|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

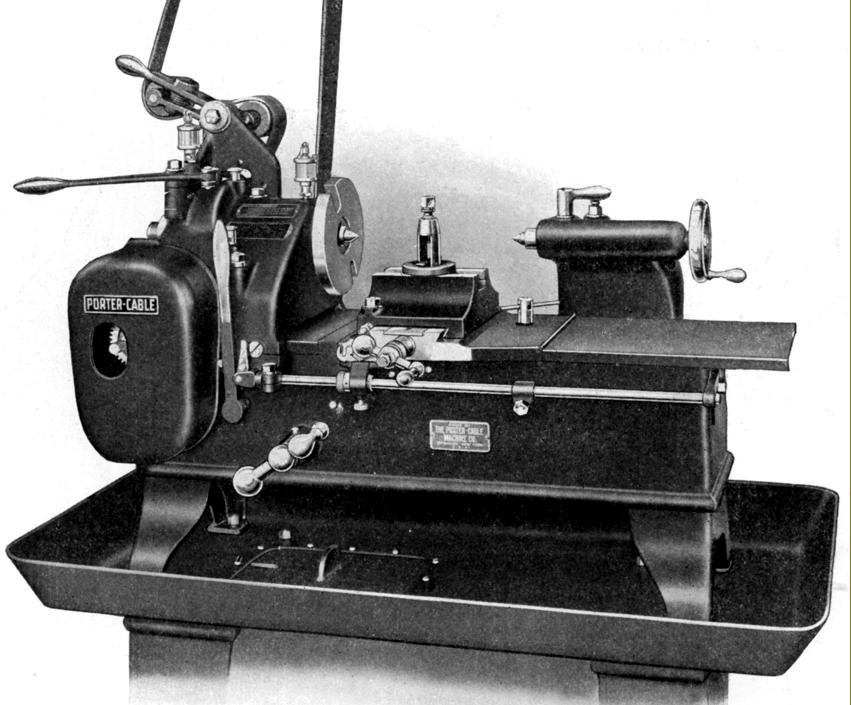

Founded in 1906 by R. E. Porter, G. G. Porter and F. E. Cable as a jobbing machine shop in Syracuse, N.Y., Porter Cable are still active today, selling a range of hand tools, wood lathes and associated products. In 1960 they joined forces with another tool Company, Delta, though the products still retained their separate brand identities.

Having begun by building conventional engine, toolroom and production lathes, during the 1920s Porter-cable turned their attention (most successfully) to hand and power-tool manufacturer - though the lathes did continue, albeit in the form of production machines only, until 1930s. Their entire output appears to have been directed at industry, with no attempt to sell machines into the amateur or repair workshop markets; as a result, as the conventional engine lathes were probably made for less than ten years (and the production types, once obsolete, mostly scrapped), they are now rare. In addition to the lathes, in early years a shaper was also manufactures (a design taken over by Logan and sold as their own) and a milling attachment.

As far as is known, three production lathes were made, each intended for repetition use on short jobs: The first, dating from 1914 (Patent 1196024 dated 1915/16), had no model designation but was described as the Rapid Production Lathe while the second, introduced in the 1930s, was a heavily revised version of the first and listed as the Carbo-Lathe. A third type, hydraulically driven, was developed during the late 1930s and known as the Carbo-Matic. In later years matters became a little more complicated with the well-known firm of William C. Lipe - who, from 1929, became W.C. Lipe Inc., Syracuse, NY. (Production Tools, Special Machines). In 1937 Lipe bought the "Lathe Division" of Porter-Cable who, at the time, were making just the early 9-inch Rapid Production, the Carbo-Lathe and Carbo-Matic. The lathe must have been relatively popular for, in 1940, Lipe announced an extension to their Syracuse-based Machine Tool Division to provide for increased production of the Carbo. Sales brochures for the range extended into the late 1940s and showed the original, unchanged 9-inch still in production as two models: the Heavy-Duty Production with two speed ranges (that spanned 139 to 841 r.p.m. and 365 to 2072 r.p.m.) and a High-Speed Production with a single speed range of 700 to 3600 r.p.m. Also offered in their established forms were the Carbo-Lathe (now described as "Semi-Automatic") and the Carbo-Matic Fully Automatic.

Compact and strongly built (it occupied a space just 421/2" x 211/2" and weighed around 1000 lbs) the original Rapid Production had a 9-inch swing and could take either 14 or 20 inches between centres. In essence this was just a robust, plain-turning lathe without screwcutting but with power feed along the bed. It was intended, according to the makers, to be a low-cost machine for the manufacture of shorter parts and arranged so that it would survive hard use in the hands of unskilled operators.

Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continued:

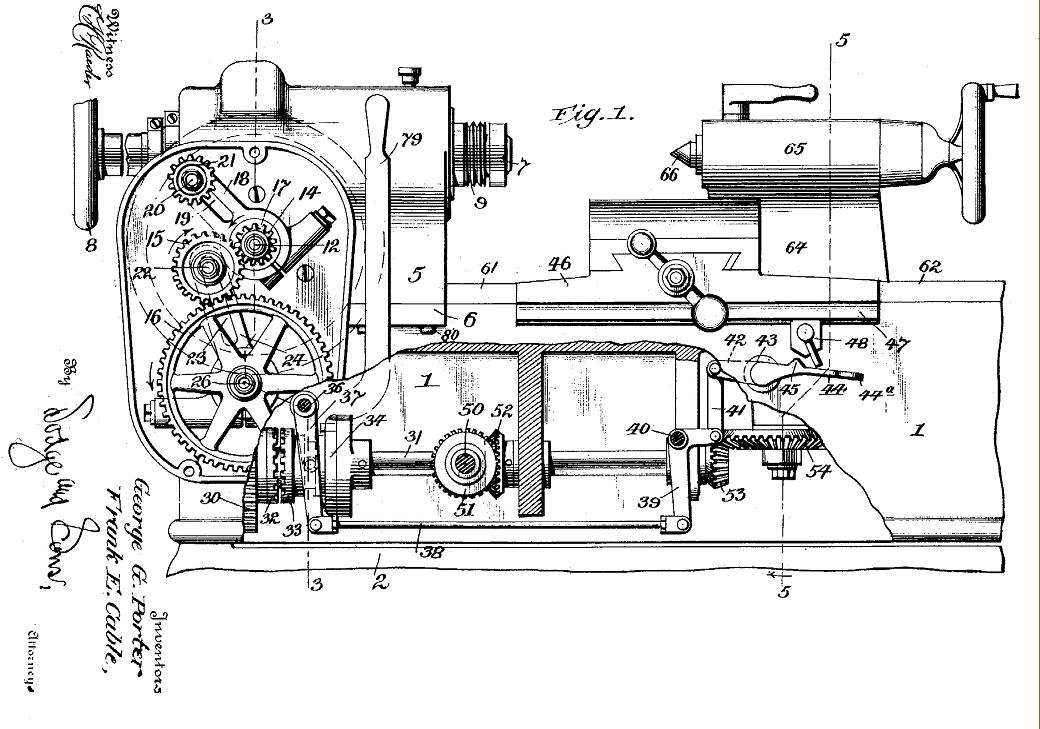

Although the concept of a simple lathe for simple jobs was not unusual, the manner of its execution was, with almost every part of the machine different to usual practice. Drive to the 1-inch bore spindle (running in massive tapered bronze bearings and lubricated by drip-feed oilers) came from a quickly changed pulley, mounted at the rear of the headstock, that was intended to be driven from either overhead line shafting or from an optional, built-on motor unit with switchgear. The input shaft, which ran from the back face of the headstock to the front, passed beneath the spindle and drove it through worm-and-wheel gearing. At the front, the shaft carried a gear that meshed with a train to take the drive down to a second shaft, parallel to the first, also fitted with worm-and-wheel gearing that drove a shaft that passed down the centre line of the bed. At the headstock end of the shaft was a multi-tooth dog clutch operated by an external lever and also connected, via a linkage, to an adjustable knock-off bar arranged along the front face of the bed. With the spindle running at 1000 r.p.m. the use of low-ratio worm-and wheel gearing meant that the centre-line shaft was turning at just 100 r.p.m. (See the patent drawings below for a full understanding of how this was arranged).

