|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

lathes.co.uk

"Amann" Lathes - France

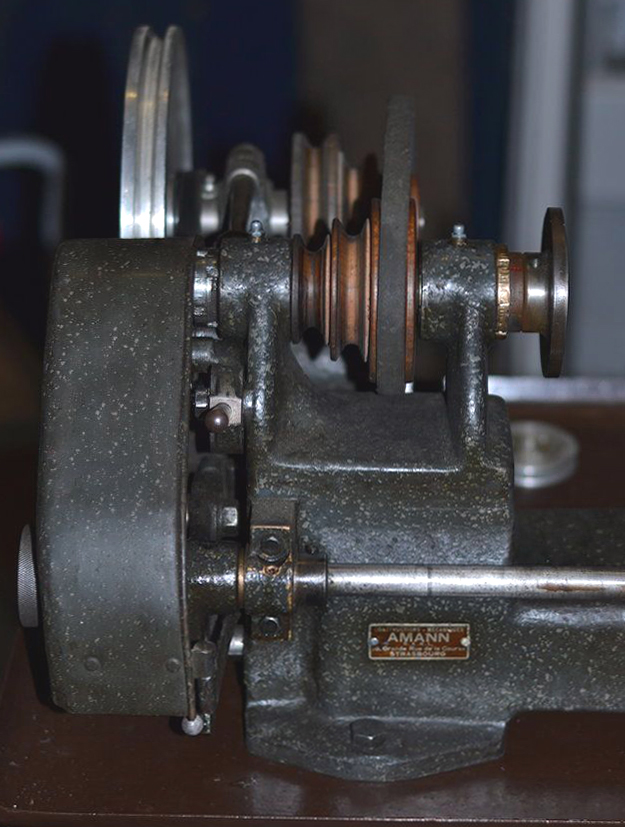

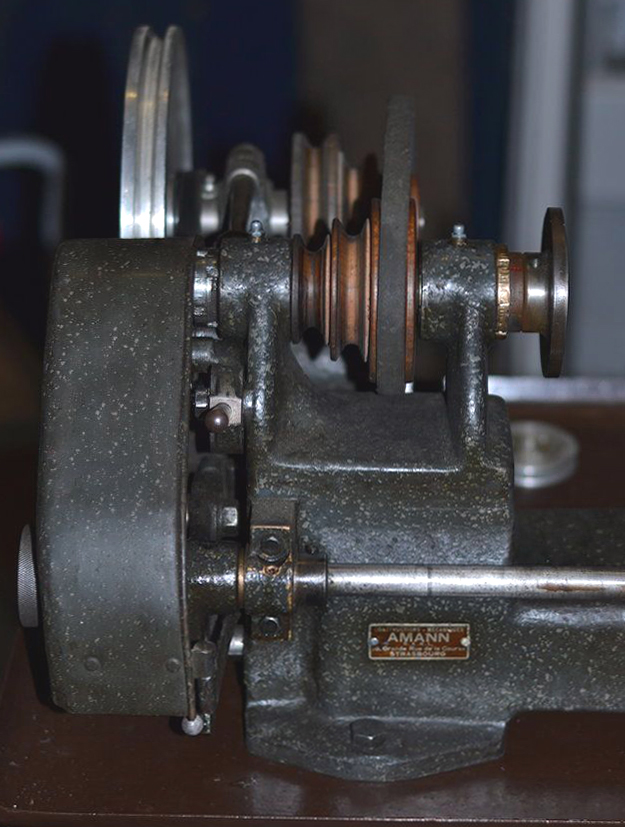

Another lathe of French origin from a maker whose existence as an actual manufacturer was, for some time, in doubt. However, in January of 2019 a contributor to a French machine-tool discussion group recalled, when very much younger, meeting Mr. Amann when the latter was involved in the production of a small precision lathe, the 80 mm x 400 mm screwcutting "Petit Tour De Précision Type A8". The owner's company, Machines-Outils Amann S.à r.l was located in Strasbourg with the factory's address given as Gare de Graffenstaden, a railway station to the south west of the city on the Rue de l'Industrie - from where in 2020, the company still traded. The original offices were located at 16 Grande Rue de la Course - a location that appears to retain all its original buildings.

