|

Portass Models X and XL

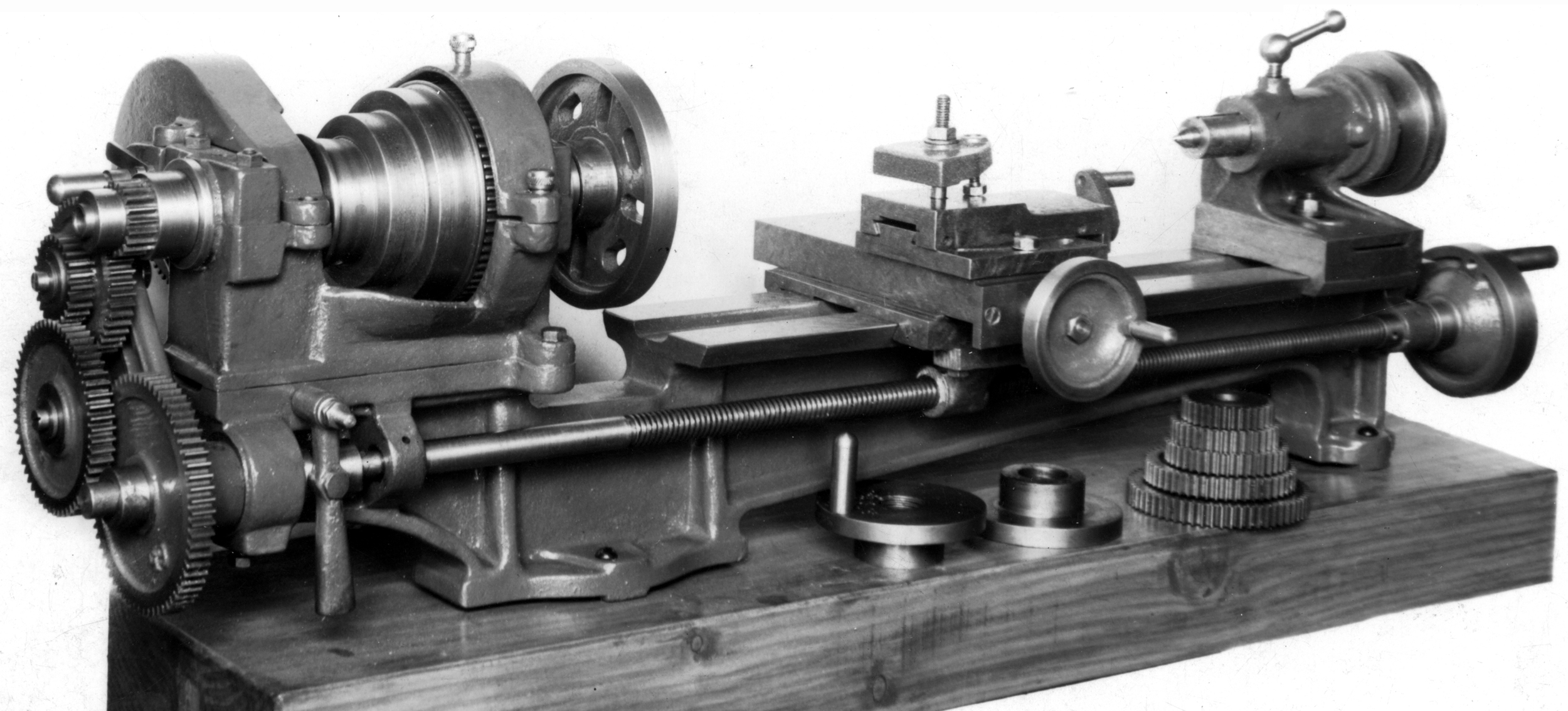

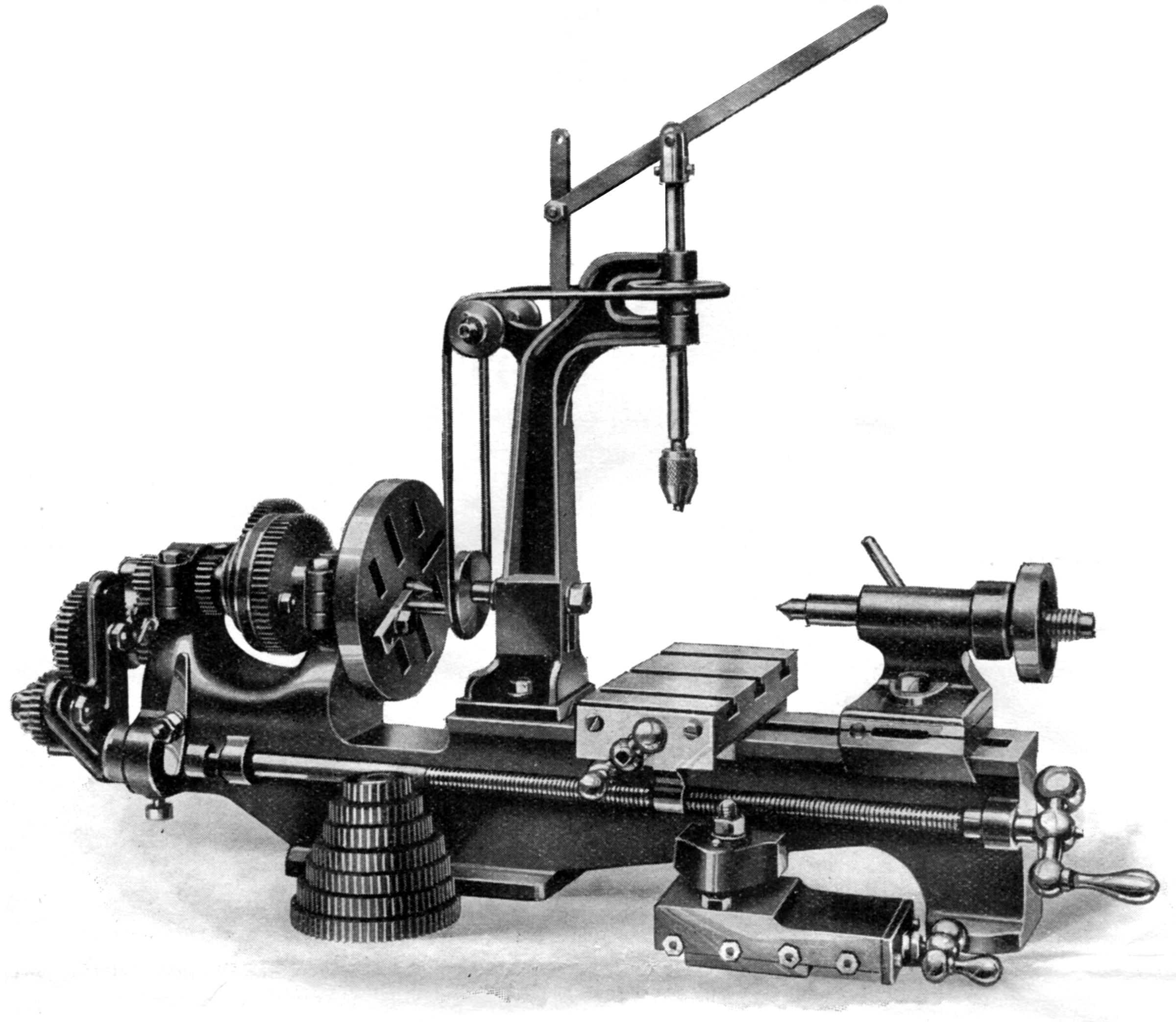

Available in two models and several forms - in the usual very confused Portass manner - the X.L. enjoyed a specification rather superior to that normally found on other Portass lathes of the early 1930s. The headstock and (gap) bed were cast as as-one, a forked and not single-slot changewheel bracket was fitted, the slide rest was a proper compound type with a swivelling top slide, backgear was at a ratio of 6 : 1, a dog clutch fitted to the leadscrew and, most surprising of all, the option of tumble reverse to the leadscrew drive. The centre height was 4 inches with either 12.5 or 18 inches available between centres. Also available was a cheaper model advertised as the "X" with a centre height of 3 inches--though you can bet some were 4. Based on the X.L, the X lacked all the features that made that model so useful and made do with a single swivelling tool slide, no set-over to the tailstock (though this has been seen on several examples so must have been available as an option), no tumble reverse (though some headstocks have casting designed to take it), a spindle running direct in the cast-iron of the headstock and, to make screwcutting more difficult to set up, a single-slot instead of a forked changewheel bracket.