In keeping with its other novel features, the carriage drive was also unconventional. The shaft that passed down the centre line of the bed ended half-way along where it drove, using bevel gears, a vertical shaft. At the top of the vertical shaft was a gear that engaged with a rack formed as part of the saddle. Instead of being guided by the usual inverted V and flat ways - or along V-edges - the centre of the saddle was formed with a male dovetail section that ran in female ways machined down the centre line of the bed.

For manual drive of the carriage a handwheel was positioned on the front face of the bed and connected to the powershaft by bevel gears. Thus, the entire drive was by gears of one sort or another (no screw threads being used), and obviously designed for heavy use and a long, trouble-free life.

On later models, instead of drip-feed oilers, an oil bath was used to lubricate the headstock internals with a simple oil slinger, fastened to the input (clutch) shaft, distributing the lubricant to the worm, worm wheel and spindle bearings.

With the massive tailstock carried on the bed's rear face on separate, widely-spaced angle-edge ways, the flat-topped bed was left clear for its full length and able to be completely covered by long, telescoping covers to both left and right of the cross slide (that on the left sliding beneath the headstock casting) an essential requirement to prevent wear on a machine in continuous, heavy-duty use. As a bonus, the entire carriage could be slid off the end of the bed for maintenance or replacement by one of another kind for special jobs.

As part of the regular equipment, just a single cross slide was fitted - though both a proper compound rest was available and a slide with a type of built-in taper turning. Toolposts were simple but rugged and included a typically American style of rocker post, a clog-heel open type and a full-length "gang" holder that could be set up with multiple tools.

Accessories included a number of useful items including: a rear-mounted, facing (cut-off) slide (Patent 1385491) driven by a cam that could be adjusted over a range of 2 inches and with 2 inches of slide travel; an angular facing attachment - similar to the standard unit but with the cross slide able to be swivelled through an arc of 180°; a taper-turning attachment; collets with closure by either an ordinary screw wheel or quick-action lever.

William C. Lipe was the brother of Charles E. Lipe (milling machine of Brown & Sharpe fame).

Brown & Lipe was Alexander Brown & Charles Lipe.

W.C. Lipe had an interest in several companies including Broom sewing machines and a foundry.

From 1929 W.C. Lipe Inc., Syracuse, NY. were listed as making "Production Tools and Special Machines".

In 1937 Lipe buys the lathe-making division of Porter-Cable - the 9-inch production lathe and the mechanical and hydraulic Carbo types.

From 1940 Lipe announces that construction is to start on an addition to the company's plant in Syracuse to allow increased production of the Machine Tool Division that manufactures the Lipe mechanical Carbo-Lathe. An improved Carbo-Lathe is announced for high-volume production turning with modern alloy tools.

If any reader has a Porter-Cable lathe of this type the writer would be interested to hear from you..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

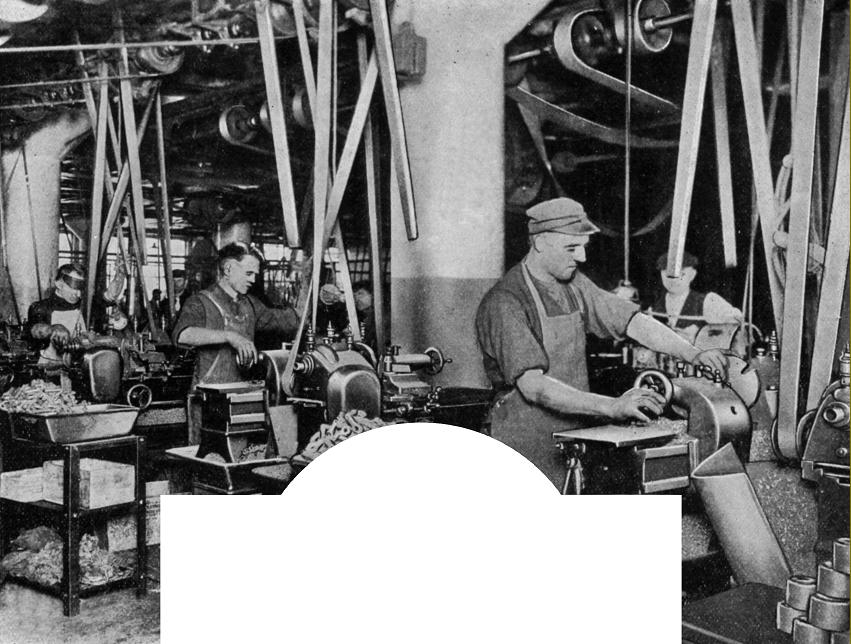

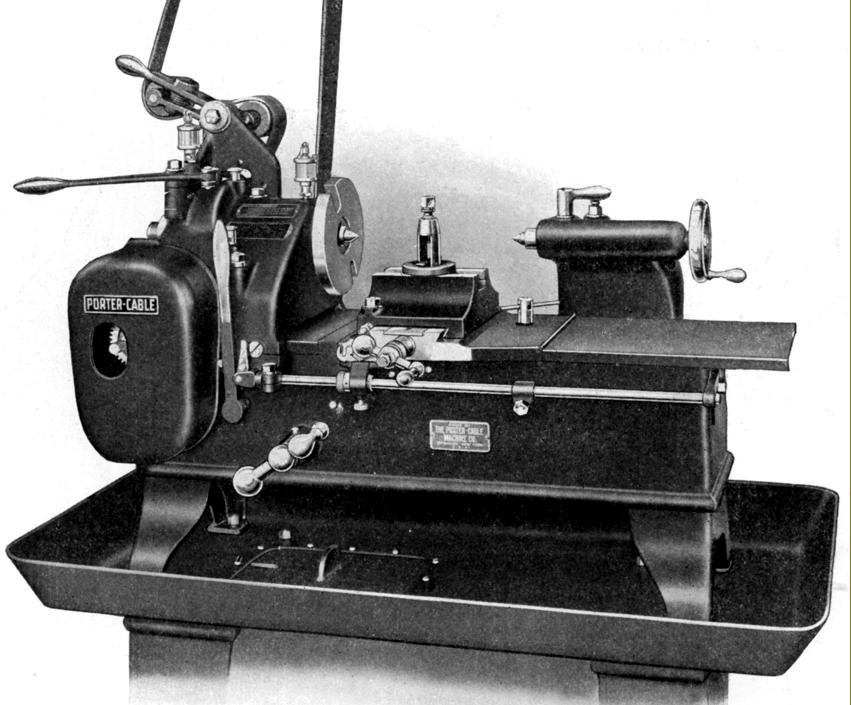

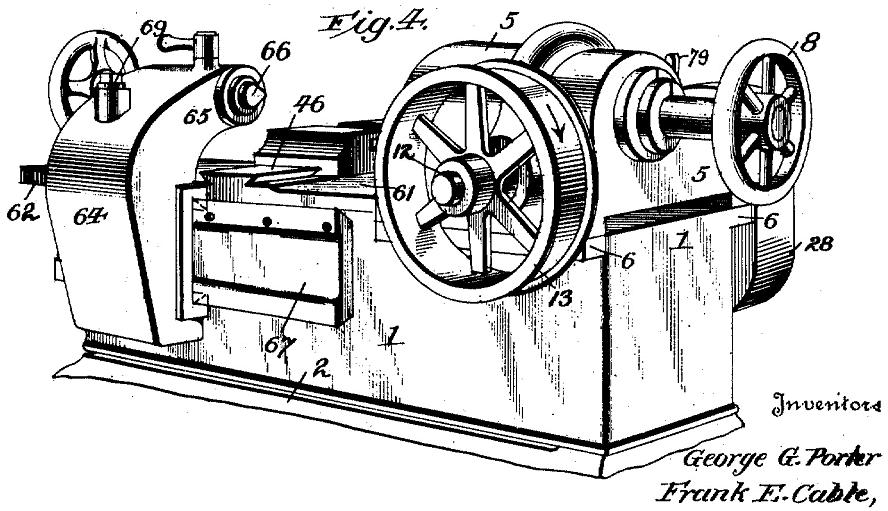

Porter-Cable Rapid Production Lathe circa 1914/19 with drive from a factory line-shaft

