|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E-Mail Tony@lathes.co.uk

Home Machine Tool Archive Machine Tools For Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues Belts

Modern Leinen and Boley & Leinen - Page 1

WW Watchmaker's Lathes WW82, WW83 and Reform

Modern Leinen Page 2 Modern Leinen Page 3 Leinen Home Page

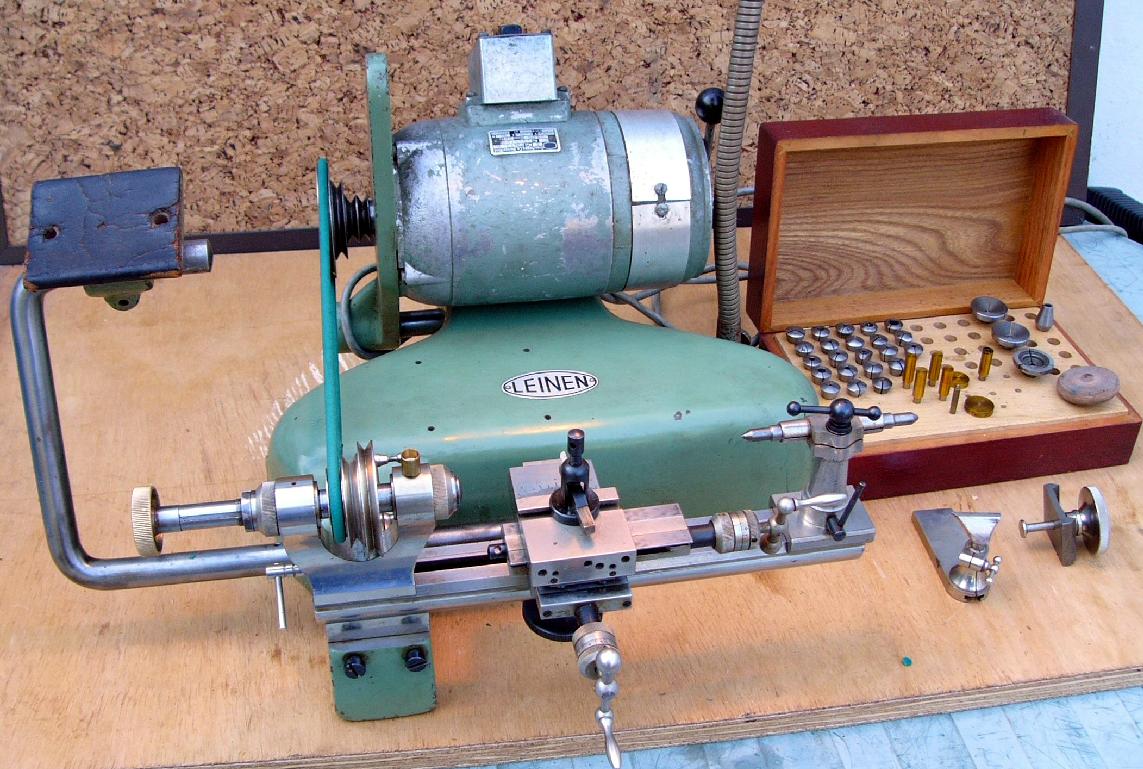

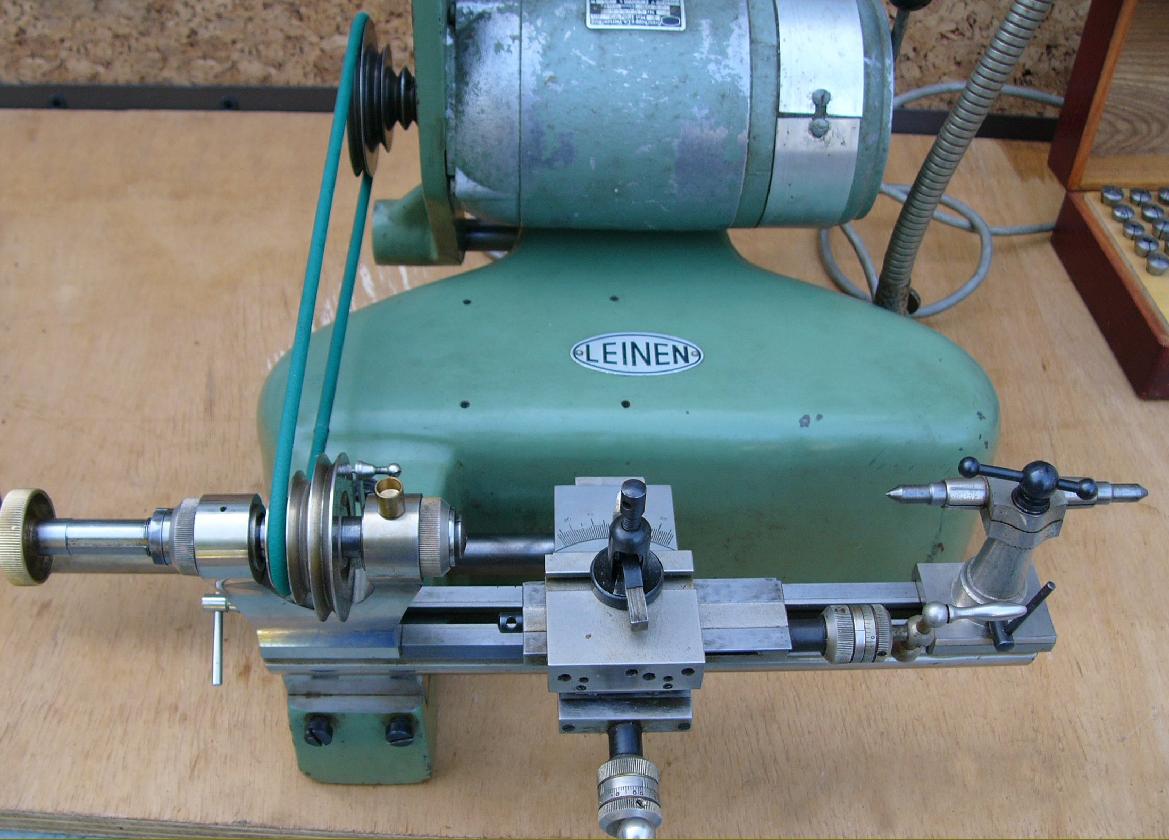

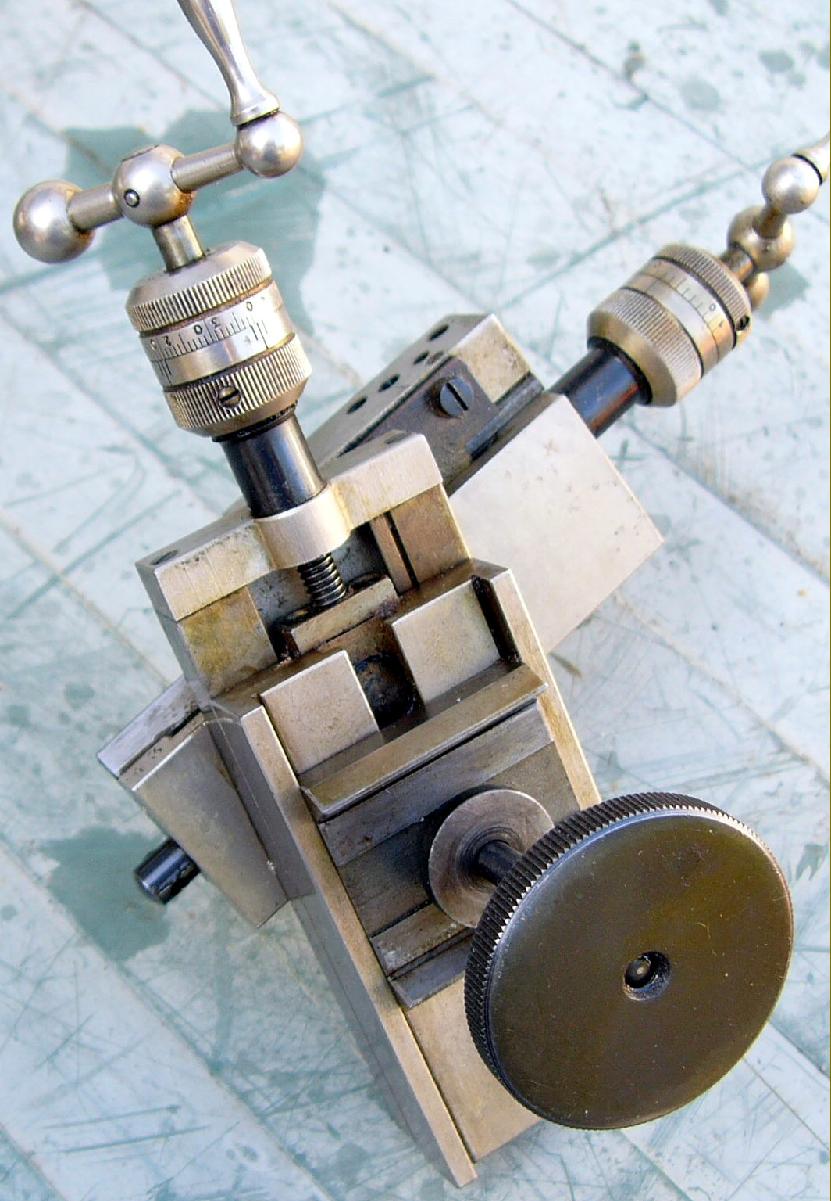

Beginning in the early 1950s, the more expensive versions of Leinen and Boley & Leinen watchmakers' lathes of the traditional WW pattern (a design originating from Webster Whitcombe in America during the late 1800s) were fitted with a much simpler (though more rigid) design of headstock. With the 3-step drive pulley overhung on the left-hand end of the spindle, the Company had adopted the design of the English Pultra concern who had introduced such a type (the very modern-looking 17/50 and 17/70) in 1946 (in a reversal of roles, IME, an English maker of small precision lathes, appears to have taken up aspects of Leinen designs in their second-generation Model 100 and Model 300 lathes introduced in the mid 1950s).

Other changes to Leinen lathes were also afoot and, although some models were to remain unchanged, on some method of mounting the bed and driving the spindle were improved. For many decades a simple round foot, appropriately slotted to take the bed at its headstock end, had been used together with various kinds of effective but untidy remote countershafts and motors. The first improvement came with the use of a variable-speed motor hinged on a heavy, remote base - the second was when the base was extended forwards to form a boss into which the bed mounting stem fitted. The next development saw more complete and integrated designs with the bed sitting in a full-length casting to give an entirely different and much more up-to-date appearance - a typical example being the popular WW82 and WW83 models shown below. Although Leinen had developed their long-established designs, there was no loss of quality - or cutting of corners - and both engineering and cosmetic standards were the same as they had always been: exemplary.

