|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E-MAIL Tony@lathes.co.uk

lathes.co.uk Home Page Machine Tool Archive Machine Tools For Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues Belts

ManSon Master Lathe

ManSon Home Page Duo Lathe Duo lathe Photo Essay Accessory Kits

MonoLathe

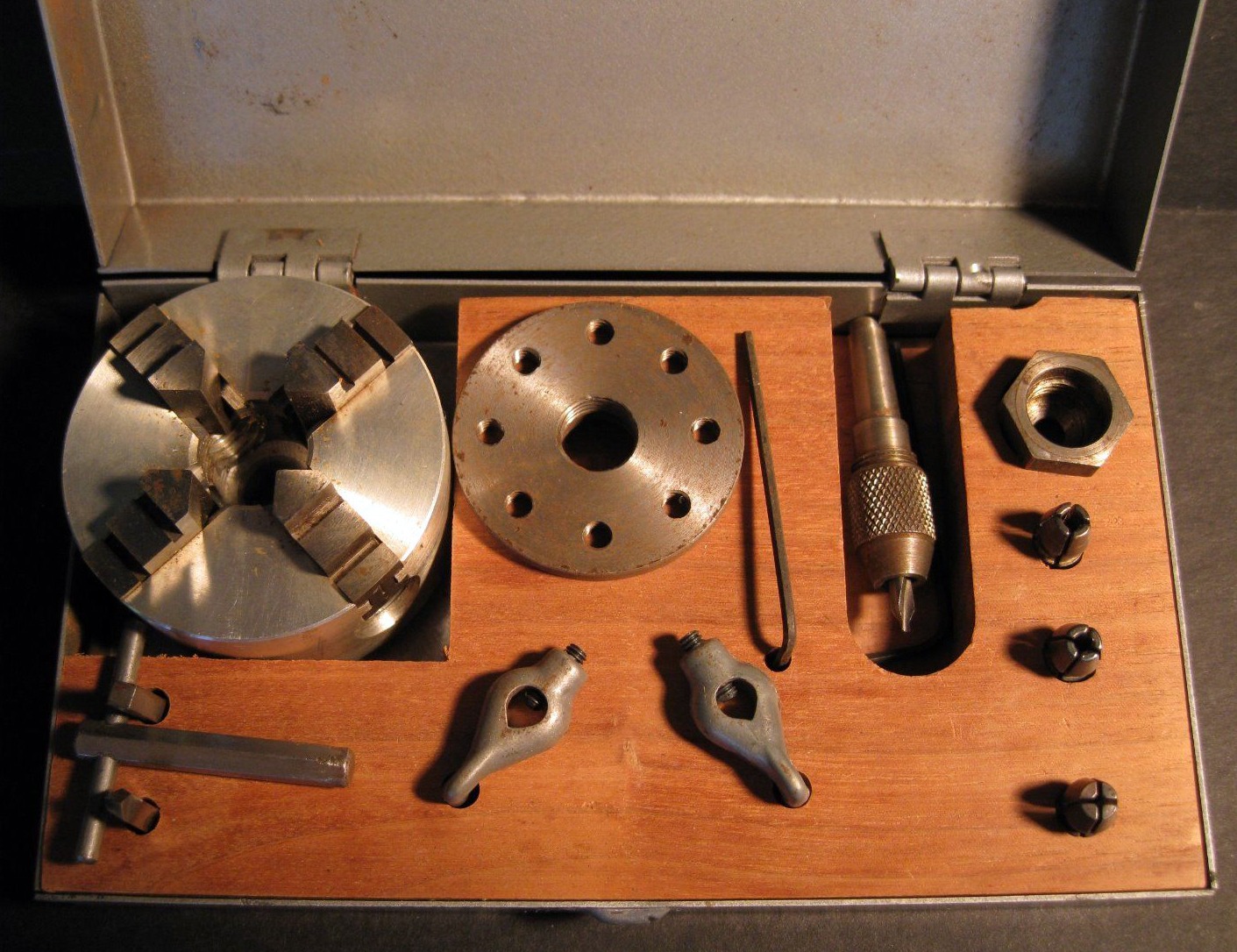

Probably so that it could concentrate its efforts more lucratively elsewhere as the post-WW2 economy in Californian machine shops started to revive, on August 4, 1949 Small Machines Incorporated was sold/spun off as going business to MasterSon Engineering Co. of 1416 Westwood Boulevard, Los Angeles. In 1953/54 (just three years before their demise) they introduced a line of three new lathes that used the model description "Master". The cheapest in the range was the Master "Model S" - for "Standard" - with simple bronze spindle bearings; a higher-speed version was also offered, the Master "Model BS" - for "Ball Bearing Standard" - with a ball-race headstock whilst the top-of the range version was the Master "Model BWW" - for "Ball Bearing Webster-Whitcombe" (Webster Whitcombe being the standard for heavier types of watchmaker's lathe). The BWW had a large-bore spindle with the nose formed to accept standard 8 mm WW type collets; as there was no thread to carry chucks or faceplates these were offered mounted, in the usual way, on collets, the faceplate being equipped with eight drilled and tapped holes instead of slots. Although the models "S" and "BS" were fitted with a set of fixed-ratio fibre changewheels (though the last in the train was brass) to provide a power feed to the carriage the "BWW" was also offered with changewheels for screwcutting - though this is a very rare machine indeed. Also listed amongst the accessories (it shared much the same range as the DuoLathe) was a thread-dial indicator, a micrometer-dial equipped tailstock to take WW collets, a push-type WW collet tailstock with stop collar, a tip-up tool rest, 3-jaw self-centering chuck, a 4-jaw chuck (both chucks had hardened jaws), a tailstock drill chuck and centre drill, drill V-pad, a drill chuck adapter for the headstock, a small standard tap and die set by Morris with four taps and four dies (sizes 00-90, 0-80, 1-72, 2-56), one tap and die holder, four bushings and one set-screw wrench. Astonishingly, in 2003 the Morris Company was still in business and selling the same set. Other items included a built-in countershaft unit to give a wider range of spindle speeds, individual WW collets from 0.004" to 0.315" (or sized fractionally from 1/64th to 5/16") and a box to hold 40 collets.