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

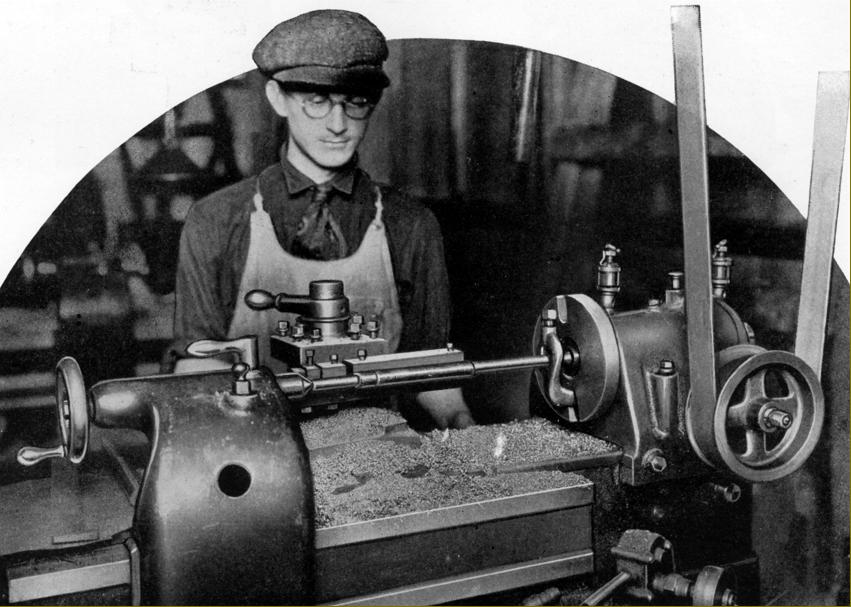

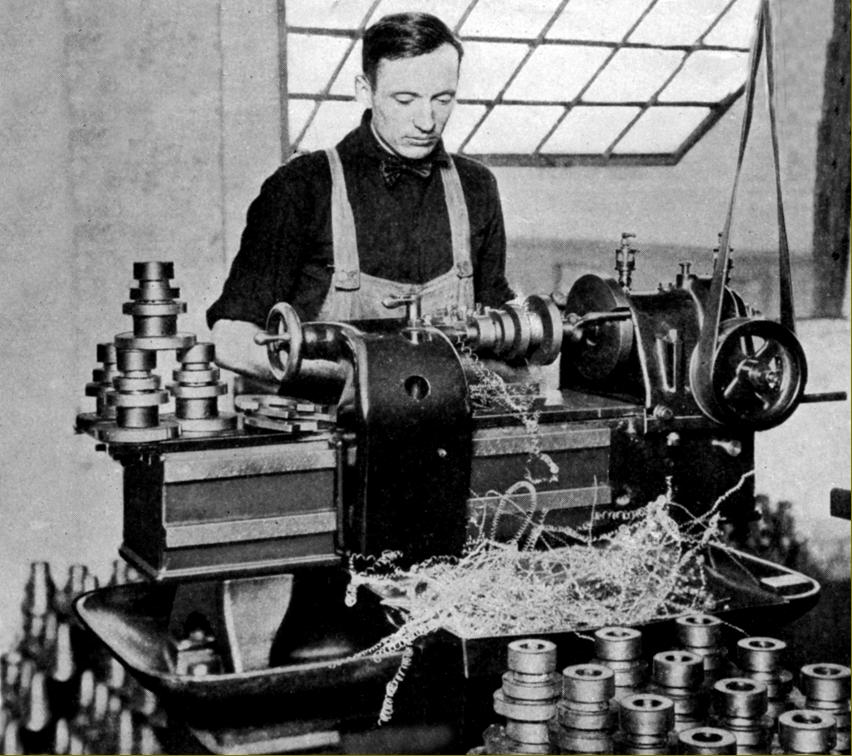

Four tools being used at once to grove and chamfered a 3.5% nickel steel n armature shaft. As no longitudinal movement was required an extra-long tool holder was fitted with just in in-and-out movement to complete the job at the rate of 30 per hour.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

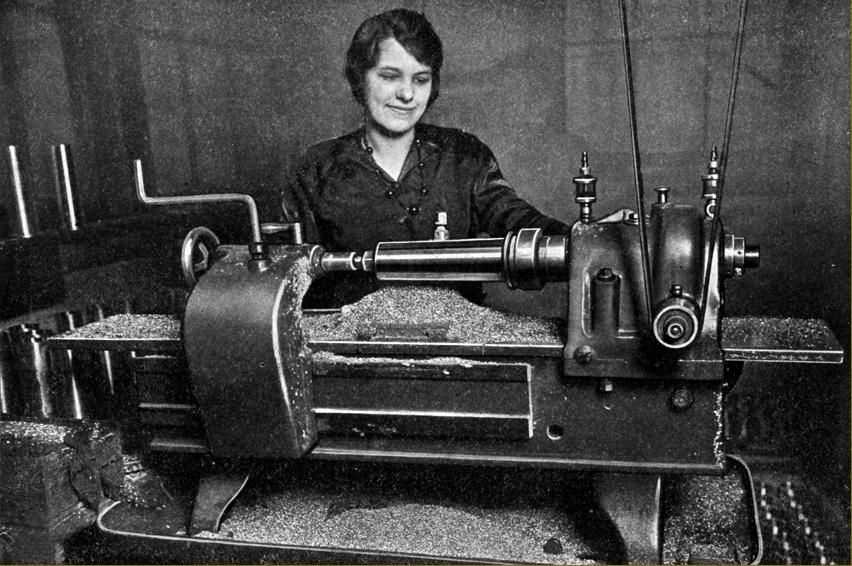

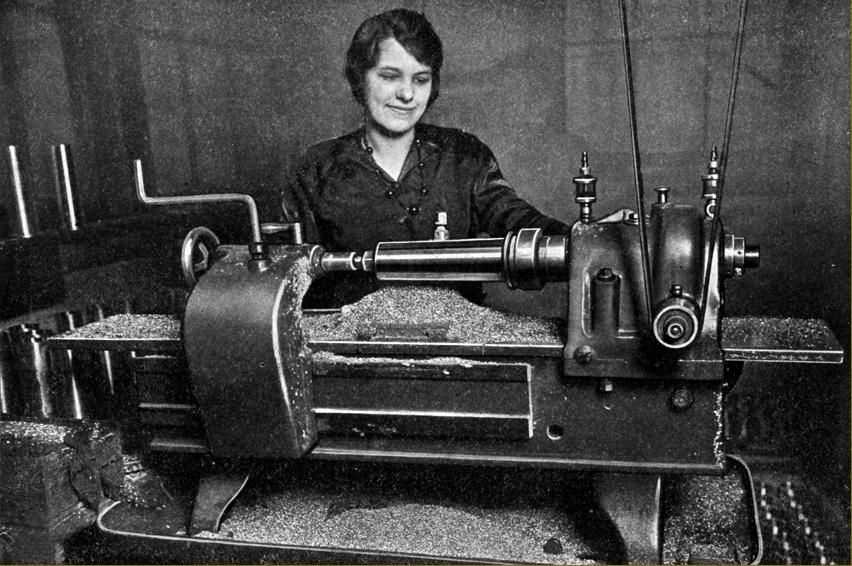

A bronze hub liner for a 56" artillery wheel being turned on an expansion arbor. If the girl operator really was a shop-floor worker (though judging by her bead necklace, had been drafted in from the office to add a touch of glamour), it's unlikely that her benign smile would have lasted - the work rate for this piece being 300 per hour.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

