|

Better known in the decades spanning the late 18th and early 20th centuries for their extensive range of blacksmith equipment, the Blower & Forge Company of Lancaster, PA, also dipped their toe into the manufacture of lathes by producing, in the 1930s, a number of entirely conventional backgeared and screwcutting types. Today they are rare, with (in October 2013) just five 9-inch, two 10-inch and one 13-inch - but no 16-inch versions known to have survived. Should any reader have a Blower & Forge lathe the writer would be interested to see photographs.

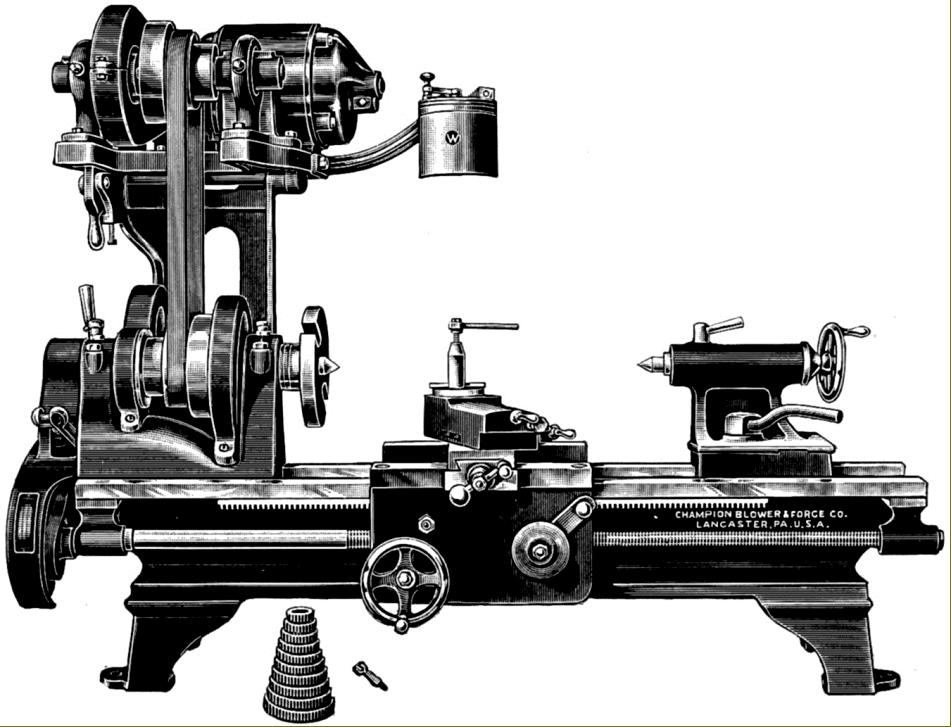

