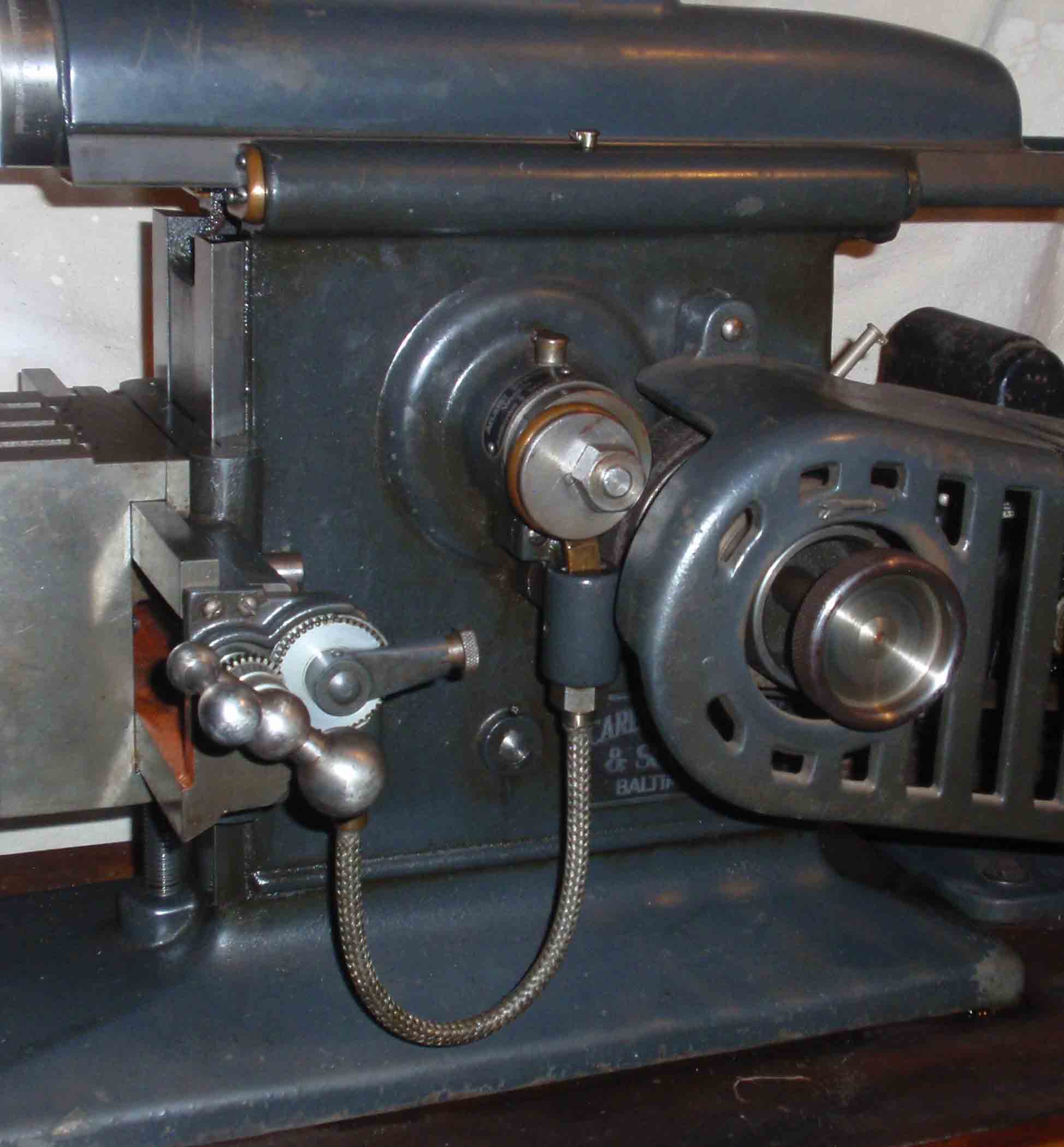

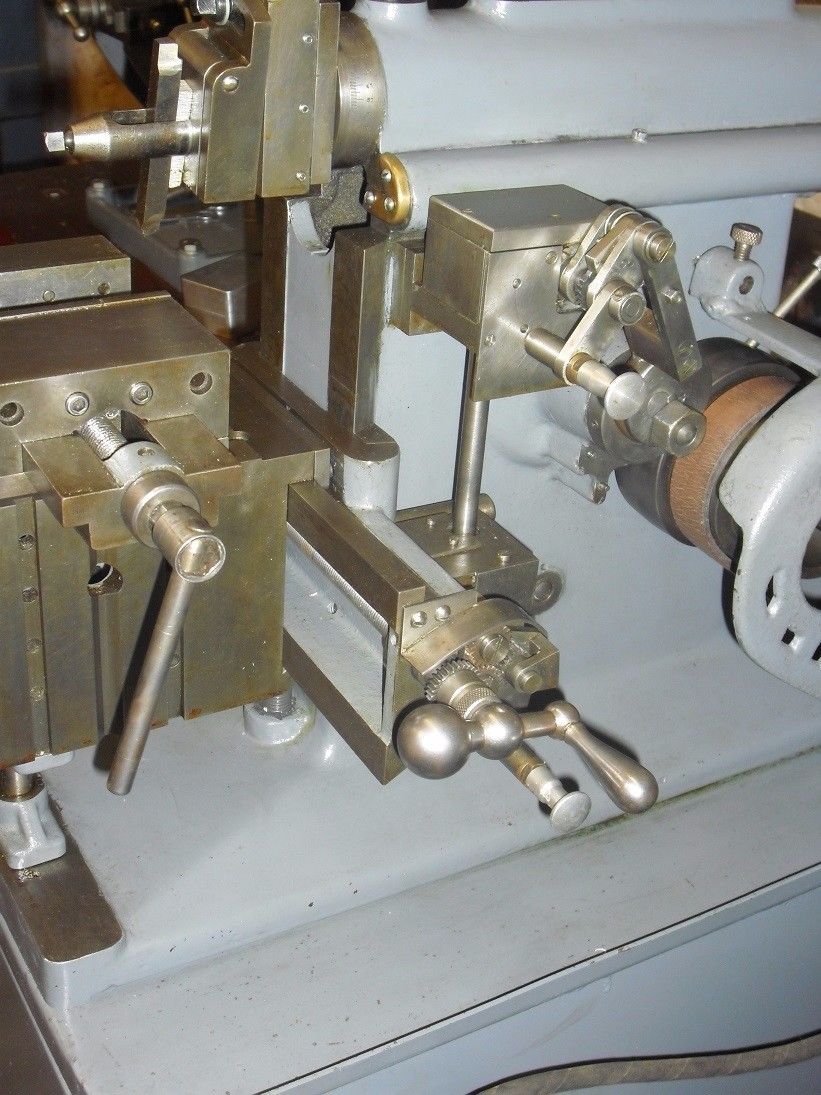

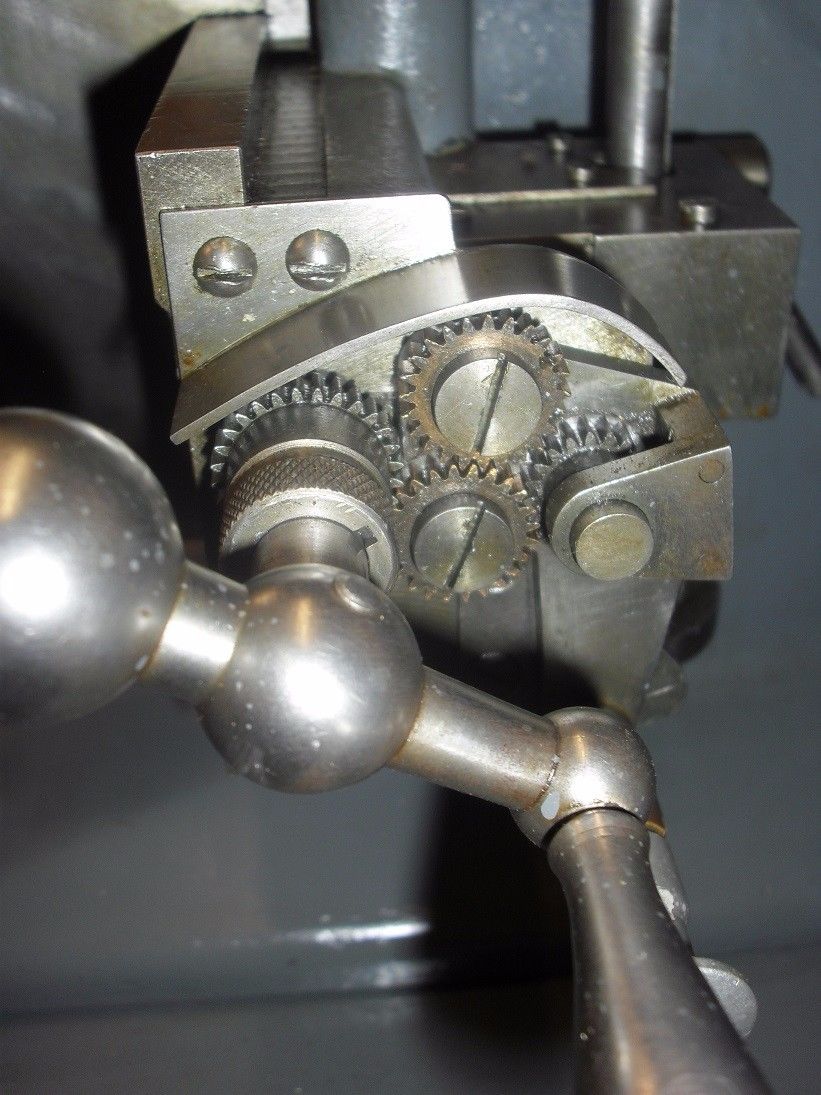

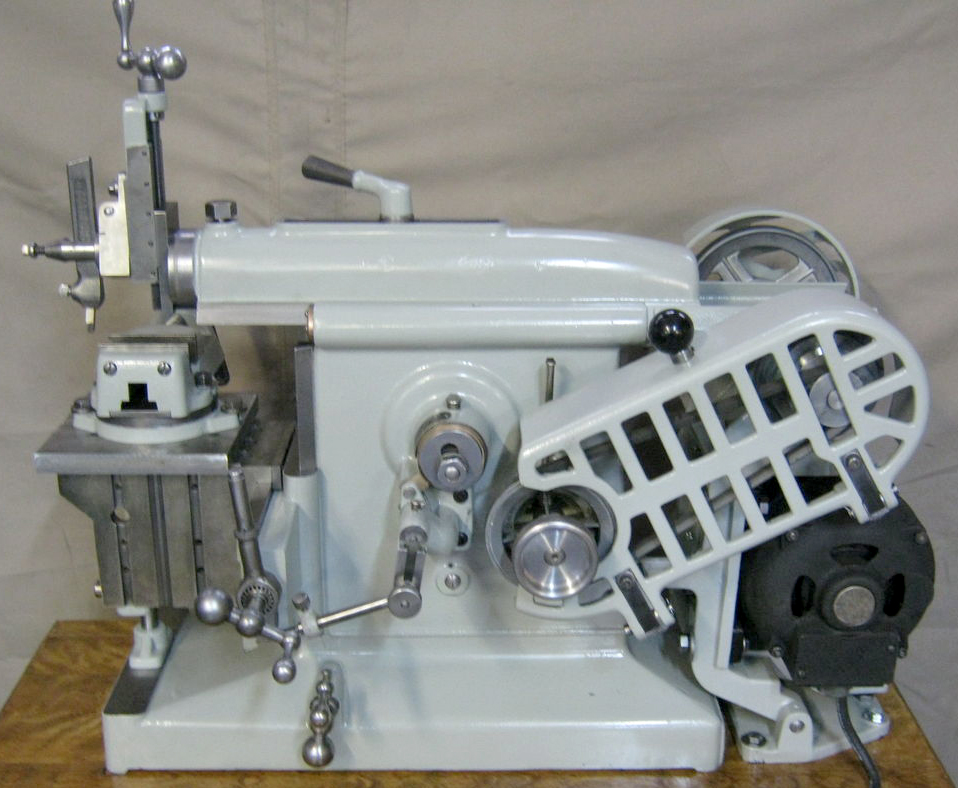

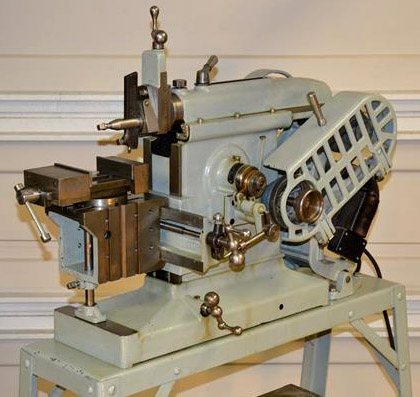

By the time shapers get down to below a 7" stroke, they usually come to resemble something other than a standard industrial machine - but not so the American "Ammco". This almost "miniature" shaper, made by Delta Rockwell and sold by the Automotive Maintenance Machinery Co., 2112 Commonwealth Avenue, North Chicago, was constructed exactly along the lines of larger machines. It had five rates of reversible automatic cross feed - though the feed dial was ungraduated and there was no slide lock. The box had a horizontal travel of 9.5", vertically of 4.25" and could be moved to within 1.125 inches of the ram or extended to be some 5.25 inches away. The toolholder had a maximum travel of 3.25 inches. A useful safety feature was that the box would run off its feed screw if left on self-act - and because shaper work is so steady, there is a terrible temptation to set it running, and forget …...