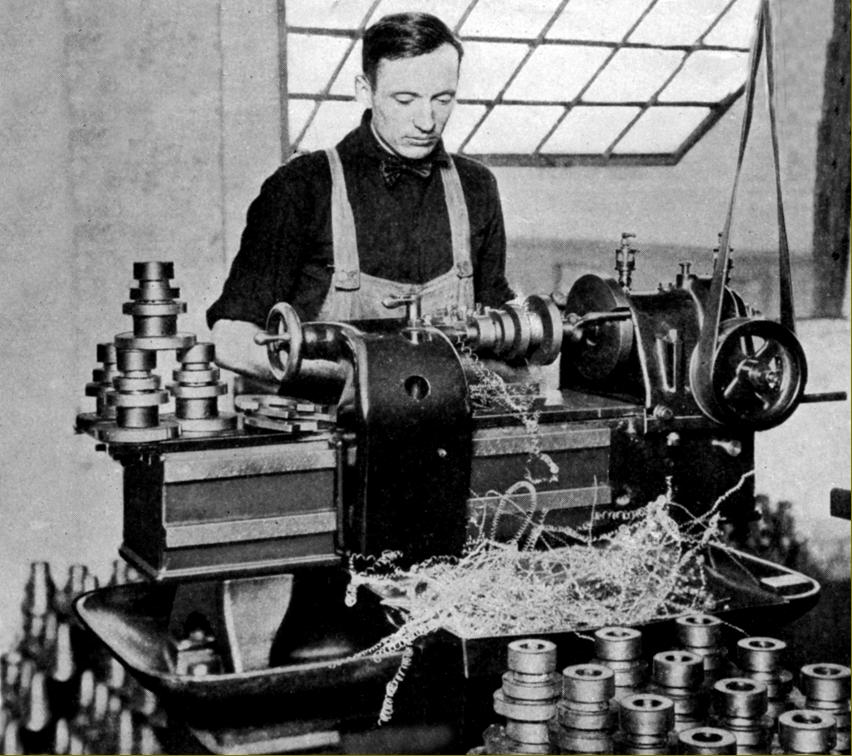

Automobile transmission gear blank. The four diameters were turned to plus or minus 0.001" with 30 completed every hour

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

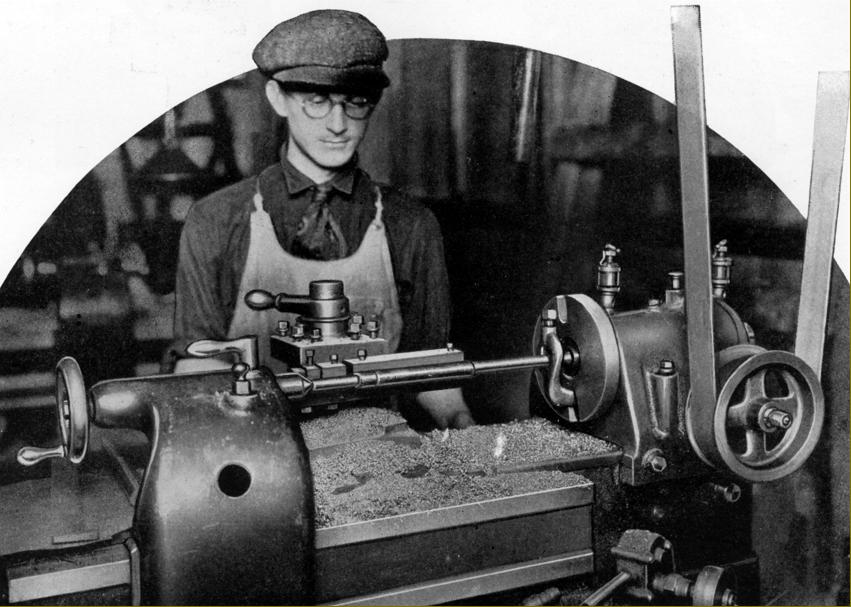

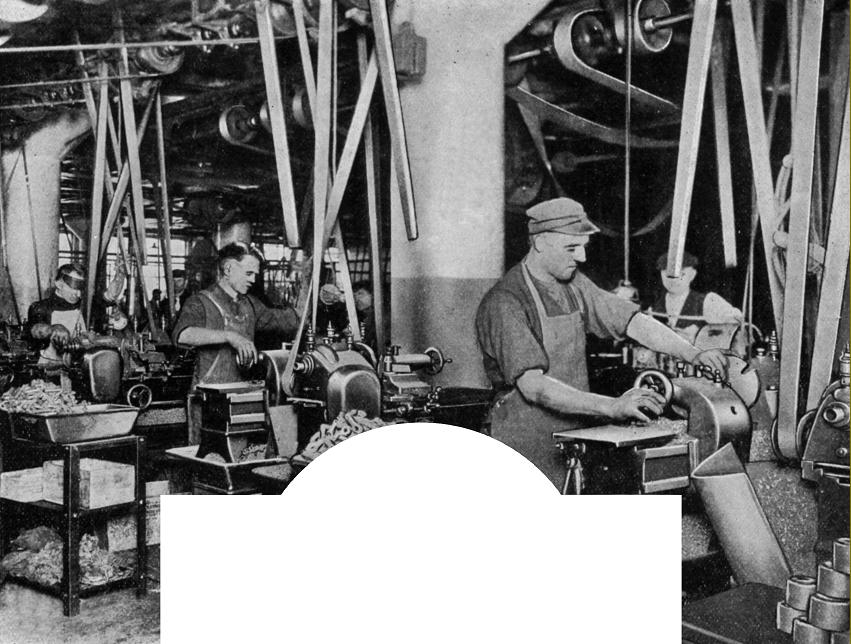

The factory of the Stewart-Warner Speedometer Corporation in Chicago. The main job was to machine bars of malleable iron with a turned section 9/16" in diameter and 21/2" long. In an Eight-and-a-half hour day each lathe could produce 925 pieces

