|

U1, V1 & P1, U2, V2 & P2, U3, V3 & P3, U4, V4 & P4 Victoria UO, PO & H0 Victoria U2, V2 & P2 Victoria U3, V3 & P3 Victoria U4, V4 & P4 Elliott Omnimills Elliott 181 Instruction & Parts Manuals are available for these and most other Victoria millers |

|

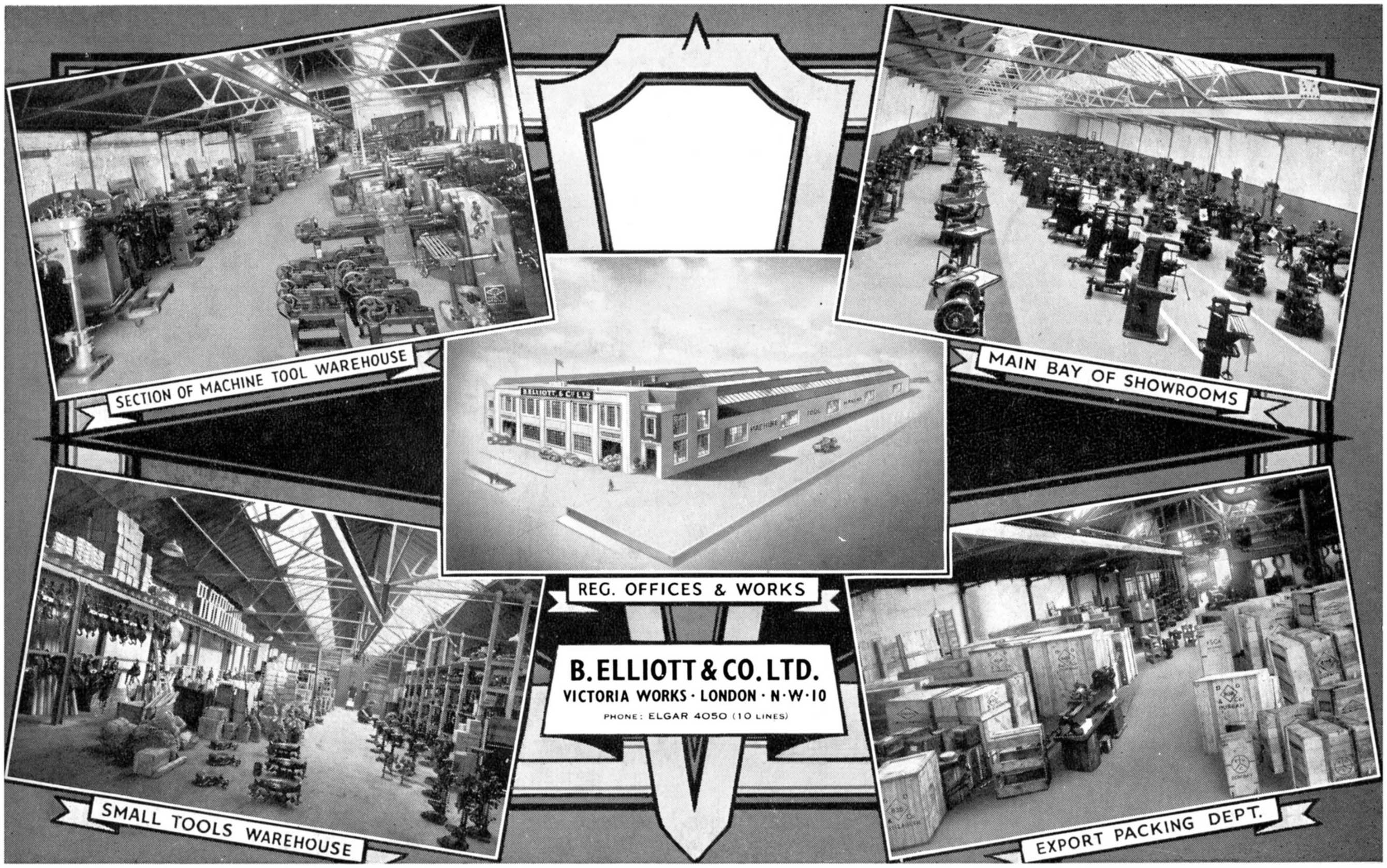

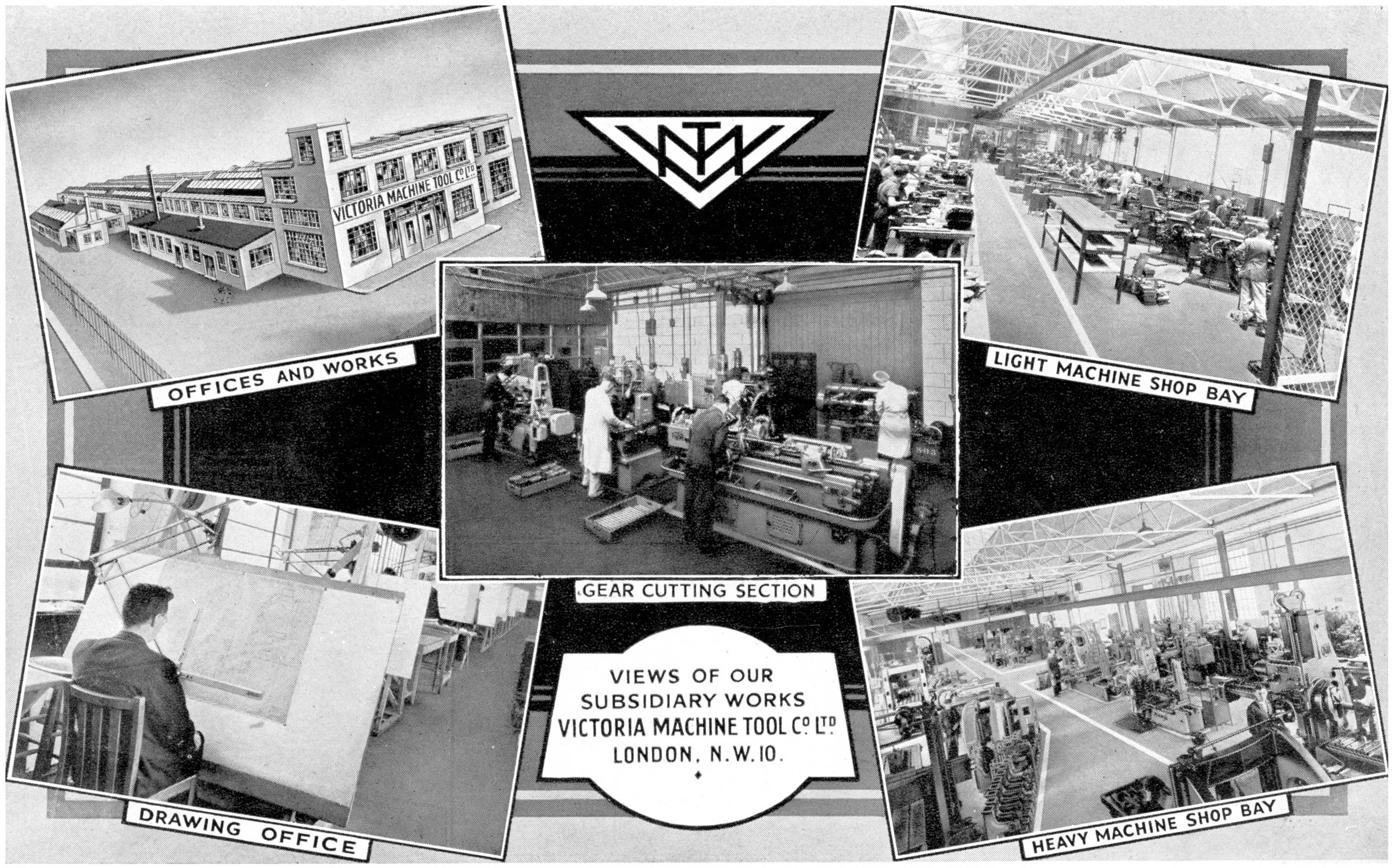

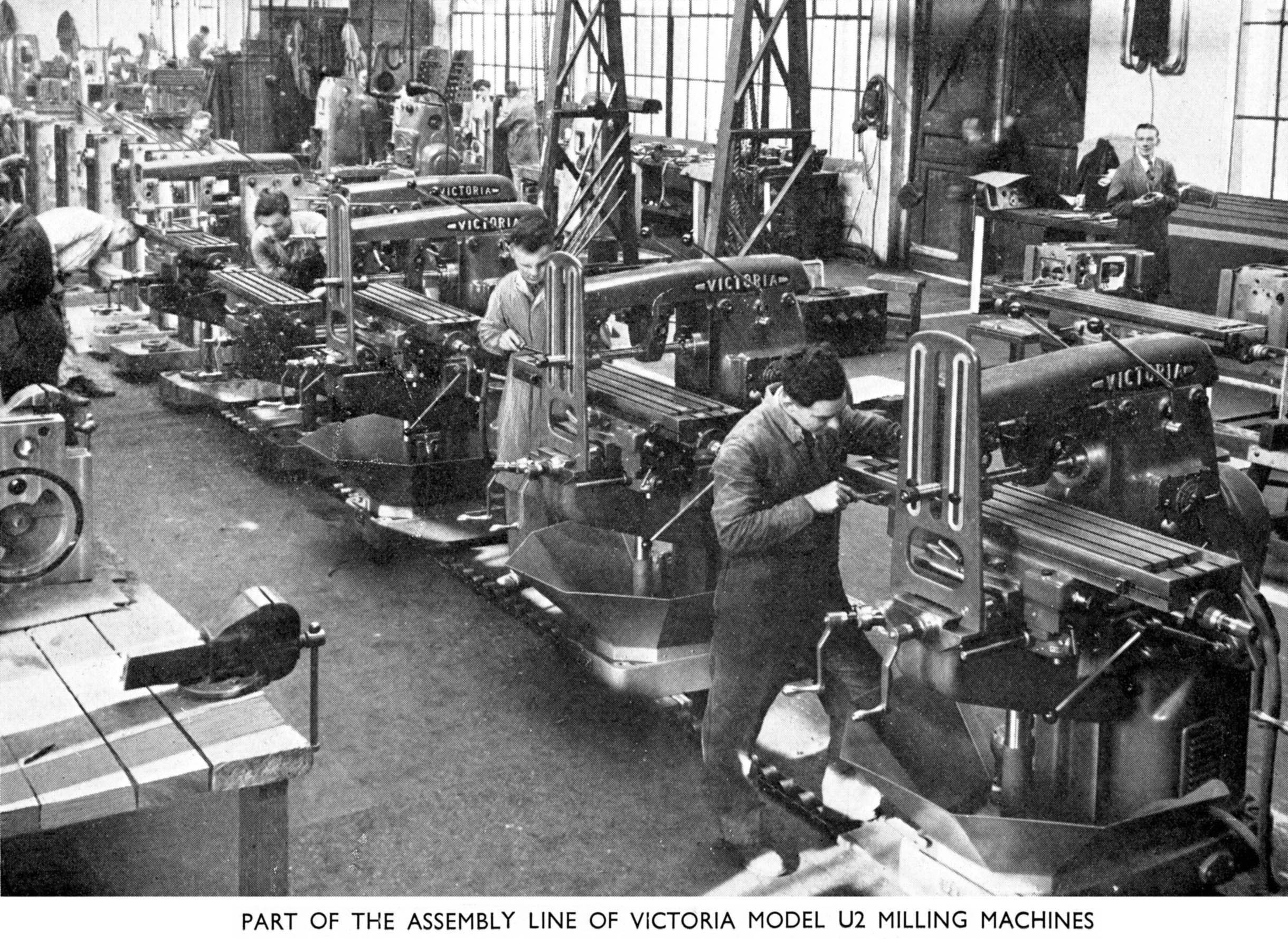

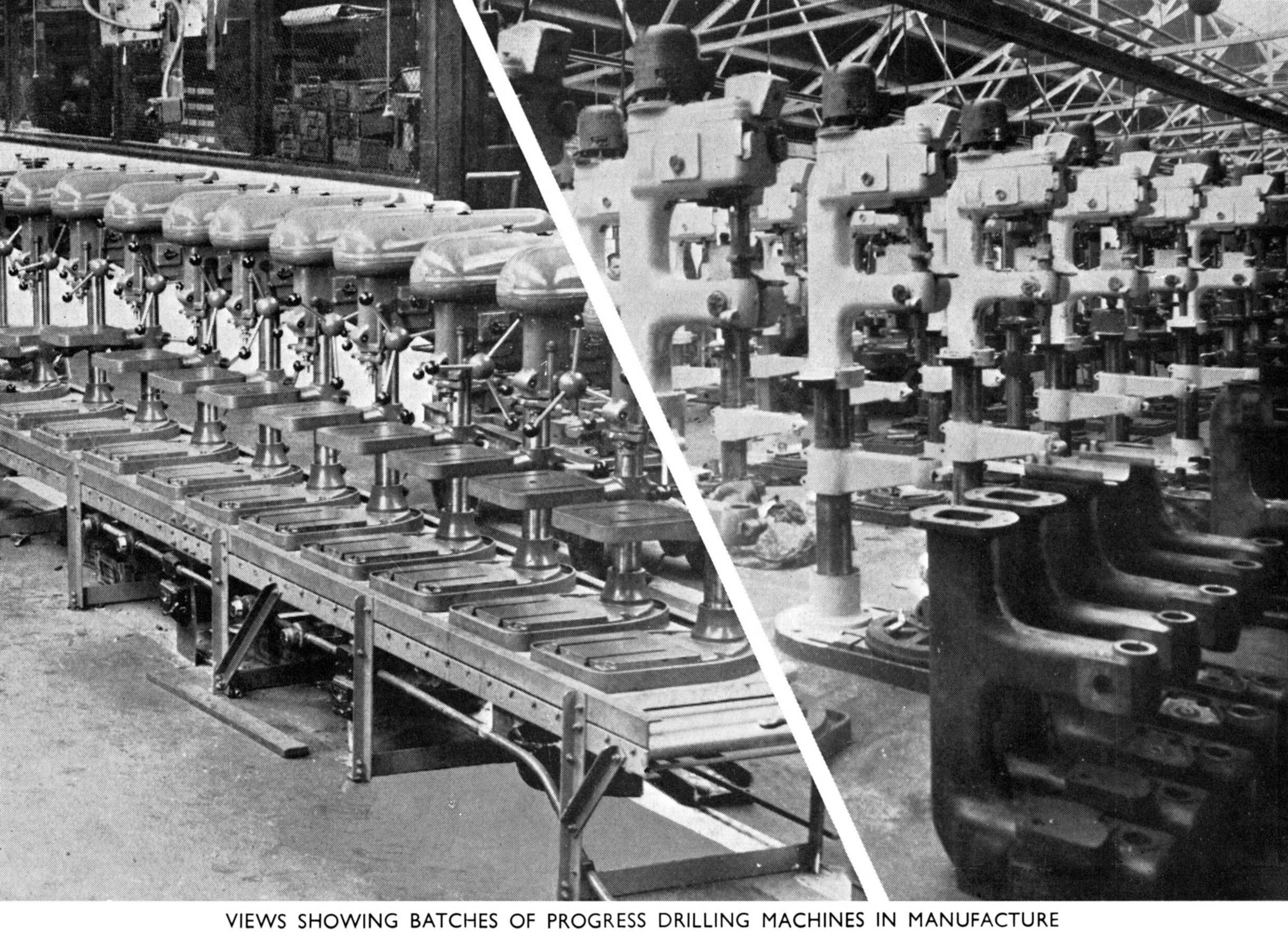

