|

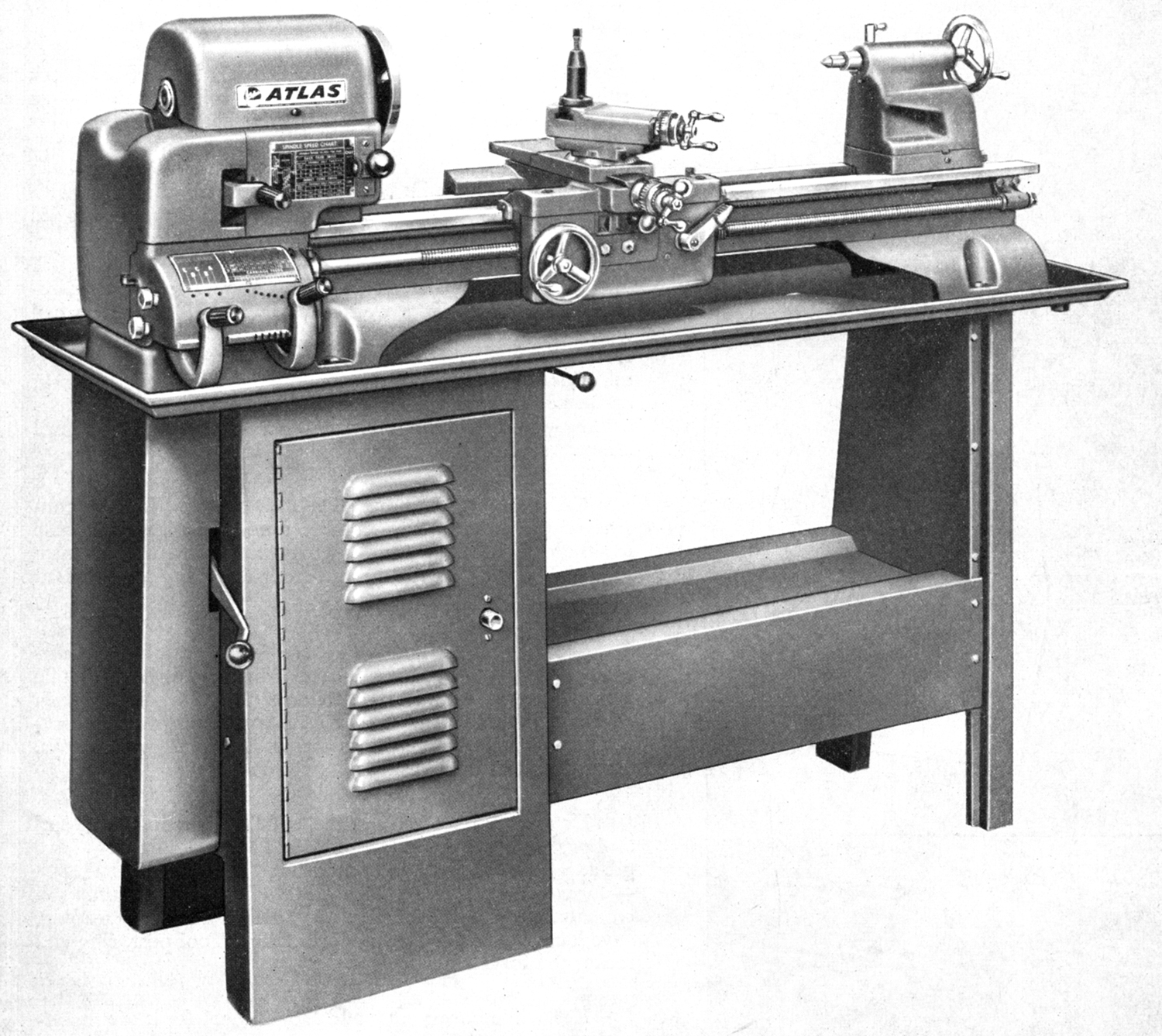

Atlas 12" x 36" long-bed Series 3000 on the maker's underdrive stand

As the last 12-inch Atlas was assembled on the 6th of March, 1981 it brought to an end a production run of lathes that can be traced back to the original 9-inch Atlas model of almost 50 years before. Marketed from the start of production simultaneously as the Sears Craftsman Metalcraft, it was to be developed steadily through numerous changes until a final, much-improved version was introduced in 1957 and designated in publicity material as both the "Late-model 12-inch Atlas" and the "Series 3000". In addition to a completely new underdrive stand, the revised range included four traditional versions for bench mounting, the Models 3980, 3981, 3982 and 3983. The lathe was also sold through Sears badged as the "Craftsman" and "Craftsman Commercial" - the Sears 1 958 spring edition of their "Big Book" showing bench versions of the machine (by the early 1980s the headings and descriptions in sales catalogs had been changed to "Sears Craftsman".)