|

|

|

|

|

|

|

|

|

|

|

|

|

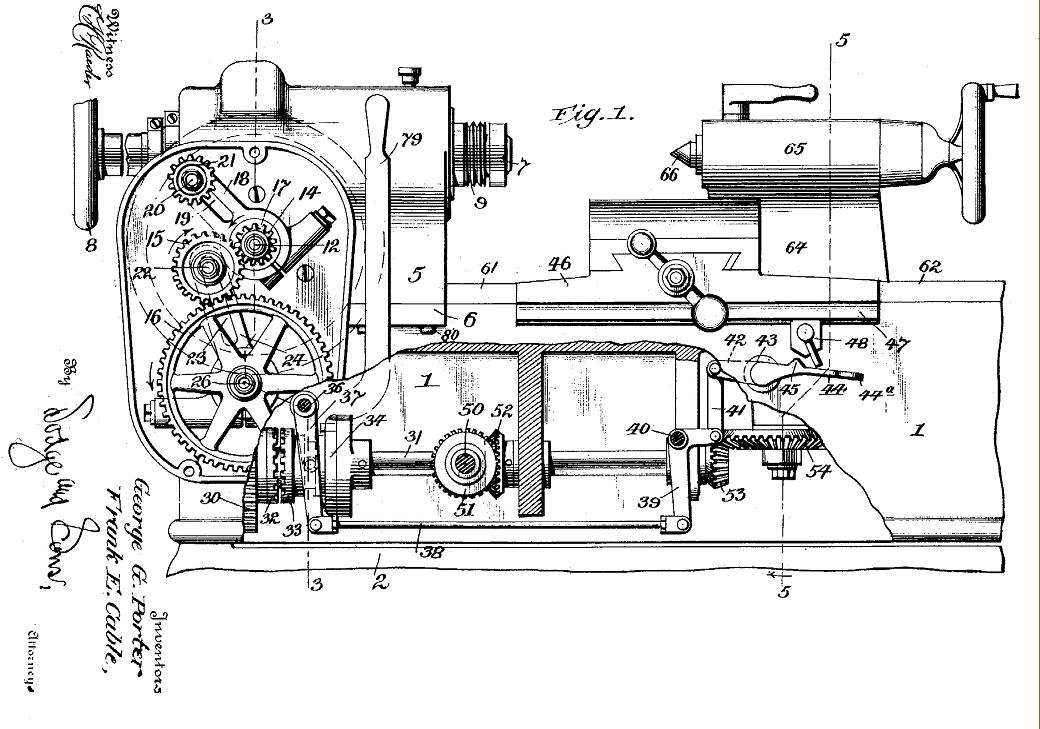

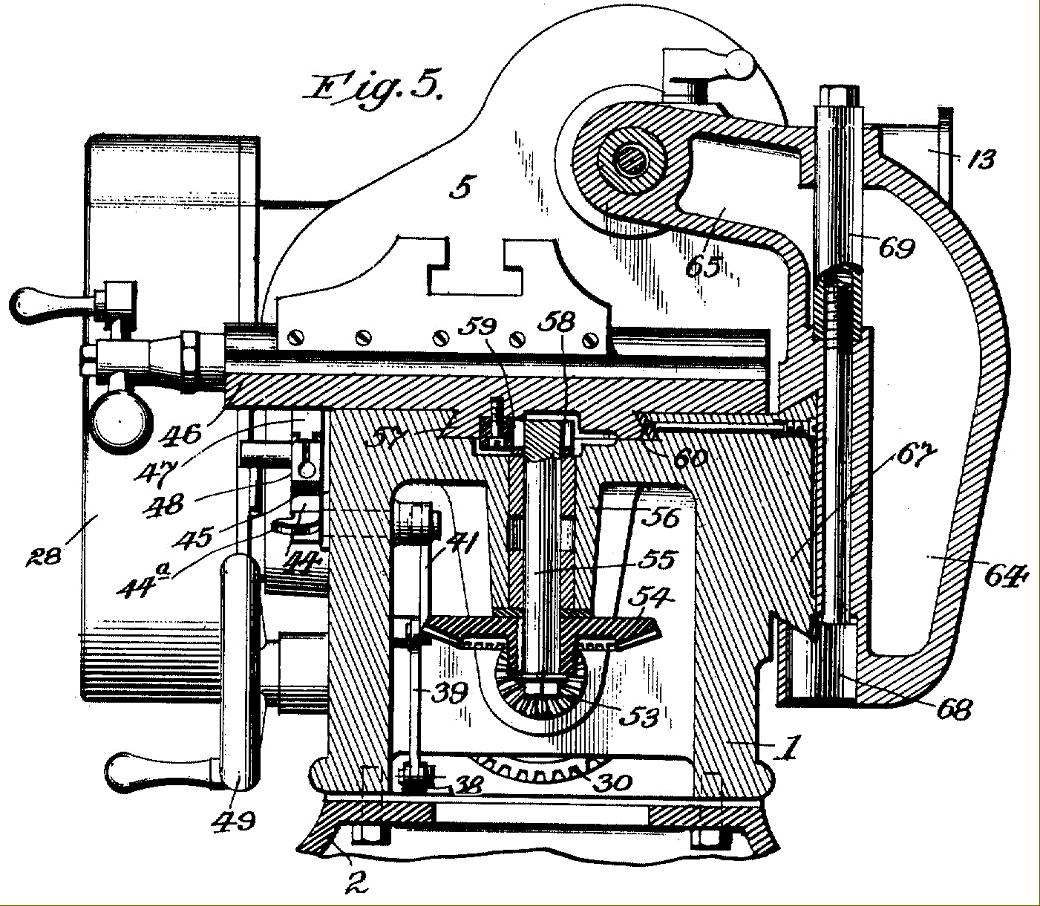

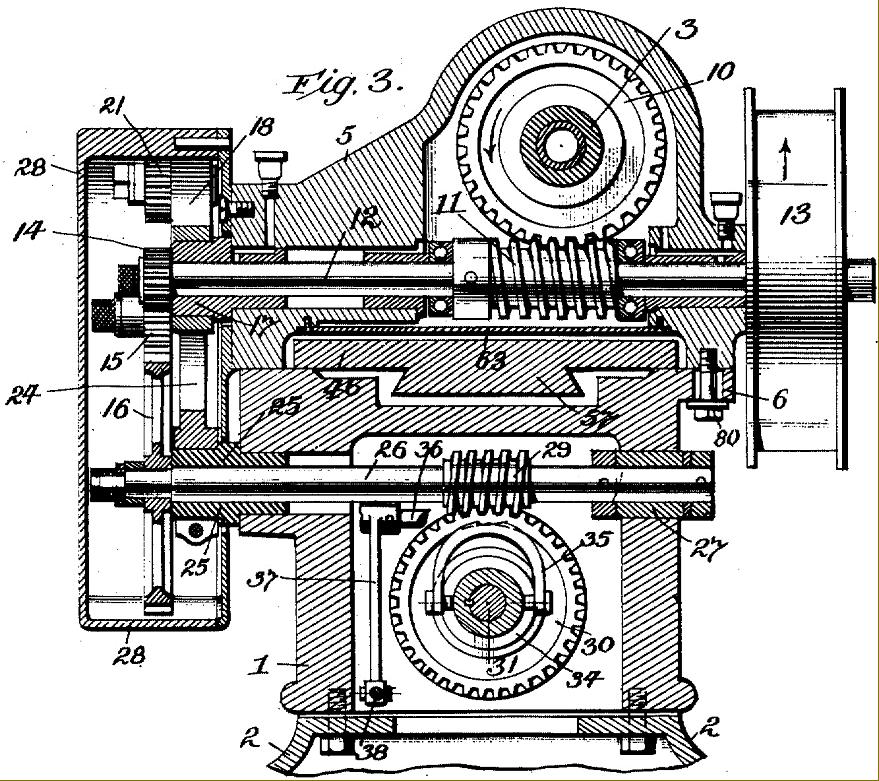

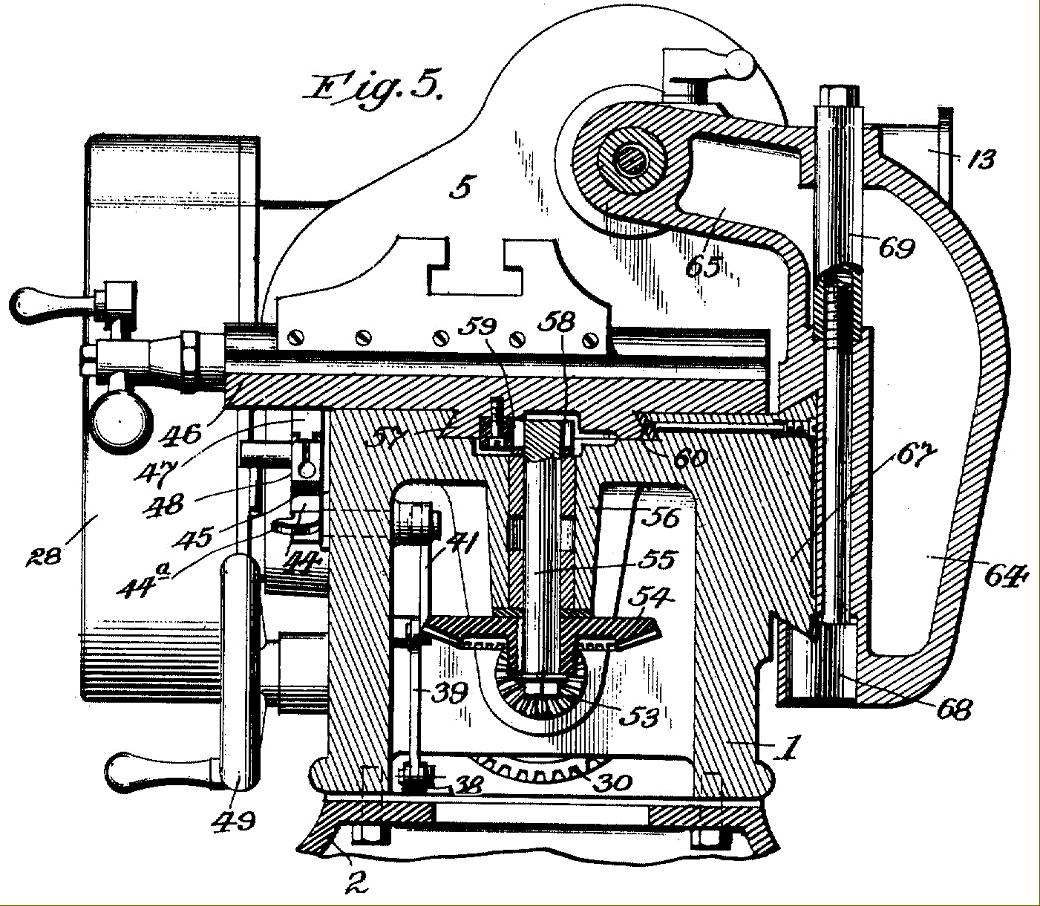

Section though the 1915 patent drawing showing the various drive arrangements. Parts 32 and 33 are the clutch for the horizontal drive shaft; parts 50, 51 and 52 are the bevel gears and shaft for hand movement of the carriage; parts 53 and 54 are the bevel gears that take the drive vertically to a rack-and-pinion drive that moves the carriage along the bed.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