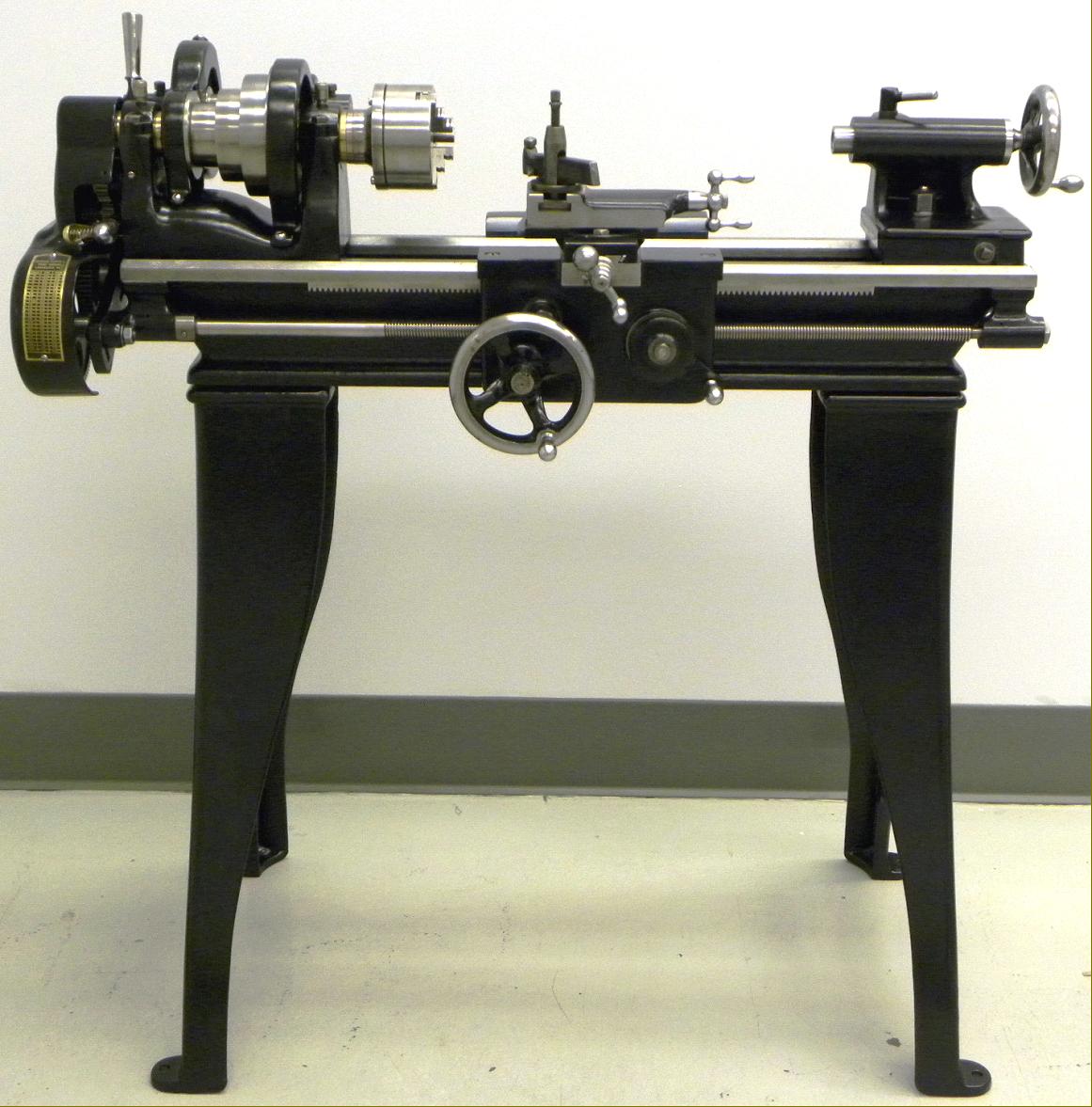

Smallest in the company's very limited range was the 9-inch swing Model 9L with, as part of its standard specification: backgear, tumble-reverse, heavy cast-iron guards over the gears and the option of a neat, built-on motor-countershaft unit complete with reversing electrical switchgear. Unsurprisingly, the 9L resembled other contemporary models of the same size (though its appearance was rather out-of-date) notably the popular South Bend and Dalton (examples of these must have been to hand when the designer set to work).