One very rare accessory was a full screwcutting set. This comprised a bracket at the headstock end of the lathe - that, surprisingly, included a tumble-reverse mechanism - together with a set of 18 changewheels: 25, 30, 35,40, 45, 50, 55 , 60, 65 ,70 ,75 ,80 , 95 ,100, 110, 120, 125 and a 127t metric transposing gear. Drive was taken to the top slide by the usual universally-jointed shaft. When fitted with the screwcutting attachment, a special collet drawbar provided with, to clear the gears, a reduced diameter over an inch or so just before the handwheel.

Another, similar version of the lathe is shown here and an adaptation of it, for specialist use in the optical trade (with dial-test indicators for precise positioning of the slides) here.

Additional modern Leinen watchmakers' lathe here and here

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

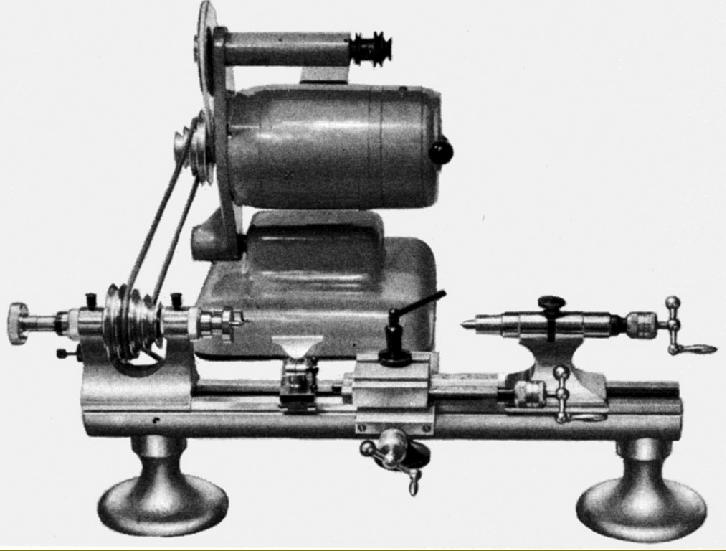