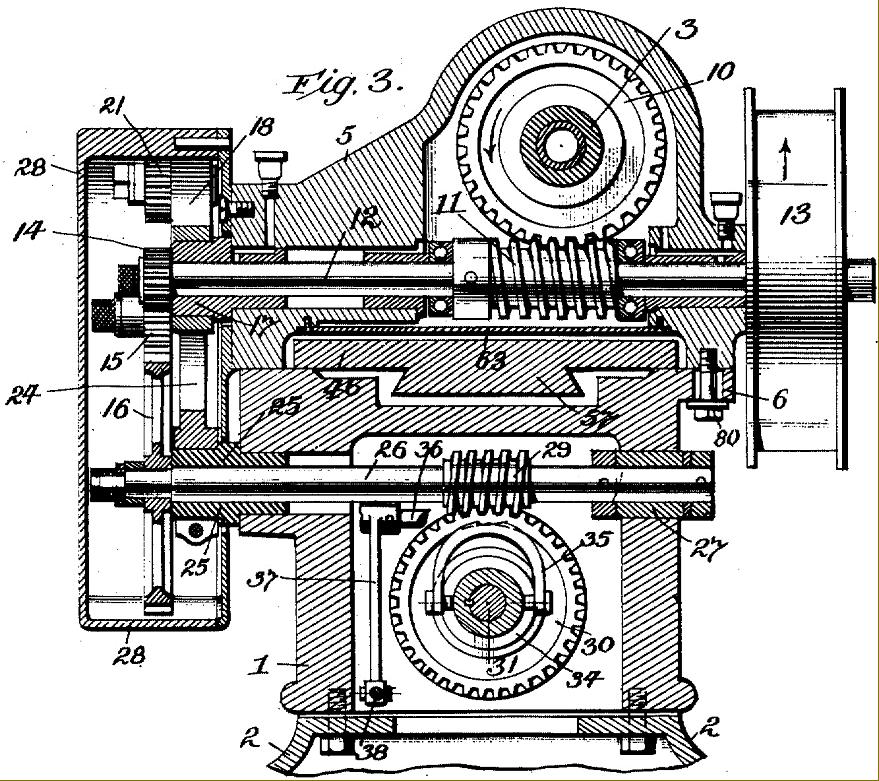

Section across the headstock and bed showing the input pulley (13) and upper transverse shaft (12) driving the headstock spindle (3) through worm-and wheel gearing 10 and 11). The lower transverse shaft (26) was also fitted with worm-and wheel gears (29 and 30) that turned a shaft running along the centre line of the bed to eventually drive the carriage.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

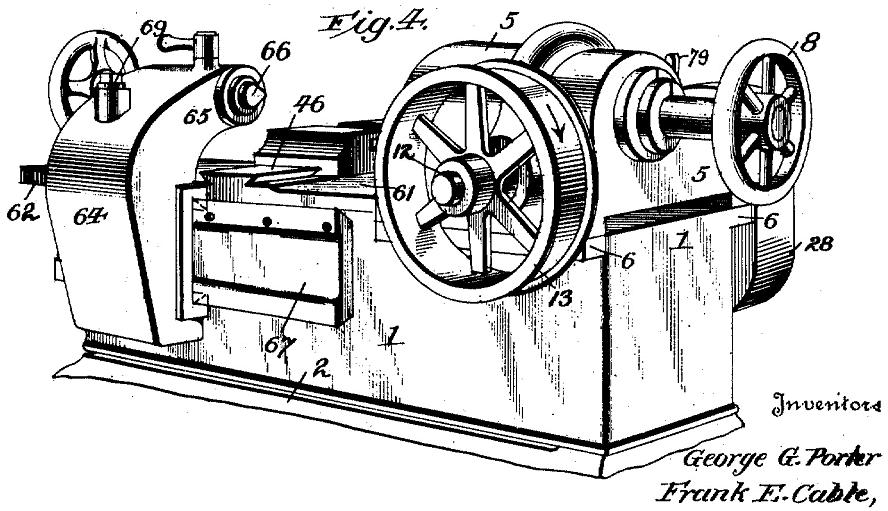

Section showing the vertical drive (55) to the rack-driven carriage and the tailstock 64) and its ways (67)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

