|

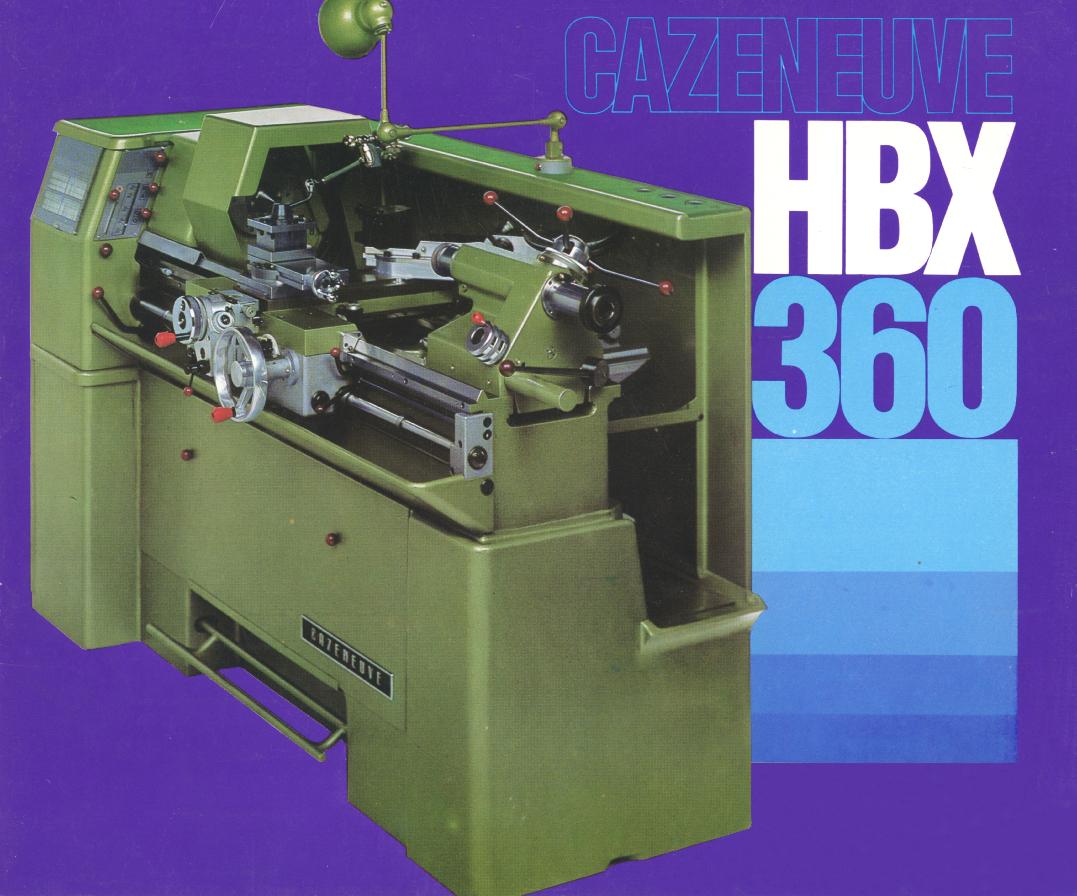

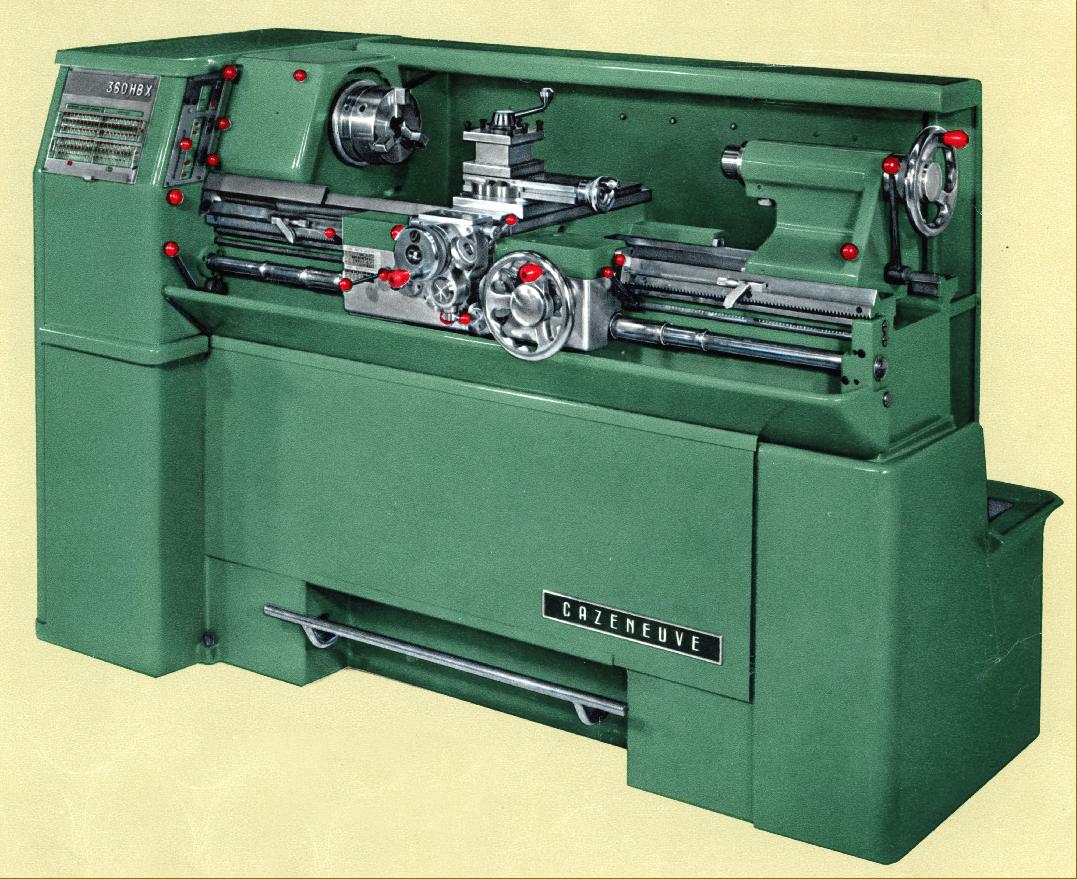

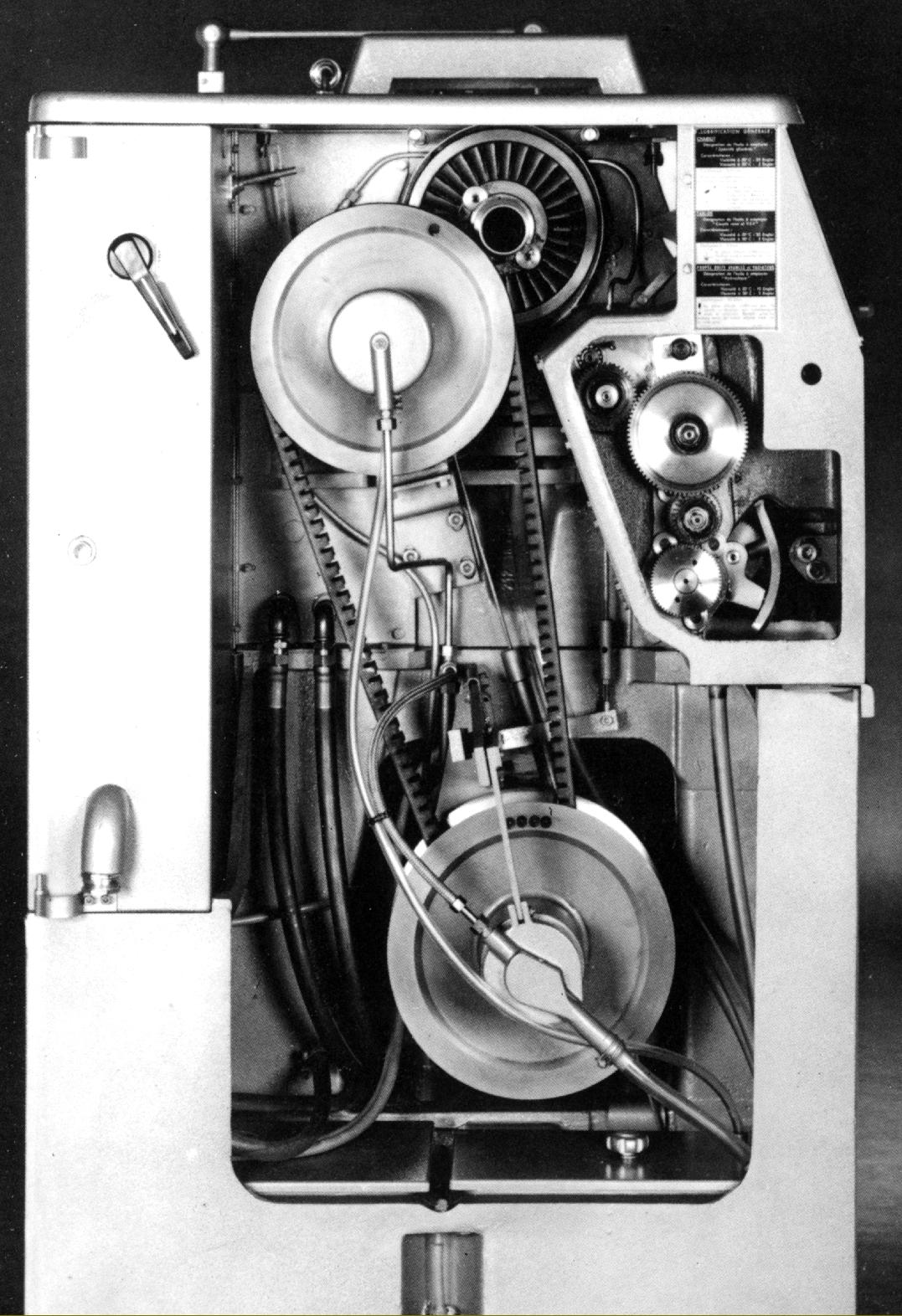

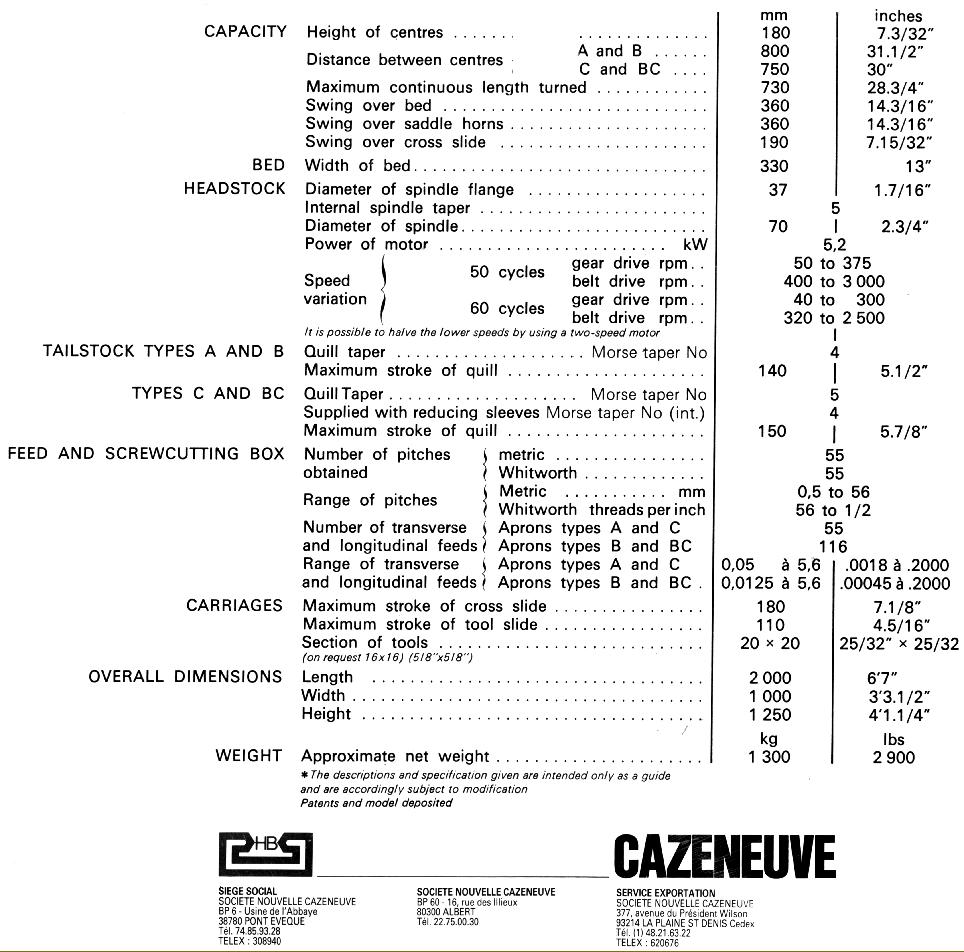

Manufactured from 1966 until 2006, the Cazeneuve HBX lathe was a heavy (2900/1316 kg) toolroom machine of impeccable quality if rather unusual and complex design. With a swing of 14 inches (360 mm) over the bed and 7.15 inches (190 mm) over the cross slide, it admitted 30 inch between centres and was powered by a 7.5 h.p. (5.2 kW) 1450 r.p.m. 3-phase motor. Able to run from 50 to 3000 rpm, the spindle speed was continuously variable and, very helpfully, could be pre-set to give an almost instant change of rate. The drive was mechanical, using expanding and contracting pulleys but with control by a clever (and patented) hydraulic system. Known to leak hydraulic fluid, by the time the last versions were in production the hydraulic- mechanical drive had been dropped and, like many other machine tools, equipped with drive by a VFD (inverter-controlled) motor.