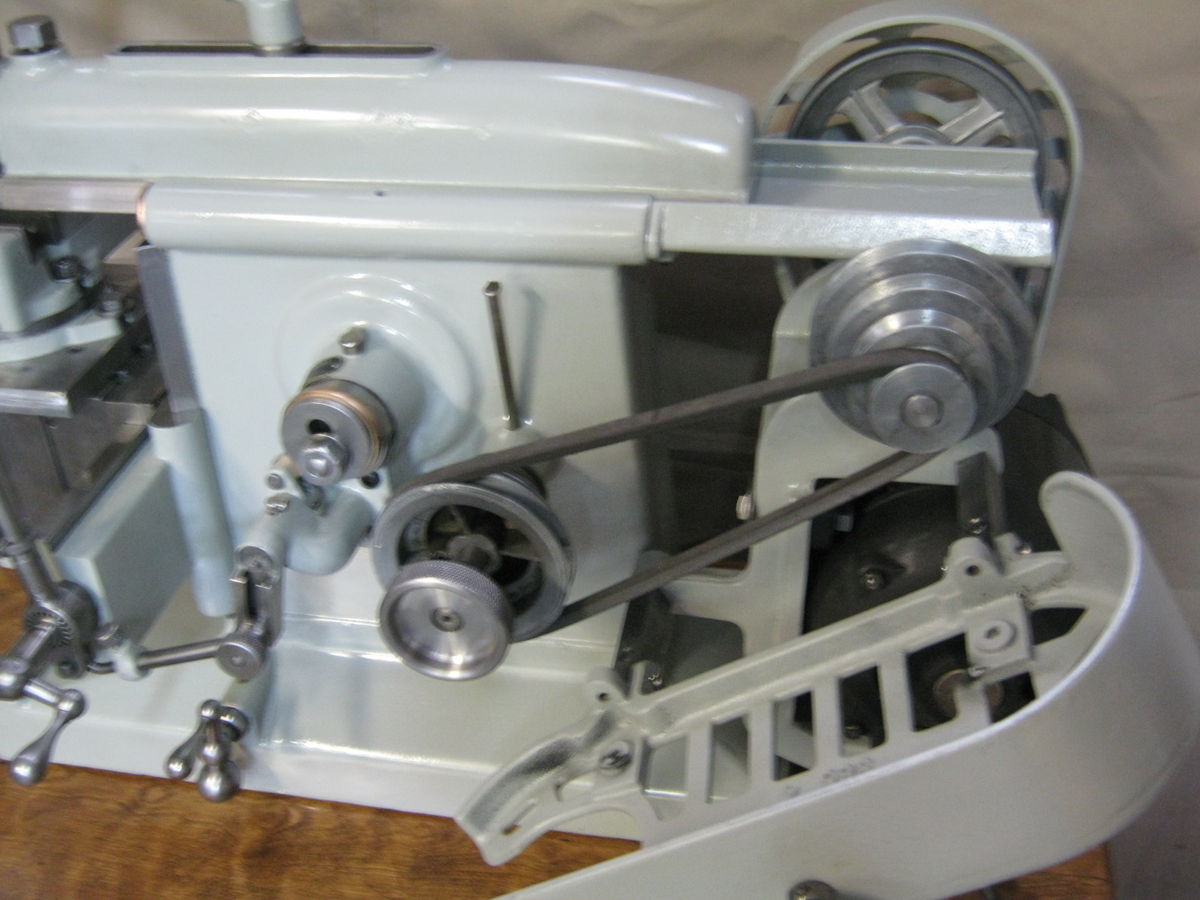

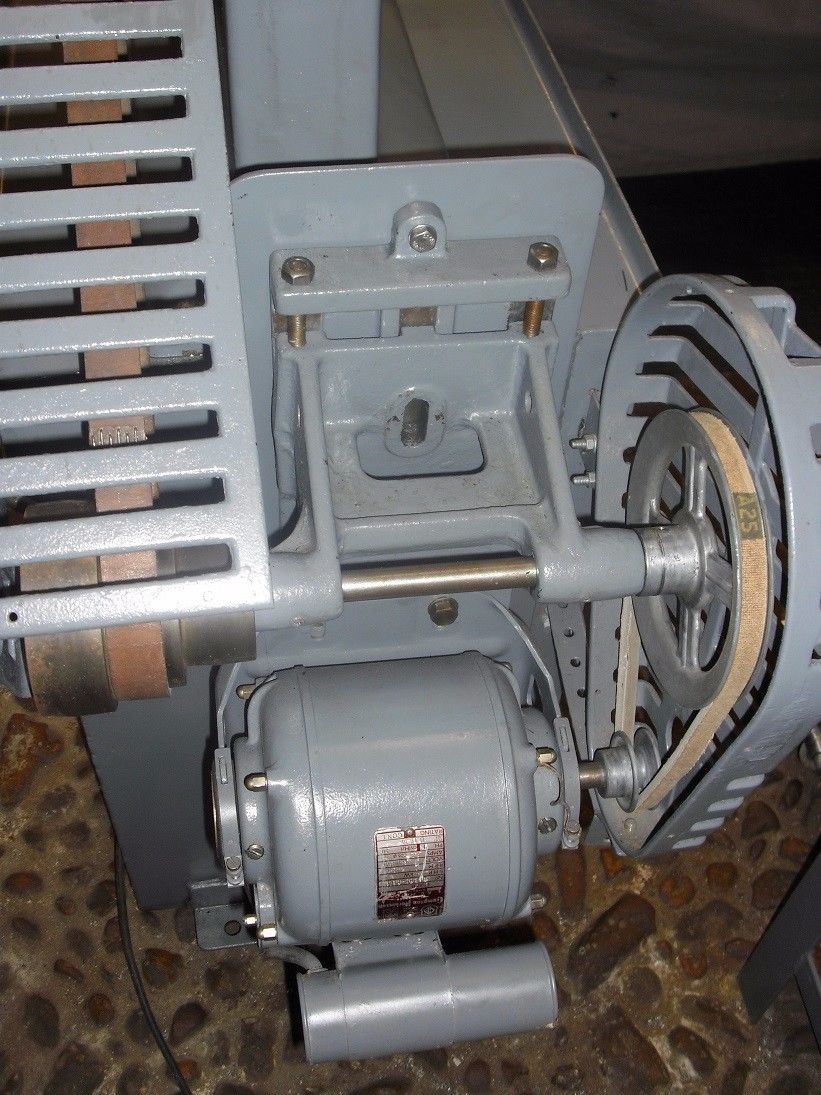

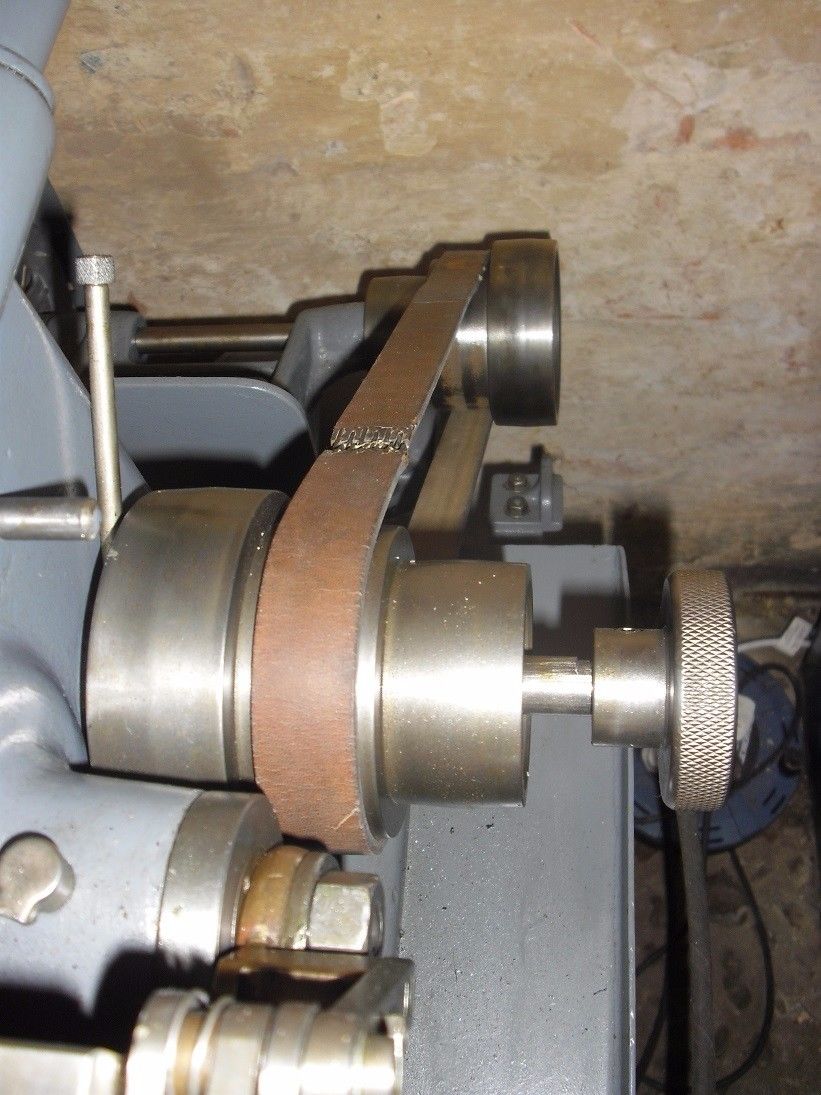

Four ram speeds were provided - of 40, 70, 115 and 180 strokes per minute - from a rear-mounted motor that drove to a large pulley - the supporting shaft of which passed through the rear of the body casting and carried at its other end a four-step pulley to drive the crank. Each of the two drive belts were arranged so that they could be independently adjustable for tension.