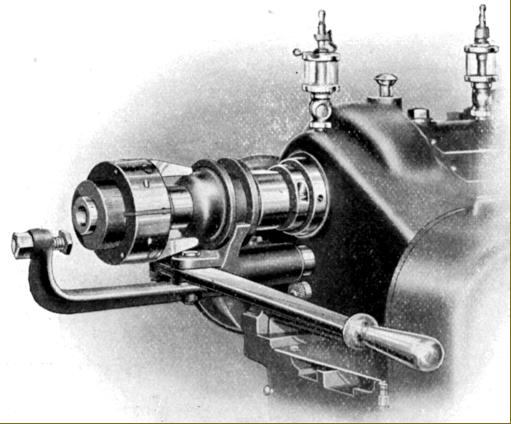

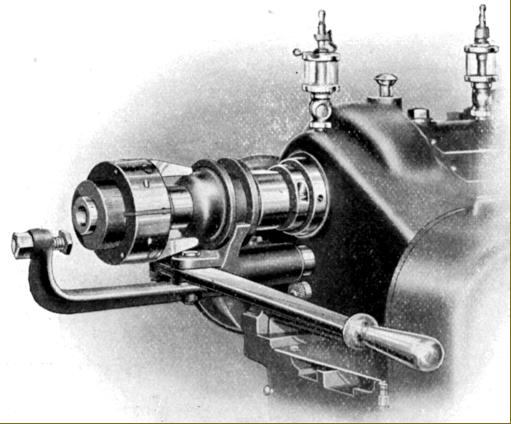

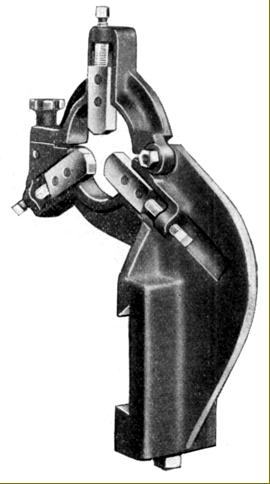

Lever-action collet closer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

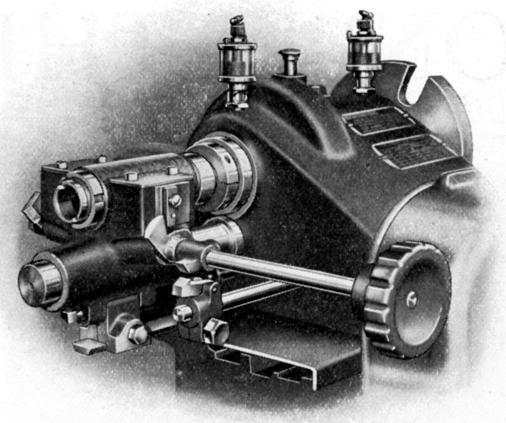

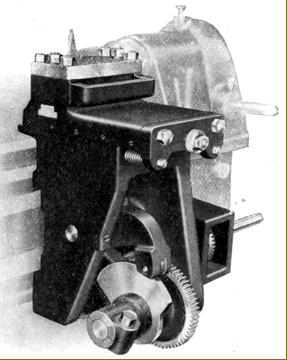

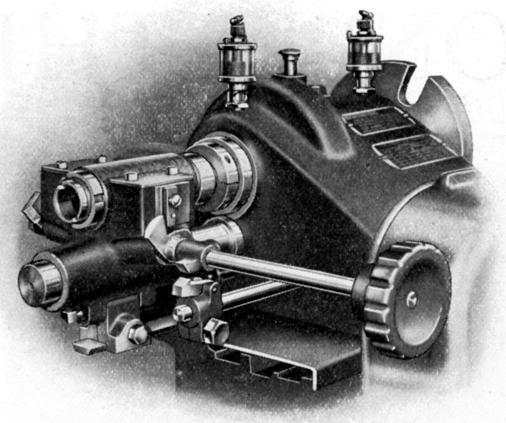

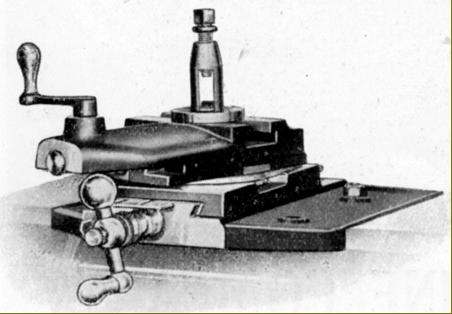

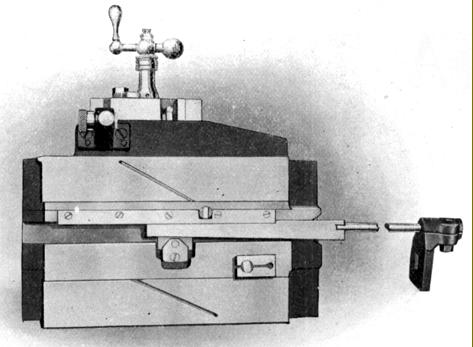

Carriage quick-return

attachment - powered by gravity

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

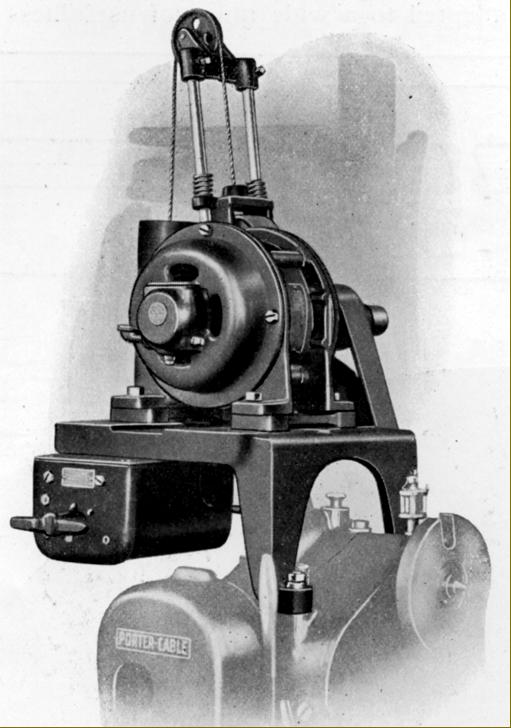

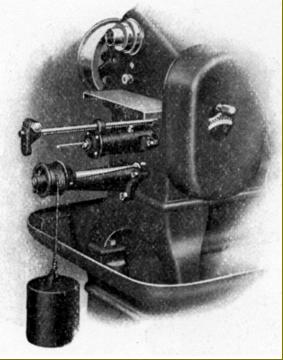

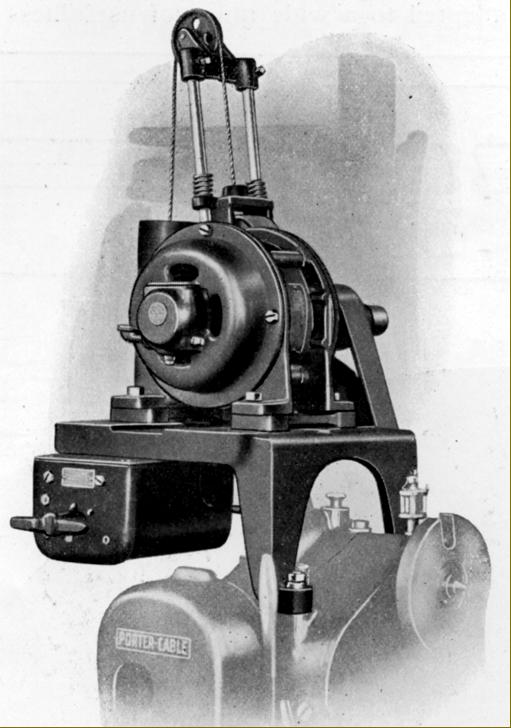

Motor and switchgear attachment with a

counterweight to tension the 2-inch wide drive belt

|

|

|

|

|

|

|

|

|

|

|

|

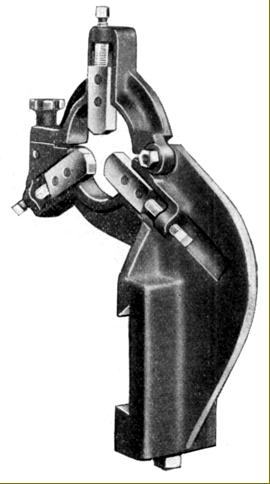

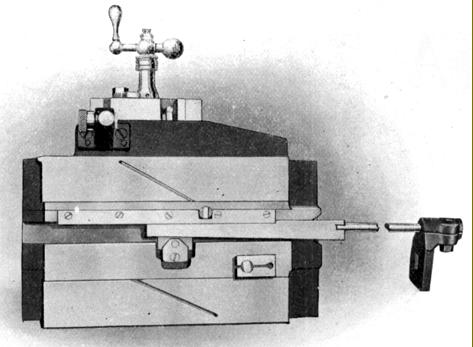

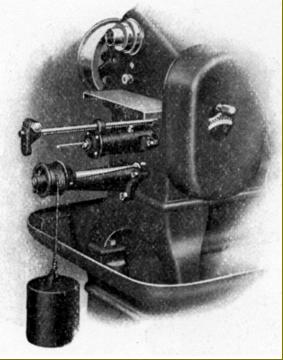

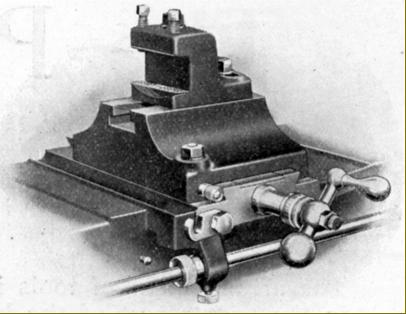

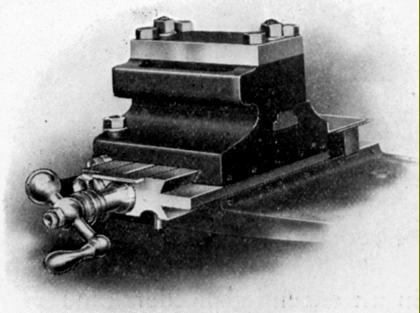

Power cross feed (facing) attachment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