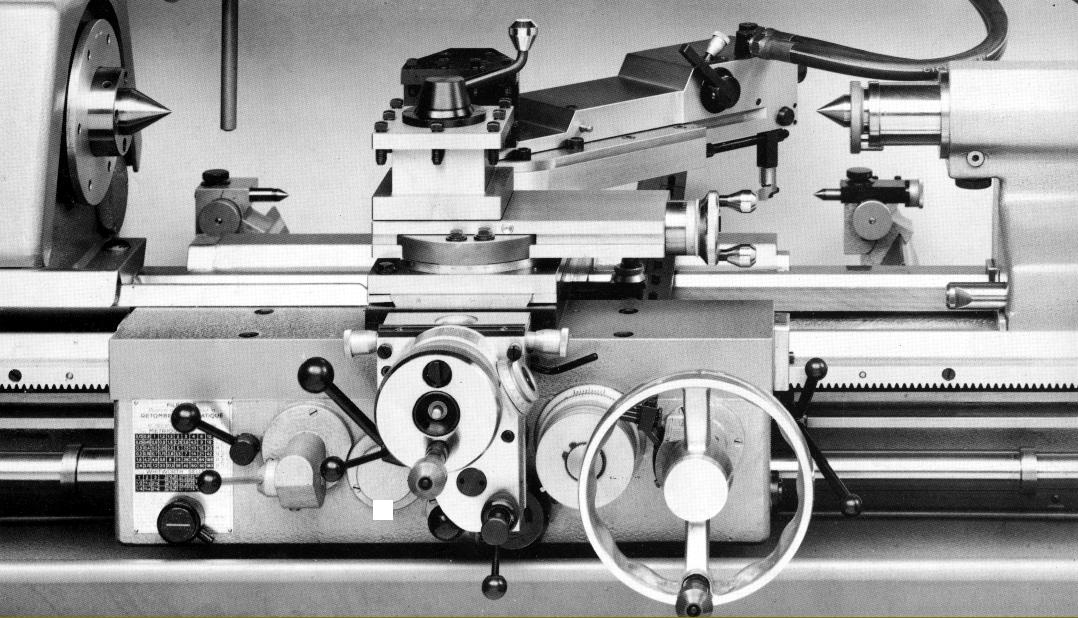

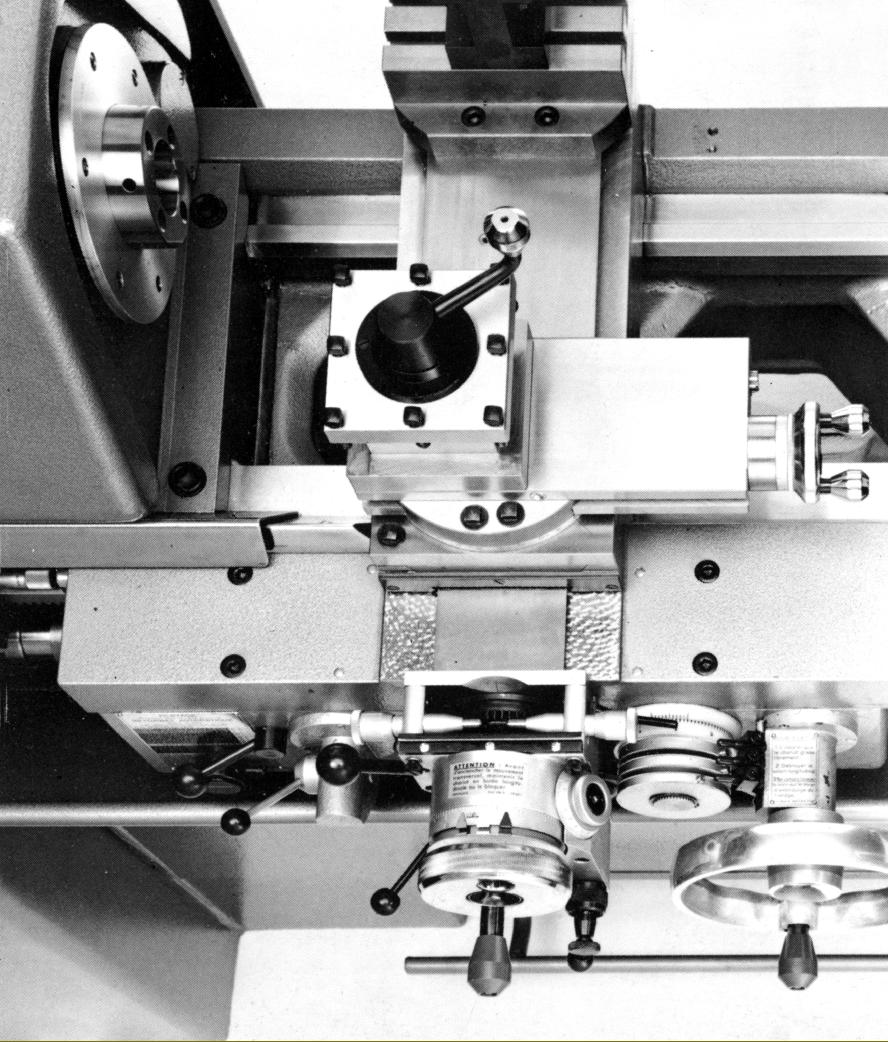

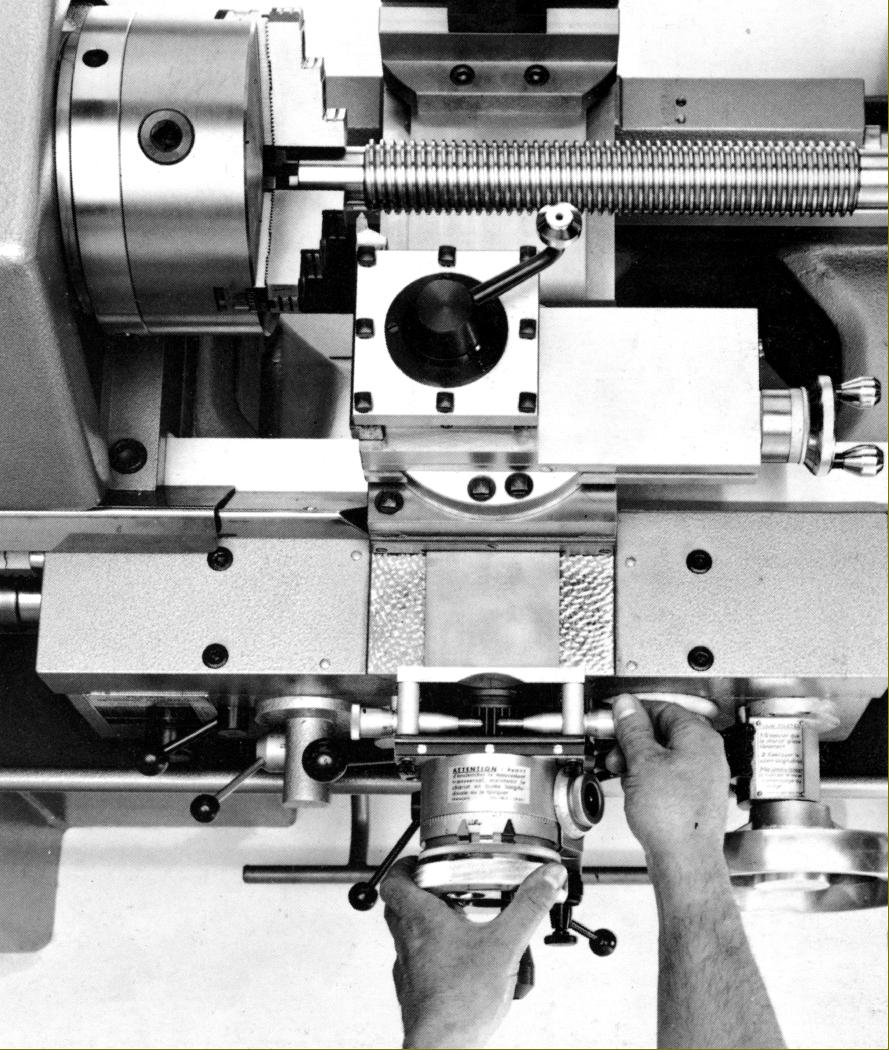

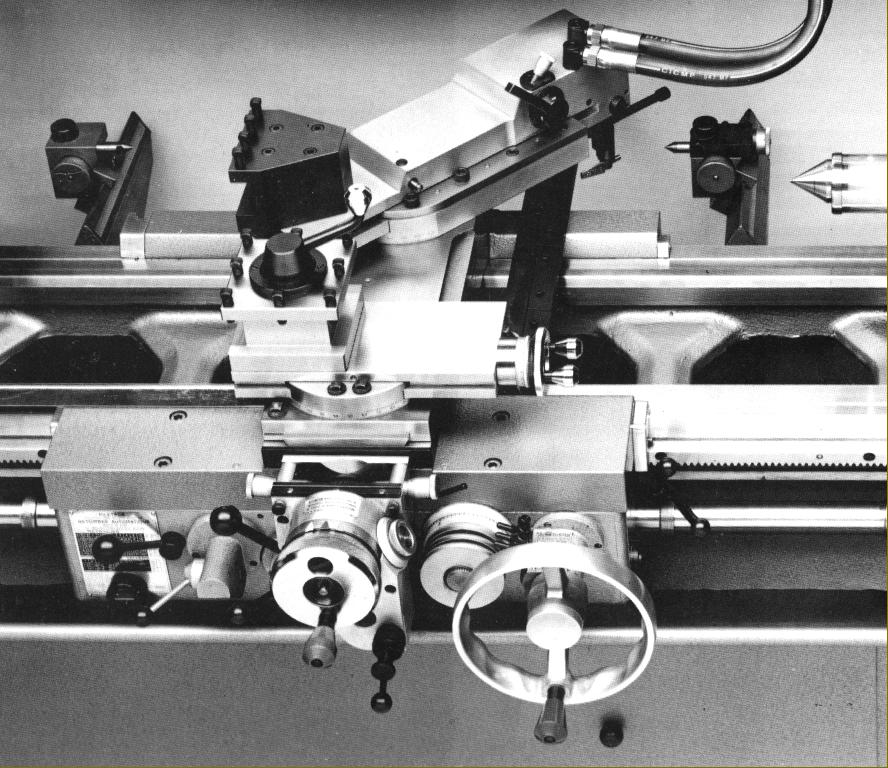

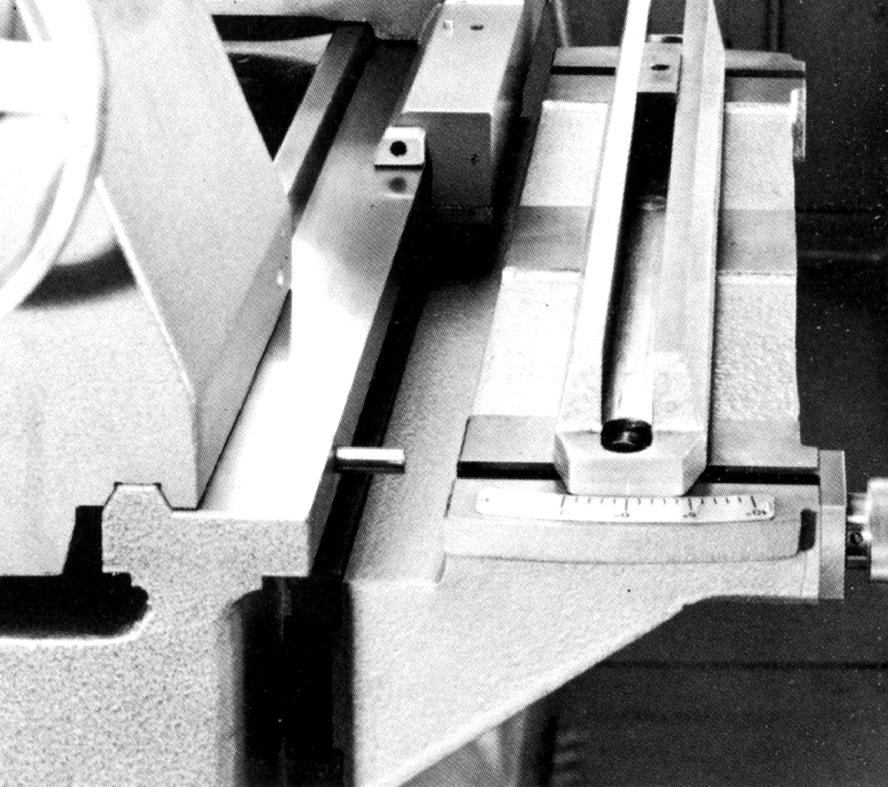

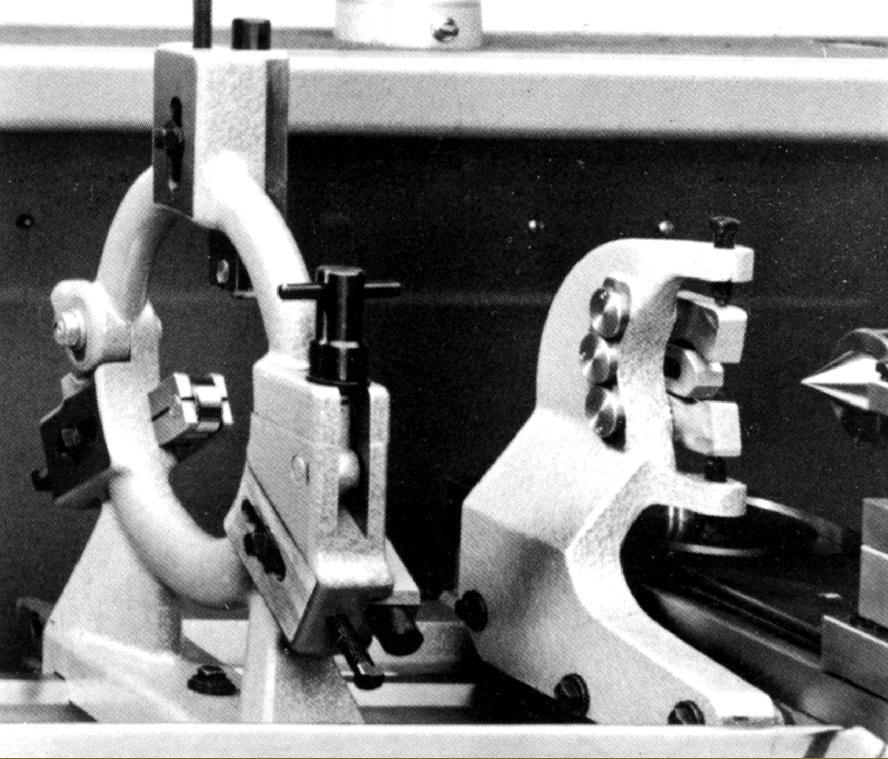

Amongst the unusual features - designed to help the operator get the best from the lathe - were a variable speed control that could be actuated with a flick of the wrist, a spindle stop/brake operated by a foot pedal and, at extra-cost in place of a conventional tailstock, a most unconventional type without a spindle but with a "quill" able to be used in three different ways: with a permanently-fitted capstan handwheel for rapid feeds, by small handwheel for finely-controlled slow feeds or, linked to the carriage by a bar, with the quill moving at one-half the rate of the carriage sliding speed A novel fitting was a screw under the front of the quill that, when engaged, moved the quill out of line so that tapers could be machined..