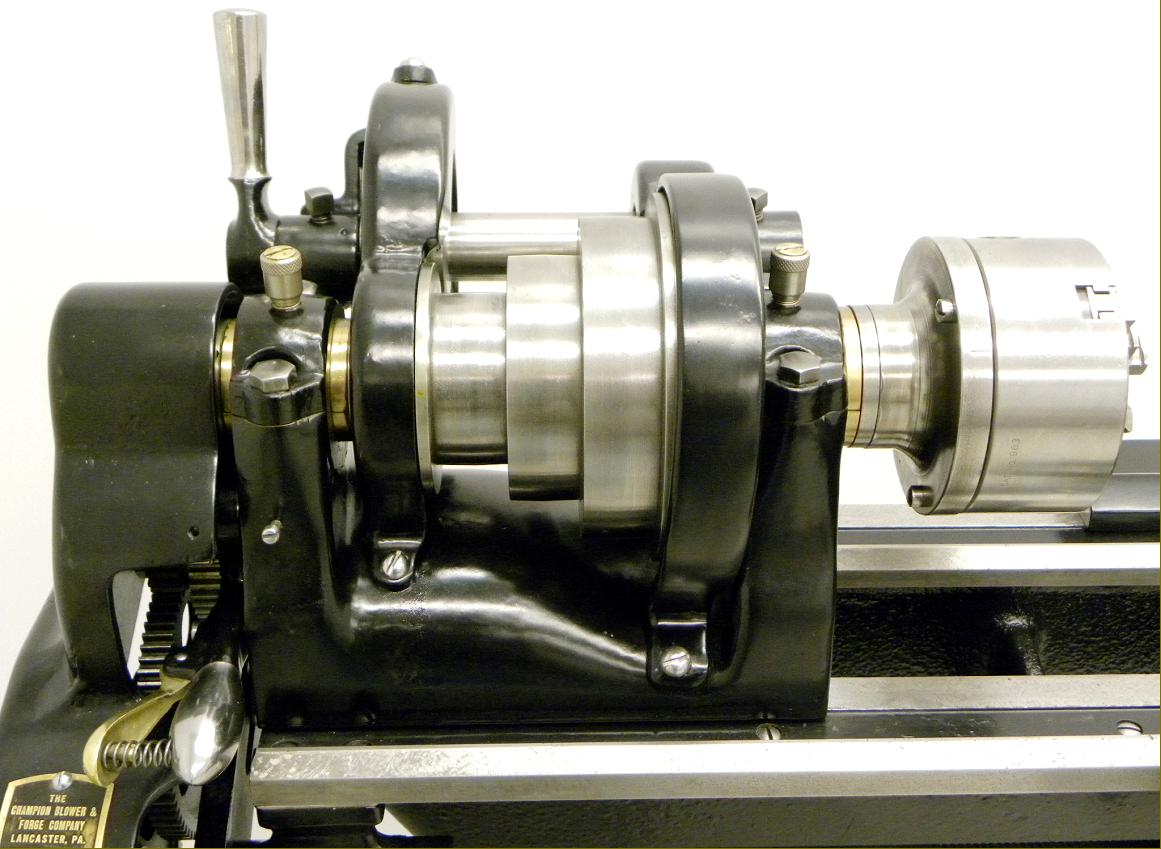

Of a decent width, the straight bed (either 3 or 4-feet long and giving 18" and 29" between centres respectively) was well cross-braced with integral feet and separate pairs of V and flat ways to guide the carriage and tailstock. The headstock was pure South Bend, with simple, cap-type phosphor bronze bearings lubricated through top-feed oilers and hand scraped to match the 3/4-inch bore, ground-finish 60-point carbon crucible steel spindle with its 1.5-inch, 8 t.p.i. No. 2 Morse taper nose. However, all known earlier examples were fitted with a rather less convenient specification, the rather fine-pitch 17/16" x 12 t.p.i. spindle nose no doubt causing some practical problems in service and being difficult to unscrew unless not over-tightened and kept clean and oiled.

Closely resembling that used on the South Bend "Junior" model of the mid 1920s, the apron was of the single-side type - and entirely adequate for its purpose - with reduction gearing between the full-circle carriage handwheel and bed rack. Oddly, the leadscrew-bearing hanger brackets and tailstock were styled to look like those on a Dalton of the 1920s - yet the saddle and compound slide (with its usual-for-the period, far-too-small micrometer dials) appear unique to the machine. When set at an angle the top slide overhung the rather narrow cross slide, with the feed-screws handwheels (ordinary 60-degree V-threads were used, not Acme) also looking rather Dalton-like.