Bored through 3/8", the No. 1 Morse spindle ran in parallel split gun-metal (bronze) bearings nipped down by screws. While early examples were fitted with a 3-step headstock pulley designed to be driven by a 5/16" round leather rope, later types had the no-cost option of a 3/8" flat-belt drive - and so a more useful work capacity. The lathe was often supplied fastened to a substantial cast-iron chip tray - and sometimes complete on cast-iron standards (legs) - the headstock-end one of which carried a treadle-operated flywheel or. Very rarely, when a customer must have worked lots of overtime in the steel works, he might have ordered his lathe with a self-contained electric drive that, instead of using an ordinary countershaft system left the flywheel assembly in place - as on the Dreadnaught machines). Wound up to full speed, such a set-up would have taken a considerable time before any job, even a lighter one, came to a stop. A cut-out in the chip tray - in line with the headstock pulley - gave clearance for the drive belt - with round-rope and flat-belt versions similarly equipped.

Driven along the bed by an 8 t.p.i. Square-thread leadscrew fitted with a dog clutch at the headstock end and a balanced handwheel at the other, the carriage had a proper compound slide rest, the cross slide of which was T-slotted - but the tool slide retained by just a single bolt on which it could be swivelled. In line with other contemporary Portass lathes no micrometer dials were fitted to either slide. the

Was this the first ever Portass to be fitted with a tumble reverse to the leadscrew? It would appear so, the Model X shown in photographs below having the correct castings in place - but no gearing - while the X.L. has the complete mechanism in place. However, the tumble gears were of a horribly coarse pitch and must have caused quite a racket when run at speed.

Supplied with the lathe was a full set of machine-cut screwcutting changewheels: 20, 20, 25, 30, 35, 40, 45, 50, 55 and 60t.

Prices in the lathe 1930s were £10 :10s : 0d for the short-bed X.L., £12 : 0s :0d for the 18-inch model, with an extra £4 : 4s : 0d for the flywheel-equipped stand and a charge of 7s : 6d for backgear guards and the same for a changewheel cover. Somewhat cheaper, the inferior Model X was listed at £7 : 16s : 0d for the short-bed and £9 : 6s : 6 3/4d for the long.

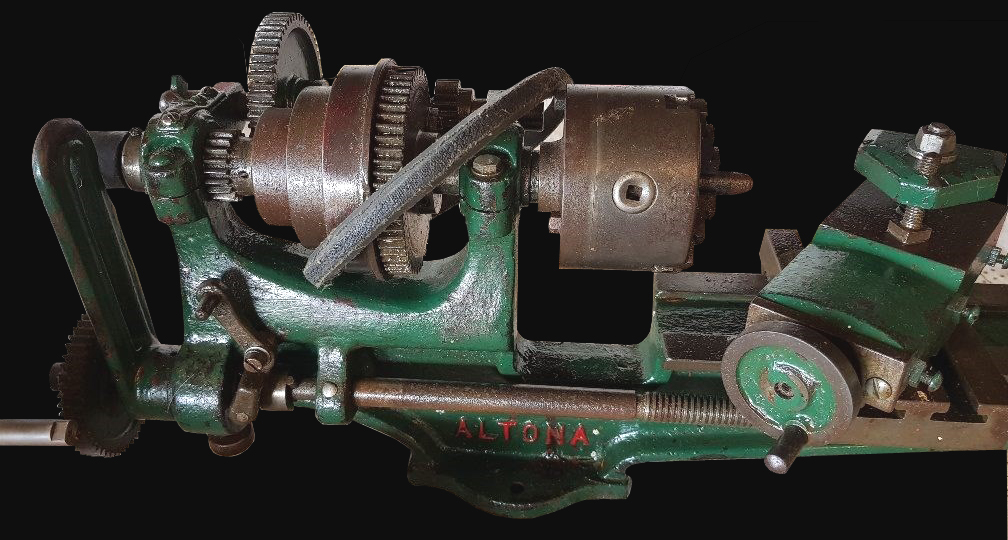

The X - and possibly the XL - were also badged as the Altona, as was the Portass Model S. However, to date, no Altona models have ever been found in the UK, all residing in Australia.