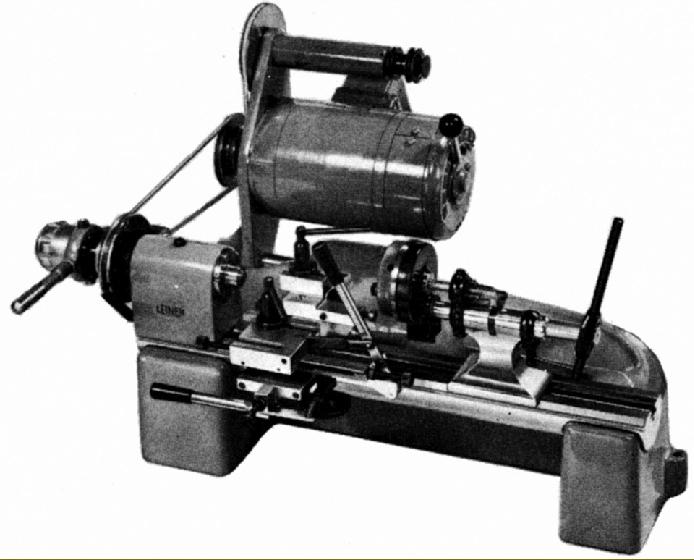

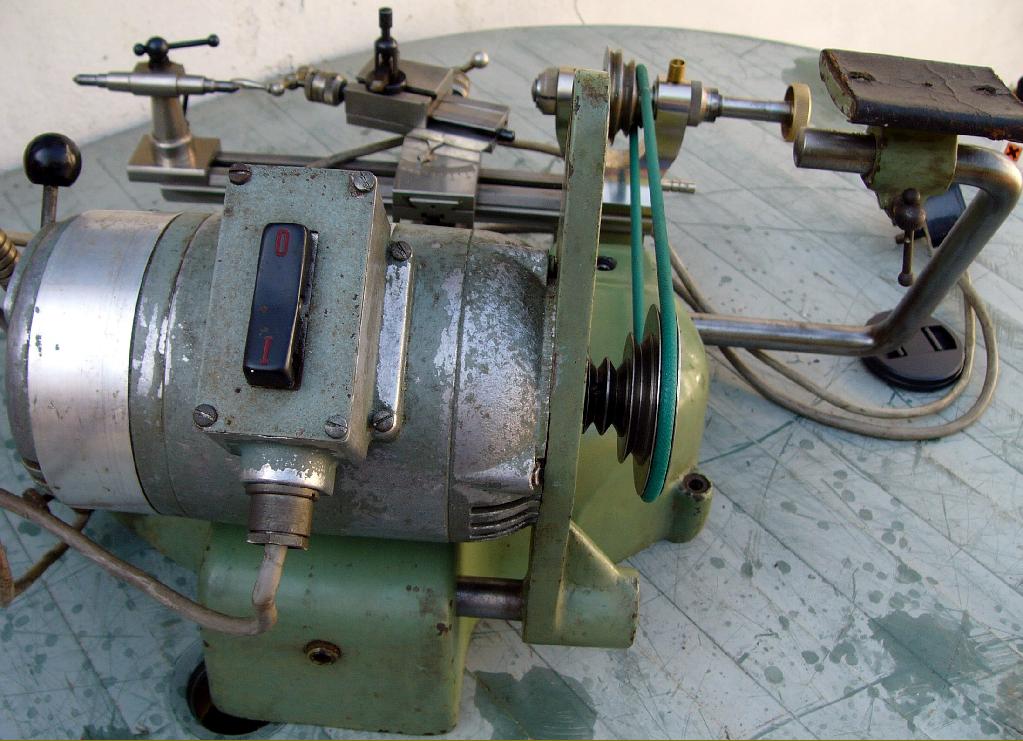

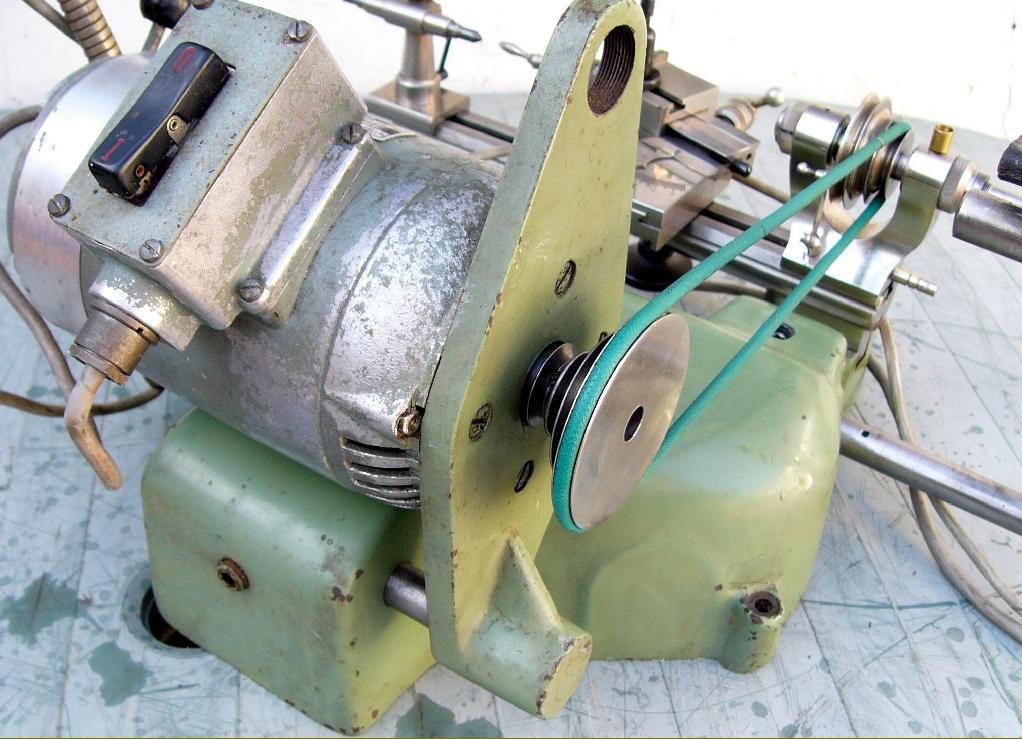

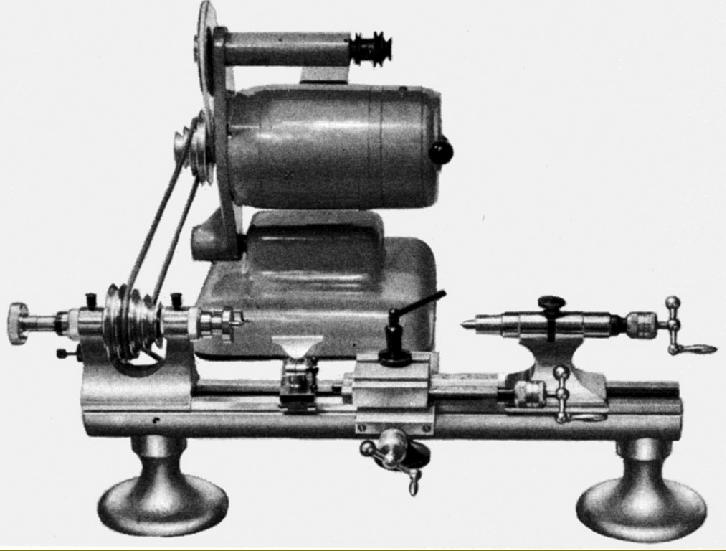

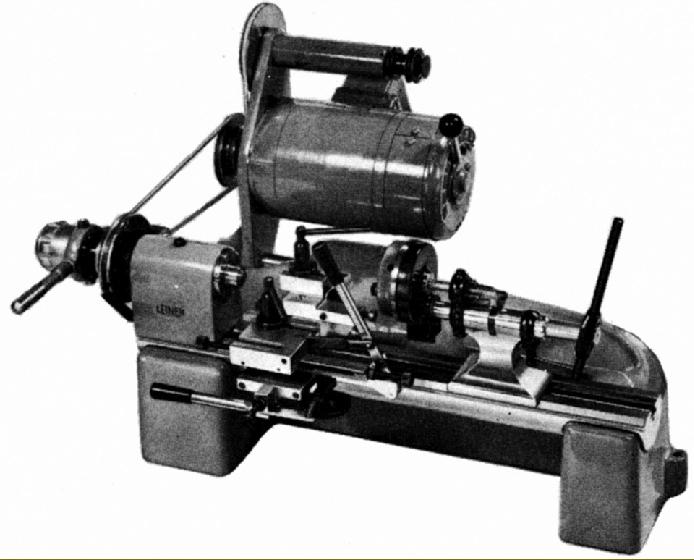

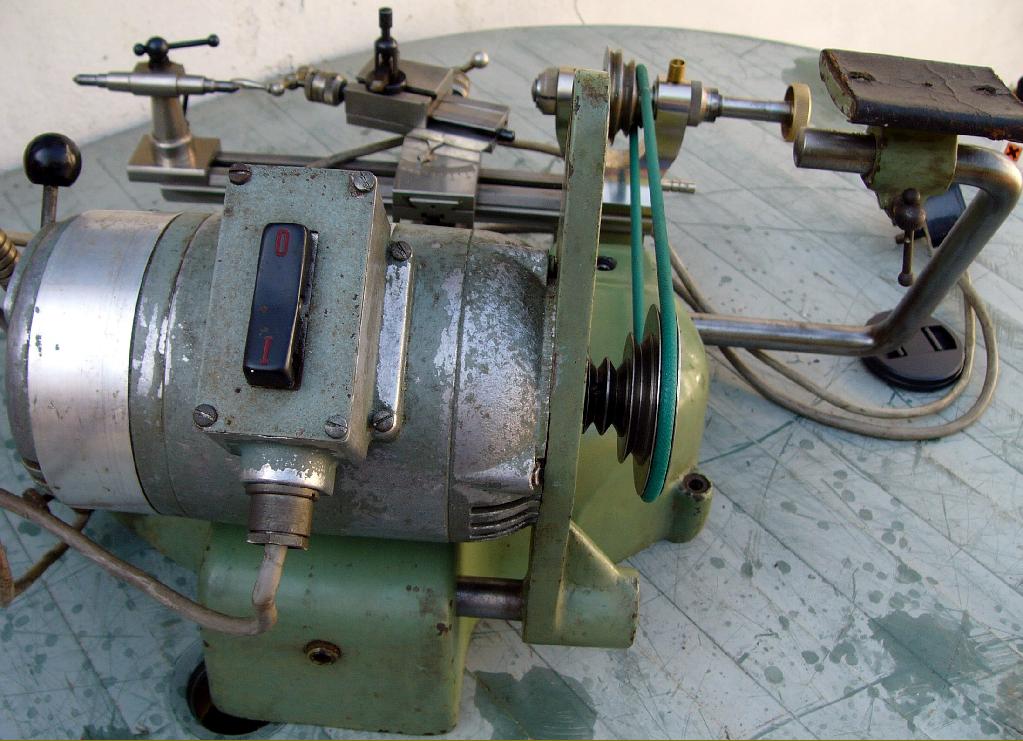

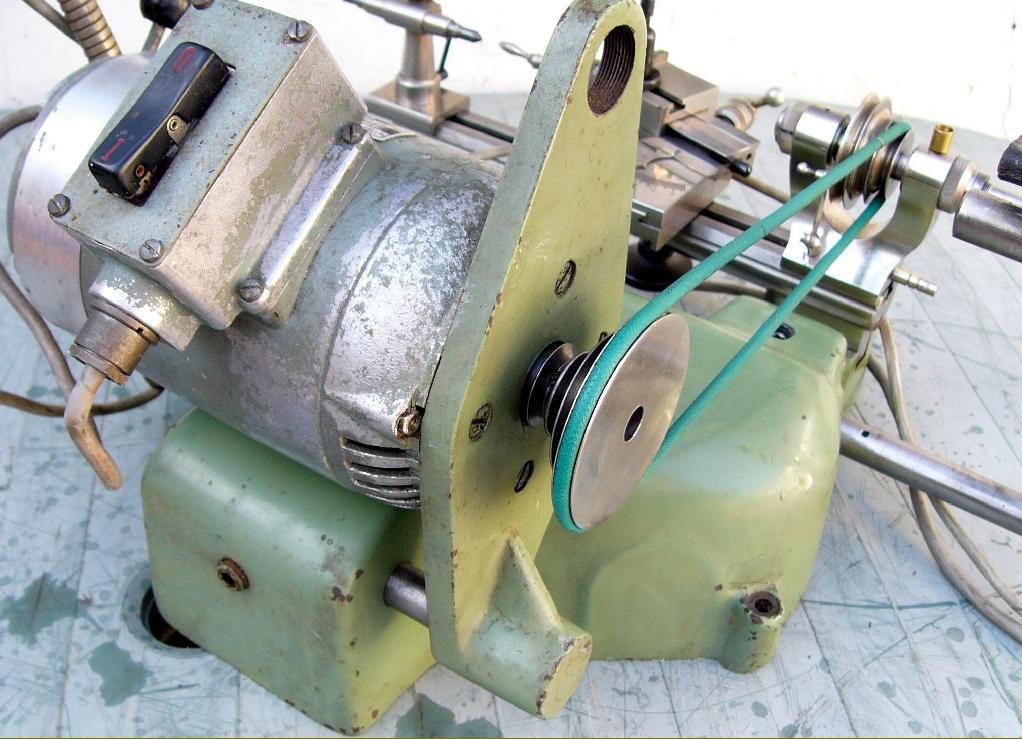

The first stage in the improvement of the WW type came with the use of a variable-speed motor hinged on heavy, remote base.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The new drive system still included the facility to power an "overhead" to run toolpost-mounted drilling and grinding attachments.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

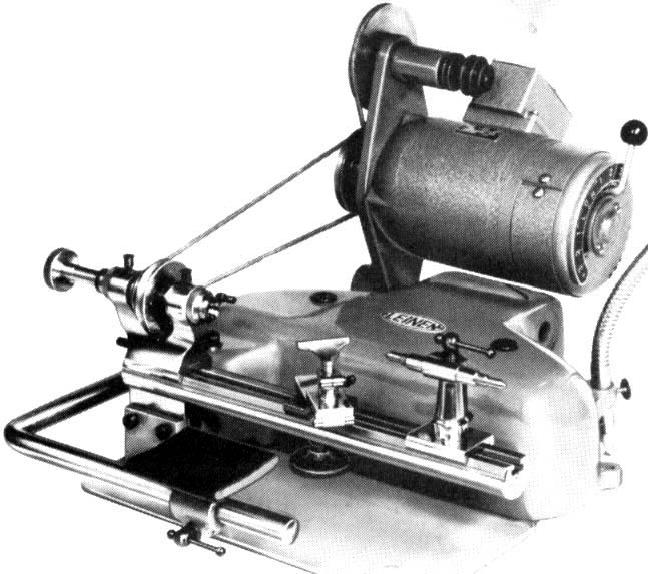

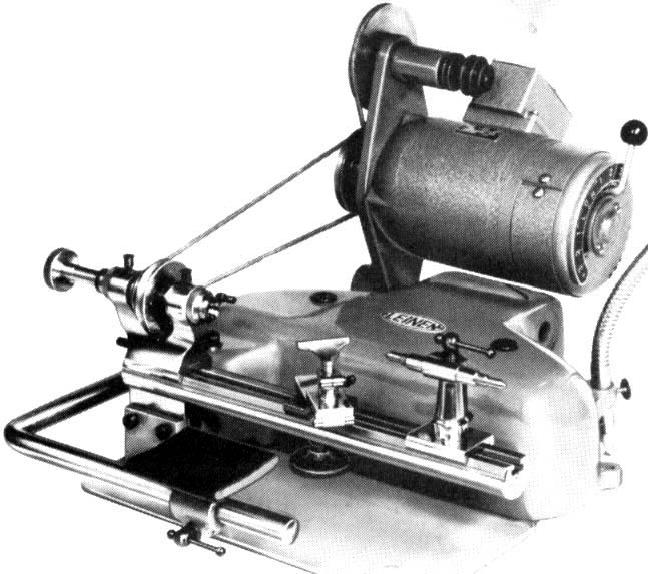

Motor Mount Type 154. By extending the motor-mount casting forwards a convenient socket was made to accommodate the headstock end of the bed.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