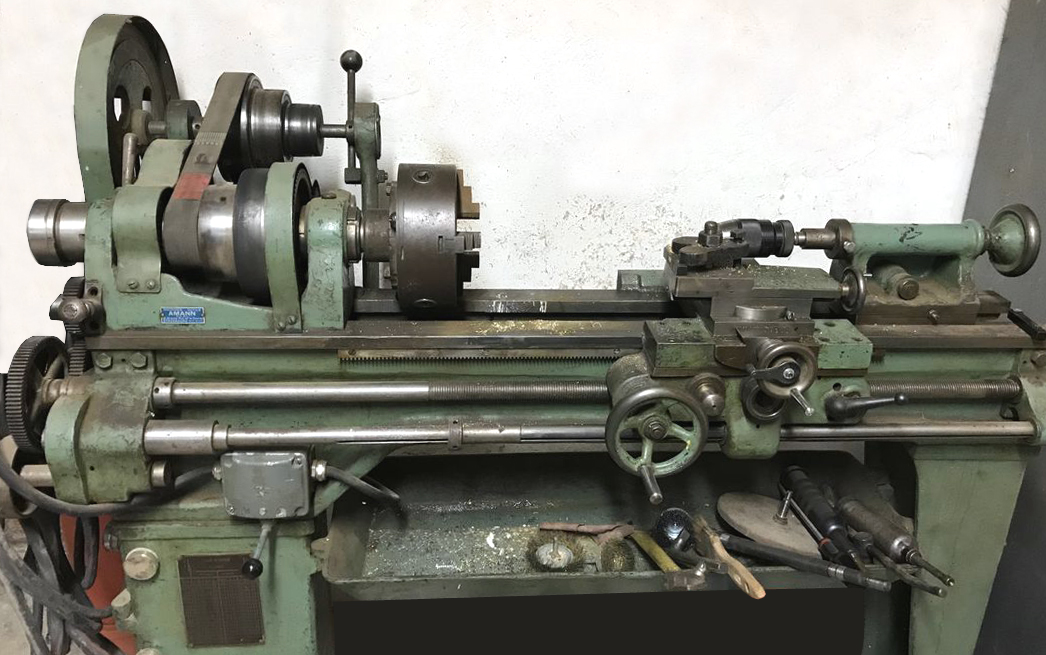

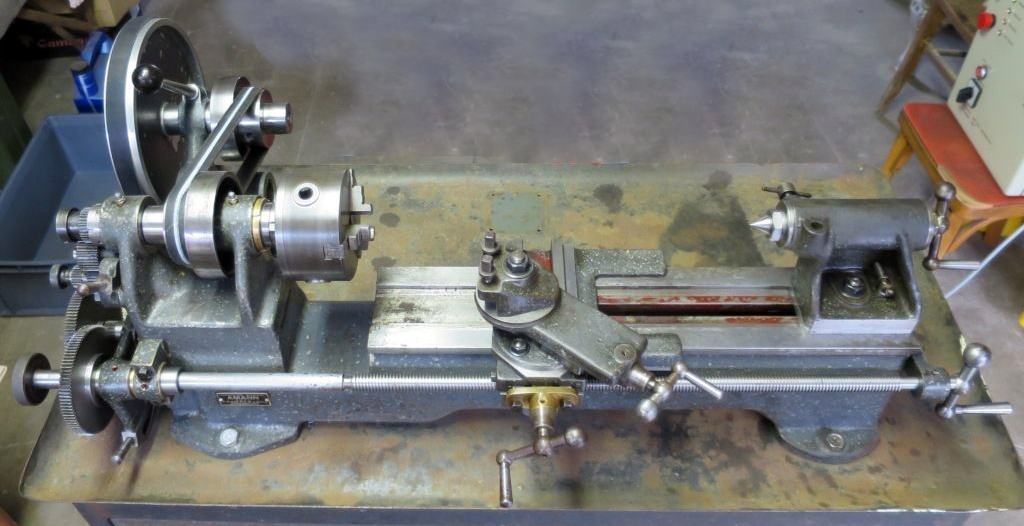

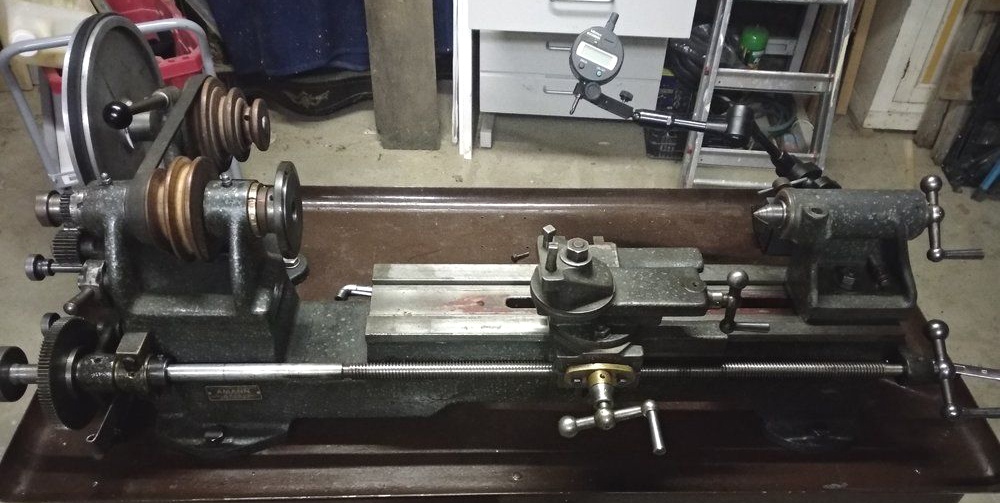

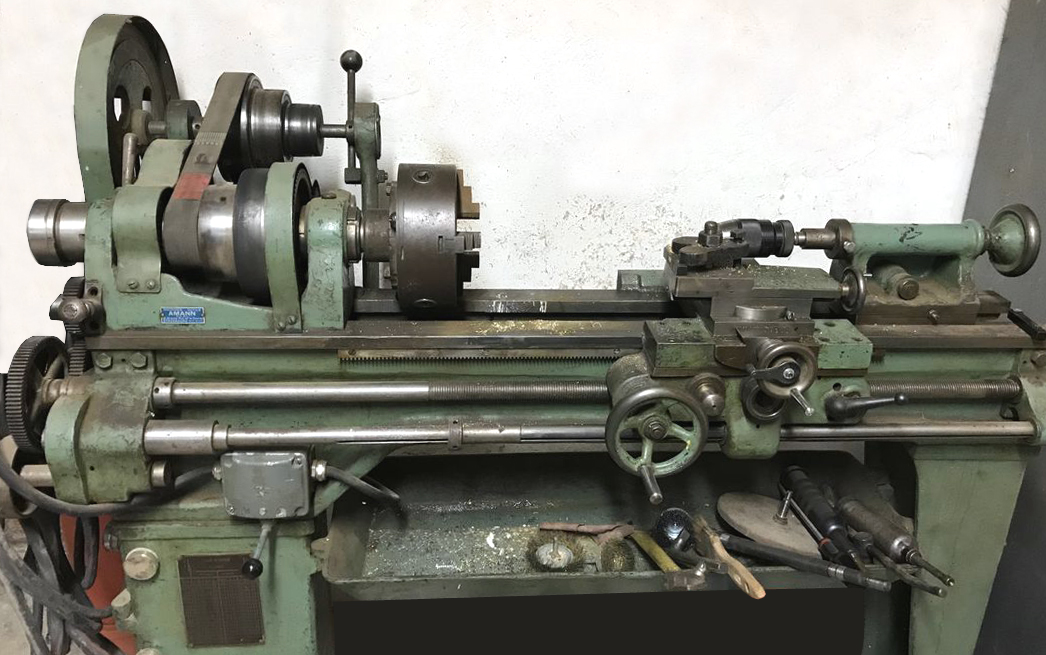

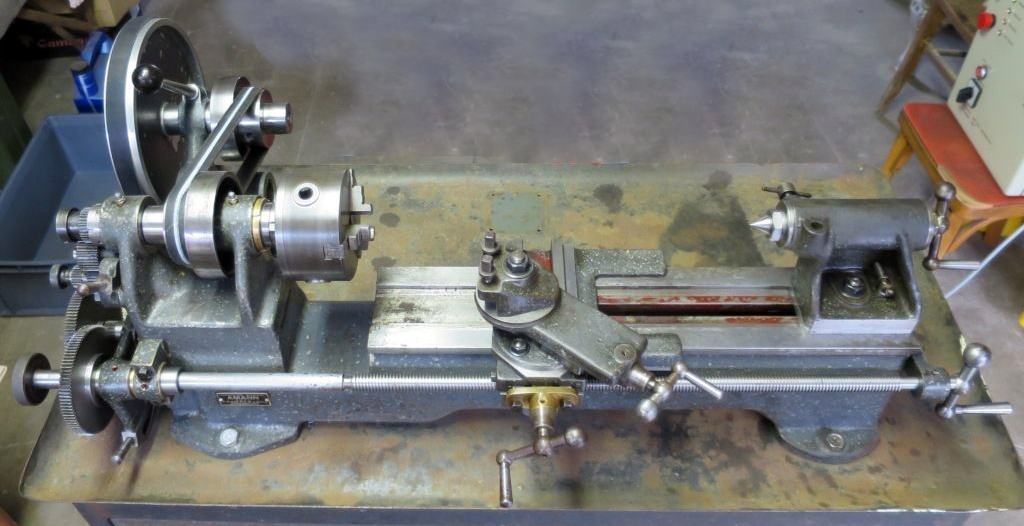

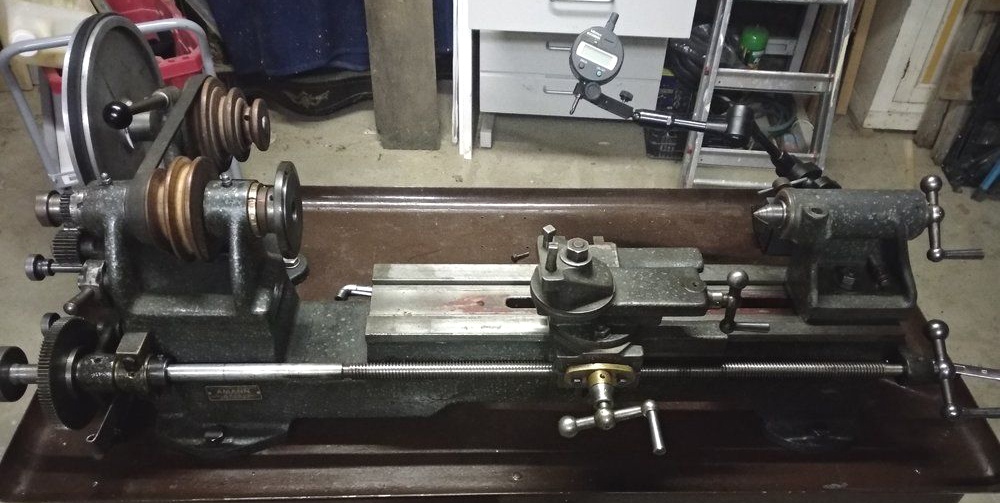

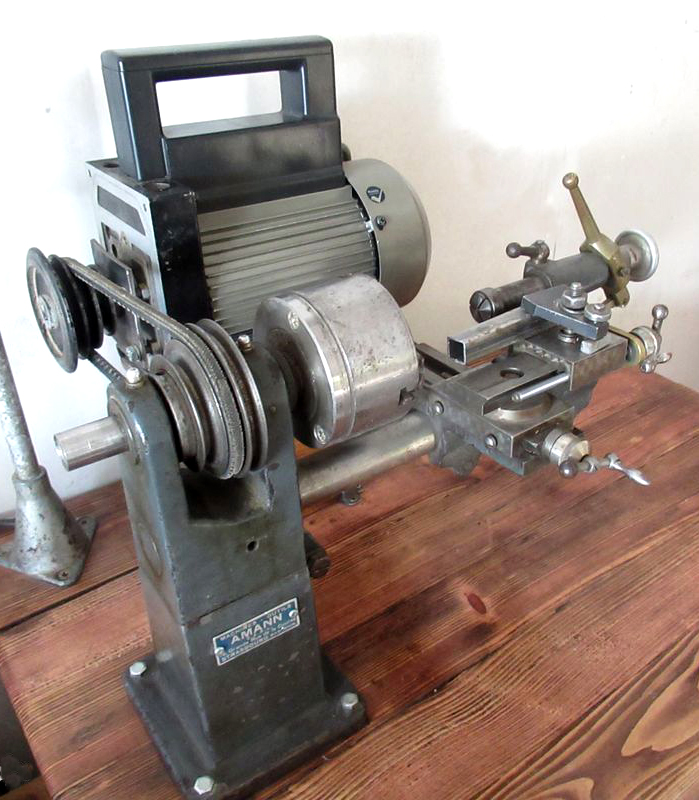

Amann appear to have manufactured a variety of lathes from a tiny and rather crude watchmaker's type (shown at the bottom of the page) to backgeared and screwcutting types suitable for a small professional workshop or home machinist. Dating from the 1940s to early 1950s, the first Amann lathe shown below was of conventional design but, for its class, heavily-built. Backgeared and screwcutting, the lathes had a bed of deep section but - at an estimated 115 mm (4.5 inches) - a relatively low centre height, giving the machine something of a squat appearance. Flat-topped, the bed featured English-type narrow vertical ways guiding a carriage with long, plain, symmetrical wings and a centrally positioned cross slide. Both cross and top slide had feed screws fitted with small micrometer dials - that on the cross slide perhaps having the facility to be set using an external lever mounted concentrically with the feed screw.