Portass Model S

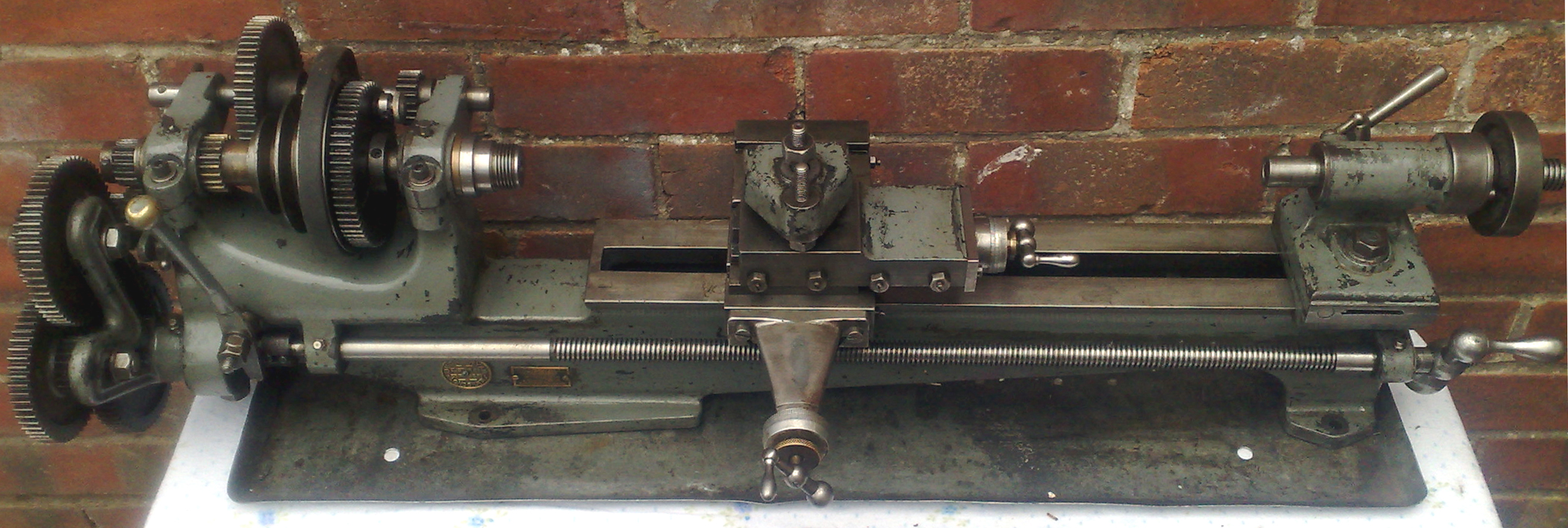

Made in considerable numbers both before WW2 and from 1951 onwards, when it was re-introduced, the Model S was the most common of the smaller and cheaper Portass backgeared and, screwcutting range of lathes Although there would have been ample scope to allocate the various adaptations of the Model S Model designations - or at least identifying numbers - just like the company's determination to use "Dreadnought" to describe all their larger lathes, the label "Model S" was applied to a number of lathes all with different capacities and specifications. Unfortunately, Portass appear to have been rather casual about Model and Types designations and it is not known for certain how (or even if) the factory catalogued the very first examples made during the late 1920s. With bed and headstock cast as one (and a long foot under the bed gap) a compound slide rest, round leather "rope-drive" headstock pulley and a set-over tailstock these were distinctly different in details to later versions, in fact sufficiently so as to allow them to be designated as the Mk. 1 and later types as the Mk. 2 . Of the latter, least four versions were offered with centre heights of 3" (to swing 71/2" in the gap); 33/8" and 35/8" and between-centres' capacities of 121/2" and 18". Each type also featured a number of minor differences in detail and appearance with some models (usually the basic 3") having a simple, swivelling top slide while others (usually, though not exclusively, the larger versions) had both a T-slotted saddle and cross slide and a proper top slide with 21/2" of travel. The first illustration below shows one of the last made (in the mid 1950s); this had a redesigned bed some 35/8" wide with vertical stiffening ribs cast into the section beneath the gap, a larger 1" diameter, 3/8" bore spindle running in split, bronze bearings, a 1" tailstock barrel and a compound slide rest with a thinner top slide. The dog-clutch lever was straight and pointed downwards - rather than being dog-legged and set upright as on earlier machines. An even more heavily modified version of the "S" was also produced, although it is impossible to say if it was manufactured simultaneously with other types (and perhaps built at the request of a retailer) or just a more highly-developed example. The main improvement centred around a headstock with a heavier and stiffer build with the bearings braced by raising the front of the casting until it was level with the bearing clamp slits. A longer cross slide with transverse T-slots was used and the headstock (almost identical to that on the final Portass lathe, the PD5), was also fitted on at least one version of the lathe sold under the Gamages label.