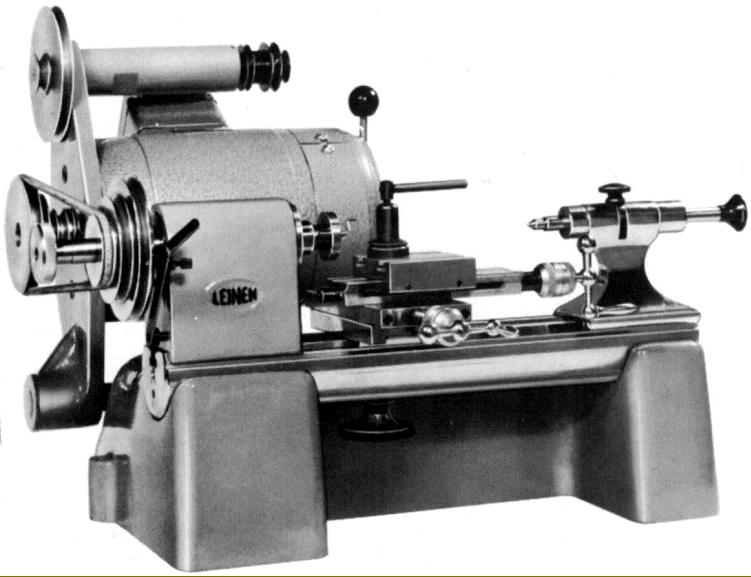

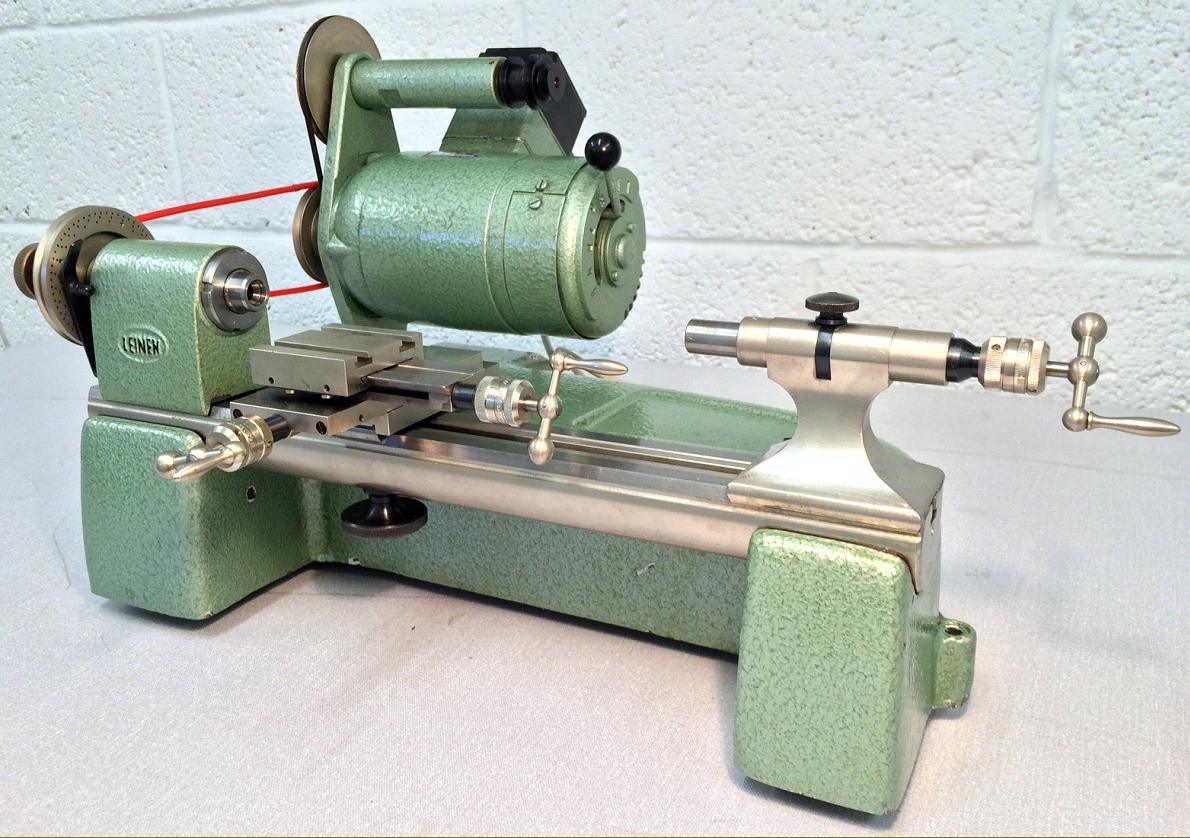

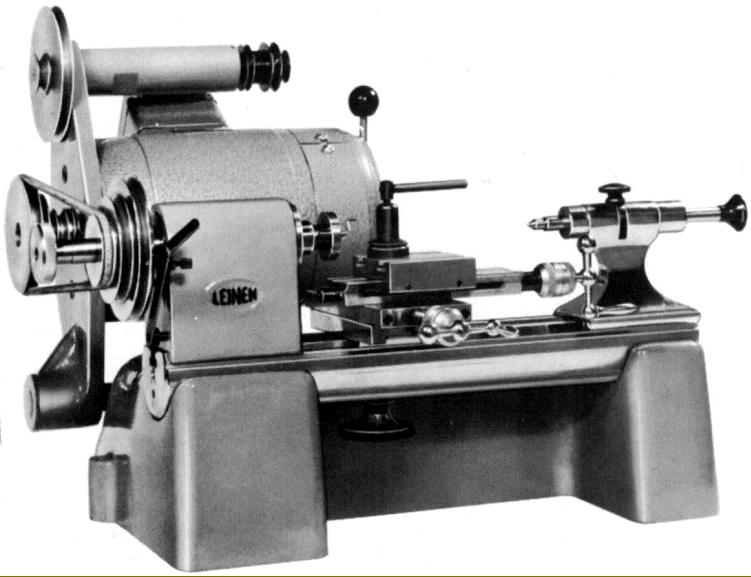

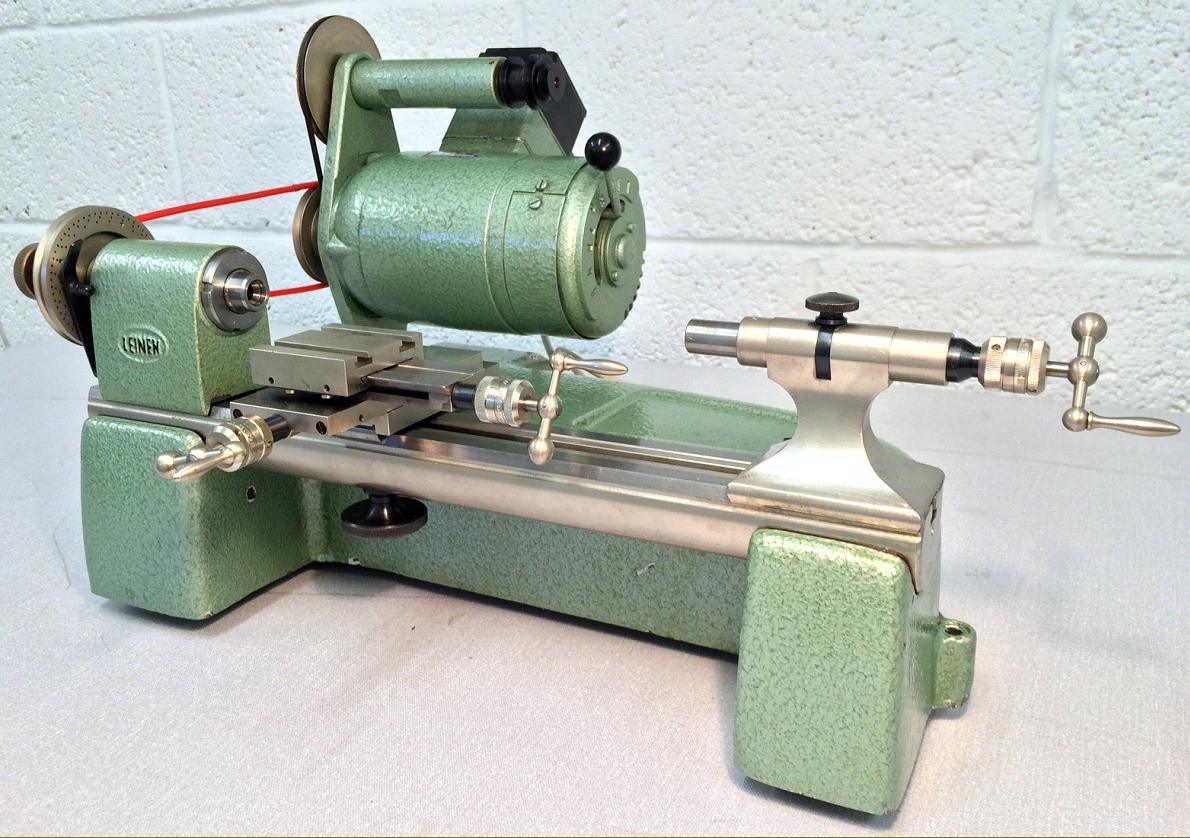

Leinen WW82 and WW83. The 82 (above) was the shorter of the two with a capacity between centres of 105 mm and the 83 (below) much longer, taking 200 mm. Still a WW-type bed from the 1880s but now mounted in a full-length cast frame and featuring an overhung headstock pulley and a built-on drive system.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

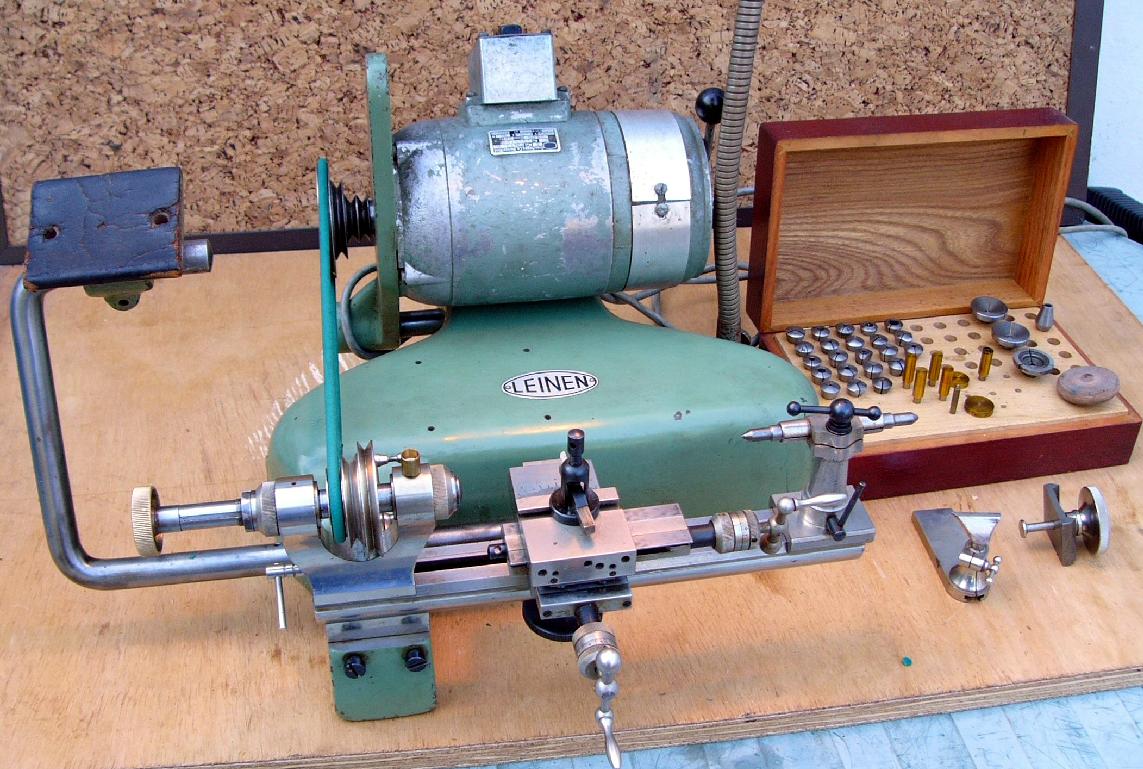

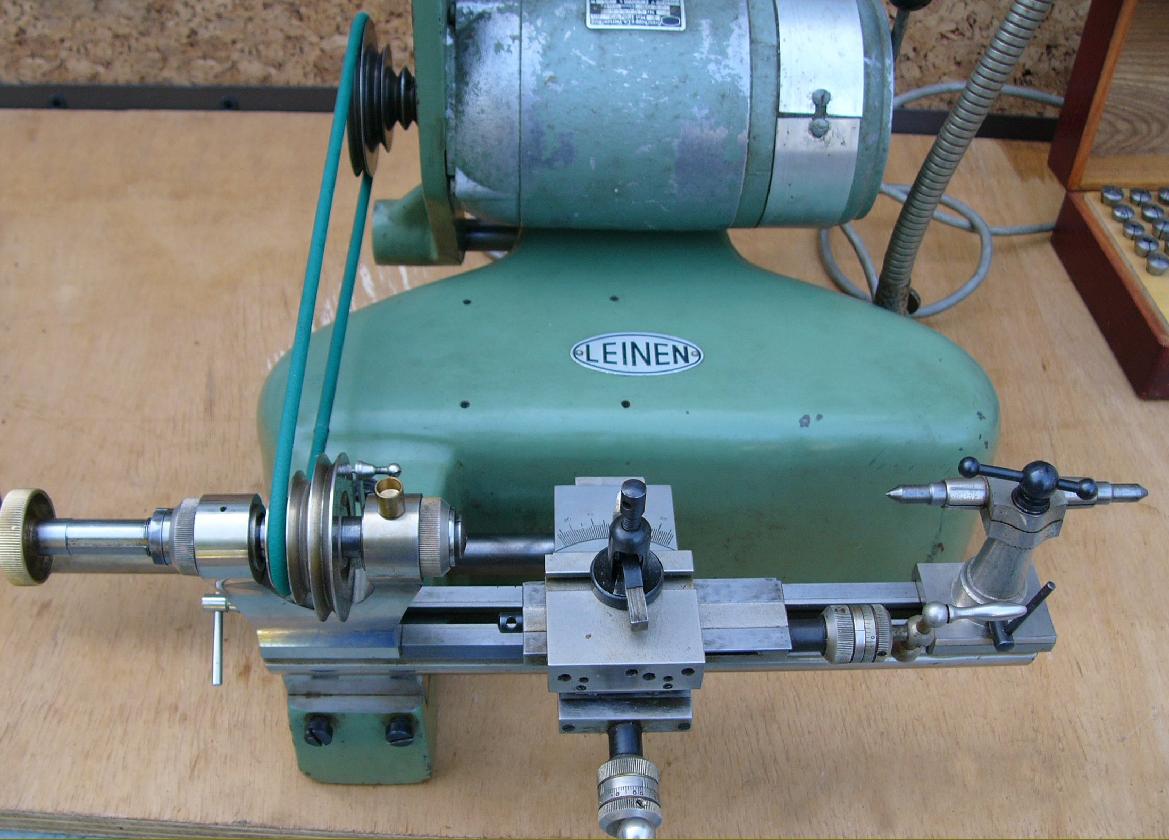

Leinen WW83 long-bed watchmakers' lathe with built on motor drive

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Leinen WW83 long-bed watchmakers' lathe with the rare screwcutting attachment. 18 gears were included: 25, 30, 35,40, 45, 50, 55 , 60, 65 ,70 ,75 ,80 , 95 ,100, 110, 120, 125 and a 127t metric transposing gear