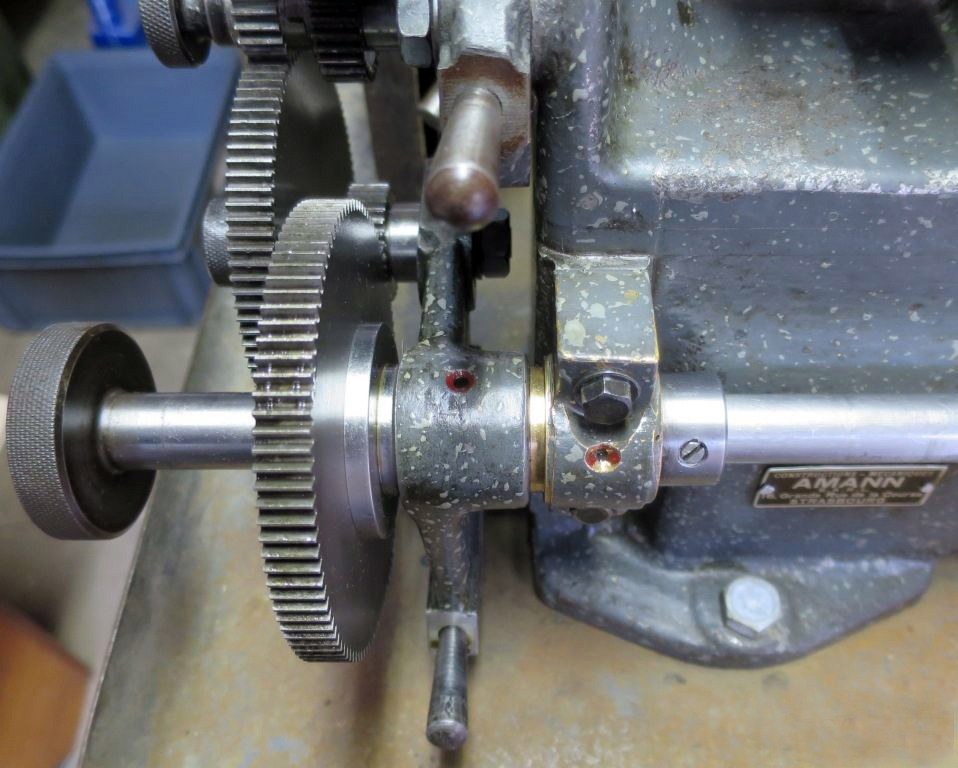

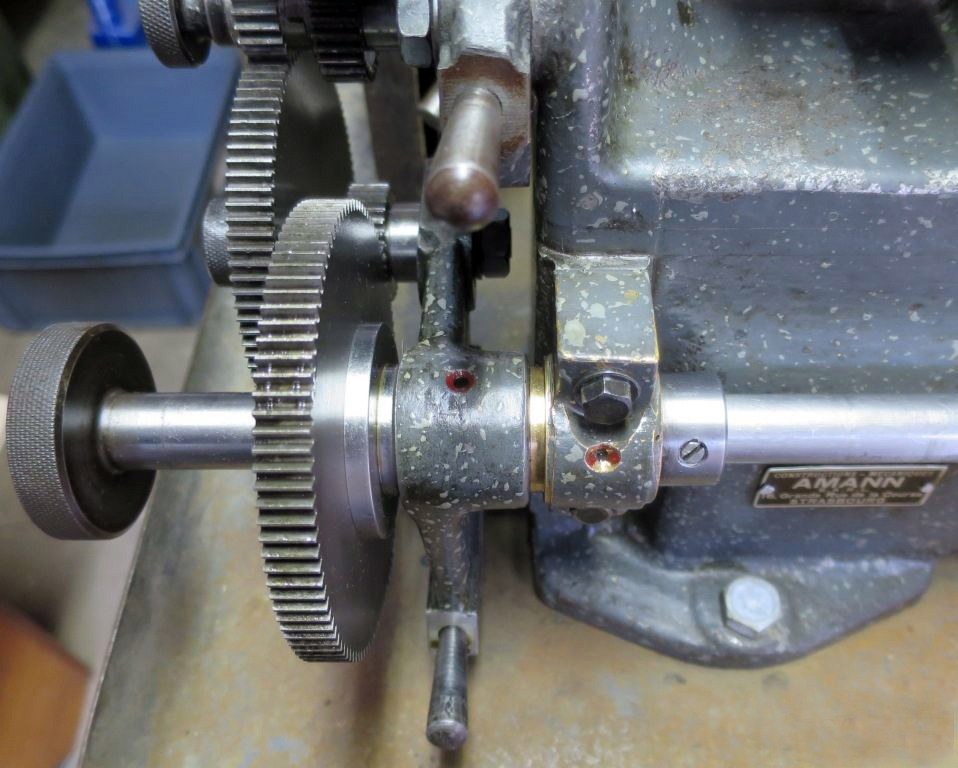

Fitted with a large diameter leadscrew of rather fine pitch, screwcutting was by changewheels working through an ordinary tumble-reverse mechanism - the lathe also being fitted with a feed-shaft gearbox, the drive being taken by a gear from the leadscrew. While most other lathes with this simple system provided three speeds for each setting of the change wheels - the basic Harrison L5 being a typical example - the Amann appears, at a glance, to have had only one. However, the possibility exists that, out of sight on the left-hand face of the box, is a push-pull knob that did provide a change of ratio.

Of unusual appearance, the apron contained a train of reduction gears between the carriage handwheel and bed-mounted rack and a push-pull knob that selected the power sliding and surfacing feeds. It seems that the feeds would have been engaged and disengaged by a centrally-mounted, screw-in-and-out, knurled-edged dial. This method, if fitted, often results in a drive "winding up" during heavy cuts and, in consequence, very difficult to disengage.