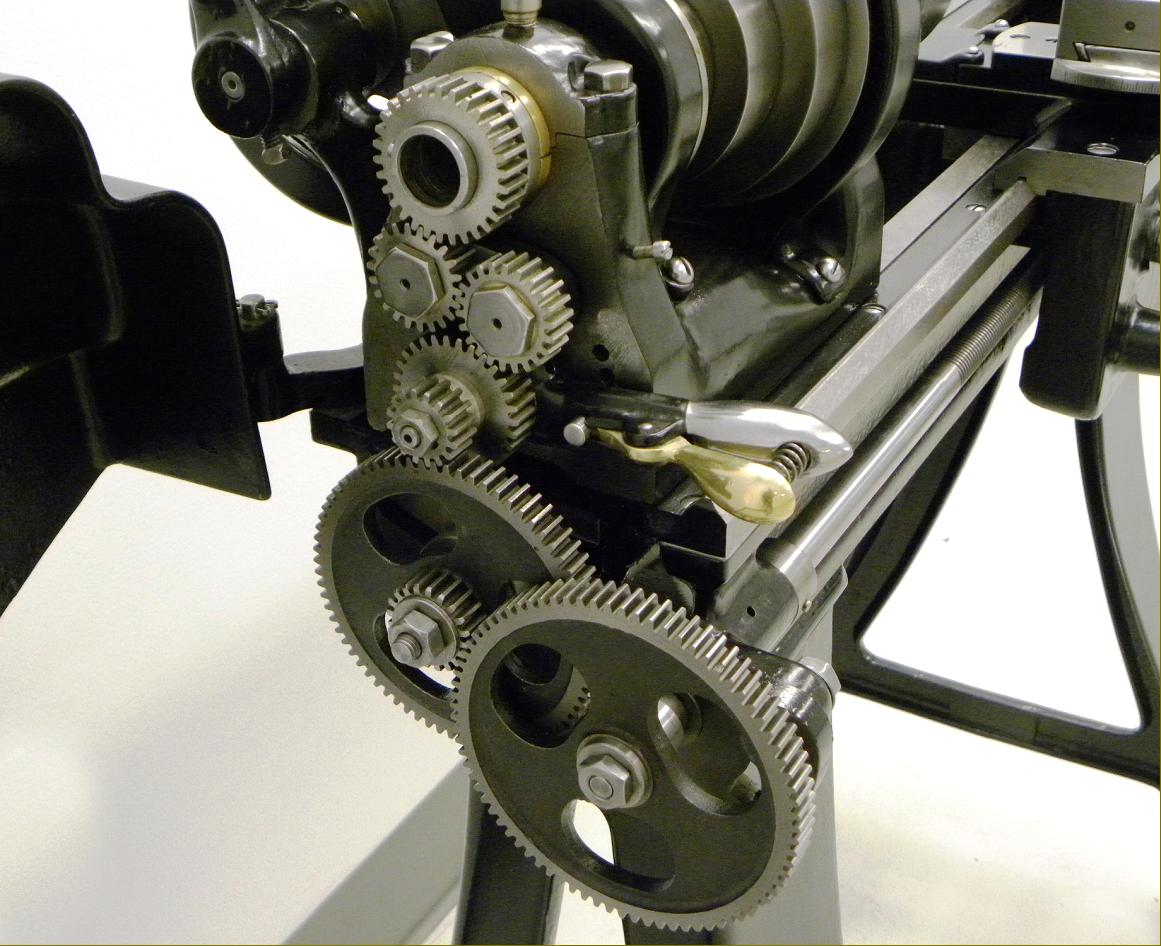

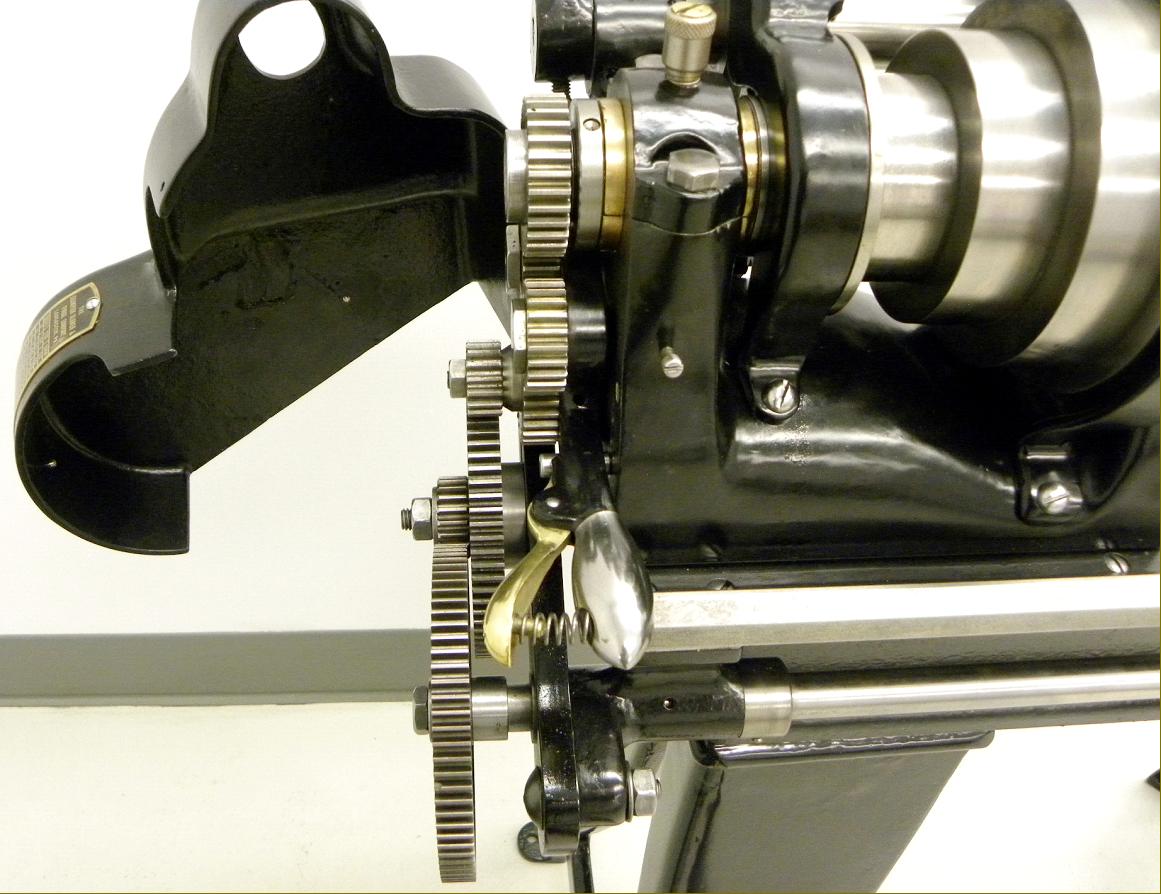

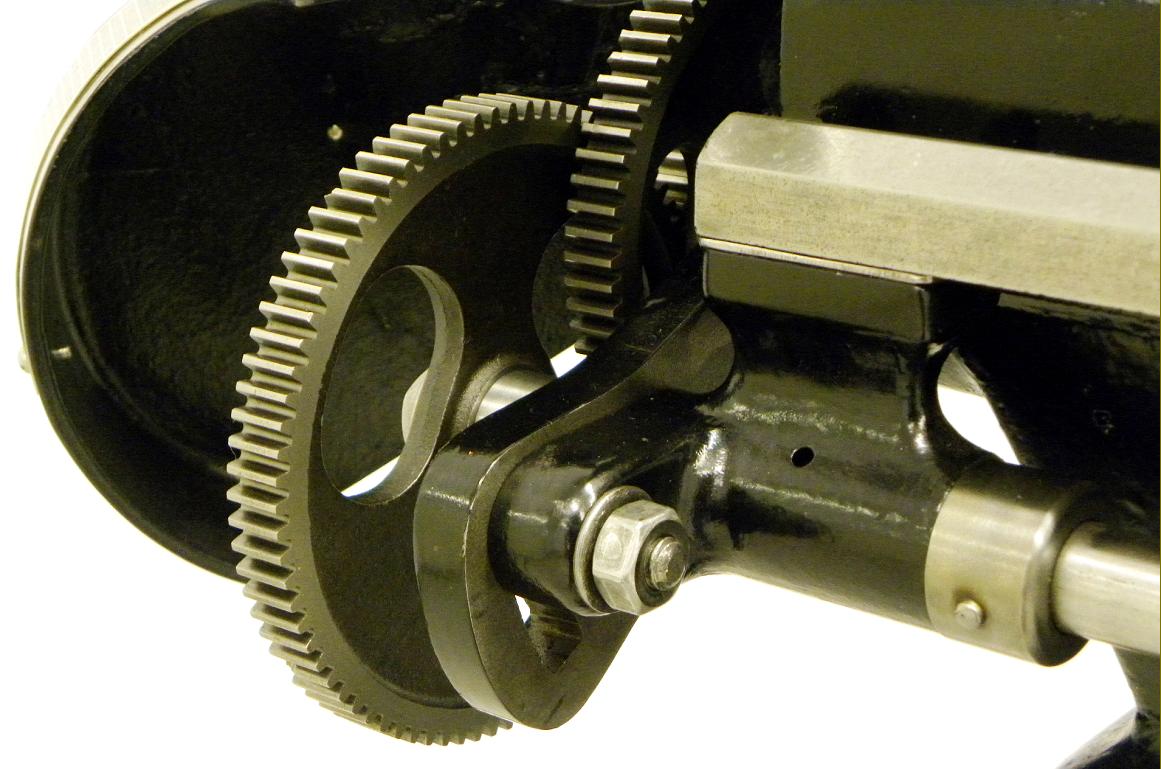

Screwcutting was by changewheels (of which a set of seventeen may have been supplied) the drive passing through a tumble-reverse assembly with the threading range extending from 4 to 40 t.p.i. Instead of being bolted in position - as on so many cheaper lathes - the tumble reverse on the Blower Forge used a quick-change mechanism with a spring-assisted bronze trigger.

Using simple but effective self-aligning plain bearings, the maker's standard countershaft for wall or ceiling mounting was equipped to carry a striking mechanism to shift the 1-inch wide belt from fast to loose pulley. A 3-step headstock pulley (25/8", 33/4" and 47/8") was used that gave speeds, with a 340 r.p.m. countershaft, from 35 through 65, 115 in backgear and 185, 340 to 635 r.p.m. in open drive. However, the previously mentioned complex, built-on countershaft (with V-belt drive from the ¼-h.p. motor) was a unit that could hardly have recovered its investments costs if the very limited number of surviving 9-inch models - four to date - is any guide.

Holding a hard crucible steel No. 2 Morse taper spindle, the tailstock could be set over to turn slight tapers; unfortunately the nut that locked it to the bed had to be tightened with a loose spanner, the nature of which guaranteed it the mystical power of being self-hiding.

From a recent examination of an original 9L, it is apparent that the only flat surfaces subjected to hand finishing were those of the bed, all the others showing tool marks caused by the use of either a planing or shaping machine. Backed by the considerable resources of Blower Forge it seems surprising that the 9L did not become better known - though the market for light workshop lathes was very competitive and required mass-production of the Atlas kind to be profitable. Even Dalton, with their specialised skill and experience, struggled to make money. An example of the 9L lathe is currently undergoing restoration by the leading US restorer of antique machinery, Dennis Turk, and pictures can be expected in the not too distant future.