Additional pictures towards the bottom of this page

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Leinen WW83 fitted for production work with lever-operated slides and a capstan tailstock unit

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

An early 1950s "Reform" WW-pattern lathe of traditional design with an integrated drive system from a variable-speed motor. The model was badged "Leinen" on the main casing and "Boley & Leinen" and "Reform" on the end faces of the bed

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

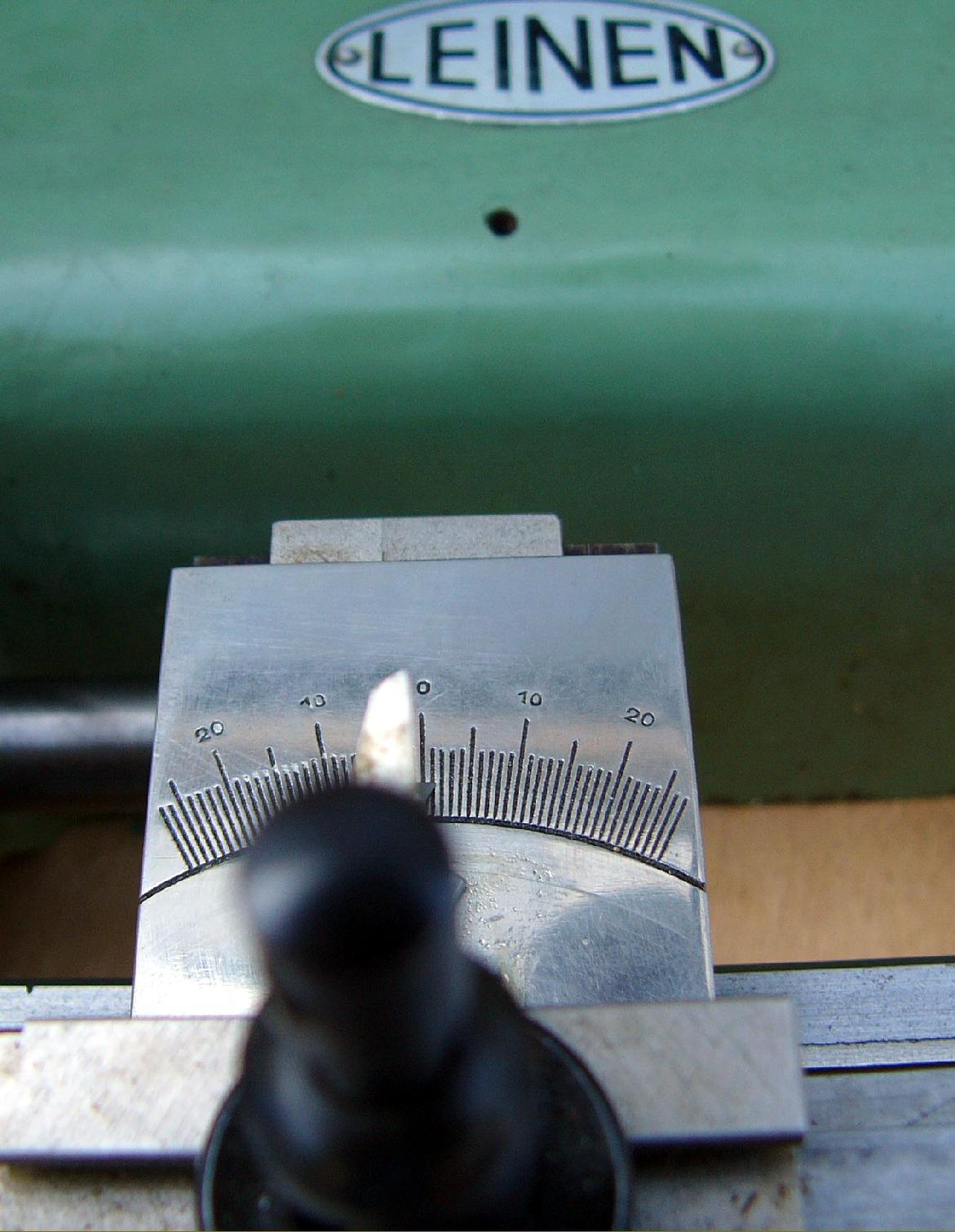

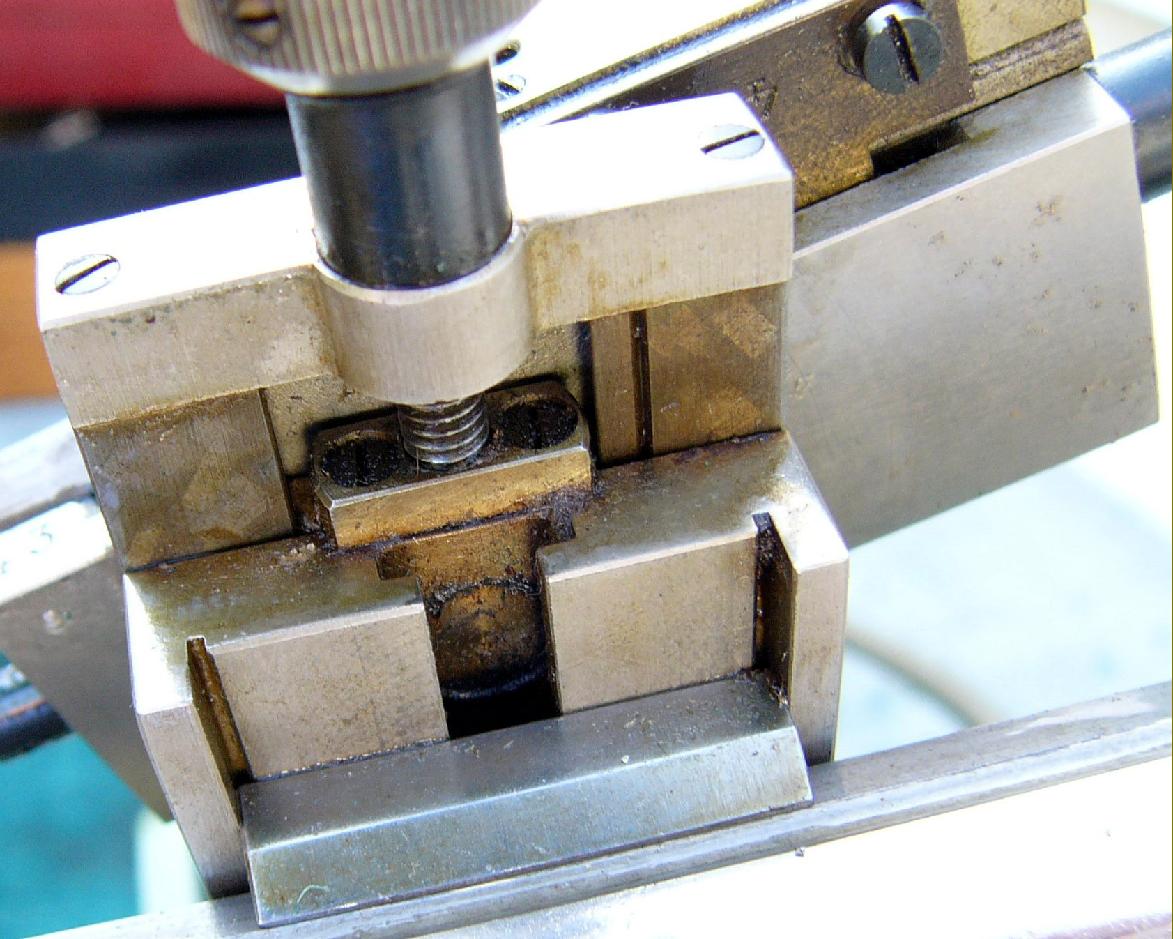

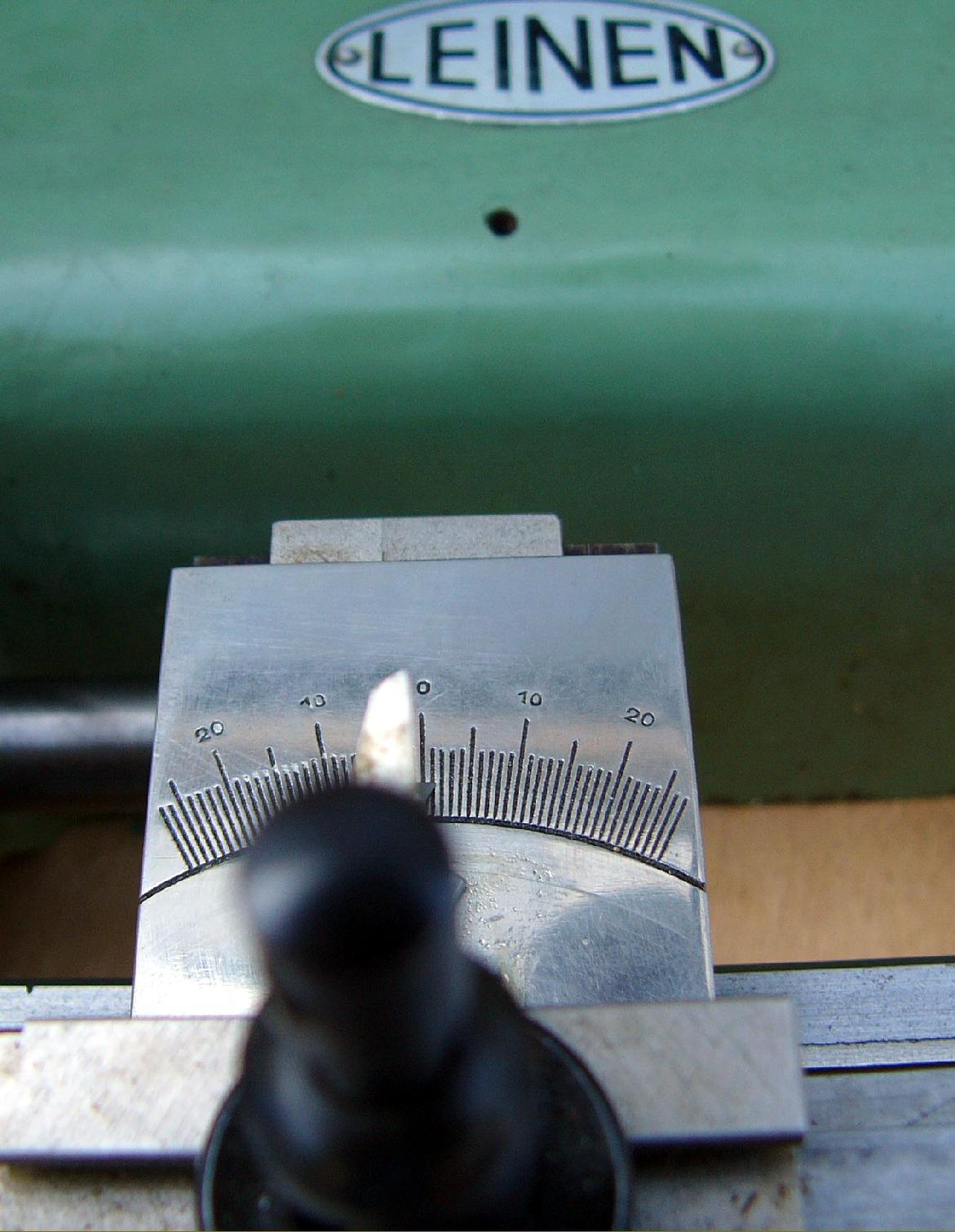

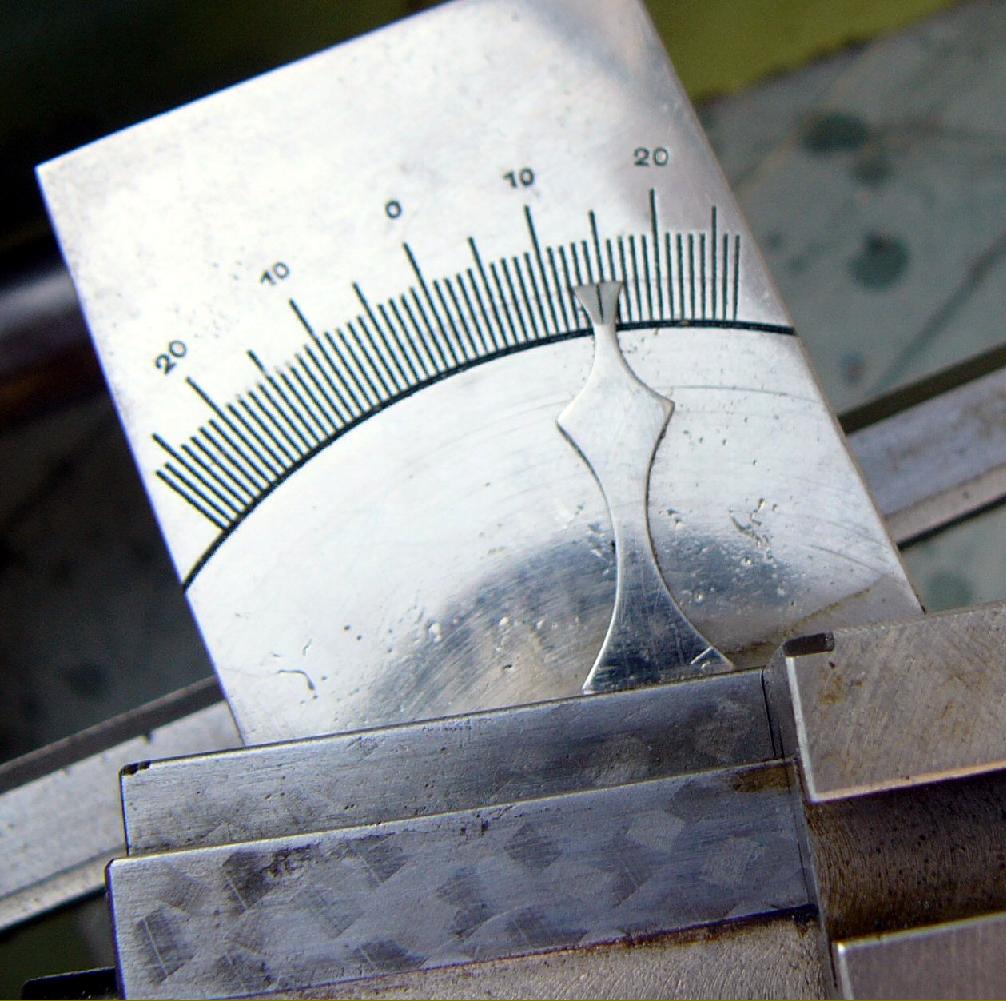

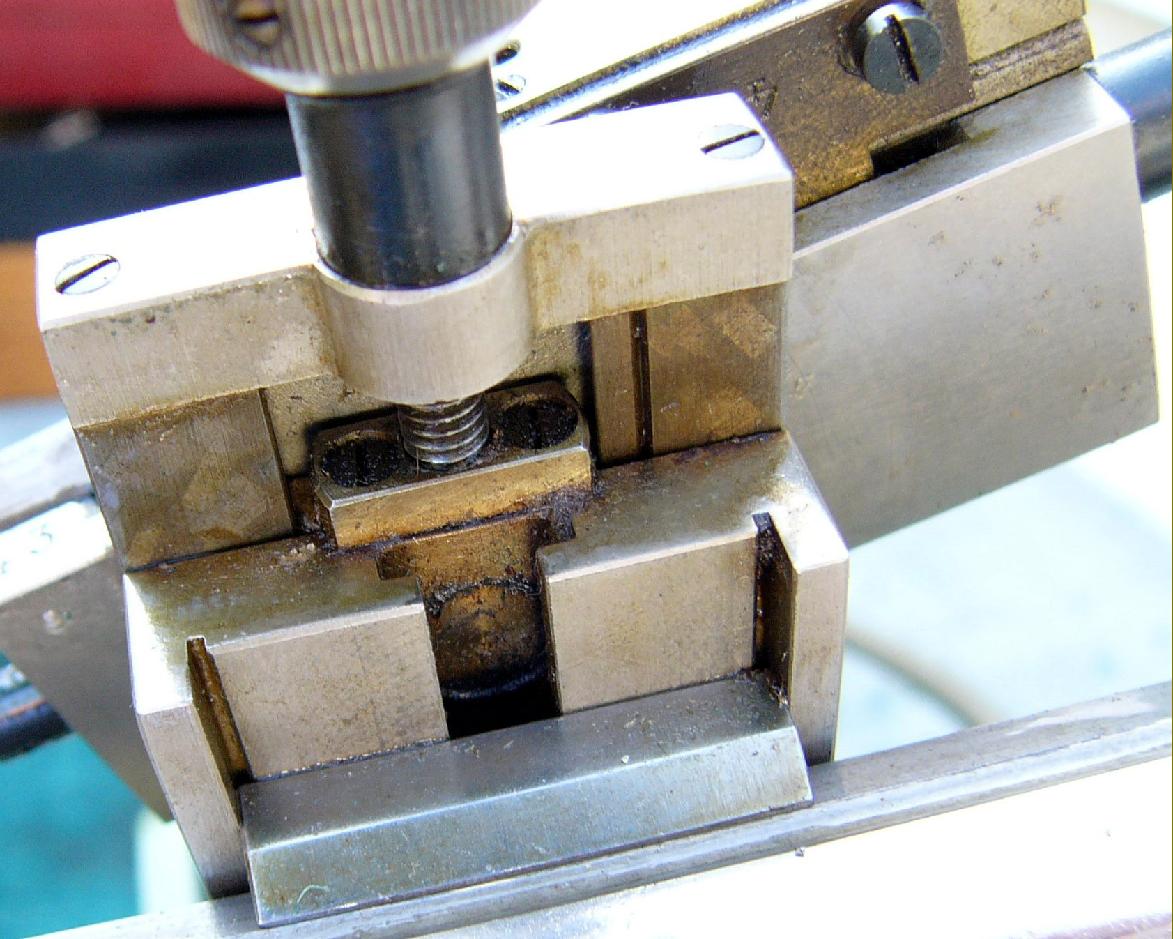

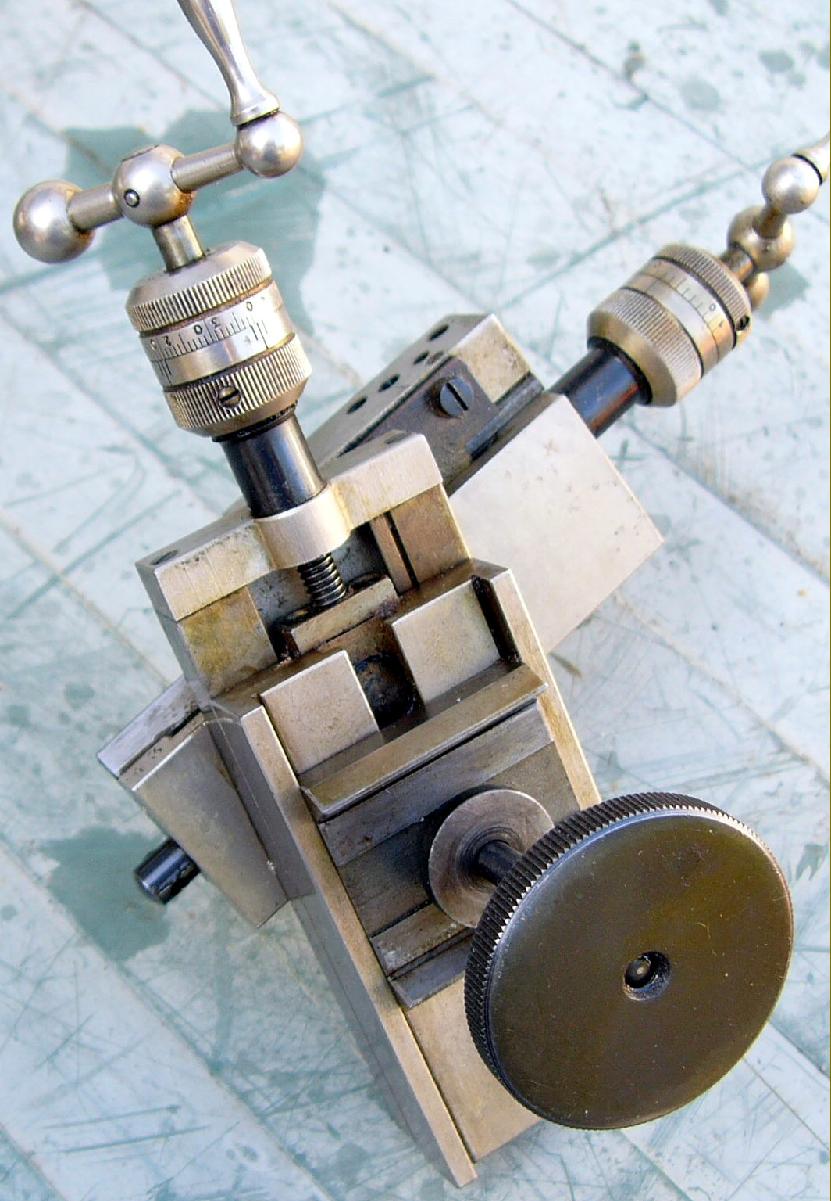

By the 1950s the designers had improved the compound slide rest by increasing the diameter size of the previously tiny micrometer dials