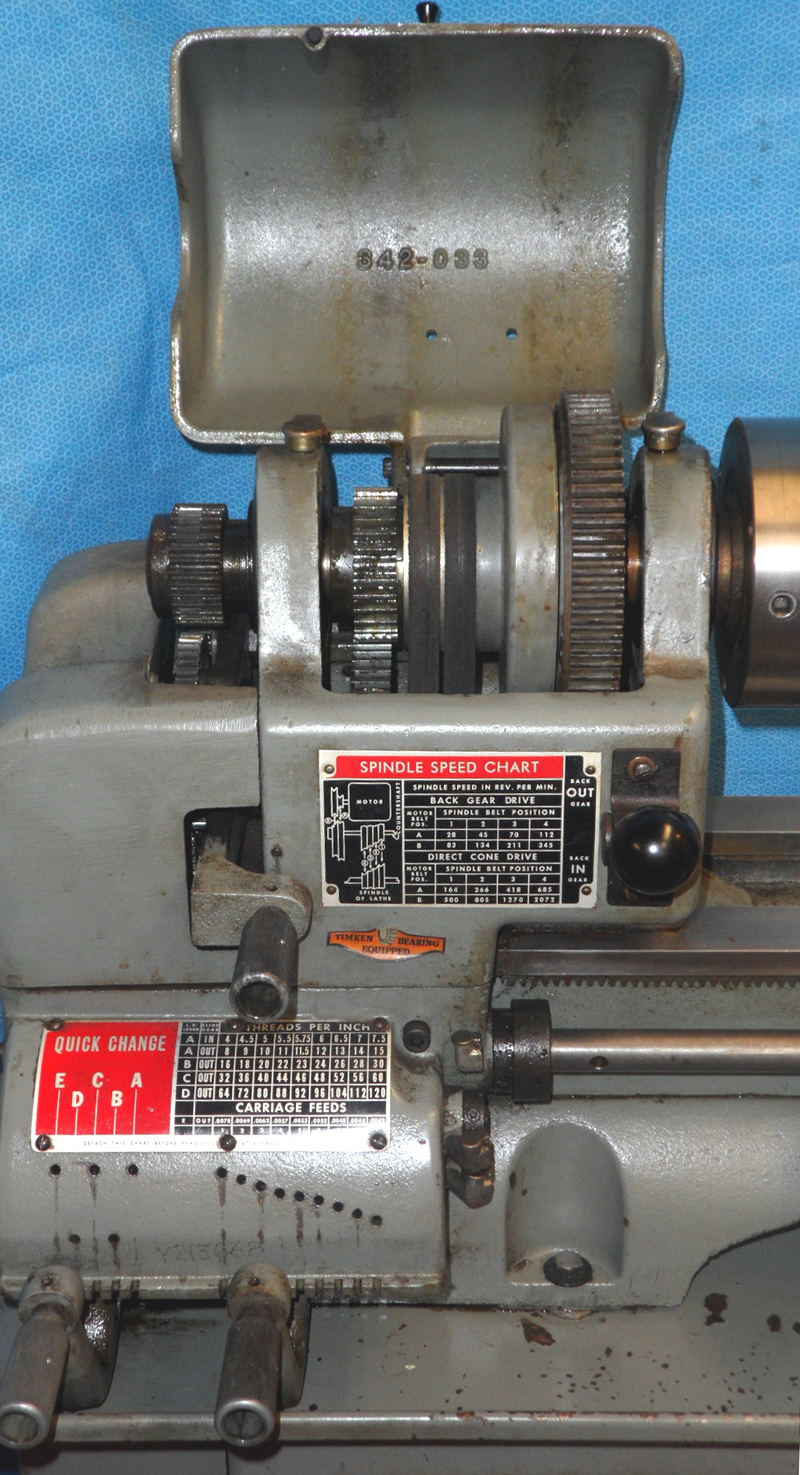

Although the flat-topped "English-style" bed (with 0.5-inch thick ways) still flew in the face of American preference for inverted V-ways, the rest of the machine was heavily revised with numerous detail improvements and few parts were interchangeable with the earlier model. It was available in two versions, for either bench or stand mounting, the former having a bronze-bearing countershaft (of rather agricultural construction) and an integral hinged (cast-iron) motor mount that bolted to the bench behind the lathe (with a bracing arrangement to the back of the headstock). A lever-operated mechanism simultaneously slackened both headstock and motor belts. The stand-mounted lathe sat atop a neatly-constructed, 190 lb cabinet (made from 3/16" thick steel with a chip tray as standard) that held a simple but robust under-drive countershaft with its pulleys overhung on 3/4"-diameter shafts from each side of bearings contained within central plumber blocks. Both models had an almost ideally-useful range of 16 spindle speeds that ran, in backgear, from 28 through 45, 70, 83, 112, 134, 211 to 345 rpm and, in direct drive, from 164 through 266, 418, 500, 685, 805, 1270 to 2072 rpm. Neat cast-aluminium covers guarded both the headstock and motor belt runs and the changewheels.