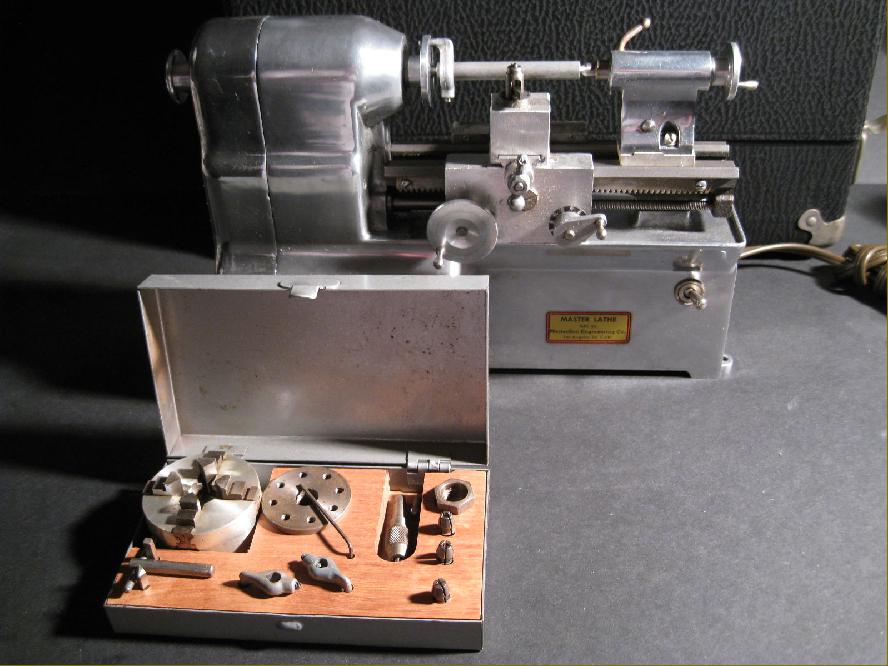

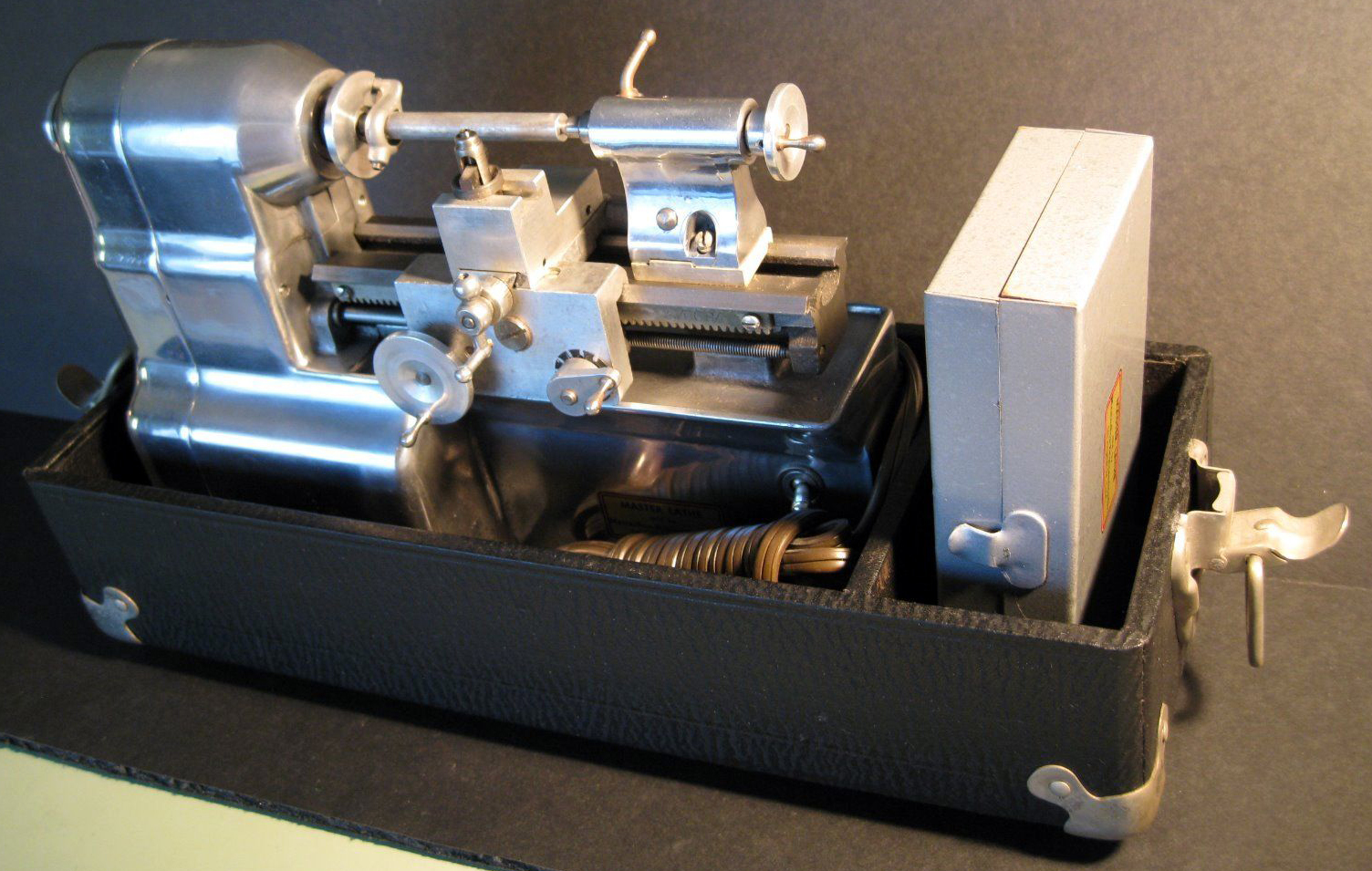

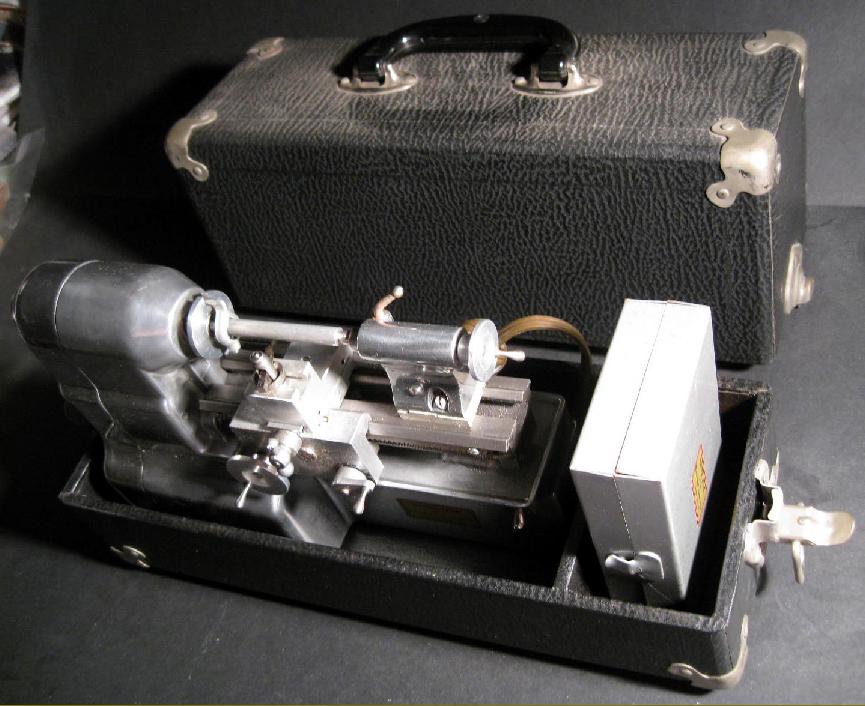

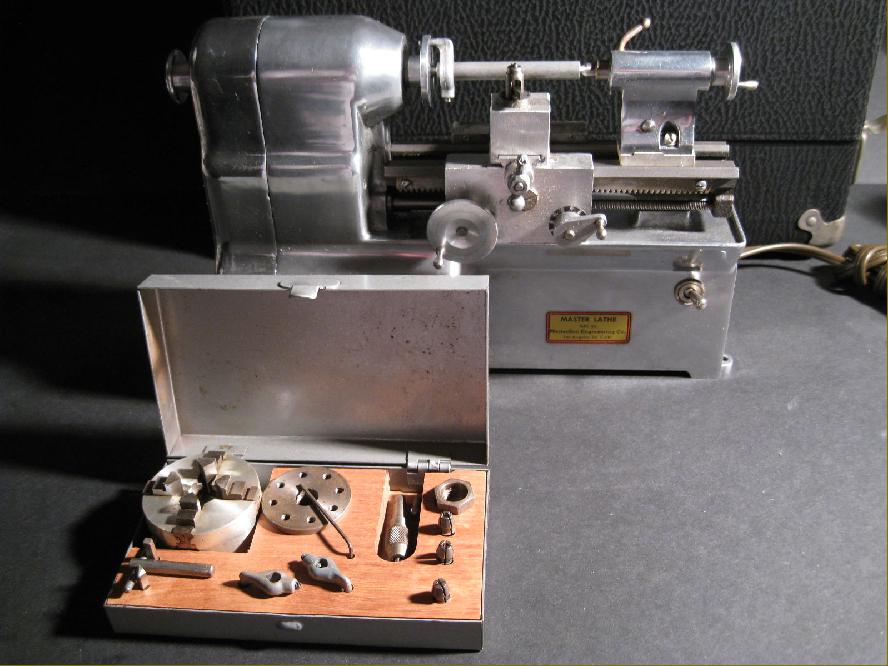

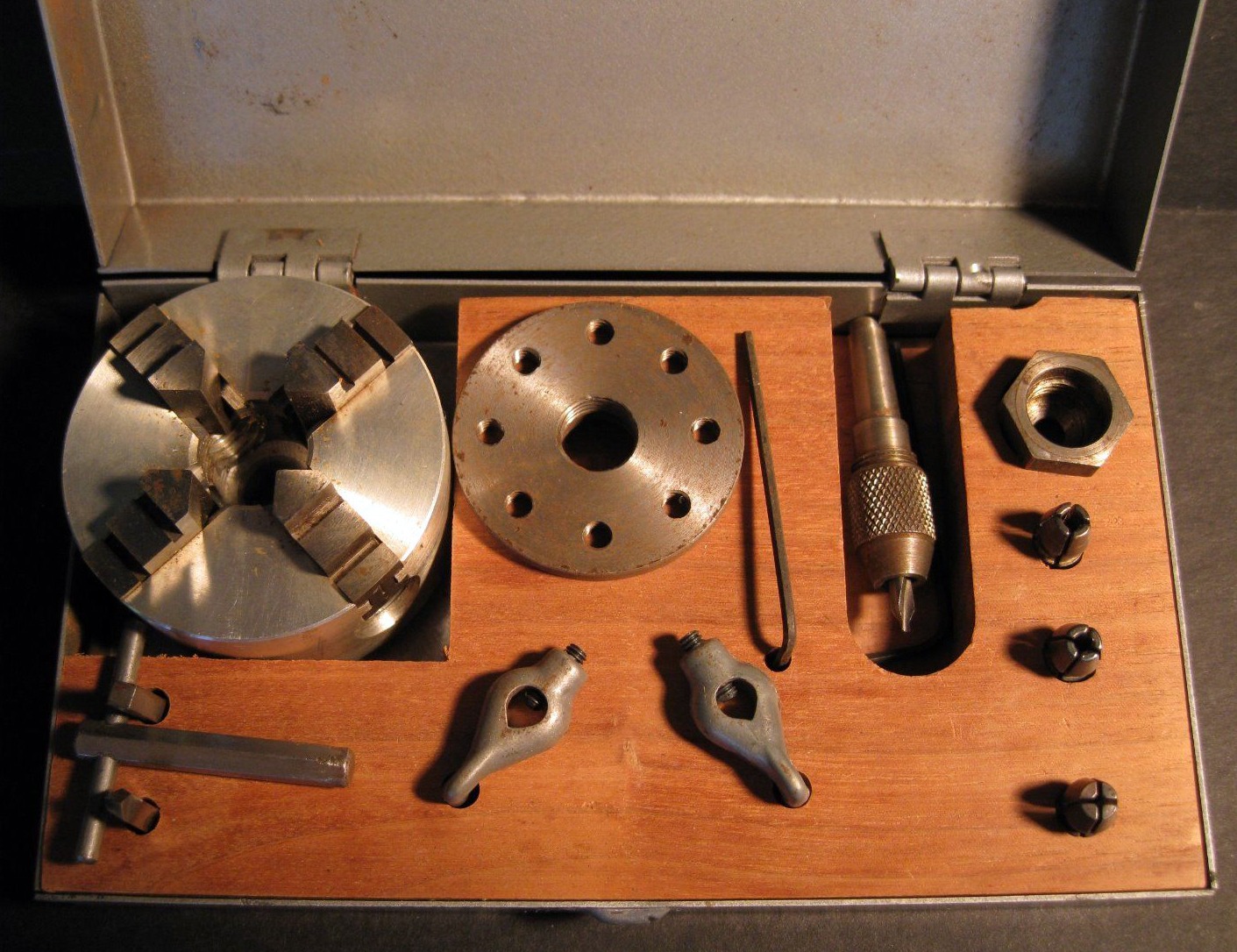

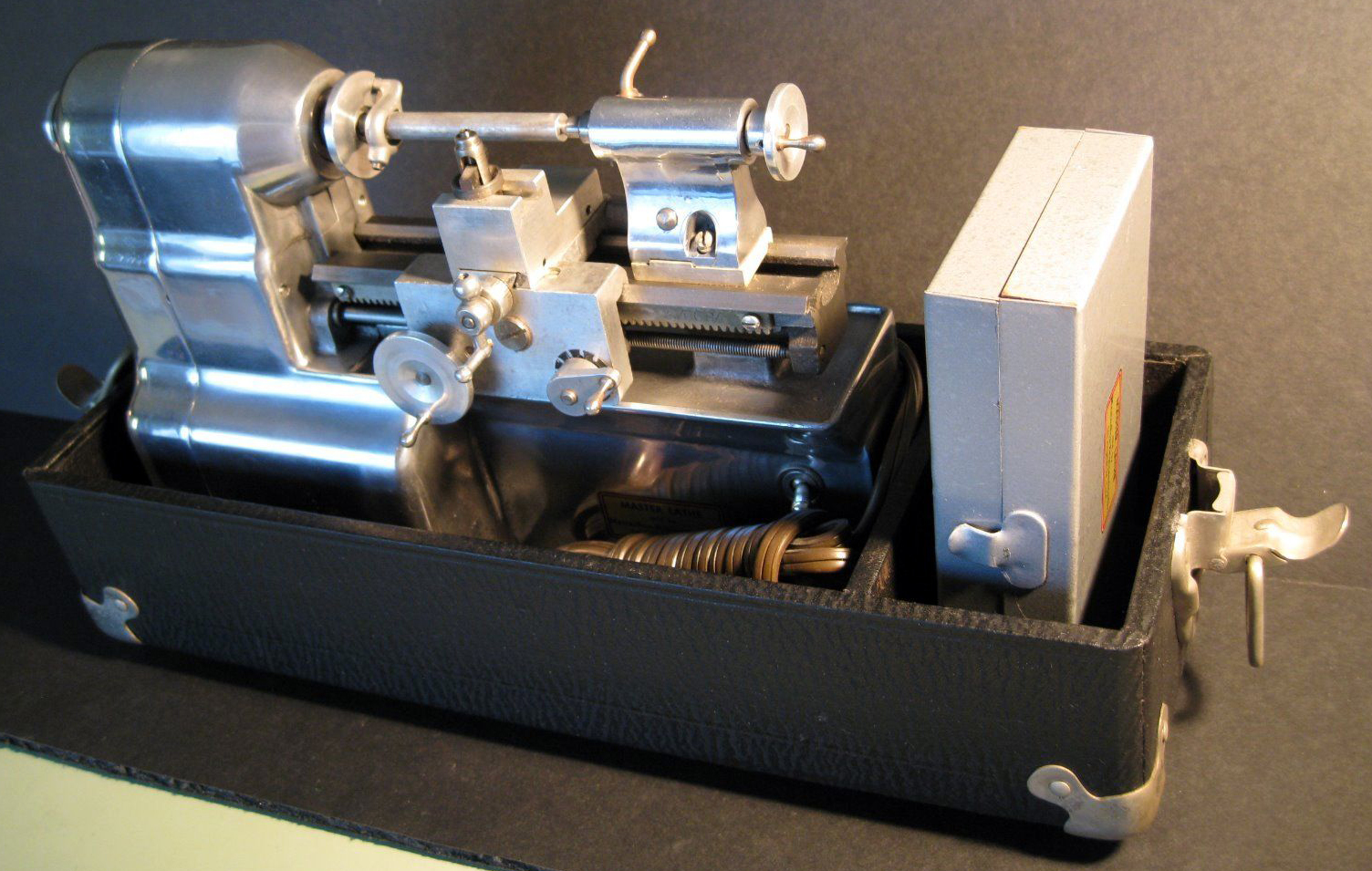

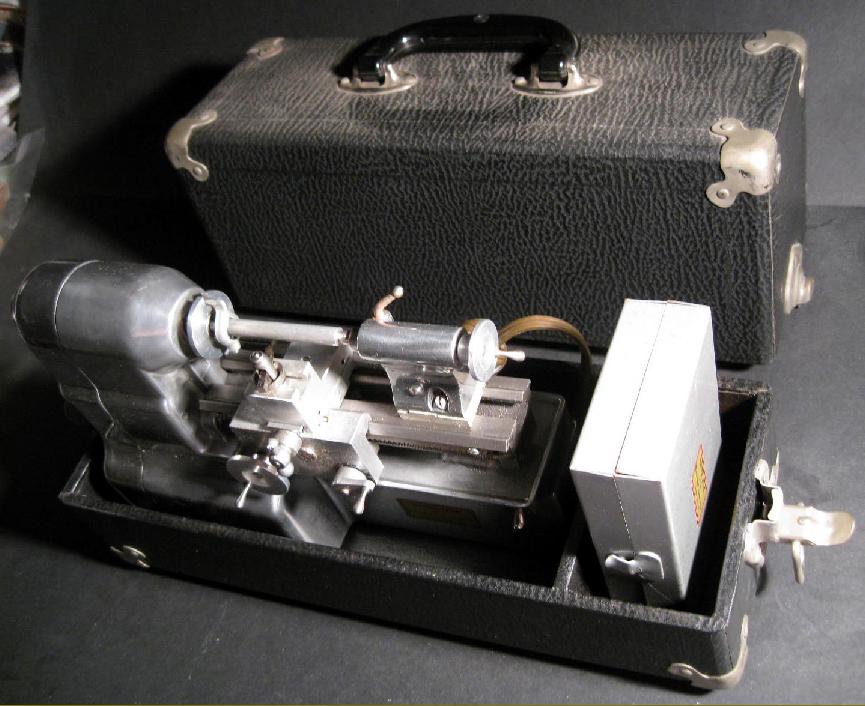

Unfortunately the Master range did not have the backgear arrangement of the DuoLathe and MonoLathe, nor as part of the regular equipment the variable-speed motor, but it did retain the graduated cross-feed screw micrometer collar and greatly-improved design of tailstock. Instead of the cross-slide gib strip being a non-adjustable "corrugated" strip of spring steel, the Master range was equipped with two pusher screws fitted through the right-hand face of the slide. By this time the accessory case had become metal (neatly made and carrying a small company badge), while also available (and shown at the bottom of the page) was a neat, leatherette covered carry-case with reinforced corners designed to house the lathe and its accessory kit in the base with a top cover held down by toggle clamps.

