|

Continued:

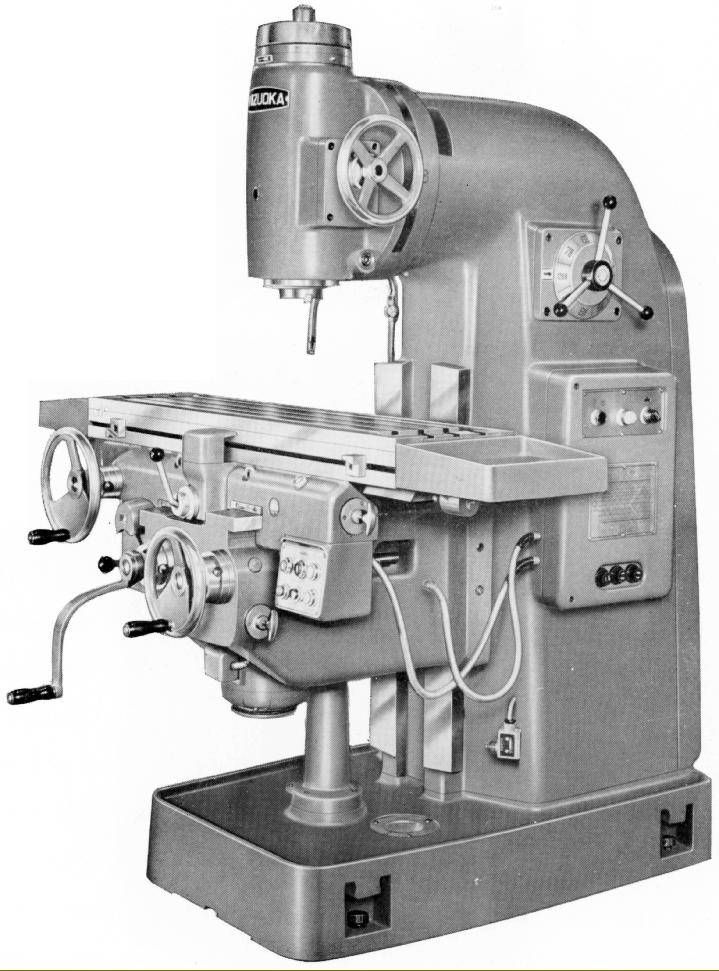

Horizontal Drive

Driven by a 5 h.p. (3.7 kW) 3-phase motor, the horizontal spindle had an NST40 socket end and nine speeds of: 78, 109, 155, 227, 315, 447, 612, 850 and 1200 r.p.m. - though later models had the range altered so that the highest speed became 1400 r.p.m. The drive passed through a speed-change gearbox controlled from the right-hand face of the column by a single, capstan-handled control fitted a direct-reading dial. From the centre line of the spindle the minimum clearance to the table was 1 3/16" (30 mm) and the maximum 18 15/16" (480 mm).

Although the SV had a substantially built vertical head, with an NST40 spindle, the fine feed travel by handwheel was just 3.5" (90 mm) and there was no provision for a quick-action drilling feed by lever. The head could be swivelled through 120° each side of vertical with a minimum clearance between spindle nose and table of 5/8" (20 mm) - and a maximum of 27.5" ( 470 mm). Final drive to the head was by bevel gears that tuned the drive through two right-angles; however, for a vertical miller, speeds were on the low side, being identical to the horizontal model with a range of nine from 78 to 1200 r.p.m.,

Lubrication

In addition to the gearbox oil sump, lubrication was provided by two plunger pumps whose handles protruded from the right-hand face of the saddle and knee - a one-shot system whose success depended, unfortunately, upon either the operator's conscience, memory, or both. From the pumps oil was directed to the sliding surfaces of the column, saddle and knee as well as the various bearings and table feed screws.

Coolant was held in the machine's foot and delivered by a 0.075 kW (1/10 h.p.) pump to a distribution head pivoting from the left-hand face of the column.

Standard Equipment and Accessories

Supplied as standard with each new miller was: coolant equipment, a horizontal cutter-holding arbor, base levelling screws, a set of spanners, oil gun, tool box, inspection certificate and a copy of the maker's instruction book. Additional equipment included a fixed-quill vertical head to mount on the socket of the horizontal spindle, a variety of cutters including stub-arbor types and contemporary optical readers for the table and knee travels.

Weights varied only slightly between the two models: the vertical being approximately 2050 kg and the horizontal 1900 kg..

|

|