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

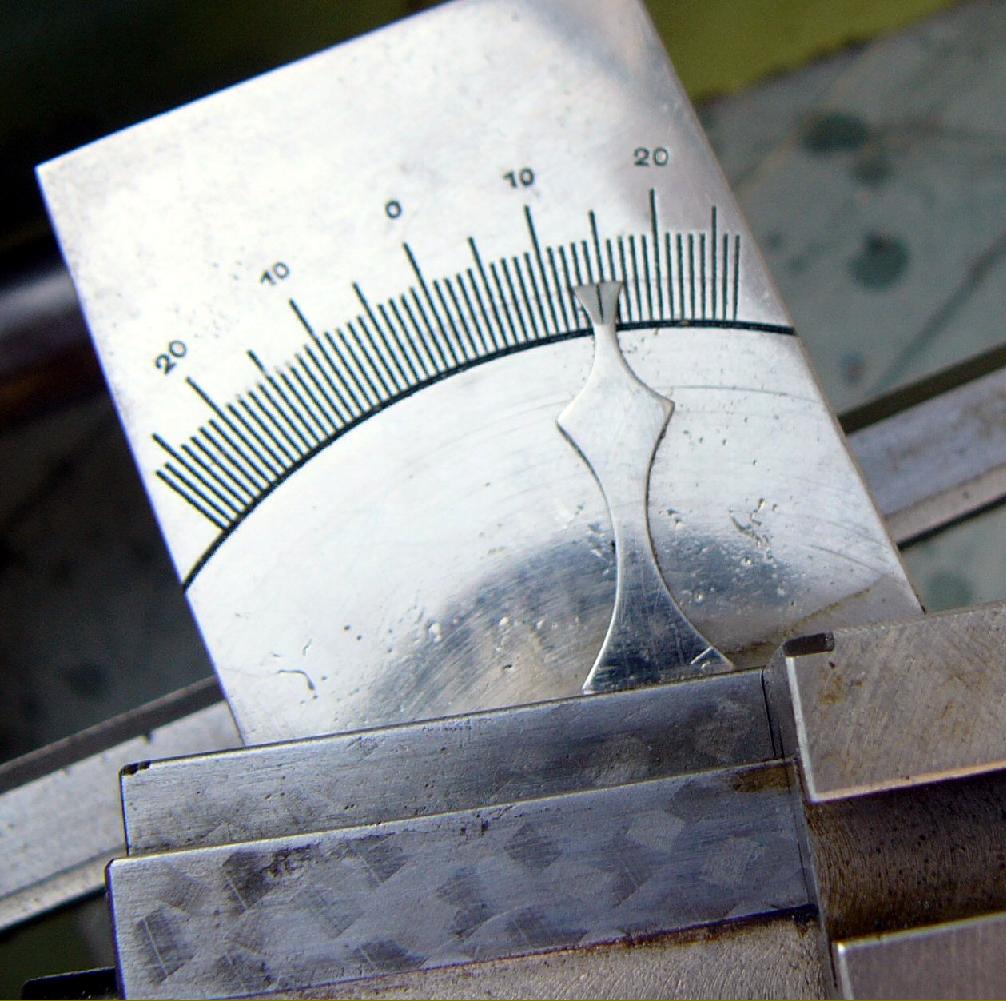

To increase the accuracy of the top swivel setting many other makers of watchmakers' lathe also used a remote degree scale and pointer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

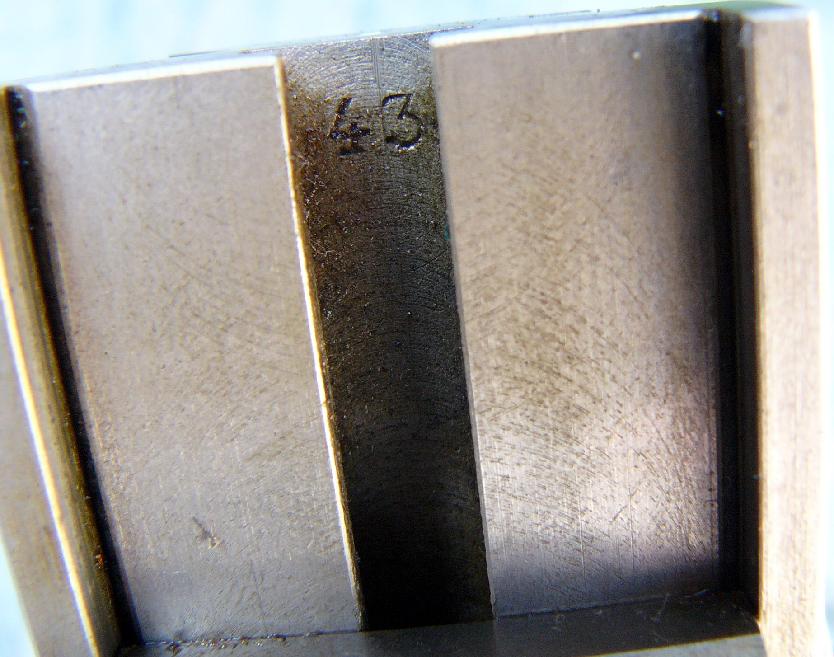

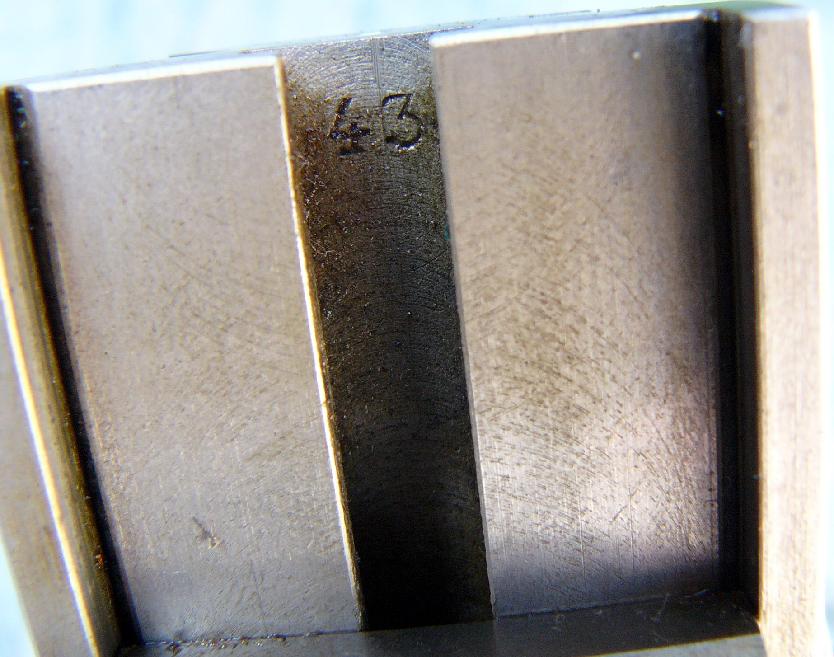

The bed section was of the American WW (Webster-Whitcombe) type

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

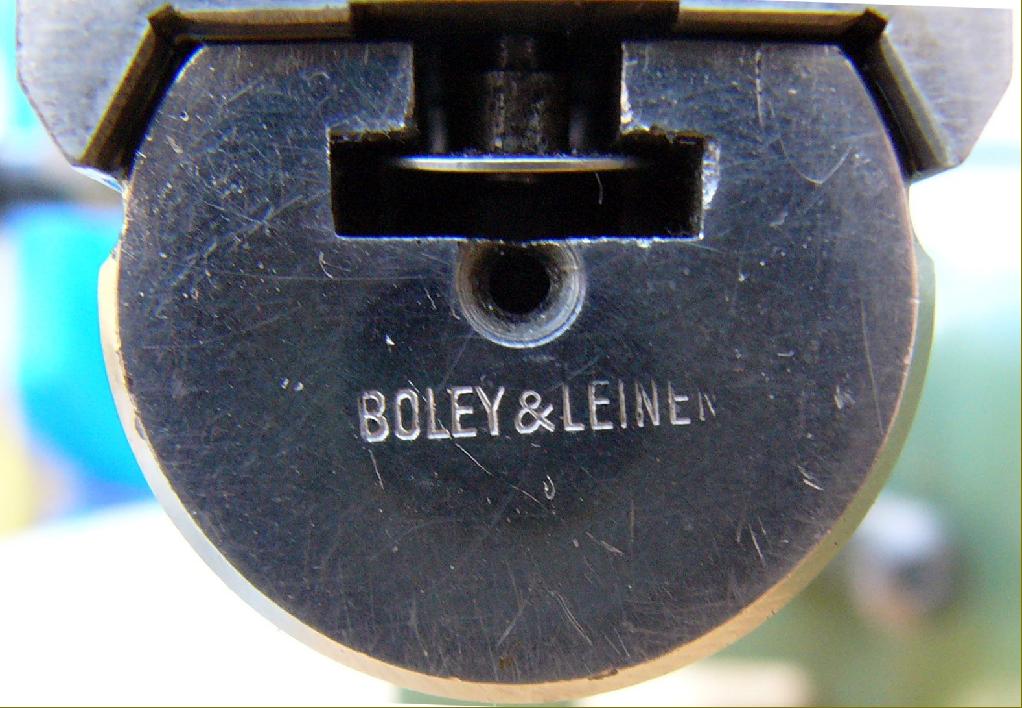

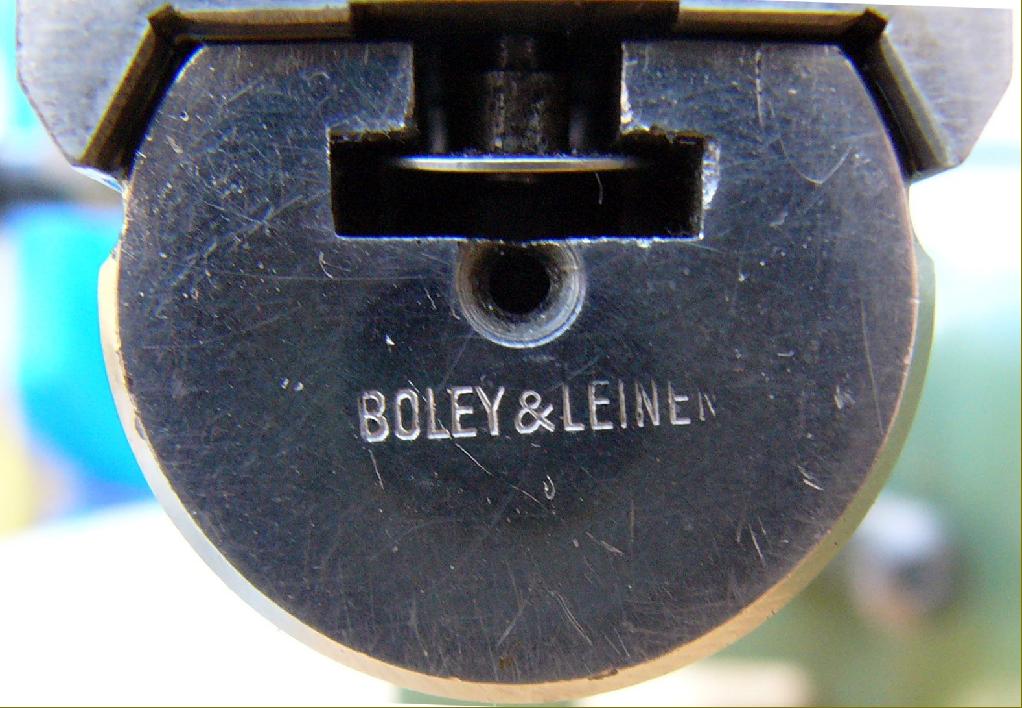

Sloppy work by the punch man - more Boley than Leinen...