Fitted as standard with a 110V induction motor (with switch with a 6-foot cord and plug) an alterative was offered (at $35 extra) in the form of a "universal motor" with foot rheostat control able to be used on 105-120 volts AC or direct current that gave a range of infinitely variable speeds from 300 to 3000 r.p.m.

With so few years in production sales of the Master must have been limited - the last known dated information originating from the Company was marked by the printers '1957' , three years after the introduction of a small lathe was to dominate its market sector for many years - the Emco "Unimat"

If any reader has an example of a Master BWW in their ownership, the writer would be interested to hear from you..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

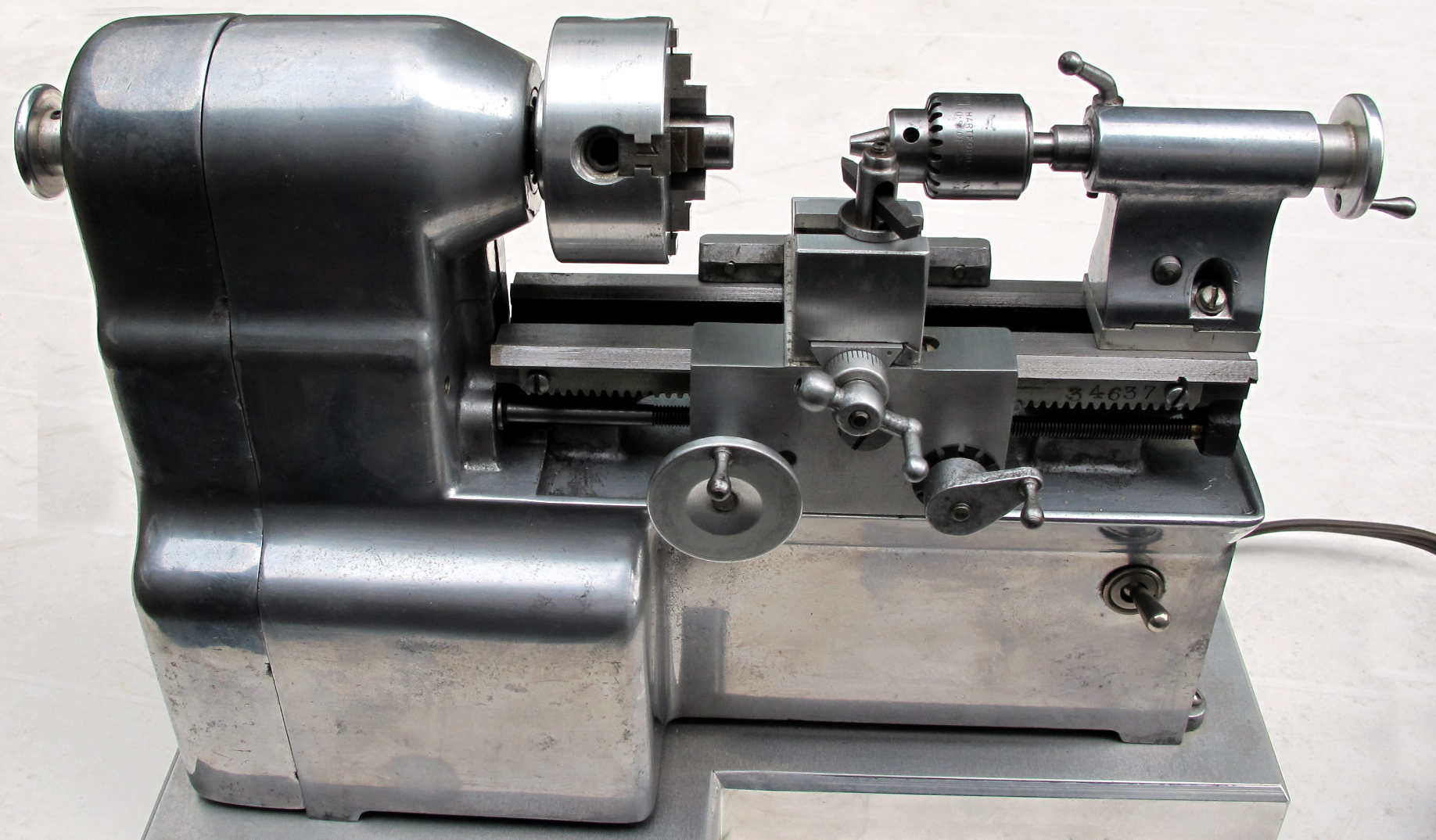

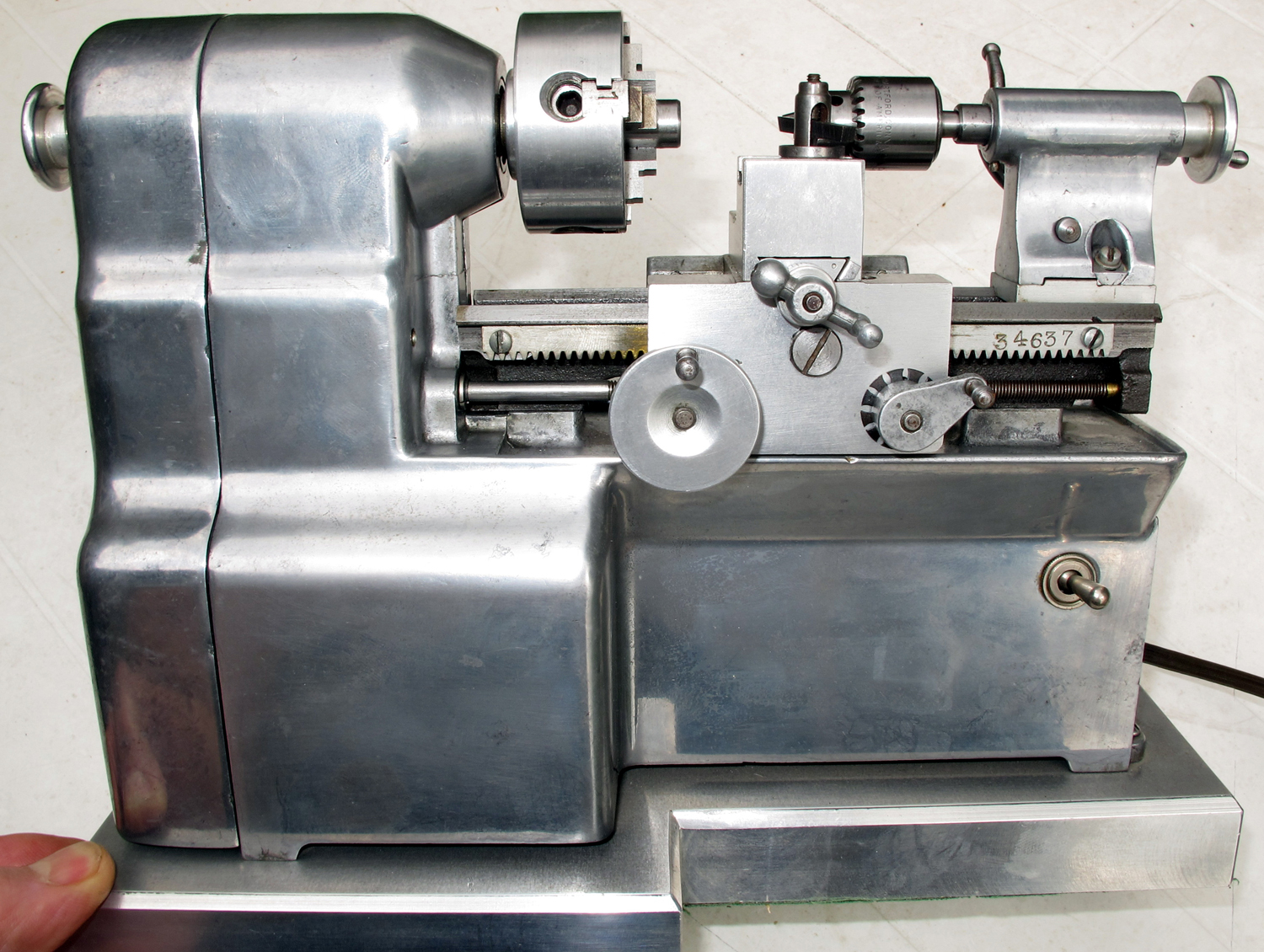

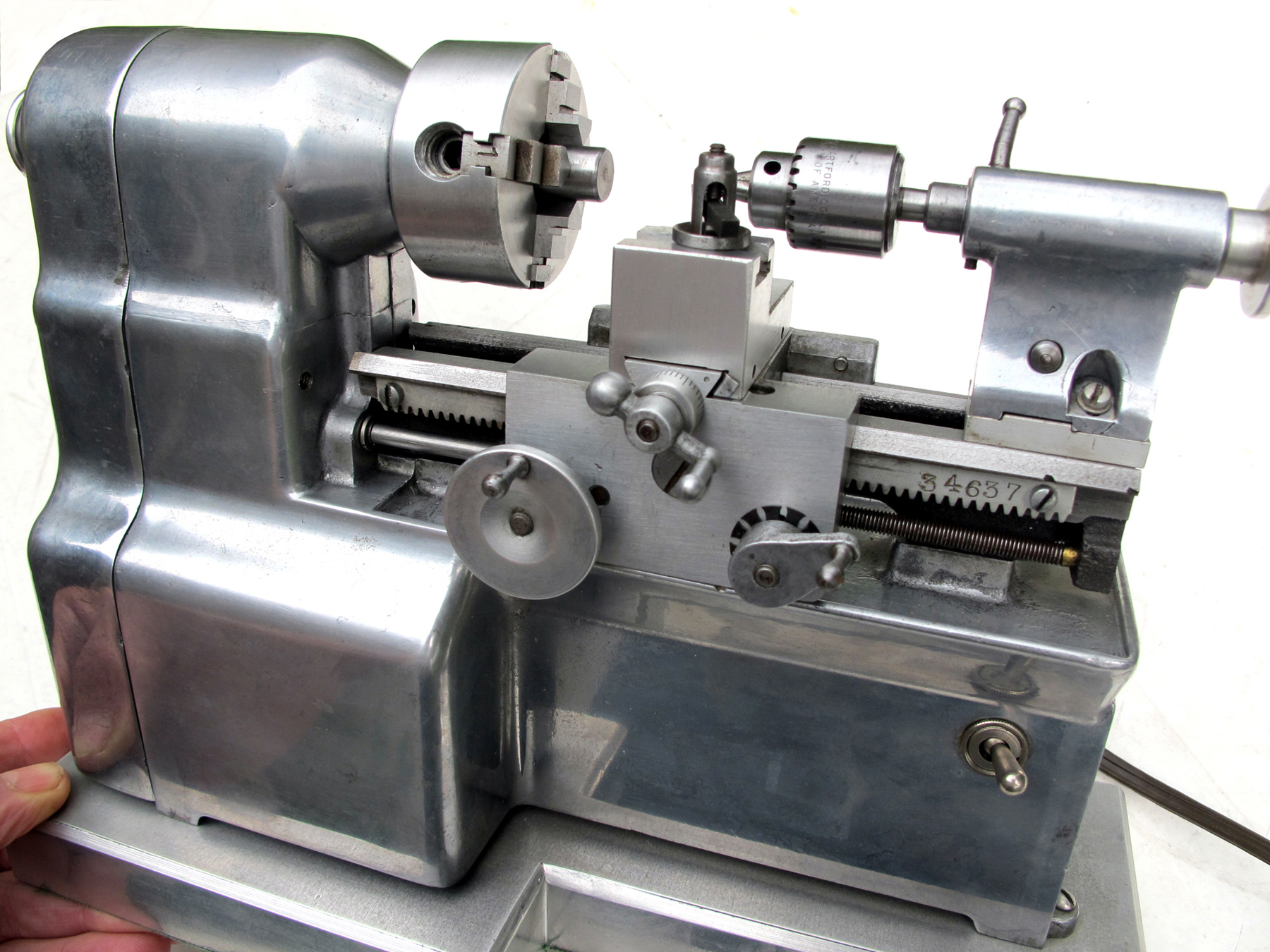

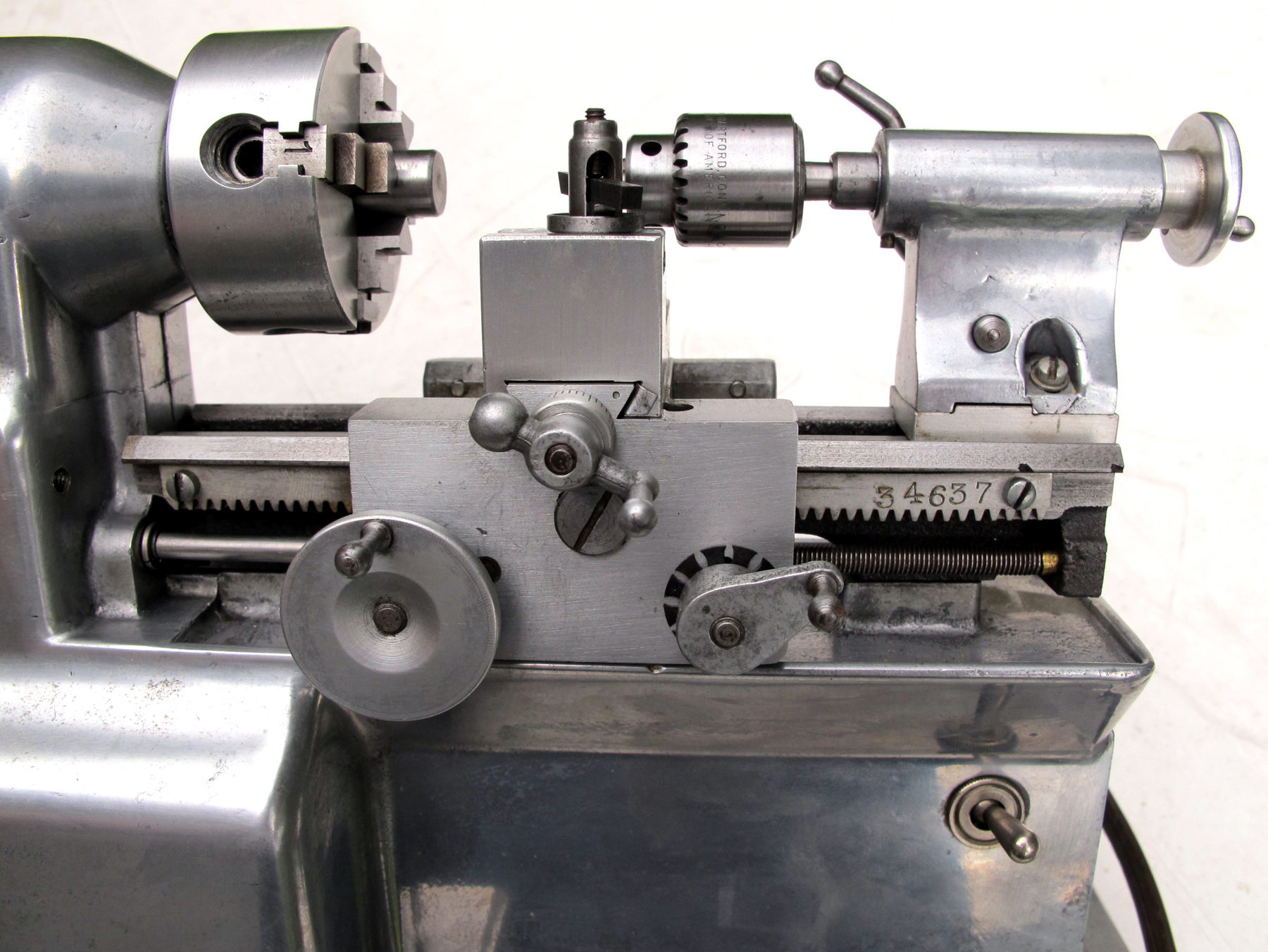

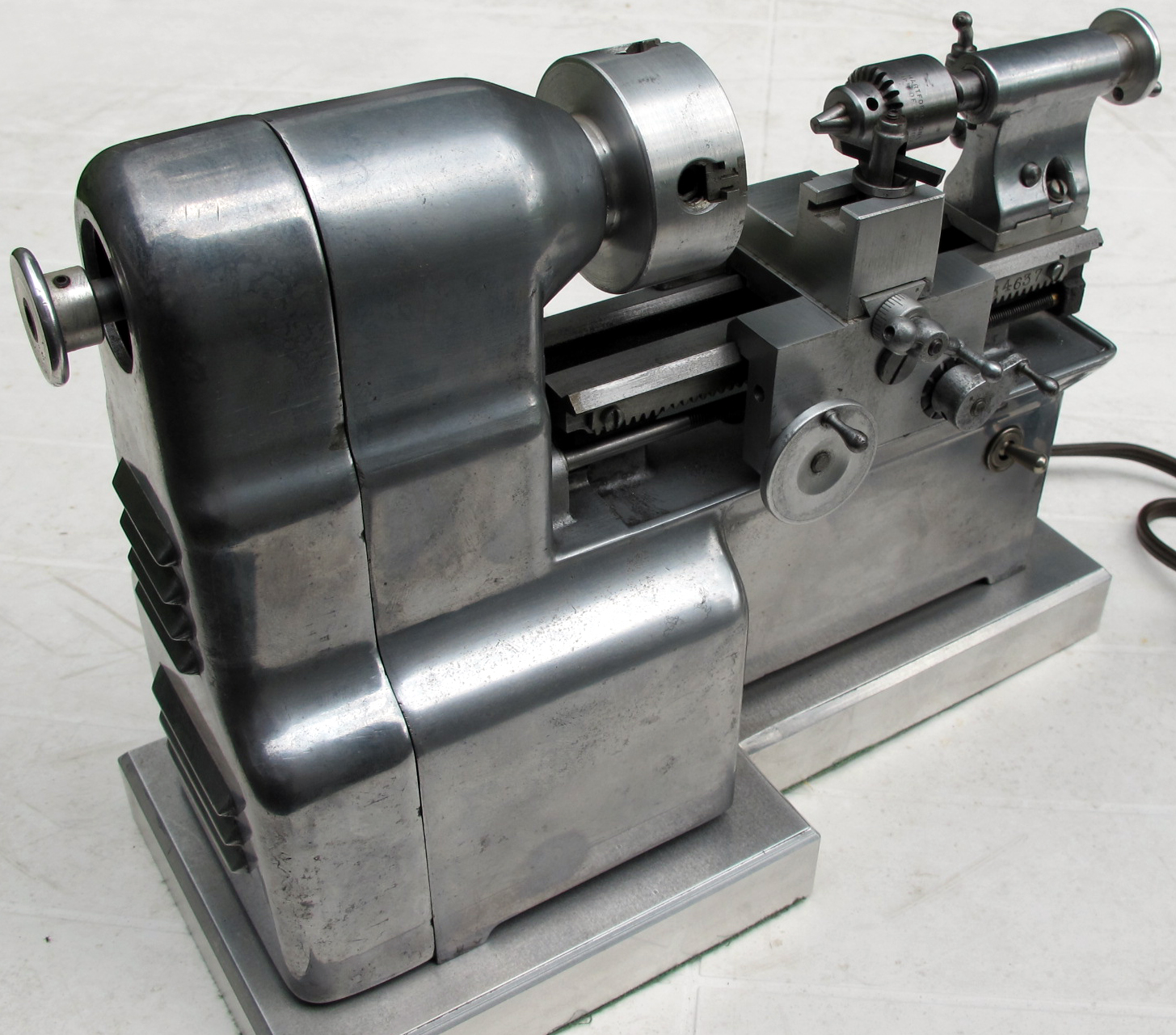

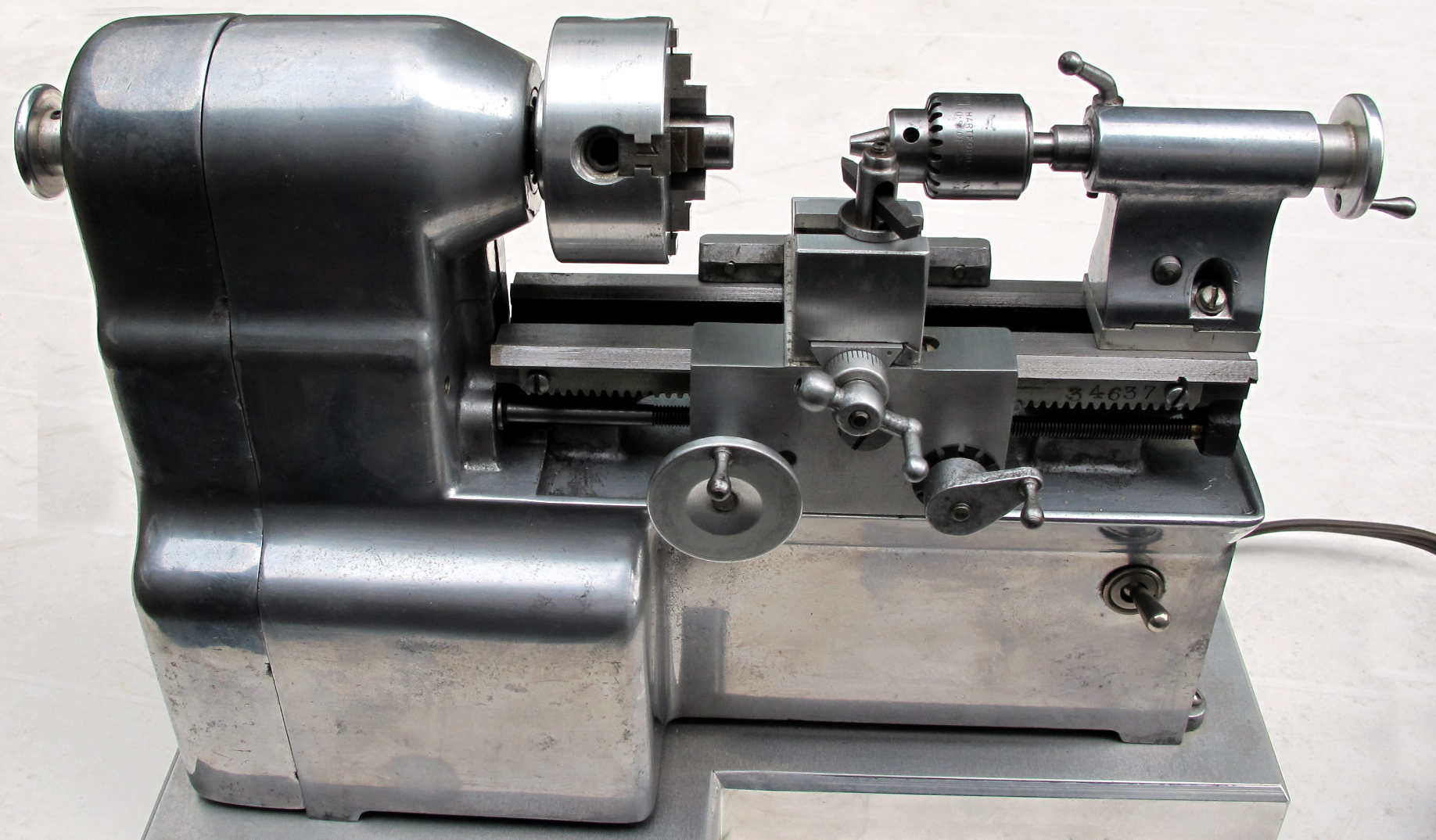

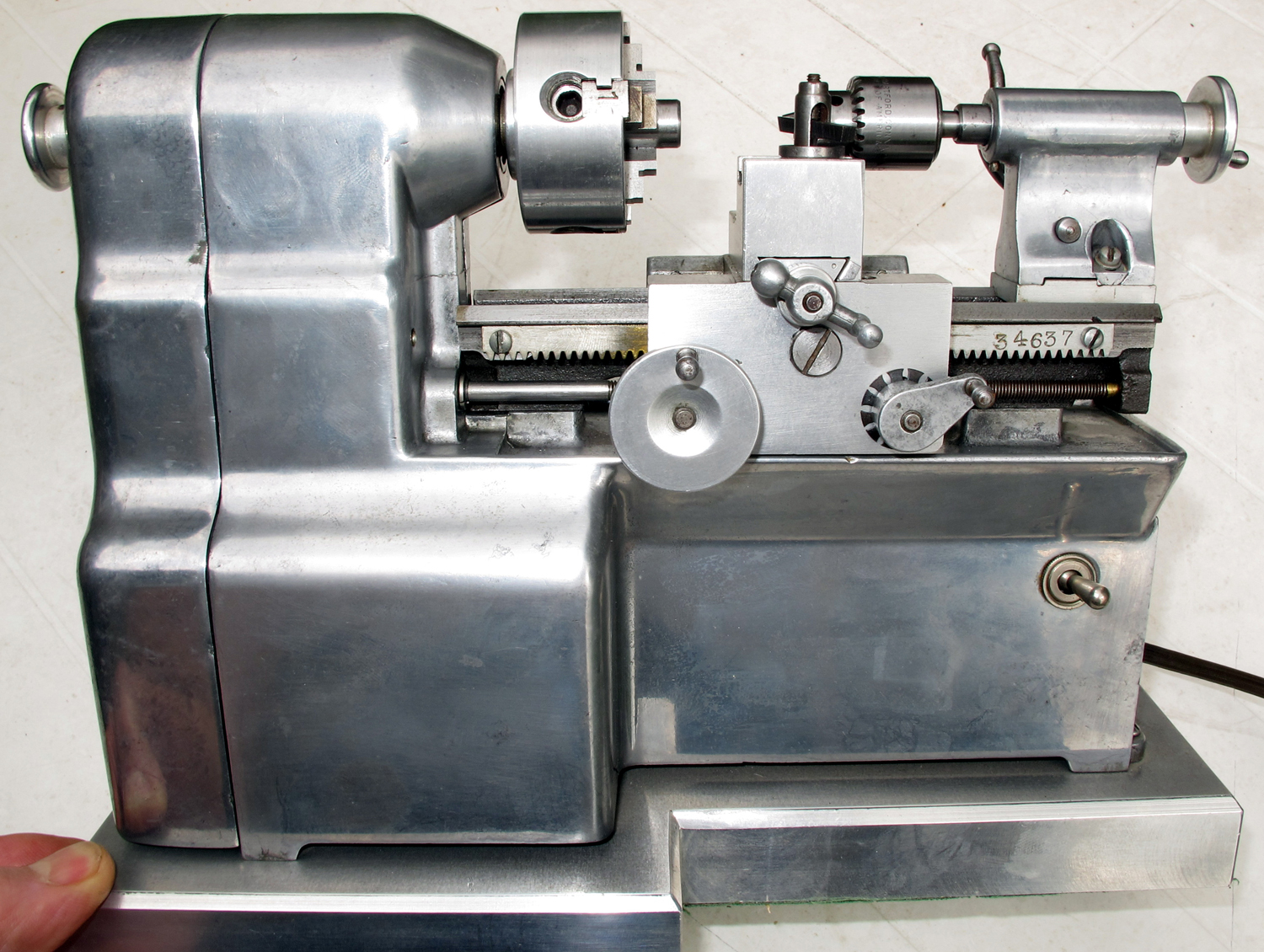