Thanks to Robert Downs in the United States, a single example of a hitherto unknown version of the late-model Atlas has come to light, a Model 12700 with the serial number 106462 - a lathe in all respects identical to the 3995/3996. With 3995/3996 Models having serial numbers beginning at 100,000 (and the last so far traced being No. 106781) a production date of around 1979 seems likely. While the lathe was identical in specification to the Model 3996, the stand was different with a larger portion of that under the headstock being wider and the underdrive system fully enclosed behind a single (probably locking door). Unlike the headstock-end plinth used on the more common Commercial model, which are somewhat narrower at the top than at the bottom, that on the 12700 has all its corners "square", i.e. the same front-to-back dimension at the top as at the bottom. The side walls of the oil pan also appear to be vertical, instead of sloping - and a guess might be that it was a model made for use in schools and training establishments as the locking door would have prevented injury to inquisitive fingers.

Fitting the complete speed-change countershaft inside the cabinet stand brought an additional advantage, final drive by two side-by-side V-belts. Experienced users of the bench model, with its 4-step headstock pulley that has just one belt for each speed, report that, under heavy loads the belt can slip. Not so on the underdrive models, the two belts allowing the lathe to be used to the limits of its strength. However, there is a drawback, the two-belt arrangement can often lead to trouble when worn or unmatched belts are used. If your 12-inch underdrive suffers from a noisy headstock, vibration or a poor finish on turned work, look first at the final drive to the headstock spindle and check (by putting a chalk line across them and running the lathe) that the two belts are exactly the same length, if they are the chalk marks will stay in line. A solution - and one that saves having to dismantle the headstock and countershaft to replace the belts - is to use the modern T-link type.

While almost every 3000 Series lathes appears to have been fitted with a screwcutting gearbox, some were made with a standard changewheel set up; the sales catalogues were a little vague on this point with publications for the American market sometimes listing the gearbox as a standard fitting on both stand and bench models - but also as an extra on the bench model only. However, export editions (at least to the UK) managed to show it as standard and, simultaneously, amongst the extra-cost accessories for both versions (the lathe was heavily promoted in the UK, with full-page advertisements taken in the Model Engineer Magazine and other publications). The gears in the box were of unhardened steel with all the bushes, whether for gears or rotating shafts, of the simple bronze Oilite kind lubricated through handy, dirt-excluding flip-top oilers. The "English" box was able to generate feeds from 0.0042" to 0.520" per revolution of the spindle and 54 threads from 4 to 240 t.p.i while that fitted to the rare all-metric machines gave feeds from 0.089" to 6.0 mm and 29 threads from 0.1 to 6.0 mm pitches. In the right-hand section of the box was a safety over-load clutch that protected the drive against damage - one of the problems with earlier lathes being the tendency for the cast-in key on the ZAMAK gear that engaged with the leadscrew to shear off. The 3/4"-diameter 8 t.p.i leadscrew was slotted and carried a sliding key that drove, via a bevel-gear system within the apron, the power cross feed mechanism. End thrust in both directions was absorbed against radial need-roller bearings and, fitted at the headstock end of the shaft, was an over-load protection device designed to slip and prevent damage to the gearbox, its (steel) changewheel gears and the apron mechanism.

With a 1.5" 8 t.p.i. nose, 25/32" bore and 1/2" collet capacity the headstock spindle ran in Timken taper roller races; however, instead of being mounted to the rear of the spindle in traditional fashion the backgear assembly was built into the lower part of the headstock, rather like an early Clausing or Raglan lathe, and engaged by a convenient lever protruding through the front face of the headstock below and just to the left of the spindle nose.