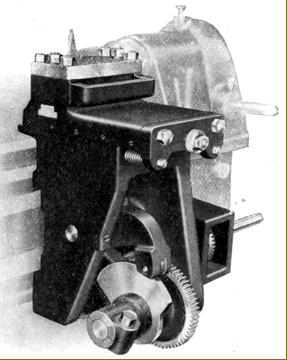

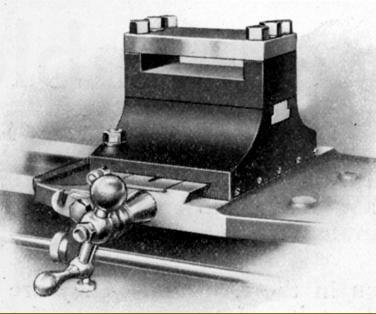

Fixed steady for mounting on the tailstock ways at the back of the bed

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

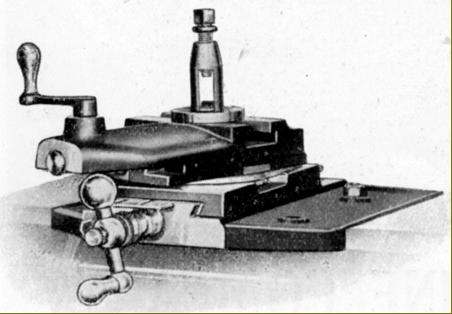

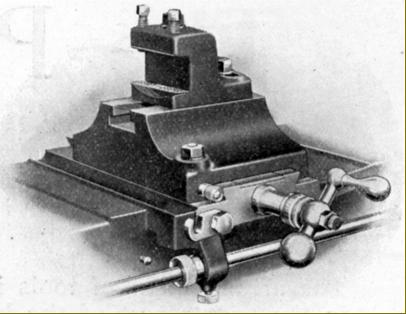

Open slide tool holder with rocker base

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

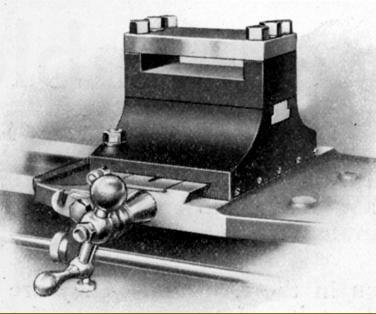

Gang tool holder closed type

|

|

|

|

|

|

|

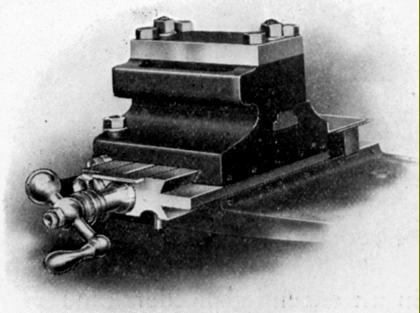

Gang tool holder open type

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

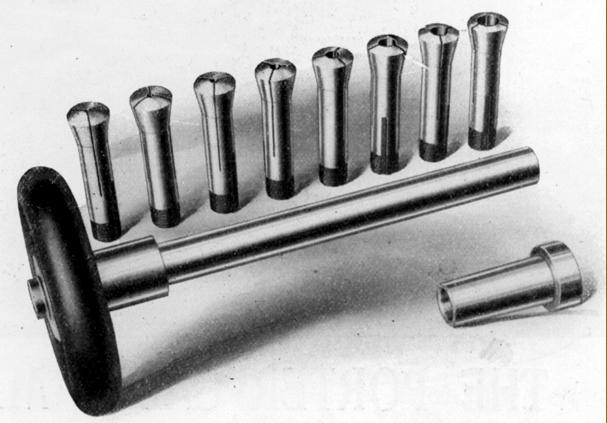

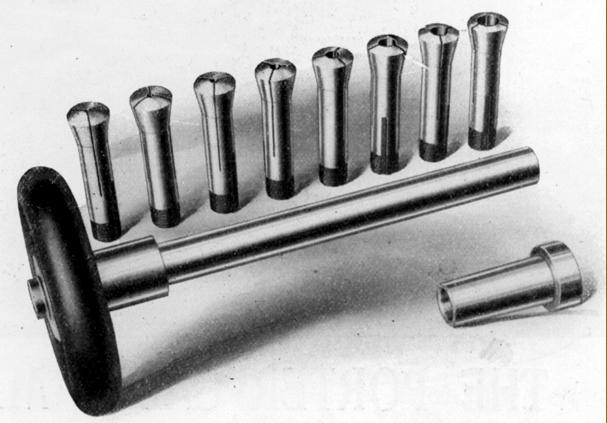

Standard wheel-operated collet set with nose-piece adapter

|

|

|

|

|

|

|

|

|

|

|

|

|

|

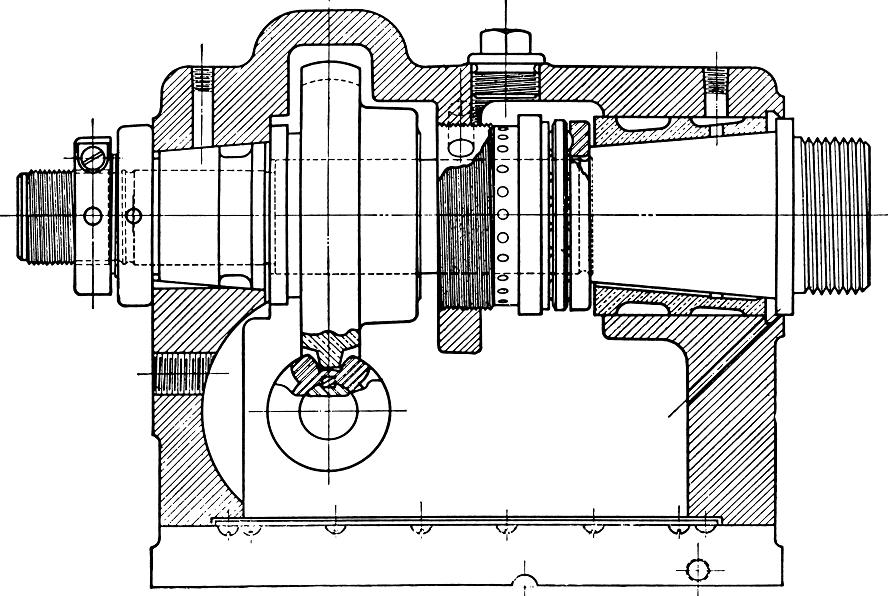

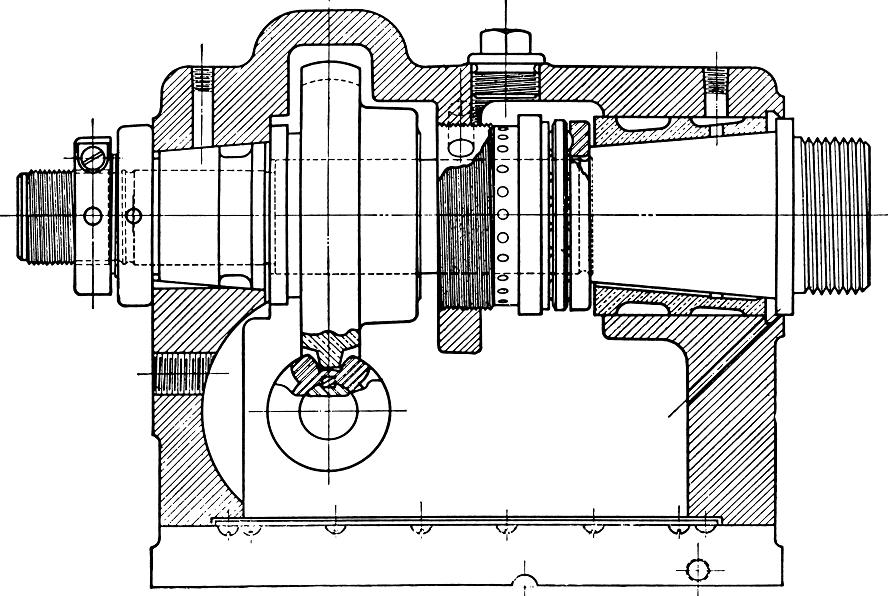

Section through the headstock of a late model plain-bearing 9-inch Rapid Production Lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|