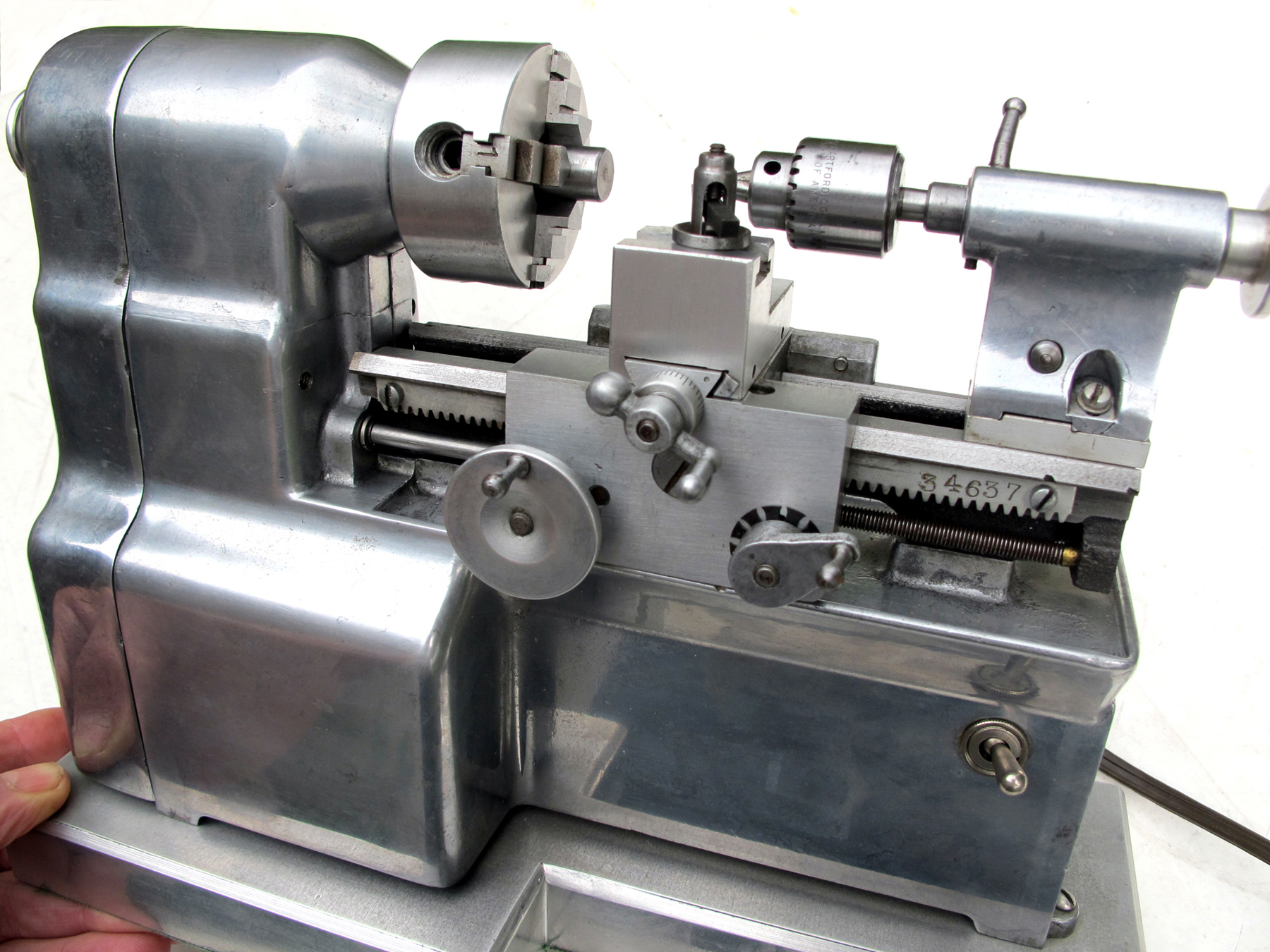

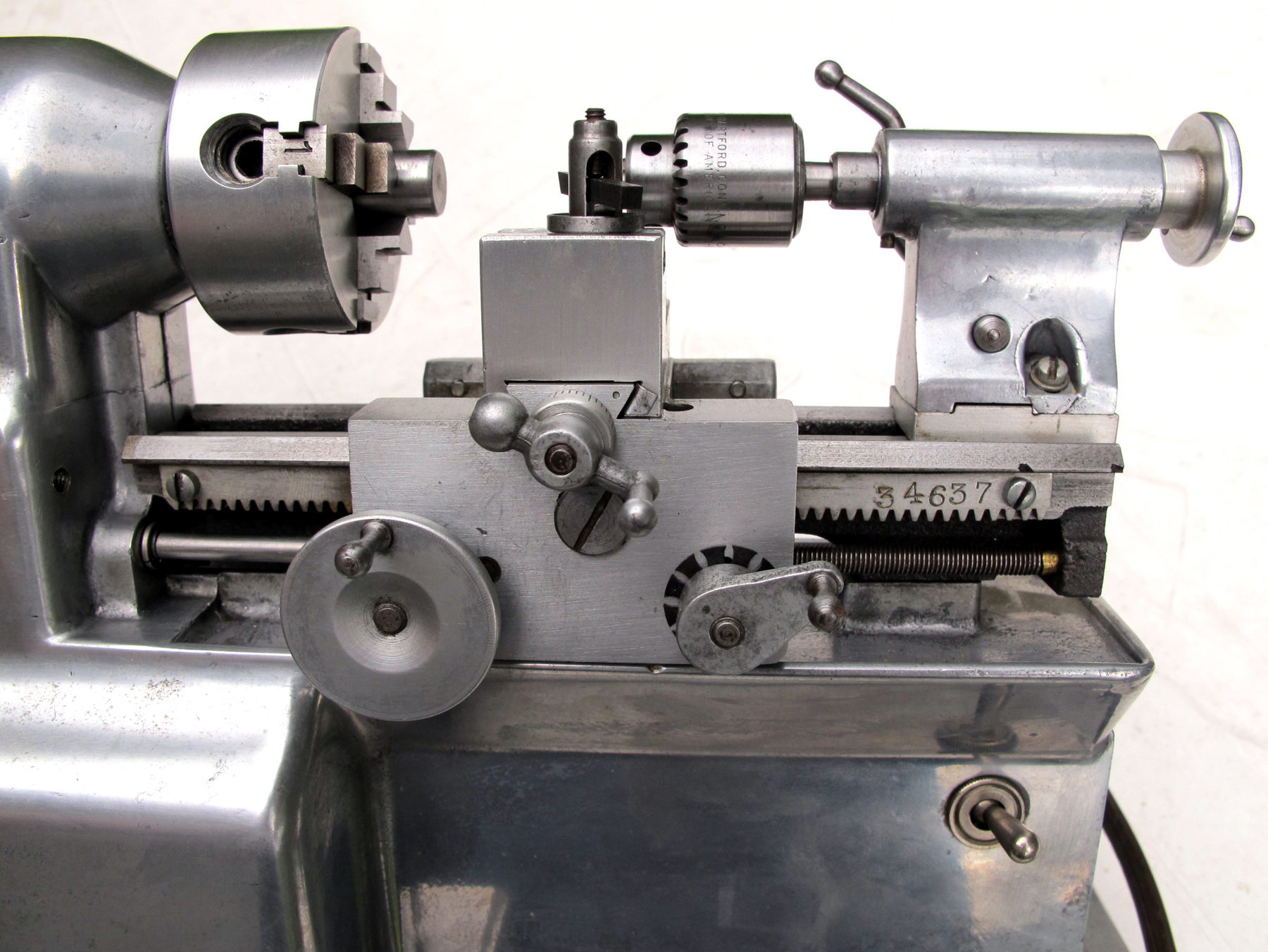

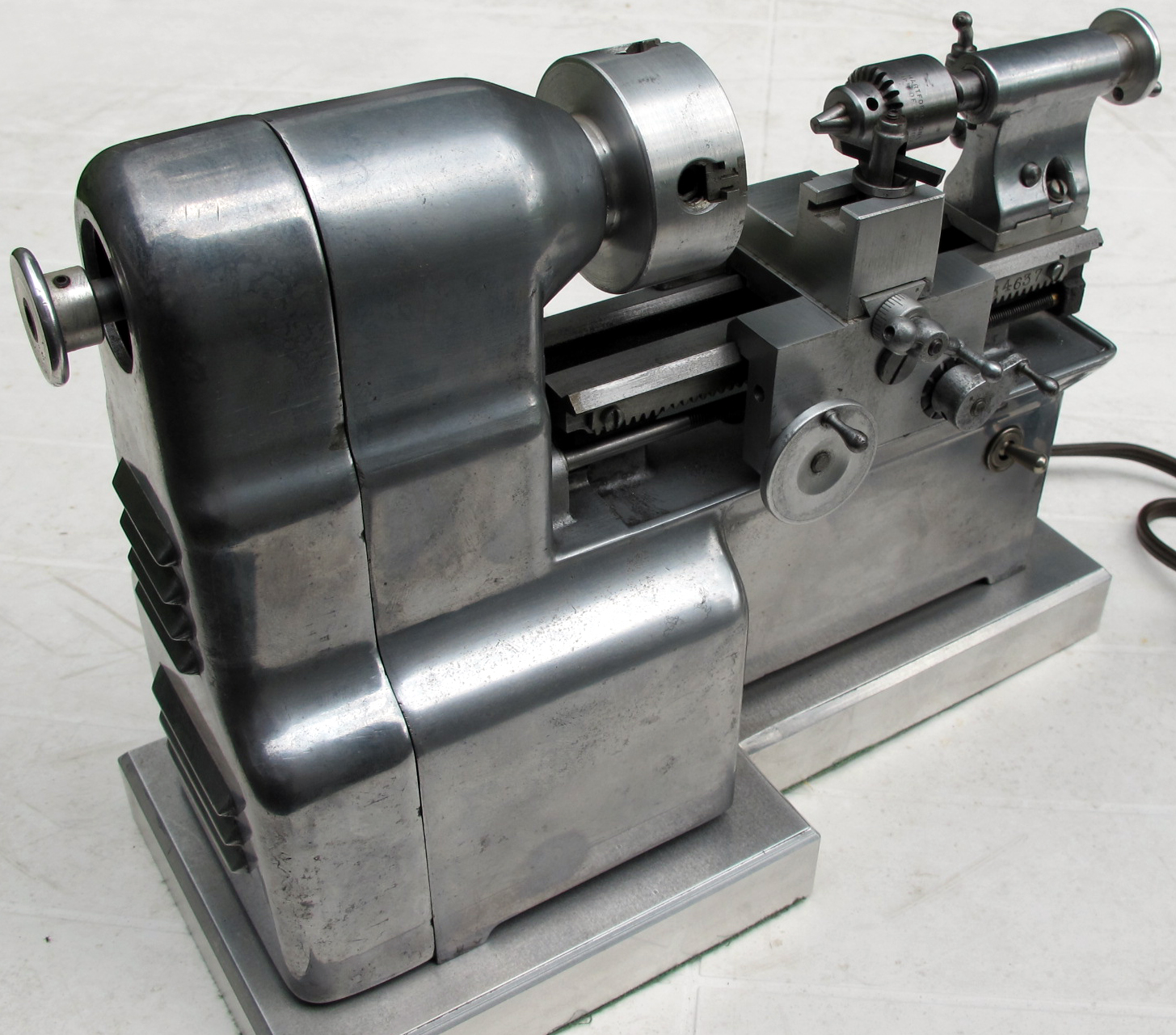

Master "Model BS" with screw-end ball-bearing spindle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

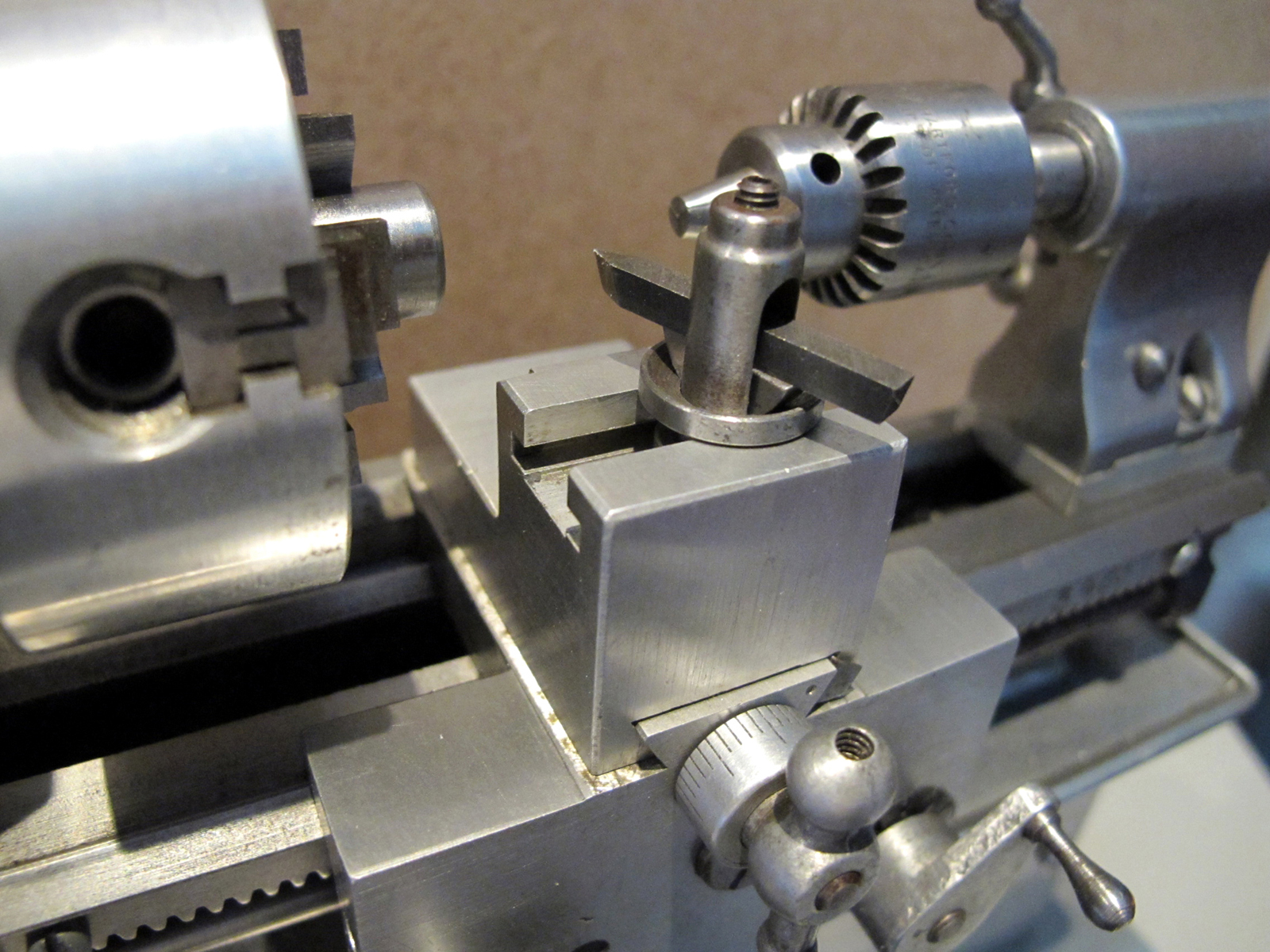

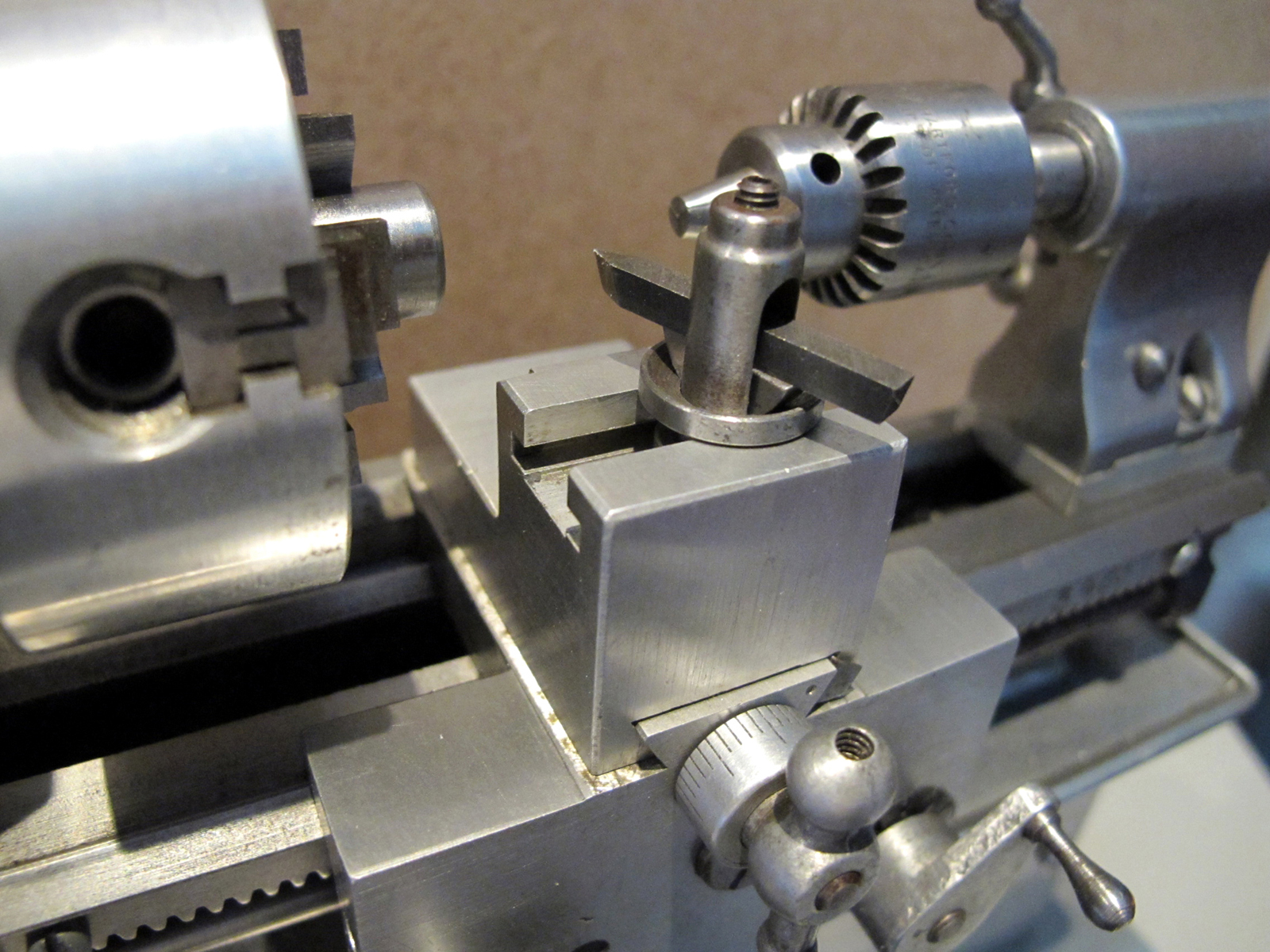

Even the toolholder was a miniature "American-type".