10-inch Champion Blower Forge lathe

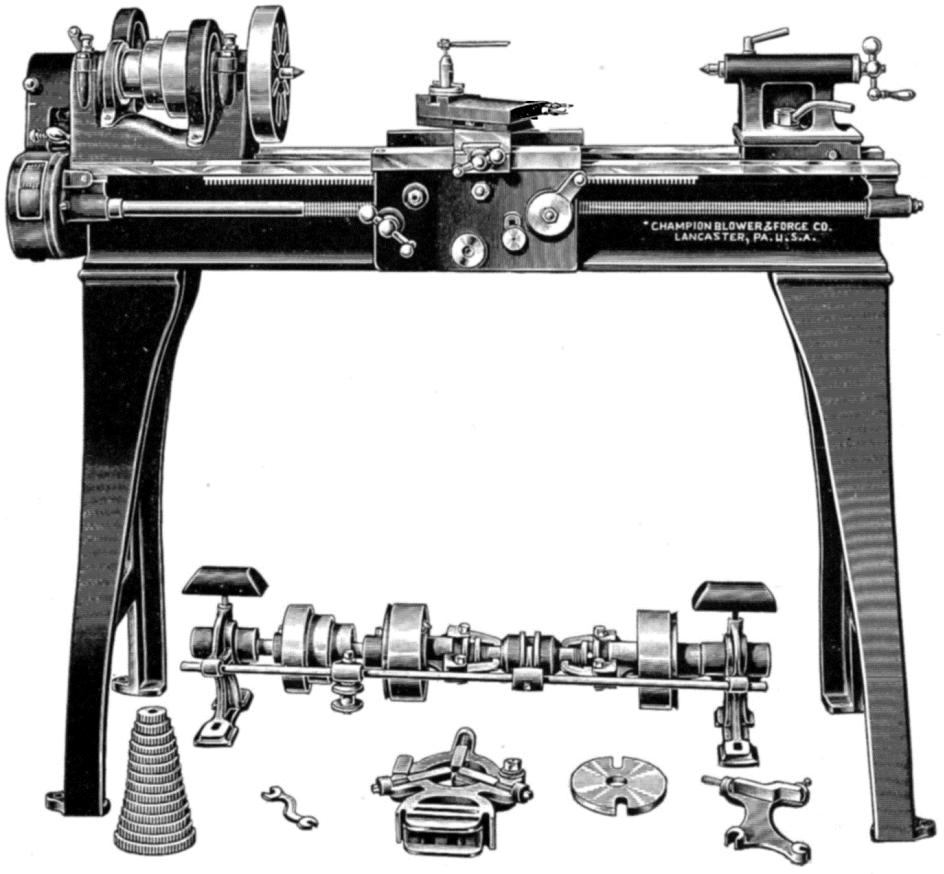

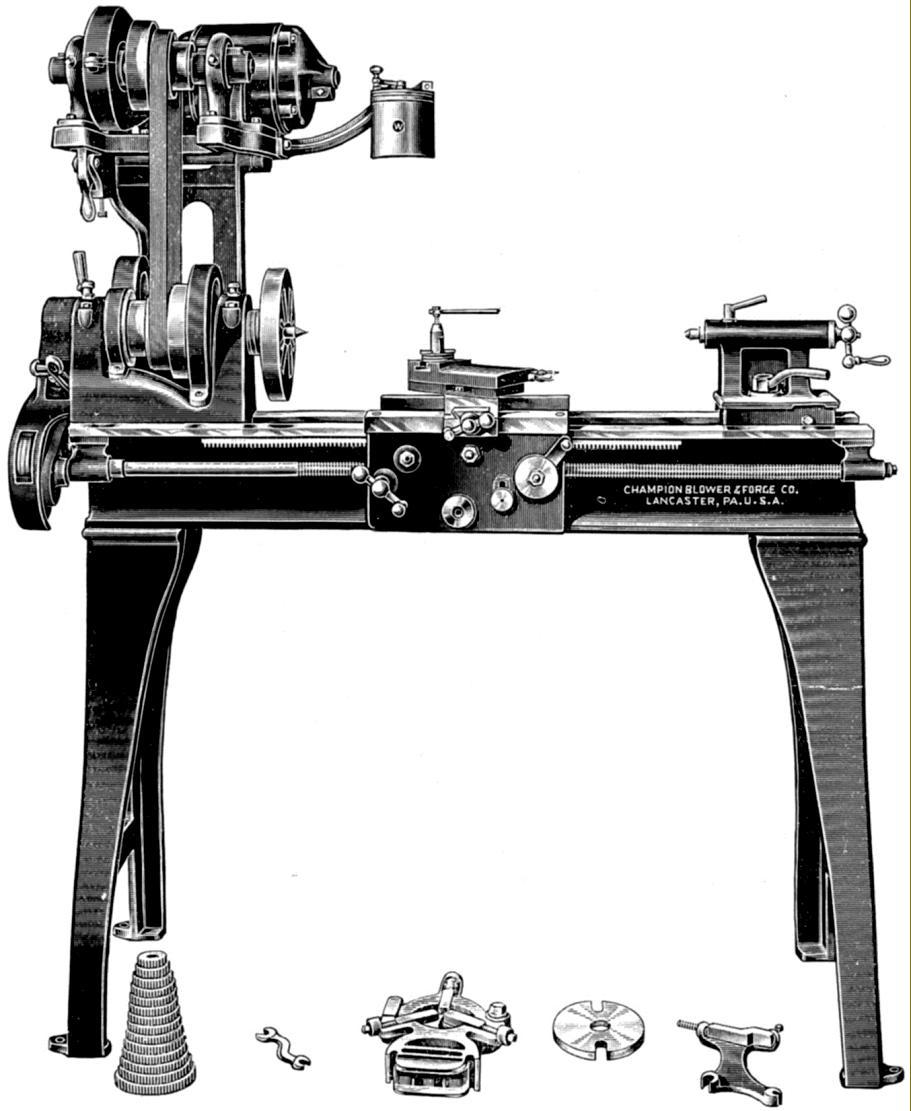

Whilst it might have been confidently expected that the next lathe in the range, a 10-inch, would have been a 9-inch with headstock and tailstock castings "built up in the sand", this was not the case. Although it followed a similar general design, it was an entirely different model and intended as a simple but efficient machine able to tackle the usual jobs encountered by a garage or general repair shop.