Most S-Types appear to have been supplied with a full compliment of 16 D.P. screwcutting changewheels comprising: two x 20t, 25t, 30t, 35t, 40t, 45t, 50t, 55t and 60t with both a 65t and 63t available, at extra cost, for metric conversions. Other equipment supplied as standard with a new ma chine included a faceplate, a spare chuck backplate and a catchplate. In 1951 the "S" was priced at £28 : 10s : 0d for the short-bed 3" model rising to £32 : 10s :0d for the 18" between-centres long-bed. A useful if limited range of extra was offered including: a choice of a simple bench-mounted, non-tensioning countershaft (termed the Mk, 5) at £2 : 19s : 6d or a rather more effective fast-and-loose unit (the P.D.5 from the smaller version of the Dreadnaught) for bench, wall or ceiling mounting at £4 : 15s : 0d. A stand and chip tray in cast iron could be supplied, though at £9 10s : 0d this was relatively expense, as was the addition of treadle gear and flywheel with that assembly, including the stand, retailing for £16 : 0d : 0d. The impecunious, who also wished to save on electricity, could choose instead a "foot motor" with its 46 lb flywheel and rig up their own bench - perhaps even splashing out on the special cast-iron chip tray sold for that arrangement. Fixed and travelling steadies, plain and swivelling vertical milling slides, extra changewheels, Morse centres, electric motors, Burnerd chucks and cone pulleys to help the new owner to construct his own drive system were also listed.

A number of firms - some associated with machines tools and other simple retailers or mail-order concerns - are known to have bought in Portass lathes and badged them as their own including: Portass was also kept busy supplying machines for retailers to re-badge as their own and examples have been found marked: Altona (shown below, and here, and only discovered, so far, in Australia - so possibly named after the Melbourne suburb), A.T.M., B.I.L., Bond's Maximus, Companion (sold by Johns in Auckland, New Zealand), "Eclipse" (for the Sheffield hand-tool makers James Neil & Sons) Excell, G.A. (George Adams), Gamages, Graves, James Grose Ltd. of London (the latter chiselling off the Portass name and substituting their own badge), Juniper, Randa, Temmah, Wakefield, Woolner and Zyto, All appear to have been based on established Portass models, nearly always a version of the "Junior" or the venerable "S Type", although in every case some small differences, usually down to cost-cutting, can be found. Not every Gamages' lathe was by Portass, the company being well known for re-branding lathes from several other makers as well. If you have an example of a Portass badged as other than the examples already discovered (those with hyperlinks) the writer would be interested to hear from you.

Unfortunately I have nothing to add to your excellent description of Portass lathes but in the late 1960's, when I was looking to buy a lathe, the choice lay between an ML7 and a Portass S which was, at the time, more within my means. However, despite the extra cost, I eventually choose the Myford - £120 including a 4-jaw chuck and a Jacobs drill chuck. There was no motor but I adopted one I had acquired to fit. I still have this lathe (2008) and it has served me very well. However, about twelve years ago, I saw an advertisement for a Portass S complete with motor and a vertical slide for £120 ponds and, looking back, just I had to buy it. Since that time it has been is the most used lathe in my workshop and has earned what I paid for it many times over. I must admit that I do not use it very often when screw-cutting, but it's a challenge I sometimes submit to! On the Portass everything comes to hand - I cannot describe it in words, but it just happens. Anyone who manages to get a Portass lathe will not be disappointed.

Donald on South Uist..

|

|