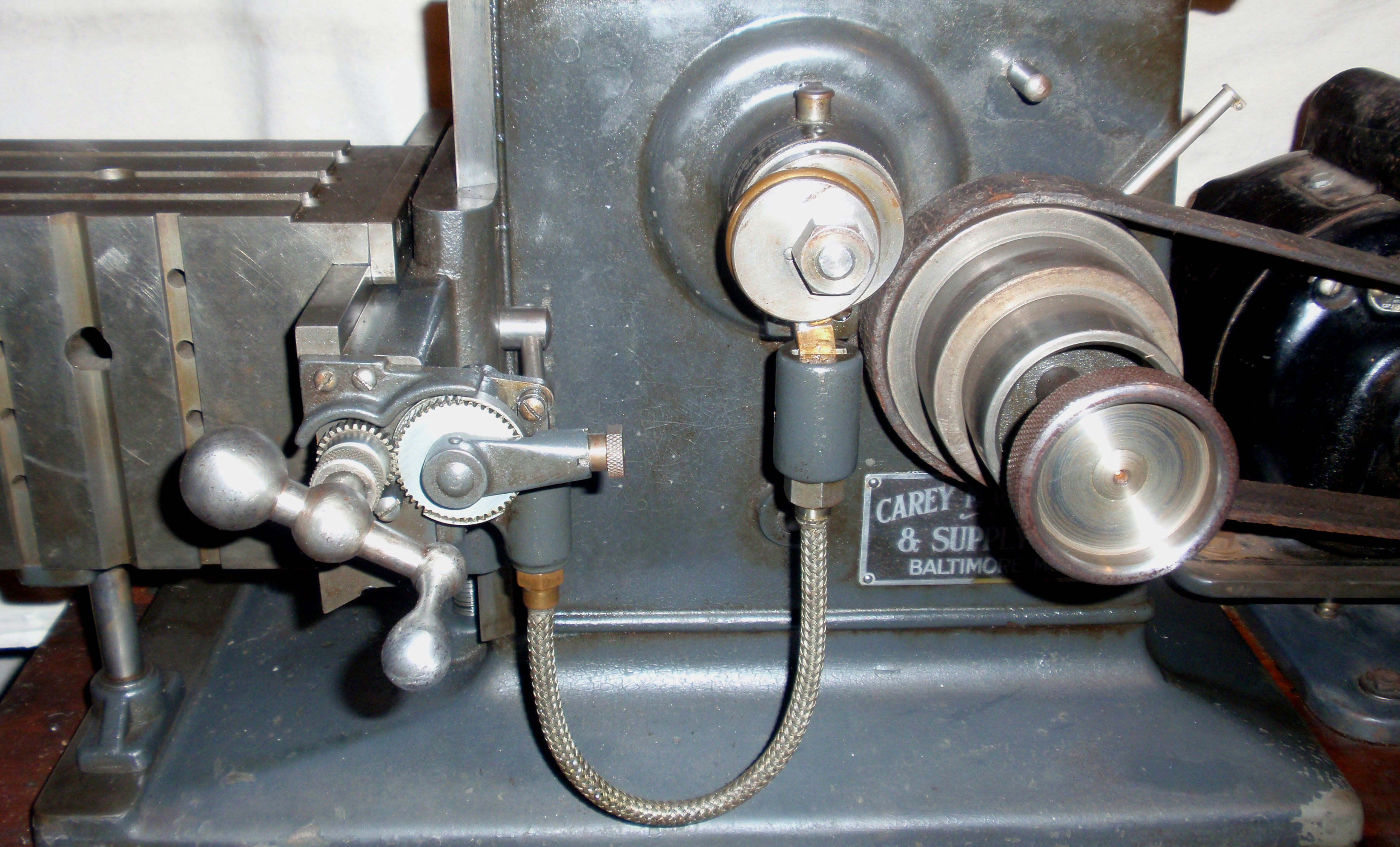

The box was properly supported at its front by a bar able to slide along a machined base while a most useful looking vice, with 4" wide jaws and an open capacity of 4.25", was supplied as standard. Unfortunately, the slots in the table were not of T section, but had plain, parallel sides. In the base of each slot was a row of plain 5/16" holes - which enterprising owners were able to tap out and use to bolt workpieces and attachments in place. The vertical adjustment handle for the box aas located within the standard cabinet stand, directly under its feed screw.

Both early and late versions of the Ammco/Delta have been discovered, the earlier having what might just be a unique method of turning the table-feed ratchet on a shaper - by a cable. While the late version had its electric motor foot-mounted onto the rear of the main body and drive by V-belts, the first version had a 3-step flat-belt cone pulley on the input shaft - this obviously being intended for drive by either overhead line shafting in a workshop or by a remote wall or ceiling-mounted countershaft.

The first version of the shaper was supplied by the makers on a fine cabinet stand, in maple, with cupboard and drawer storage and, as three identical specimens of this unit have now been found, this disproves the theory that the first might have been a home-made affair. Astonishingly, on the right-hand end of the stand was a pair of castors, a long lifting bar being provided on the left-hand face to allow the whole unit to be moved easily around the workshop.

Although claimed as a 6-inch machine by Ammco in their sales literature, the maximum stroke was actually 7.25" with Delta Rockwell themselves advertising it as a 7-inch.

The shaper was 32" long, 18" wide, 242 high and weighed 225 lbs.

Unfortunately literature for the first model has yet to be found; should any reader by lucky enough to have copies, the writer would be delight to hear from you (and also from the owner of a late model who might like to contribute a set of images).

|

|