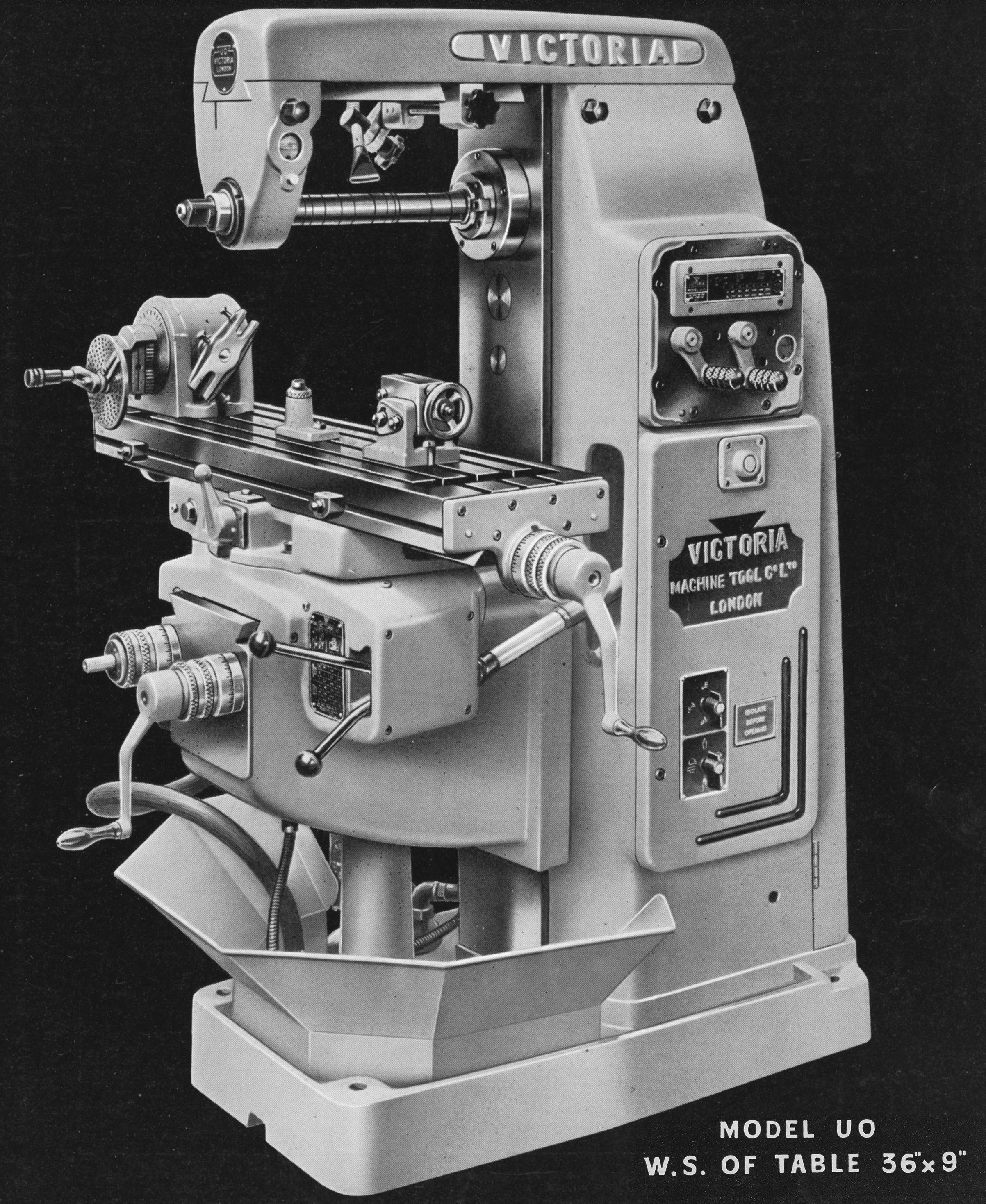

Victoria Millers were made by the Victoria Machine Tool Company Ltd., of Victoria Road, London N.W.10, England and marketed in later years by the Elliott group - the machines often carrying "Elliott" rather than "Victoria" nameplates. Heavily built, and very reliable, they were widely exported and are to be found all over the world - though, despite a range of more modern machines being developed, the factory closed in 1972. The millers were all of sturdy "workshop" rather than toolroom quality, and their use has now largely passed down into the hands of smaller professional workshops, repair organisations and enthusiastic amateurs lucky enough to have larger and better-equipped premises. |

|

|

||

|

The Victoria Elliott Model UO and PO milling machine. Easily recognised, it was the only model in the range with two levers emerging from a single slot on the right-hand side of the knee--and just two spindle-speed levers on the right-hand face of the main column. Often found with the maker's vertical head with "step-up" gearing to make the speeds more suitable for handle small-diameter cutters |

||

|

|

||

|

|

||

|

|

||

|

|

||

|

The table and knee were identical to those used on the firm's M1 horizontal machines. |

|

|

||

|

|

||

|

|

||

|

The Universal Diving head was available in two centre heights - 3.5" and 4.75" - and was supplied as standard with the Universal M1 Miller. Power was taken from a gear fixed to the end of the table feed screw. The heads were built to Schlesinger's limits and tested to 5 seconds of arc. |

||

|

these and most other Victoria millers Victoria U4, V4 & P4 Elliott Omnimills Elliott 181 U1, V1 & P1, U2, V2 & P2, U3, V3 & P3, U4, V4 & P4 |