With three V-ways and one flat, the bed (offered as 4 or 5-feet long) was crossed braced and carried a 10.5-inch long headstock holding a 7/8-inch bore, ground-finish 60-point carbon crucible steel spindle (with a 17/16" x 12 t.p.i. No. 2 Morse taper nose) running in simple, cap-type phosphor bronze bearings lubricated through top-feed oilers.

A 3-step headstock pulley was fitted (with diameters of 33/16", 45/16" and 57/16") to take 1 ¼" belt driven from either a wall/ceiling countershaft or a built-on motor-countershaft unit that was identical (apart from pulley diameters) to that used on the 9-inch model. With no option offered of a gearbox, screwcutting was by changewheels, the drive passing through a tumble-reverse assembly with the threading range extending from 4 to 40 t.p.i.

Apron design is uncertain but, as it held the mechanism necessary to drive power cross-feed gearing, may well have been of the doubled-walled type. Feeds were selected by a push-pull knob and engaged by a 2-position (in-and-out) quadrant lever.

Oddly, the lathe could be specified with either just a cross-slide (to plain specification) or with a proper compound rest, the swivelling top slide carrying degree divisions (Champion were, incidentally, one of those makers who, mistakenly, used the term compound to describe the top slide. Other, more experienced makers (including Rivett, with a very long history of lathe manufacture, always used compound to mean the complete top and cross assembly as in: to compound a pair as one).

13 and 16-inch Champion Blower Forge lathes

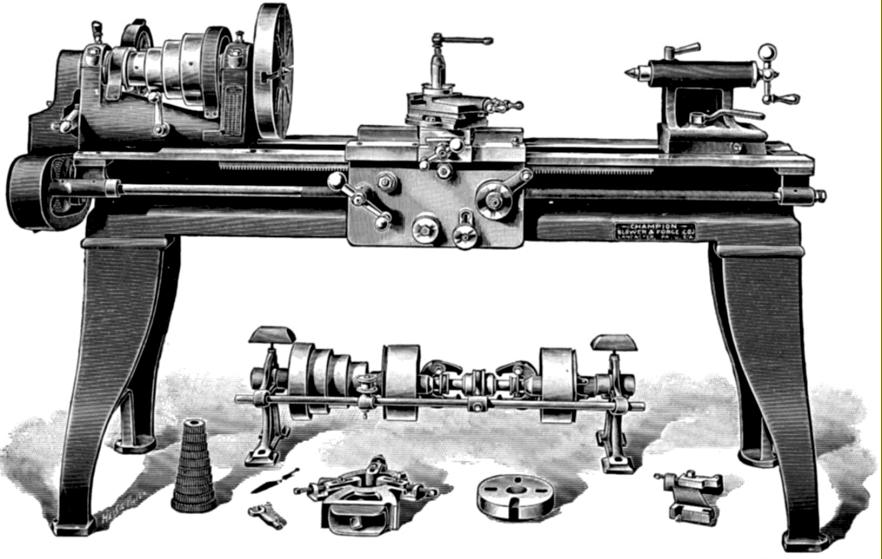

Looking very much like enlarged versions of the 10-inch model, the 13 and 16-inch were of much more robust design though (unlike similar designs from other makers), they shared few common parts and each had its own major castings. With three V-ways and one flat, the bed was offered in several lengths: the 13-inch with five, six, eight and ten-foot options and the 16-inch with six, eight and ten-foot.

Headstocks were appropriate sized, that on the 13-inch holding a ¾-inch bore, No. 3 Morse taper spindle with a 15/8" x 10 t.p.i. nose while the 16-inch had a much larger bore of 11/4", a nose of 21/4" x 8 t.p.i. - but the same No. 3 Morse taper. Each had a 4-step pulley, to take the same 2-inch width of flat belt, with that on the 16-inch being 3 3/8", 43/4", 61/8" and 71/2" in diameter and on the 13-inch 31/4", 41/2" 53/4" and 7".

Weights varied from 1300 lbs for the shortest bed 13-inch with built-on motor drive to 2455 lbs for the ten-foot 16-inch built to a similar specification..

Pictures continued here

|

|