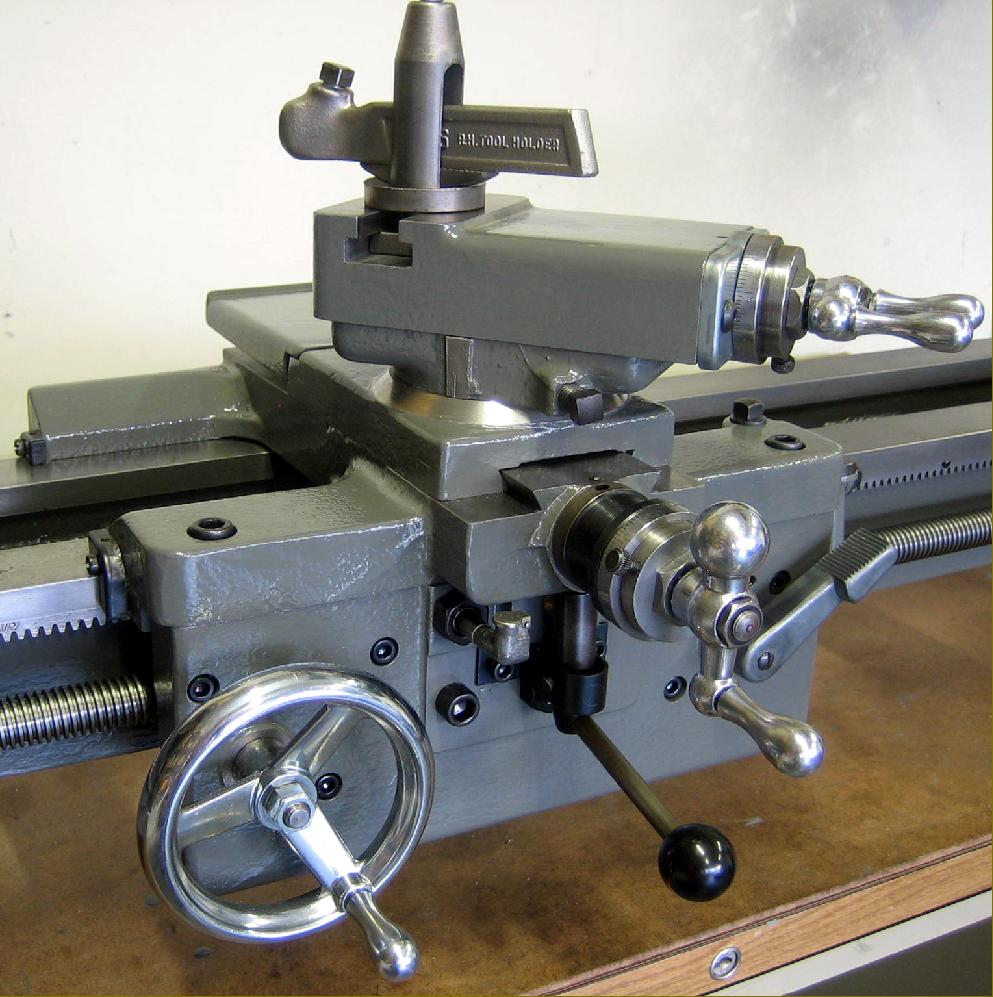

While both the apron and 11.25"-long saddle with its 33.75 square inches of bearing surface were strongly constructed - and the latter fitted to the bed by adjustable laminated shims - the compound slide rest could only be described as adequate for its purpose; the cross slide was of the type that, not being full length, caused wear across the central part of its movement. On the positive side the zeroing micrometer dials were clearly engraved and the mechanism to lock their rotation by positive-action finger screws.

In 1967 a minor change was made to the apron-mounted mechanism that engaged the (standard-fit) power cross feed with the provision of a simple, ball-ended toggle arm that slid the selector button in and out.

Provided with an adjustable gib fitting to the bed, the tailstock was held a 1.125"-diameter ground-steel ram with a No. 2 Morse taper socket and engraved ruler marks from 0 to 3" in 1/16" steps. The clamping handle was permanently attached at the rear of the casting and, because room within the back of the casting was limited, was of the type that could be swung up and round to give a ratcheting action.

The numbering system used by Atlas for this model was:

Bench Model, 24" between-centres, screwcutting gearbox (no motor) No. 3980 (later 3985)

Bench Model, 36" between-centres, screwcutting gearbox (no motor) No. 3981 (later 3986)

Bench Model, as No. 3980 but to an all-metric specification: No. 3965

Bench Model, 24" between-centres, changewheel screwcutting (no motor) No. 3982

Bench Model, 36" between-centres, changewheel screwcutting (no motor) No. 3983

Underdrive Model, 24" between centres, screwcutting gearbox (no motor): No. 3990 (later the 3995)

Underdrive Model, 36" between centres, screwcutting gearbox (no motor): No. 3991 (later the 3996)

Underdrive Stand Model, as No. 3996 but to an all-metric specification: No. 3975

Unlike earlier Atlas lathes, which were without any form of dating (apart from the headstock roller bearings), some if not all 12-inch models had the casting date on the inside of their beds: a mark such as 9-2-59 would indicate a pouring on September 2nd 1959 - providing the foundry workers had bothered to change the mould numbers, of course.

Although in 1959 a basic short-bed, 24" between centres machine with screwcutting by changewheels for bench mounting could be bought for $192 the lathe shown above (on the underdrive stand) was priced at a little over three times as much.

A bench version of the 12-inch weighed approximately 350 lbs with a gearbox and 320 lbs without; the stand-mounted lathes with a screwcutting gearbox and a capacity of 24-inches between centres weighed 505 lbs, with 36-inch between-centres versions rising to 550 lbs. .

|

|