This lathe has the larger aluminium-bodied 4-jaw chuck

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

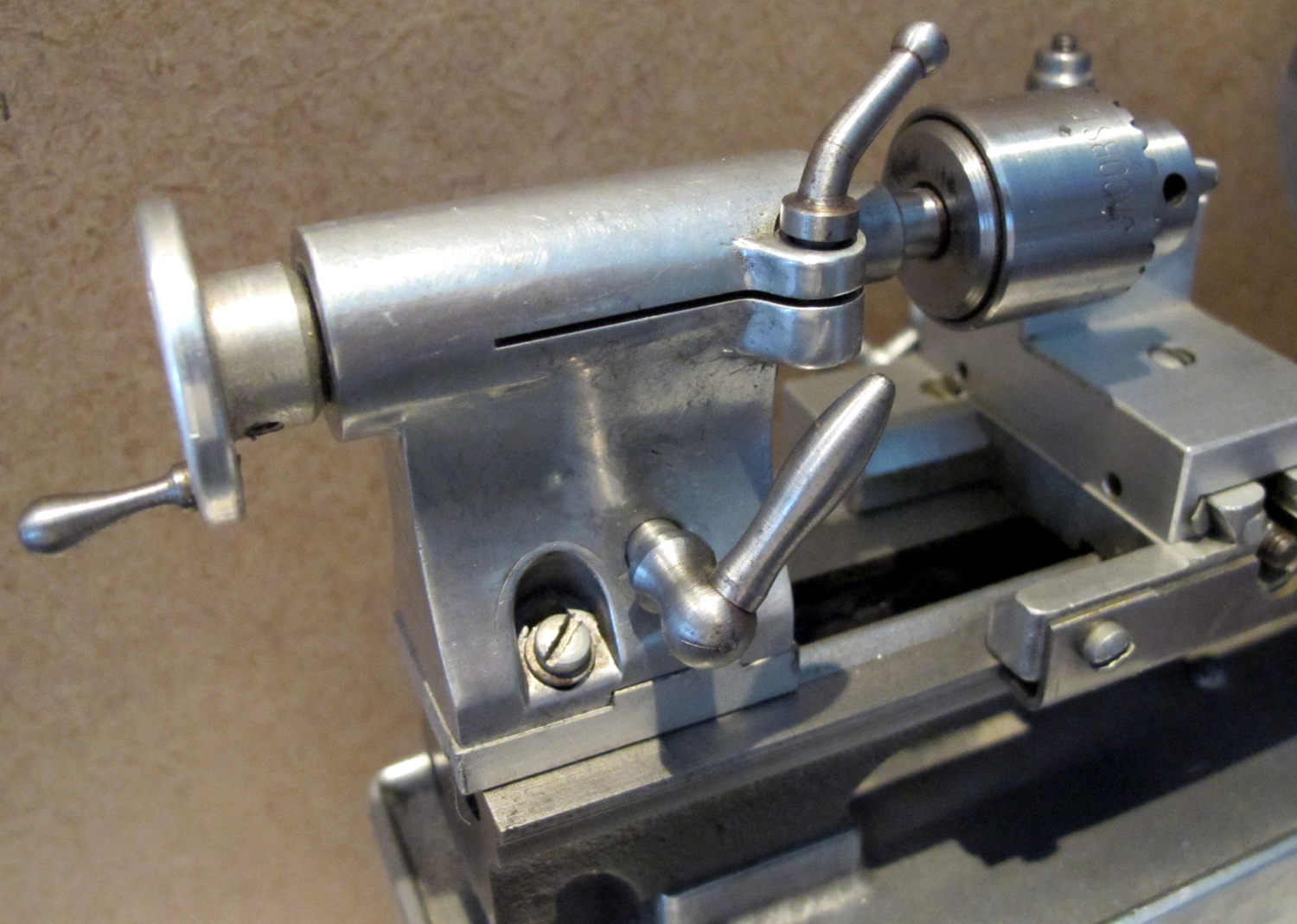

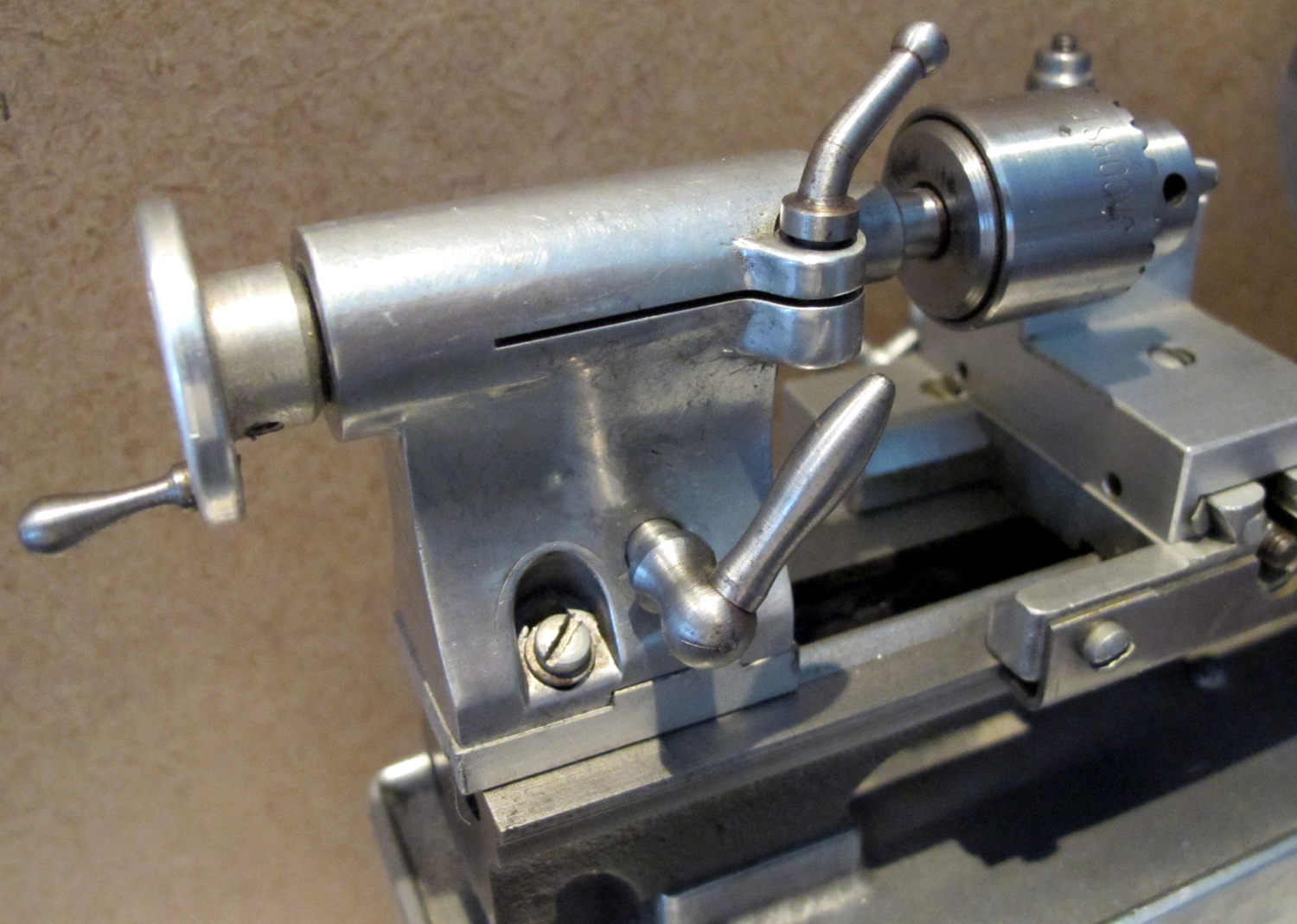

The improved tailstock on the master had a conventionally arranged handle and a longer slit to close down and lock the spindle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