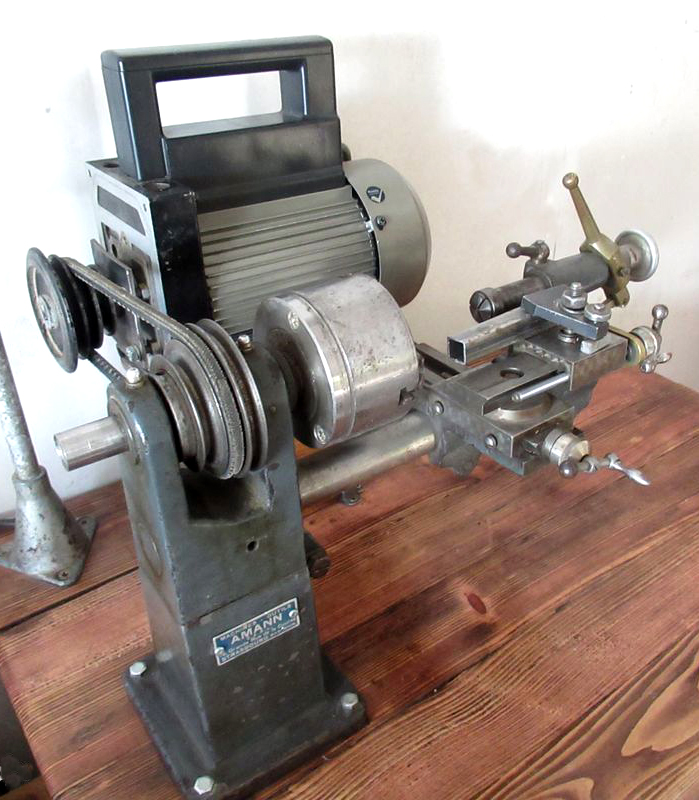

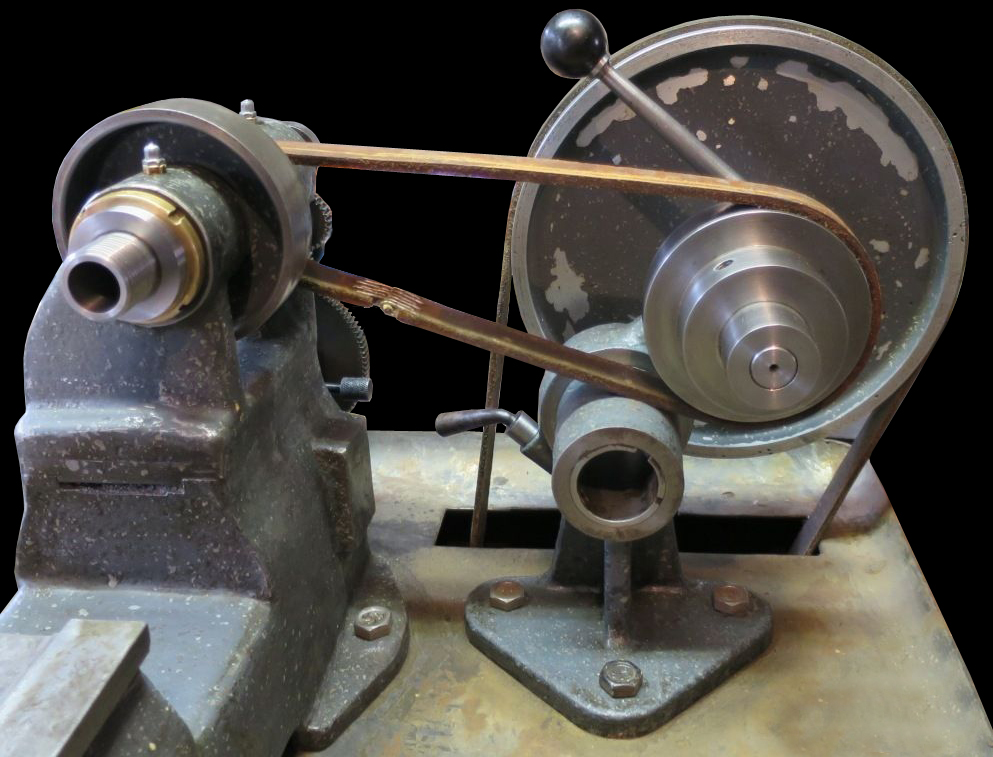

The spindle, running in bronze bearings adjustable by front and back slotted rings was driven from a ball-race supported countershaft bolted to the back of the bed. Drive from motor to countershaft looks to have been by a single V-belt, but that to the headstock spindle by a wider-than-usual flat belt running over a 3-step cone pulley. Six speeds would have been available, these likely to have spanned something like 50 to 700 r.p.m. To slacken the final-drive belt in order to change speeds, an over-centre lever was provided, presumably fitted with some sort of adjustment to set the final tension.

Do you have an Amann lathe? If so, the writer would be interested to hear from you.

Continued below:

|

|

|

|

|

|

|

|

|

|

Tours Amann - France

Un autre tour d'origine française d'un fabricant dont l'existence en tant que fabricant réel a été, pendant un certain temps, mise en doute. Cependant, en janvier 2019, un contributeur d'un groupe de discussion français sur les machines-outils s'est souvenu, alors qu'il était beaucoup plus jeune, avoir rencontré M. Amann lorsque celui-ci participait à la production d'un petit tour de précision, le "Petit Tour De Précision Type A8" de 80 mm x 400 mm à décolletage. La société propriétaire, Machines-Outils Amann S.à r.l, était située à Strasbourg et l'adresse de l'usine était la Gare de Graffenstaden, une gare située au sud-ouest de la ville, dans la rue de l'Industrie - d'où, en 2020, la société exerçait toujours ses activités. Les bureaux d'origine étaient situés au 16 Grande Rue de la Course - un endroit qui semble avoir conservé tous ses bâtiments d'origine.

Amann semble avoir fabriqué une grande variété de tours, allant d'un minuscule modèle d'horloger plutôt rudimentaire (illustré au bas de la page) à des modèles à engrenage arrière et à décolletage convenant à un petit atelier professionnel ou à un machiniste à domicile. Datant des années 1940 ou du début des années 1950, le premier tour Amann illustré ci-dessous était de conception conventionnelle mais, pour sa catégorie, lourdement construit. Dotés d'un réducteur et d'un système de décolletage, les tours avaient un banc de section profonde mais - avec une hauteur centrale estimée à 115 mm (4,5 pouces) - une hauteur relativement basse, ce qui donnait à la machine un aspect un peu trapu. Le banc, dont le sommet était plat, comportait des voies verticales étroites de type anglais guidant un chariot à longues ailes plates et symétriques, ainsi qu'une glissière transversale positionnée au centre. Le chariot transversal et le chariot supérieur étaient tous deux dotés de vis d'alimentation équipées de petits cadrans micrométriques - celui du chariot transversal pouvant peut-être être réglé à l'aide d'un levier externe monté concentriquement avec la vis d'alimentation.

Équipé d'une vis d'entraînement de grand diamètre et d'un pas assez fin, le décolletage s'effectuait à l'aide de molettes fonctionnant par l'intermédiaire d'un mécanisme de culbutage et d'inversion ordinaire - le tour étant également équipé d'une boîte de vitesses pour l'arbre d'entraînement, dont l'entraînement était assuré par un engrenage provenant de la vis d'entraînement. Alors que la plupart des autres tours dotés de ce système simple offraient trois vitesses pour chaque réglage des molettes - le Harrison L5 de base en étant un exemple typique - l'Amann semble, à première vue, n'en avoir eu qu'une. Cependant, il est possible qu'à l'abri des regards, sur la face gauche de la boîte, se trouve un bouton à tirer et à pousser qui permettait de changer de rapport.

D'apparence inhabituelle, le tablier contenait un train d'engrenages de réduction entre le volant du chariot et la crémaillère montée sur le banc, ainsi qu'un bouton poussoir qui sélectionnait les avances de glissement et de surfaçage. Il semble que les avances aient été engagées et désengagées par un cadran central, vissé et dévissé, à bords moletés. Cette méthode, si elle est utilisée, a souvent pour résultat un entraînement qui s'enroule pendant les coupes lourdes et qui, par conséquent, est très difficile à débrayer.

La broche, montée sur des roulements en bronze réglables par des bagues fendues à l'avant et à l'arrière, est entraînée par un arbre de renvoi à billes boulonné à l'arrière du banc. L'entraînement du moteur à l'arbre de renvoi semble avoir été assuré par une seule courroie trapézoïdale, mais celui de la broche de la poupée par une courroie plate plus large que d'habitude, passant sur une poulie conique à trois étages. Six vitesses étaient disponibles, et elles étaient probablement comprises entre 50 et 700 tours/minute. Pour détendre la courroie d'entraînement final afin de changer de vitesse, un levier central était prévu, probablement équipé d'une sorte d'ajustement pour régler la tension finale.

Possédez-vous un tour Amann ? Si c'est le cas, l'auteur serait intéressé par vos commentaires.