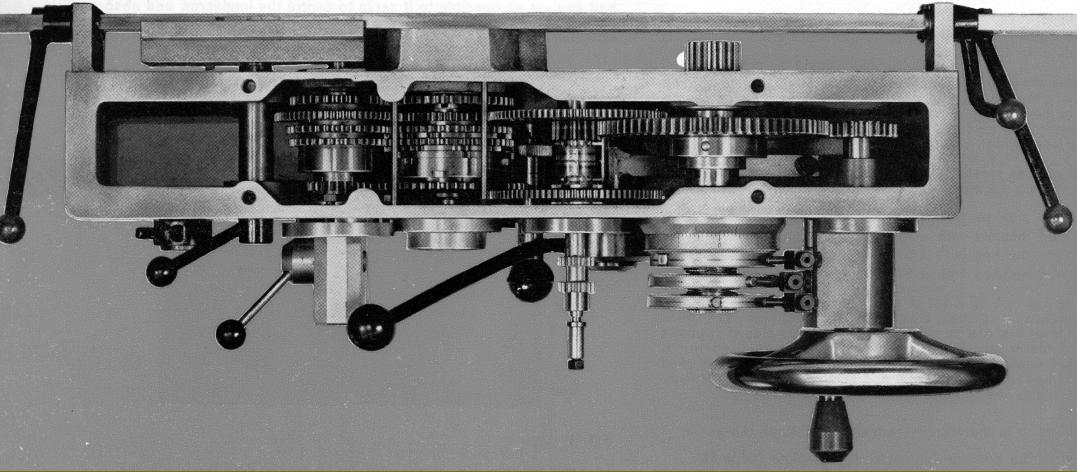

Complex in design, the apron was equipped with a mechanism that automatically disengaged both turning and screwcutting feeds while also having provision (by an ingenious system of gearing) to automatically pick-up metric or Whitworth pitches - the system allowing the use of carbide tools for threading at very high speeds. In addition there were three independent and "skippable" pre-set stop rings that, on the longitudinal feed only, gave rough, semi-finish and finishing stops for external turning, threading length internally or externally and boring. For power cross feed, two micrometer disengage stops were provided that made light work of very accurate grooving depth, threading height and shoulder height, etc.

One important refinement found on all generations and types of HBX was lubrication of the apron and leadscrew by an oil bath. The leadscrew was held inside telescopic tubes whose seals were not, unfortunately a standard part and today cost around €180 for the six special seals, two paper seals, one flat rubber seal and one small lip seal.

Early versions of the lathe were painted green and mounted on massive and rigid cast-iron base, this being changed at some point to one made as a welded fabrication when the lathes were painted grey and blue. There were at least two different generations of HBX lathes with each divided into three or four different models:

1st Generation:

HBX 360 A: standard apron with a limited range of metric pitches with automatic thread pick-up and a conventional tailstock

HBX 360 B: special apron with an extended range of both metric and English pitches and a conventional tailstock

HBX 360 C: a standard apron with a limited range of metric pitches (as Type A) and the special "sensitive and automatic tailstock"

HBX 360 BC: apron as Type B and a tailstock as Type C

2nd Generation:

HBX 360 A: standard apron with a limited range of metric pitches with automatic thread pick-up and a conventional tailstock

HBX 360 BC: special apron with an extended range of metric and English pitches and the special "sensitive and automatic tailstock"

HBX 360 I: same as A version with the hydraulically-actuated variable spindle-speed system changed to a simpler and cheaper one that used an electric motor - but still with the final drive by expanding and contracting pulleys. This version of the HBX had been developed to appeal to schools and technical training institutes and also had, as one might expect, a number of improved safety features.

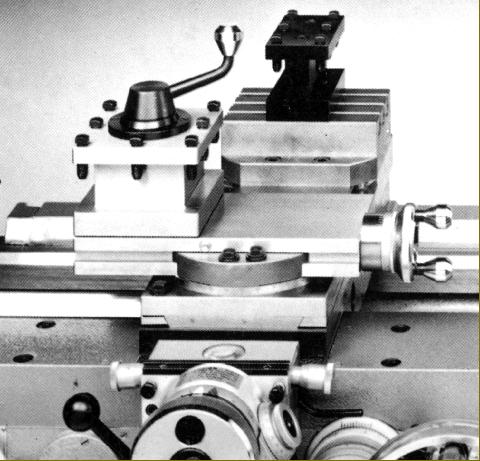

Listed as being supplied with lathes made during the 1970s (other decades may have varied) the lathe came equipped with: a precision 4-way toolpost; a fixed steady with roller-equipped fingers; 4 carriage stops for the longitudinal feed (one on the bed and the other three of the quickly-adjustable and retractable type on the apron); two micrometer-equipped and retractable stops for the cross feed; coolant system; chuck guard; a rear splash back; 2 Morse taper centres; a set of spanners and an oil gun.

Items on the options' list included a hydraulic copying attachment, taper turning, 3 and 4 jaw chuck, a faceplate-cum-4-jaw chuck, a "precision" toolroom-type drilled and tapped faceplate, travelling steady, rotating tailstock centre, 24-volt lighting system, a T-slotted platform to the rear of the cross slide and a rear toolpost.

Photographs of an HBX360 here - should any reader be able to provide addition ones, the writer would be pleased to hear from you

|

|