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

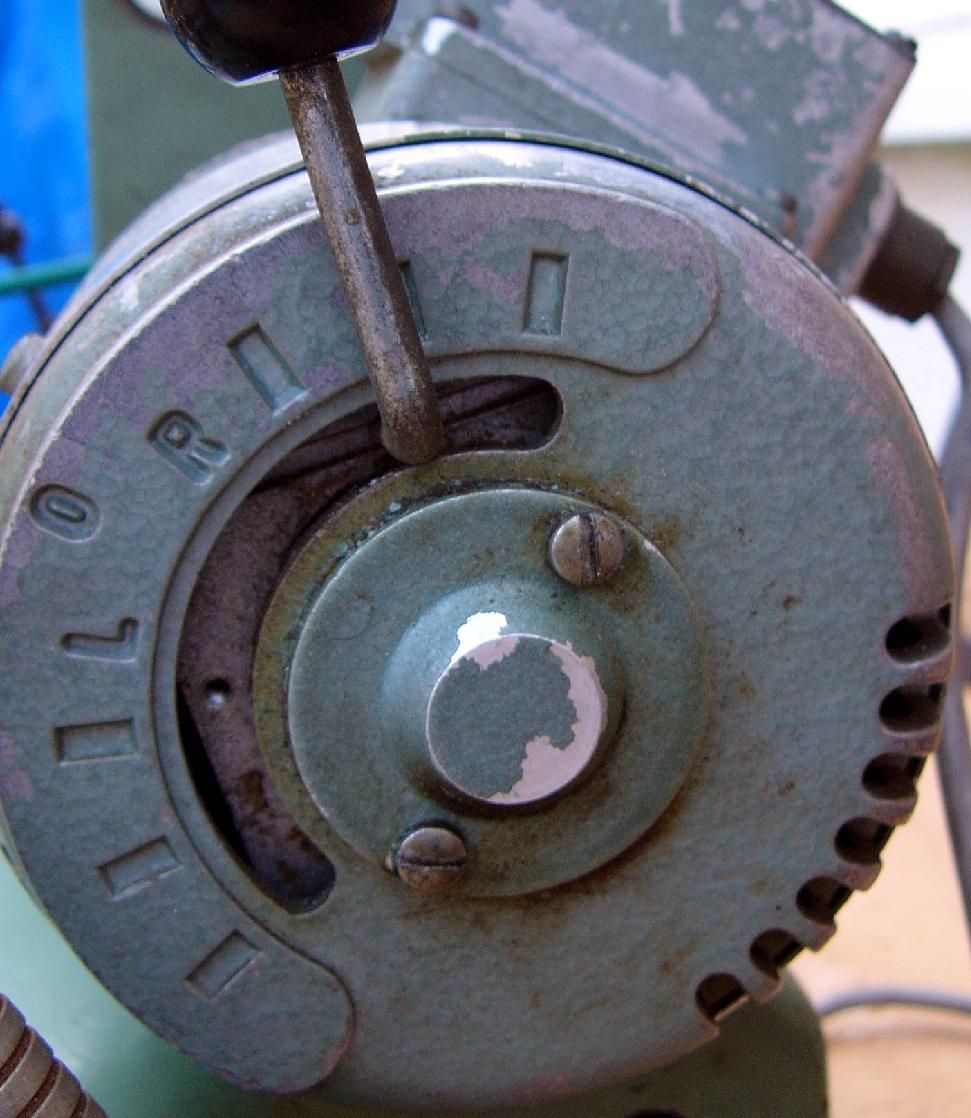

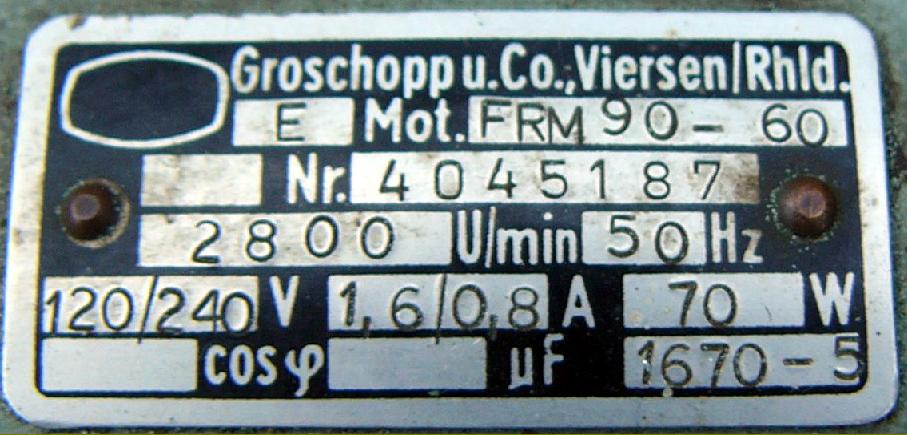

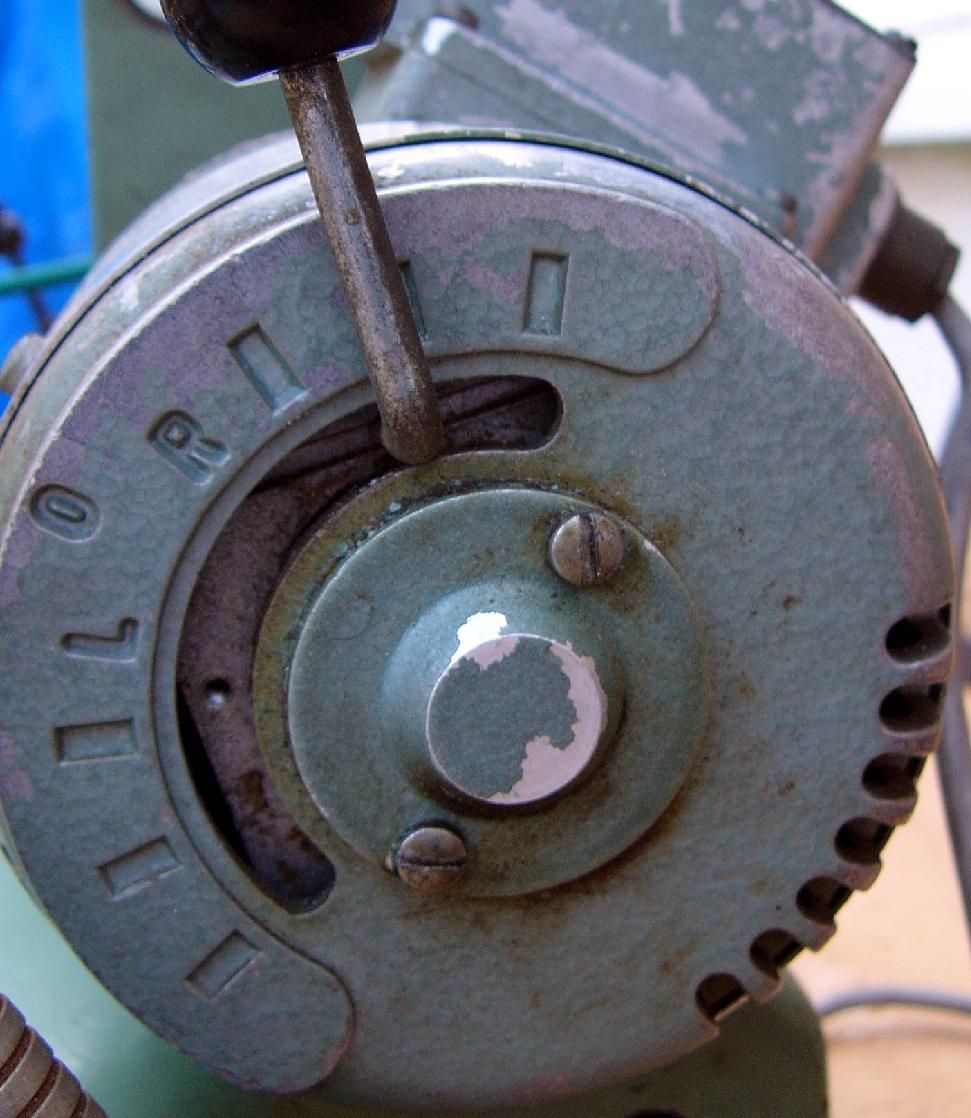

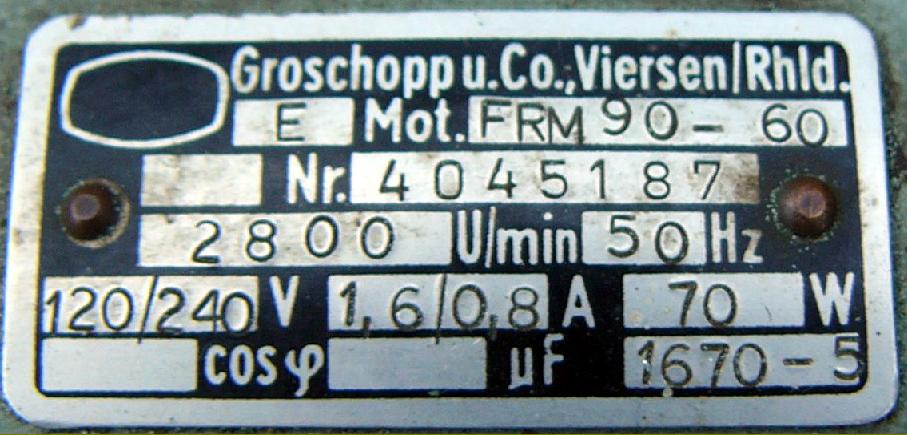

The 70 Watt AC motor had variable speed by a moving brush.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|