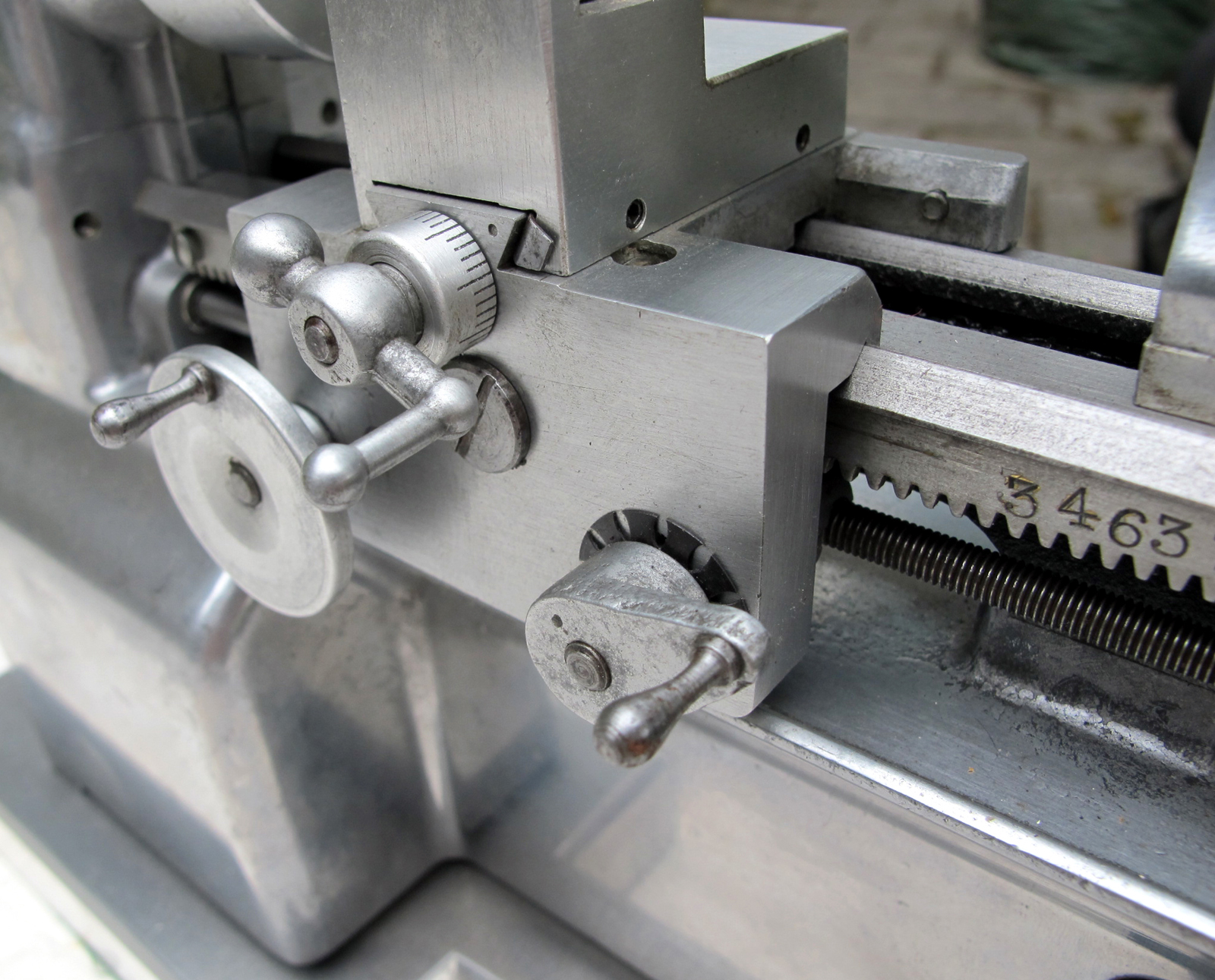

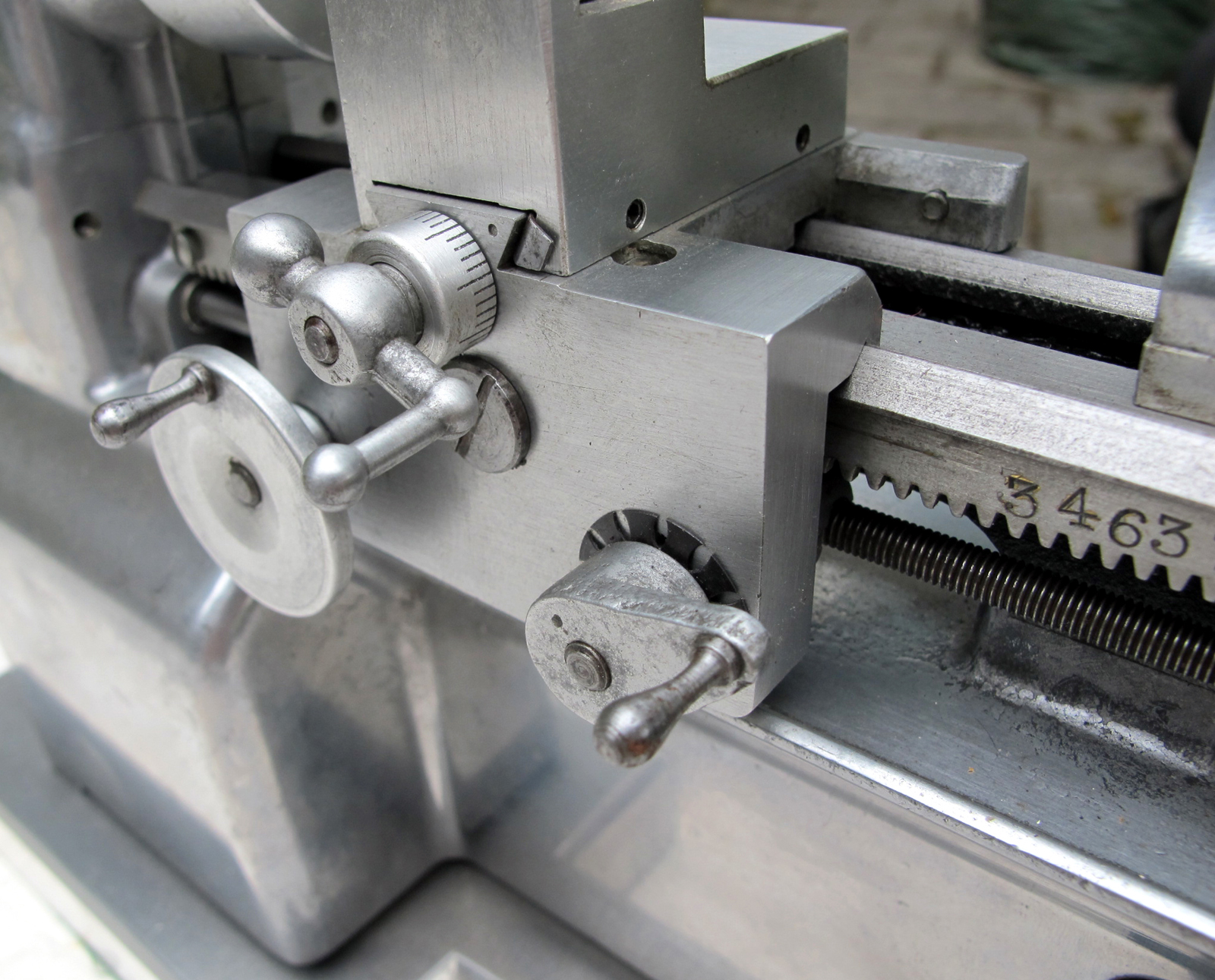

Long saddle wings gave unusually good support to the cutting tool for so small a lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

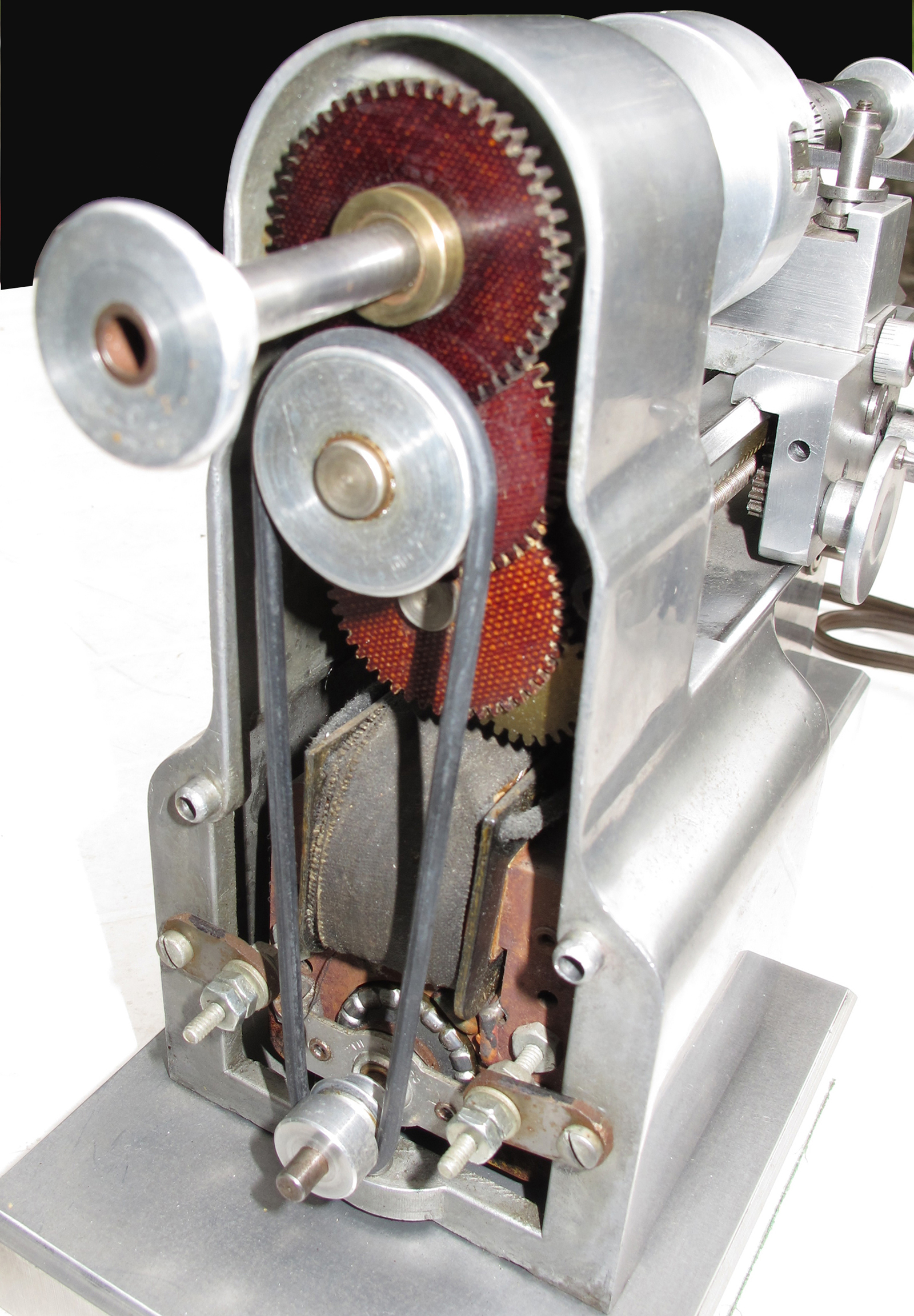

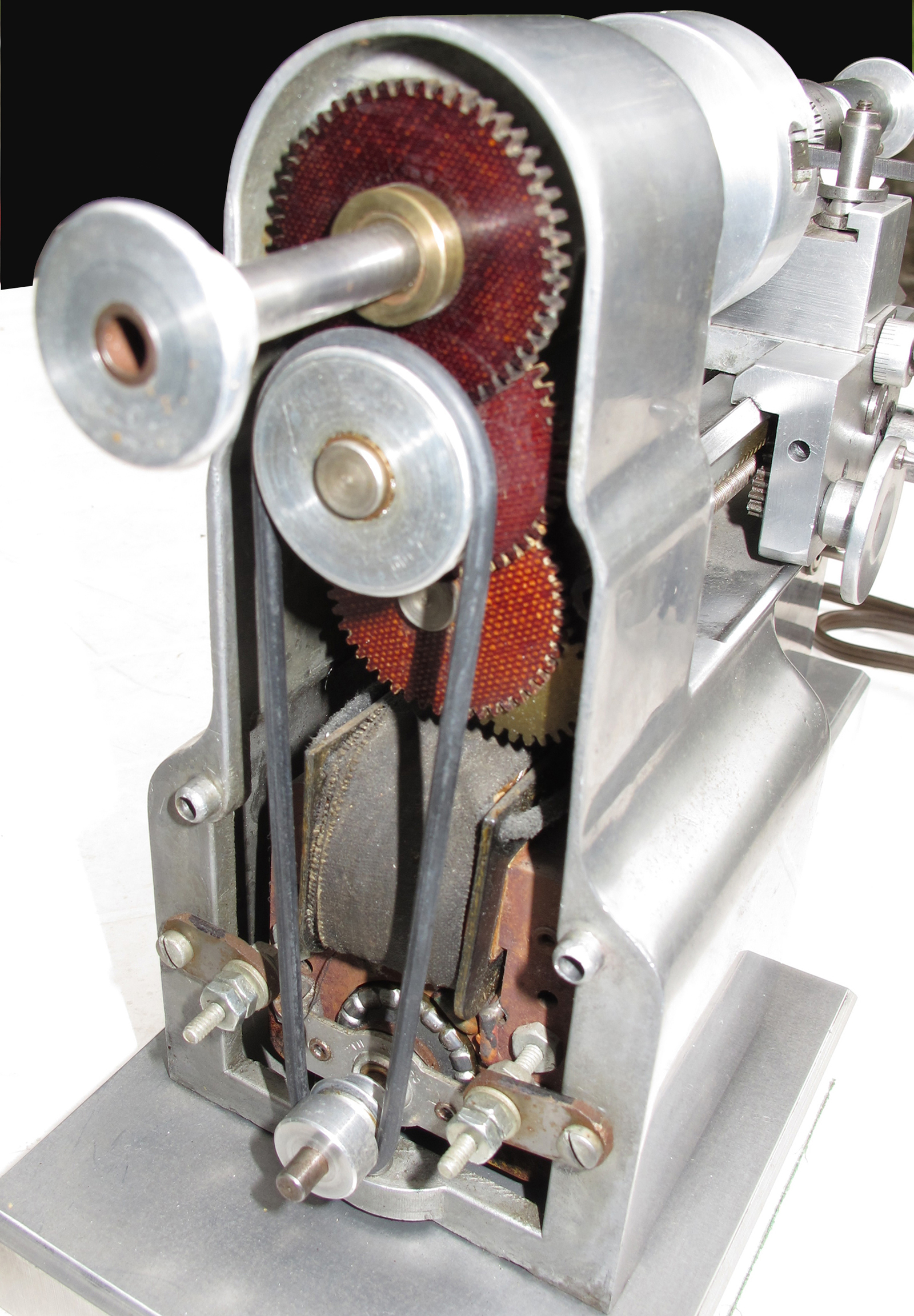

A train of fibre gears lead to a final-drive brass gear attached to the leadscrew, the arrangement proving a usefully slow, fixed-ratio, power feed to the carriage. The motor was supplied without the variable-speed control and fan cooling of the Duolathe.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Master "Model S" with plain-bearing headstock

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Master "Model BWW" with a large-diameter ball-bearing spindle to accept draw-in 8 mm WW-type collets. Note the graduated dial on the cross-feed screw.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A Manson "Master" next to its original metal accessory case.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A Master with its very rare, metal-cornered and leatherette-covered carry case

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Found amongst the paperwork with a Master lathe - a handwritten list from those who contributed to a retirement or other present?

|

|

|

|

|

|

|

|

|

|

|

|

Larry Vanice writes:

Some of those names are rather unusual, even in the USA. I tried looking them up on Ancestry.com to see if I could connect several of them geographically in the circa 1956 time frame. Bear in mind that many of the names can be found in other times and places, but they did fall in place nicely as a group, too well to be coincidence. Note especially the pairing of the Wrobel and Putko women as coworkers.

Maurice Samsel got a job as general superintendent of the Manz Corporation, a Chicago printing company in 1949. He was head of mechanical operations at another printer before that. I suspect that Manz was the employer of all the people on the list and Samsel was the big boss.

http://en.wikipedia.org/wiki/Manz_Corporation

In the Chicago area, of an age to be employed around 1956, I also found these names, not important enough to rate a mention of their occupation in a newspaper:

John Austra (Jack would have been what the coworkers called him.)

Petras Glemza (Might have called himself Peter away from family.)

Robert Bartholmey

William Boecher

Gilbert Boyk

George Hinkfus

Milos Jankovich

Faucett Scott

Armin von der Heydt

Robert Rafac

Frank Manago

Frank Boruch

Frank Brockway

Lambert Dalman

Stanley Lahart

Edward Michalic

A Chicago area newspaper social column in 1962 announced that these two women had been co-workers (place not stated) around 1955 and were visiting two others whose names were not on the list.. Wanda Wrobel

Olga Putko

The Manz Corp. went bankrupt in 1962, so a lot of jobs were lost.

|

|

|

|

|

|

|

|

|

|

|

|