Suite ci-dessous :

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

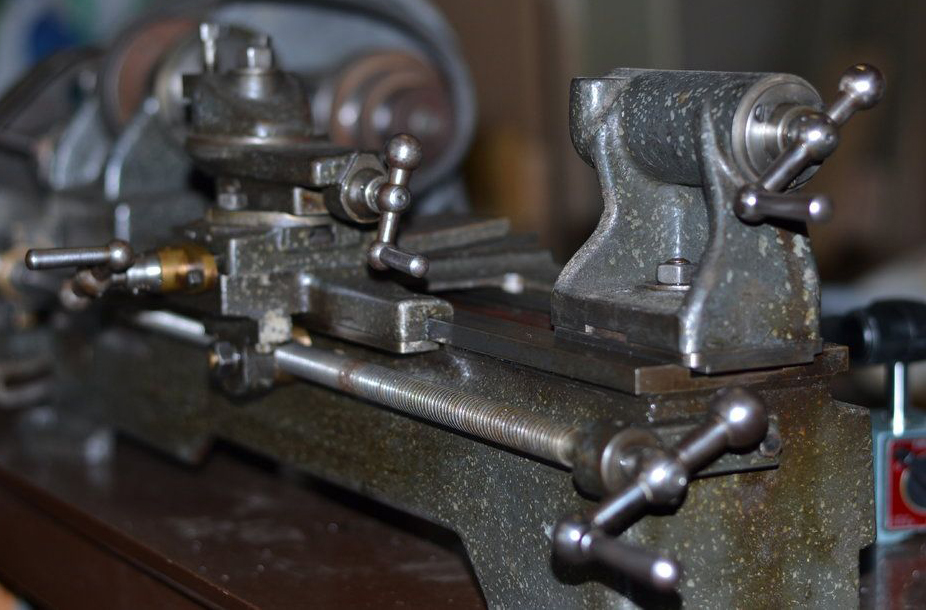

Backgeared and screwcutting, this Amann lathe had a bed of deep section but - at an estimated 115 mm (4.5 inches) - a relatively low centre height, giving the machine something of a squat appearance

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continued:

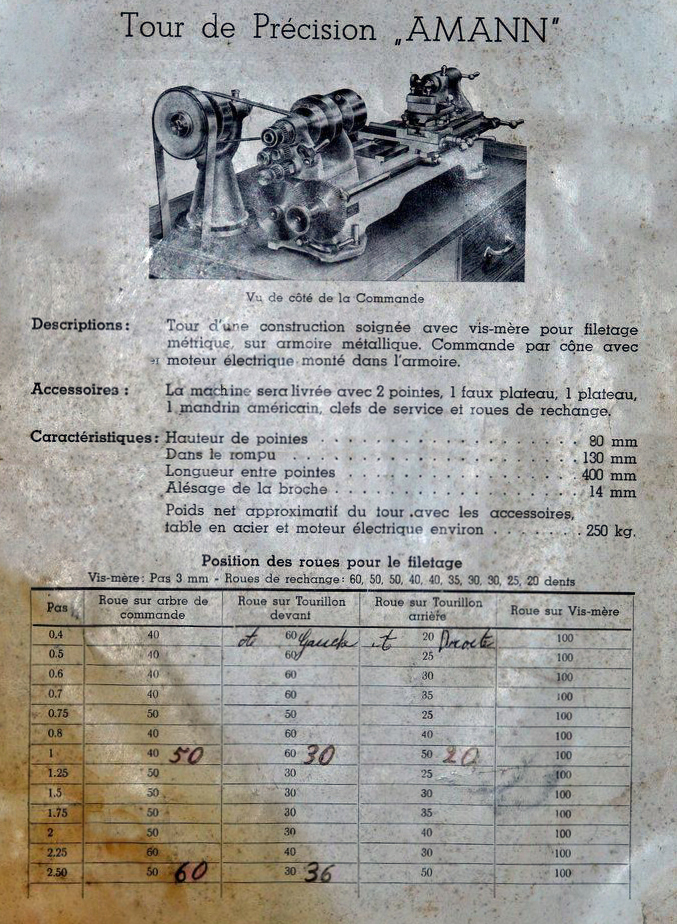

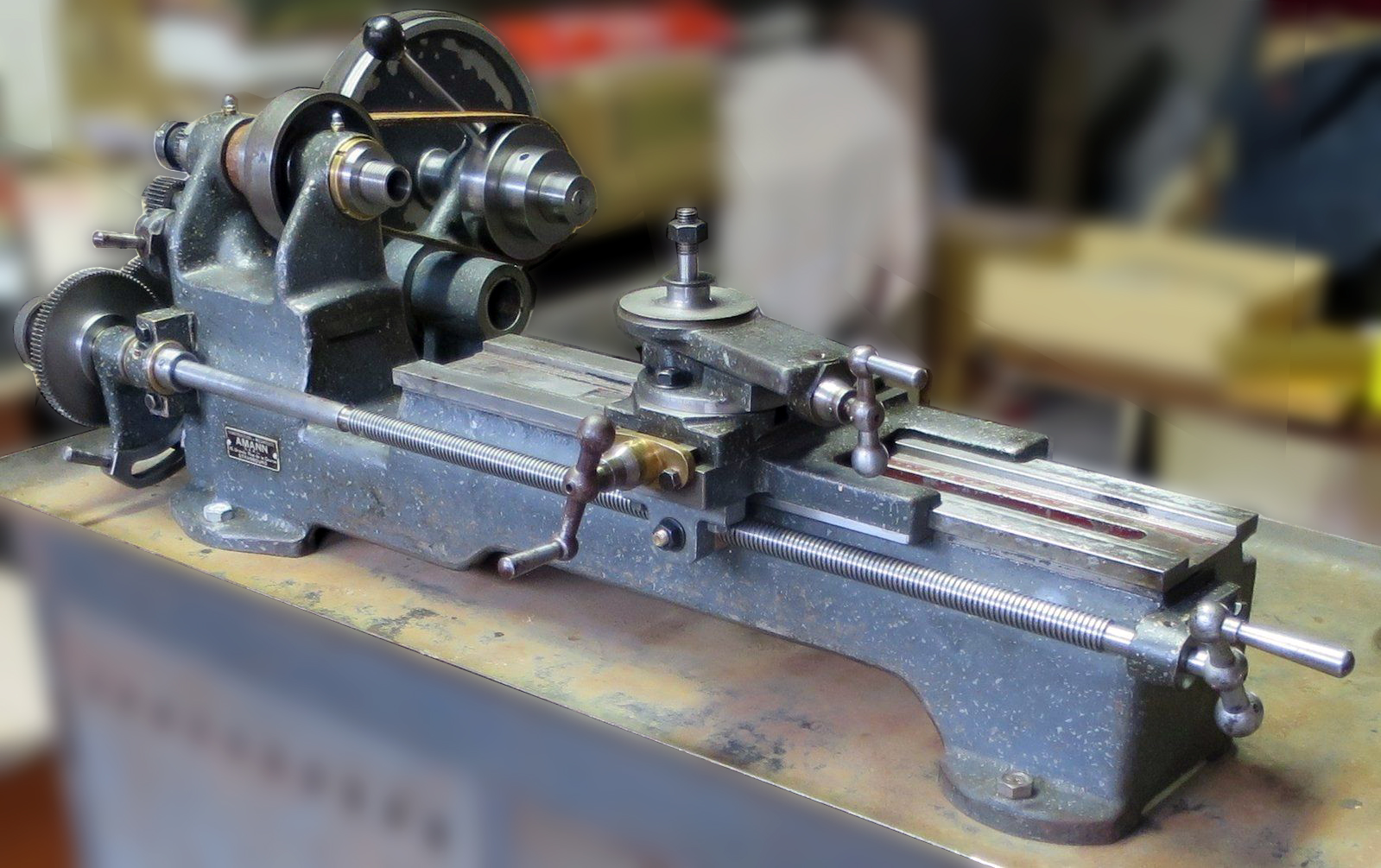

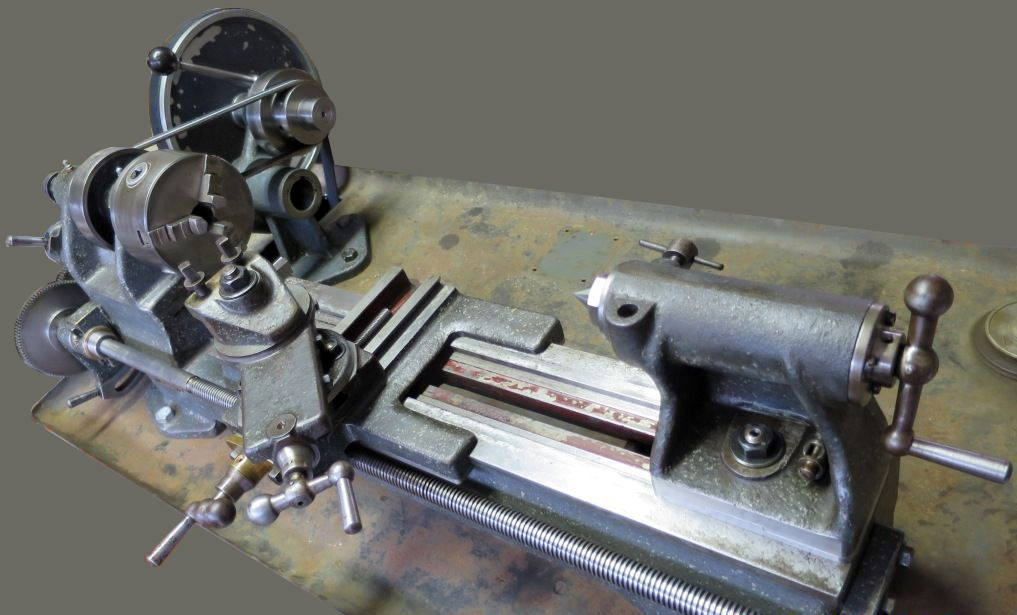

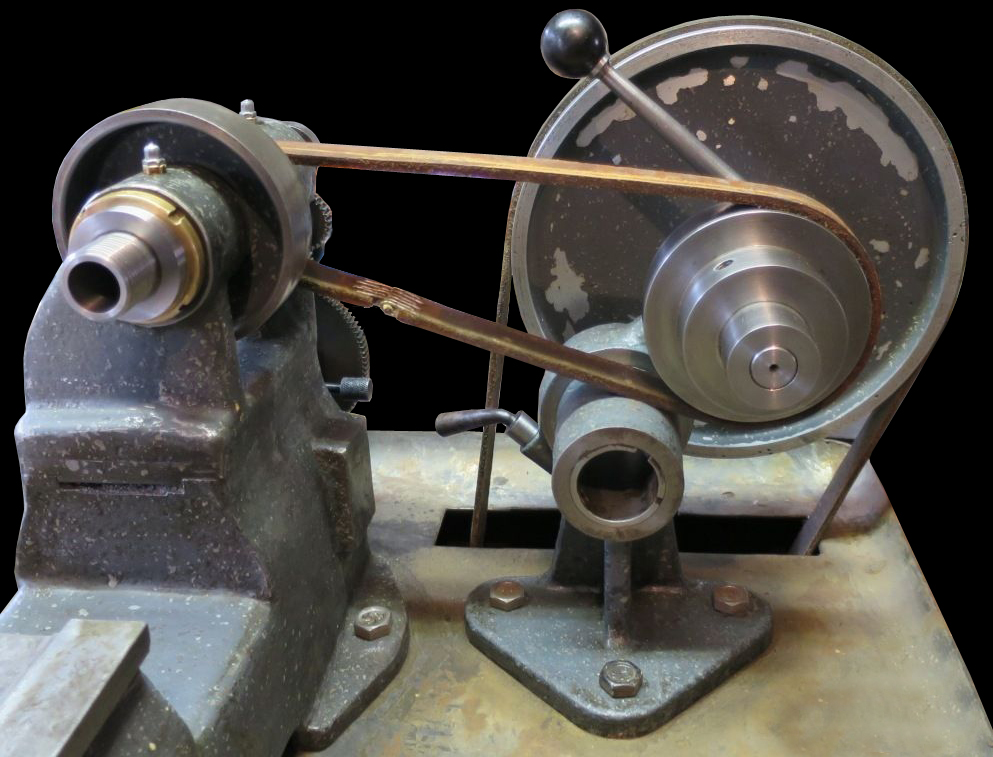

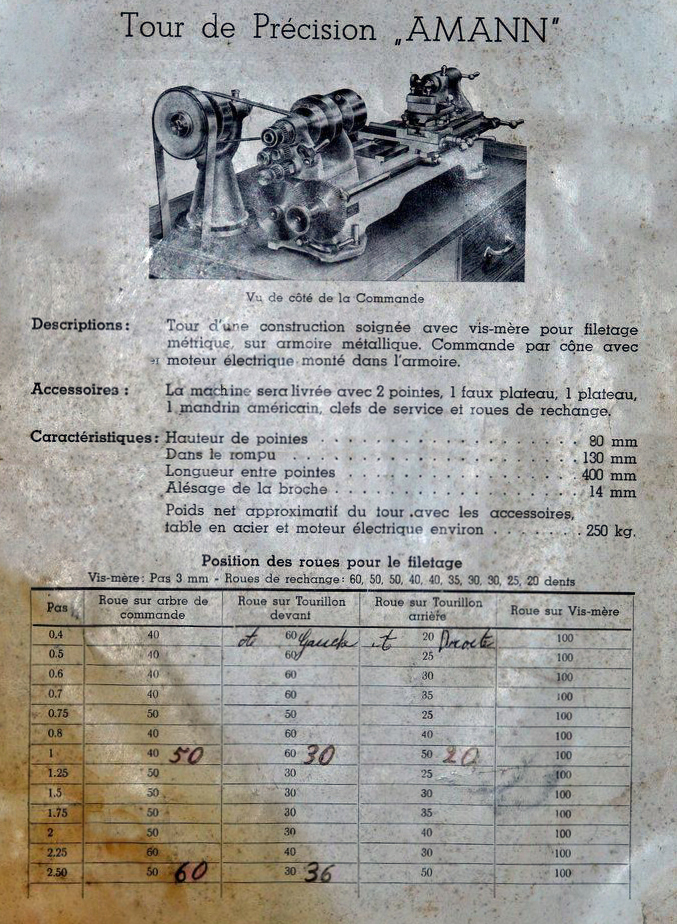

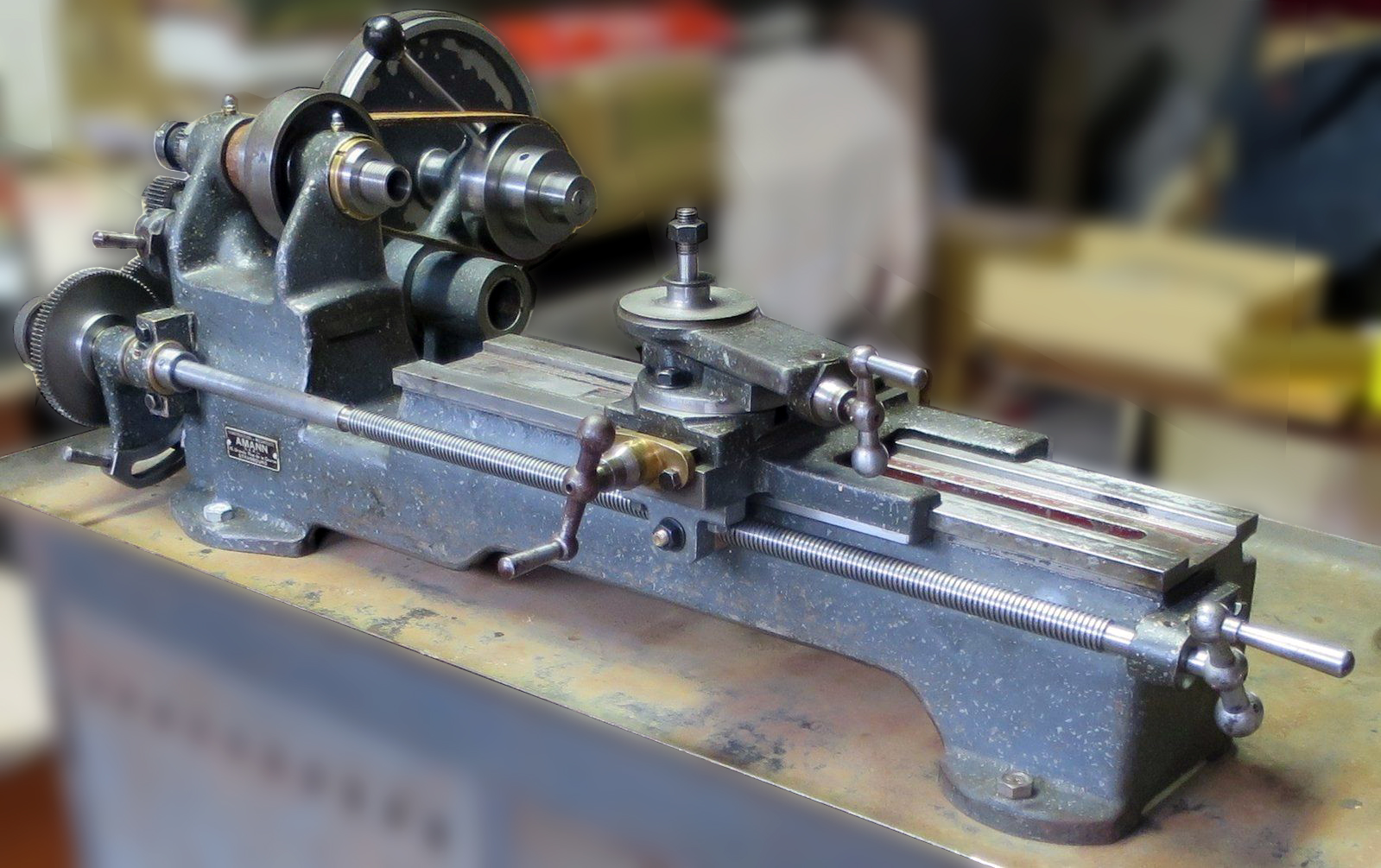

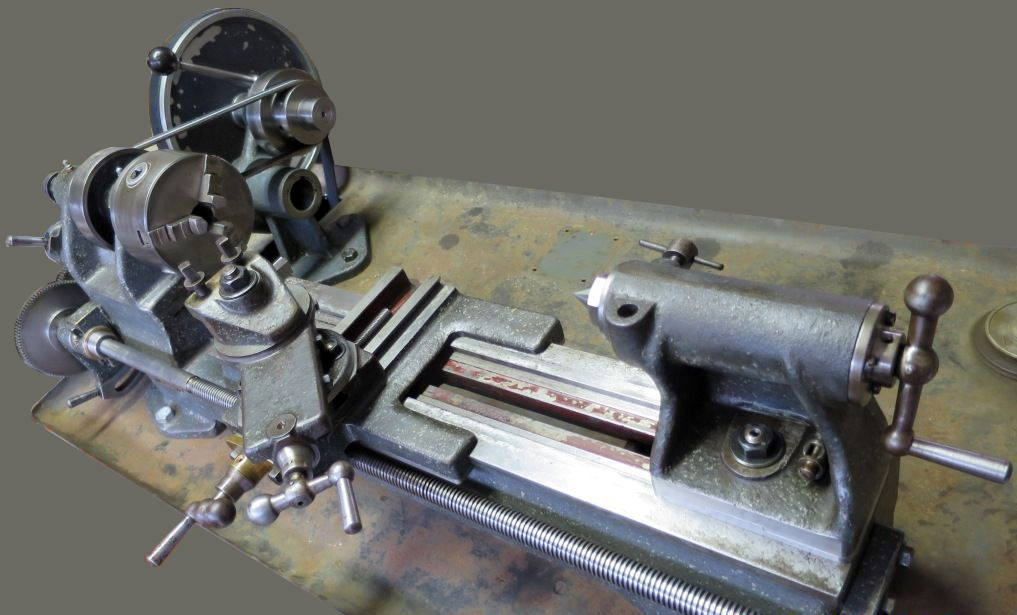

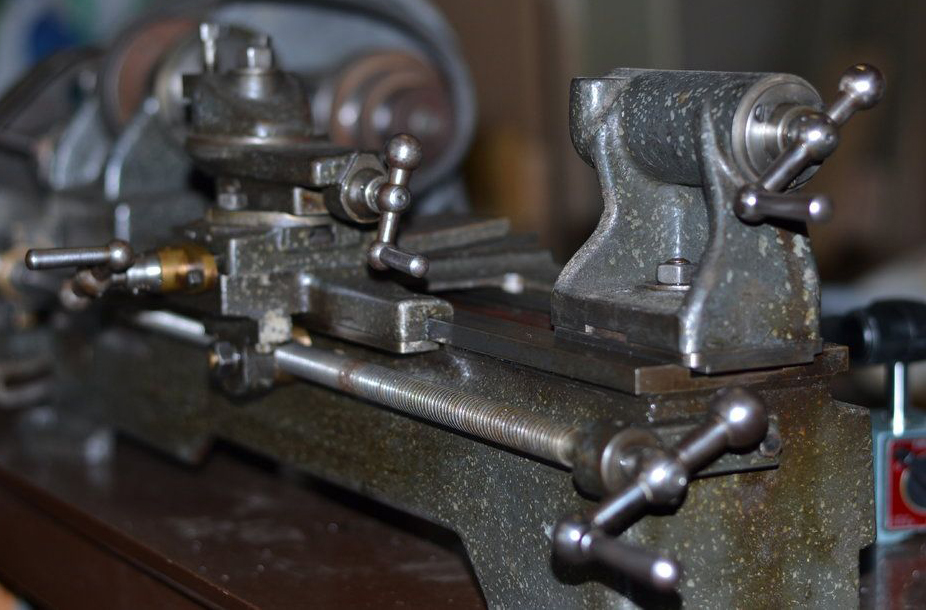

The other Amann lathe known about is the maker's original 80 mm x 400 mm "Petit Tour De Précision Type A8". This, in its class, was a rather unusual concept being heavily built with an exceptionally wide, English-type flat-topped bed with narrow vertical guides for the saddle and a permanent gap in which material up to 260 mm in diameter could be turned. Bed and headstock were cast as one rigid part, the latter carrying a large diameter spindle, bored through 14 mm, running in bronze bearings lubricated through oil nipples and fitted with a 3-step, flat-belt-drive cone pulley. Drive came from a well-made countershaft mounted remotely behind the headstock, the maker's illustrations showing this being driven from a motor held beneath inside a braced sheet-metal stand. A number of surviving examples have been found on this stand, easily recognised by, on the left, a large door perforated with circular holes and, on the right, two full-depth drawers. It appears that at least two countershaft designs were made; one having a circular, trumpet-like base with no adjustment for belt tension, the other fitted with a swing-head. Unfortunately, slow-speed backgear was not fitted, nor does it appear possible that it could have been retrofitted, the result being that, while screwcutting was fitted, a beginner attempting it would have found the high spindle speeds difficult to cope with. Using a square-form thread, the leadscrew passed through a solid bronze nut bolted to the underside of the saddle; as the nut was not of the split type, disengagement of the carriage drive was arranged not by the usual simple lever-operated dog clutch - as used on virtually every other lathe with a full nut - but by the sliding the final drive gear in and out of engagement.

With a 3 mm pitch, the leadscrew was fitted with a handle at the tailstock end and driven through changewheels that incorporated a tumble-reverse mechanism. A set of nine gears was provided - 20, 25, 30, 30, 40, 40, 50, 50 and 60 teeth - intended to generate just metric pitches.

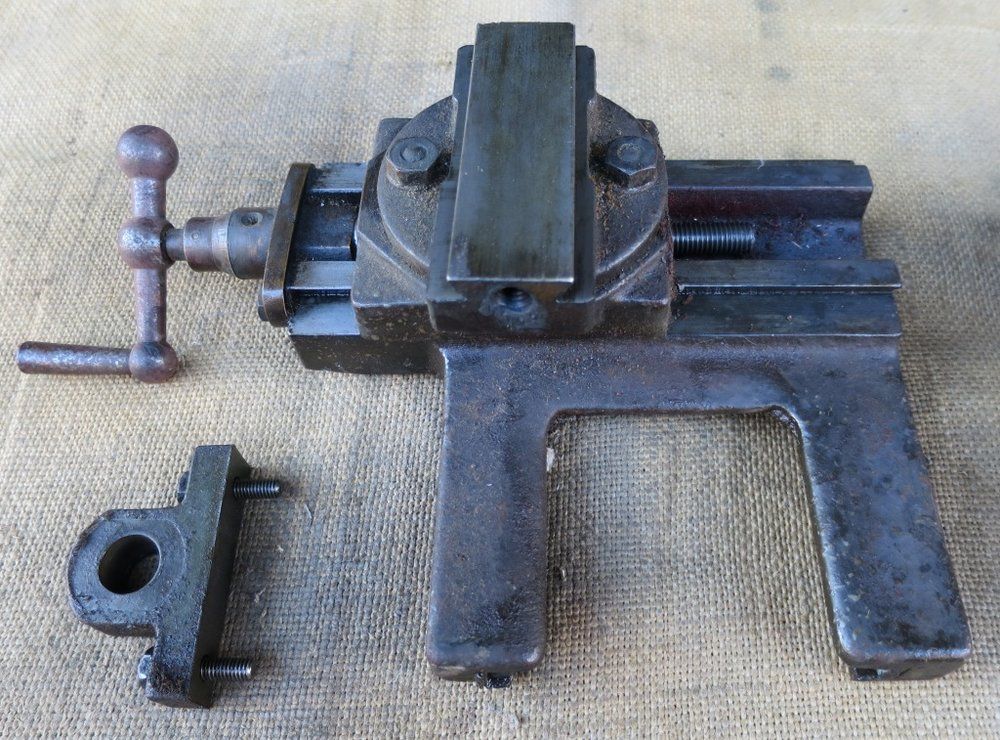

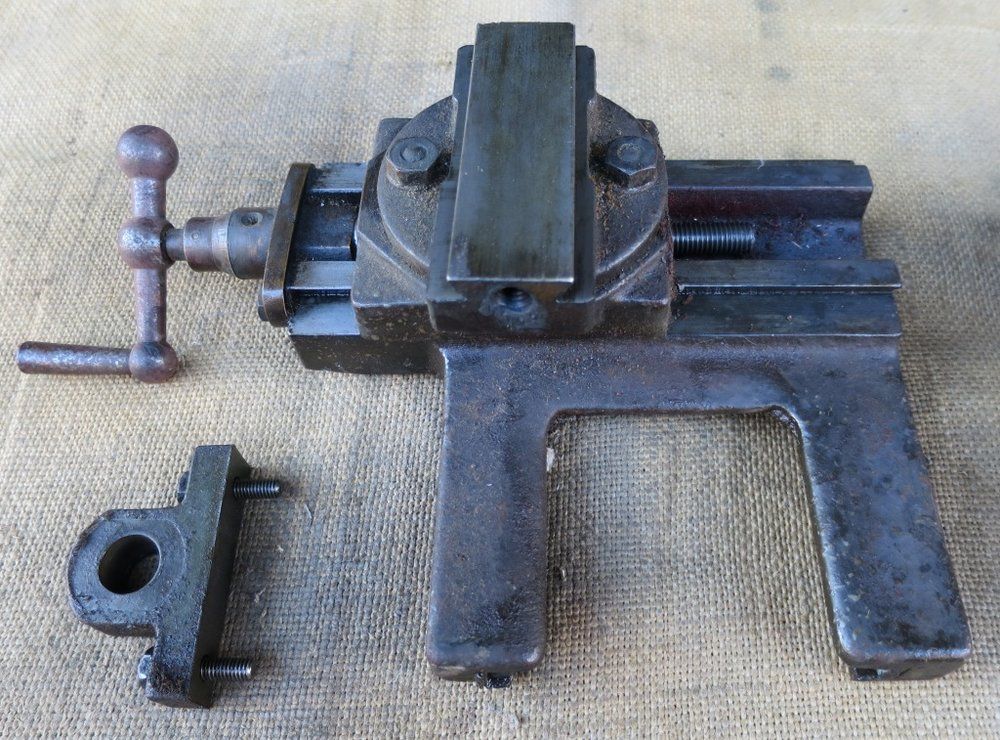

With long wings set to its right-hand side, the saddle carried an ordinary compound slide rest, the cross slide being of the short type and the top slide able to be swivelled through 360. The top slide had an unusual feature: the area upon which the "clog-heel" toolpost rested was machined as a circle rather than a square, some the writer struggles to record seeing on any other lathe. Feed screws had ordinary, 60° angle metric threads rather than the preferred Acme and were fitted with tiny, non-adjustable micrometer collars. Unfortunately, both the cross-slide ways and feed screw were left completely exposed to the wearing effects of swarf and dirt.

Cosmetically, the finish appears to have been rather like that used on the German Hommel - known as "craquellee" - a mottling, paint-splattering effect also seen on some examples of the English Haighton Cadet.

The little Amann would have been aimed at the same amateur market as the contemporary English EW - possibly the nearest lathe to it in terms of size and function, though of a very different design and construction..

|

|

|

|

|

|

|

|

Suite :

L'autre tour Amann connu est le "Petit Tour de Précision Type A8" original de 80 mm x 400 mm du fabricant. Dans sa catégorie, il s'agissait d'un concept plutôt inhabituel, fortement construit avec un banc plat de type anglais exceptionnellement large, avec des guides verticaux étroits pour la selle et un espace permanent dans lequel des matériaux jusqu'à 260 mm de diamètre pouvaient être tournés. Le banc et la poupée sont coulés en une seule pièce rigide, cette dernière portant une broche de grand diamètre, percée à 14 mm, fonctionnant sur des roulements en bronze lubrifiés par des graisseurs et équipée d'une poulie conique à entraînement par courroie plate à trois étages. L'entraînement provenait d'un arbre de renvoi de bonne facture monté à distance derrière la poupée, les illustrations du fabricant montrant qu'il était entraîné par un moteur placé sous un support en tôle renforcé. Un certain nombre d'exemplaires ont été retrouvés sur ce support, facilement reconnaissable à une grande porte perforée de trous circulaires à gauche et à deux tiroirs de grande profondeur à droite. Il semble qu'au moins deux modèles d'arbres de renvoi aient été fabriqués, l'un ayant une base circulaire en forme de trompette sans réglage de la tension de la courroie, l'autre étant équipé d'une tête pivotante. Malheureusement, il n'y avait pas d'entraînement à vitesse lente, et il ne semble pas possible de l'installer ultérieurement. Par conséquent, même si le décolletage était possible, un débutant aurait eu du mal à faire face aux vitesses de rotation élevées de la broche. Comme l'écrou n'était pas du type fendu, le débrayage de l'entraînement du chariot n'était pas assuré par l'habituel embrayage à levier simple - utilisé sur pratiquement tous les autres tours à écrou plein - mais par le glissement de l'engrenage de l'entraînement final dans et hors de l'engagement.

Avec un pas de 3 mm, la vis d'entraînement était équipée d'une poignée à l'extrémité de la contre-pointe et entraînée par des volants de changement de vitesse qui incorporaient un mécanisme d'inversion par culbutage. Un jeu de neuf engrenages - 20, 25, 30, 30, 40, 40, 50, 50 et 60 dents - était prévu pour générer des pas métriques.

Avec de longues ailes placées sur son côté droit, la selle portait une glissière composée ordinaire, la glissière transversale étant de type court et la glissière supérieure pouvant pivoter sur 360. Le chariot supérieur présentait une caractéristique inhabituelle : la zone sur laquelle reposait le porte-outil "clog-heel" était usinée en cercle plutôt qu'en carré, ce que l'auteur a du mal à retrouver sur un autre tour. Les vis d'alimentation avaient des filets métriques ordinaires à 60° d'angle plutôt que les filets Acme préférés et étaient équipées de minuscules colliers micrométriques non réglables. Malheureusement, les glissières transversales et la vis d'alimentation ont été complètement exposées à l'usure due aux copeaux et à la saleté.

D'un point de vue esthétique, la finition semble avoir été assez semblable à celle utilisée sur les Hommel allemands - connue sous le nom de "craquellee" - un effet de marbrure et d'éclaboussure de peinture que l'on retrouve également sur certains exemplaires du Haighton Cadet anglais.

Le petit Amann aurait été destiné au même marché amateur que l'EW anglais contemporain - peut-être le tour le plus proche de lui en termes de taille et de fonction, bien que de conception et de construction très différentes..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The owner of the Amann lathe has done a superb job of restoring it to full working order

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Saddle, cross and top slide of the Amann Petit Tour De Précision Type A8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Underside of the top slide showing the ordinary metric-pitch feed screw

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Les vis d'alimentation, toutes deux des filets métriques ordinaires à angle de 60° plutôt que les filets Acme préférés, étaient équipées de minuscules colliers micrométriques non réglables. Malheureusement, la vis d'alimentation transversale n'était pas couverte et restait donc exposée à l'avant et à l'arrière aux effets d'usure des copeaux et de la saleté

|

|

|

|

|

|

|

|

|

|

|

|

The feed screws, both ordinary, 60° angle metric threads rather than the preferred Acme, were fitted with tiny, non-adjustable micrometer collars. Unfortunately, the cross-feed screw was not covered and so left exposed at both front and rear to the wearing effects of swarf and dirt

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Amann watchmaker's lathe - a simple. Almost crude affair with a round bed and lever-action tailstock

|

|

|

|

|

|

|

|

|

|

|

|

|

Tour d'horlogerie Amann - un tour simple. presque rudimentaire avec un banc rond et une contre-pointe à levier.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The owner's company, Machines-Outils Amann S.a.r.l. was located in Strasbourg with the factory's address given as Gare de Graffenstaden, a railway station to the south west of the city. The works were on the Rue de l'Industrie, from where, as can be seen in this 2020 picture, the company still trades.

|

|

|

|

|

|

|

|

La société du propriétaire, Machines-Outils Amann S.a.r.l., était située à Strasbourg, l'adresse de l'usine étant la Gare de Graffenstaden, une gare située au sud-ouest de la ville. L'usine se trouvait dans la rue de l'Industrie, d'où, comme on peut le voir sur cette photo de 2020, l'entreprise exerce toujours ses activités.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|